Acrylic emulsion and application thereof

A technology of acrylic emulsion and methacrylic acid, applied in the field of coatings, can solve the problems that the color and texture of the paint film, the water resistance of the emulsion, the resistance to water white difference, and the stain resistance are difficult to meet the standard, and achieve excellent scrub resistance. , the effect of good transparency and excellent stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The preparation method of the acrylic acid emulsion described in any one of the above-mentioned embodiments in the present invention comprises the following steps:

[0074] Mix 83% water, 50% emulsifier, and PTF thickener, stir, and raise the temperature to 82°C-85°C to obtain mixture A;

[0075] Dissolving 50% of the initiator with 2% of water to obtain initiator solution 1, which is set aside; and dissolving 50% of the initiator with 5% water to obtain initiator solution 2, which is set aside;

[0076] Mix 10% water and the remaining 50% emulsifier with hard monomers, soft monomers, functional monomers, and part of the silane coupling agent, fully stir and emulsify to obtain mixture B, and set aside;

[0077] Under the condition of 82°C to 85°C, add initiator solution 1 to the mixture A, keep warm for 2 minutes, then drop part of the initiator solution 2 and part of the mixture B into the system at the same time, the dropping time is 90 minutes, Obtain mixture C;

...

Embodiment 1

[0100] This embodiment provides an acrylic emulsion and its application.

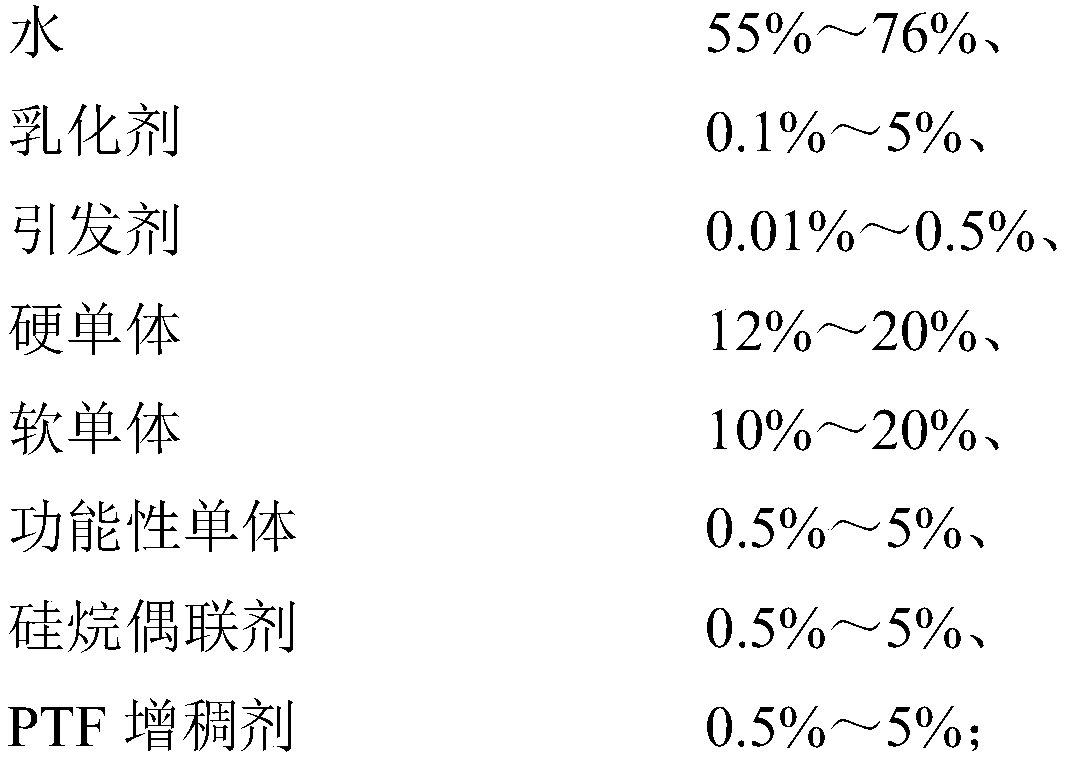

[0101] (1) The composition of acrylic emulsion is as follows:

[0102]

[0103]

[0104] (2) Preparation of acrylic emulsion

[0105] Mix 83% of water, 50% of emulsifier SR-10, and PTF thickener, stir evenly, and heat up to 82°C to 85°C to obtain mixture A;

[0106] Dissolving 50% sodium persulfate with 2% water to obtain initiator solution 1, and set aside; and dissolving 50% sodium persulfate with 5% water to obtain initiator solution 2, set aside;

[0107] Mix 10% of water, the remaining 50% of emulsifier with methyl methacrylate, isooctyl acrylate, acrylic acid, acrylamide and silane coupling agent A-171, fully stir and emulsify to obtain mixture B, set aside;

[0108] Under the condition of 82°C to 85°C, add initiator solution 1 to the mixture A, keep warm for 2 minutes, then drop part of the initiator solution 2 and part of the mixture B into the system at the same time, the dropping time ...

Embodiment 2

[0117] This embodiment provides an acrylic emulsion and its application.

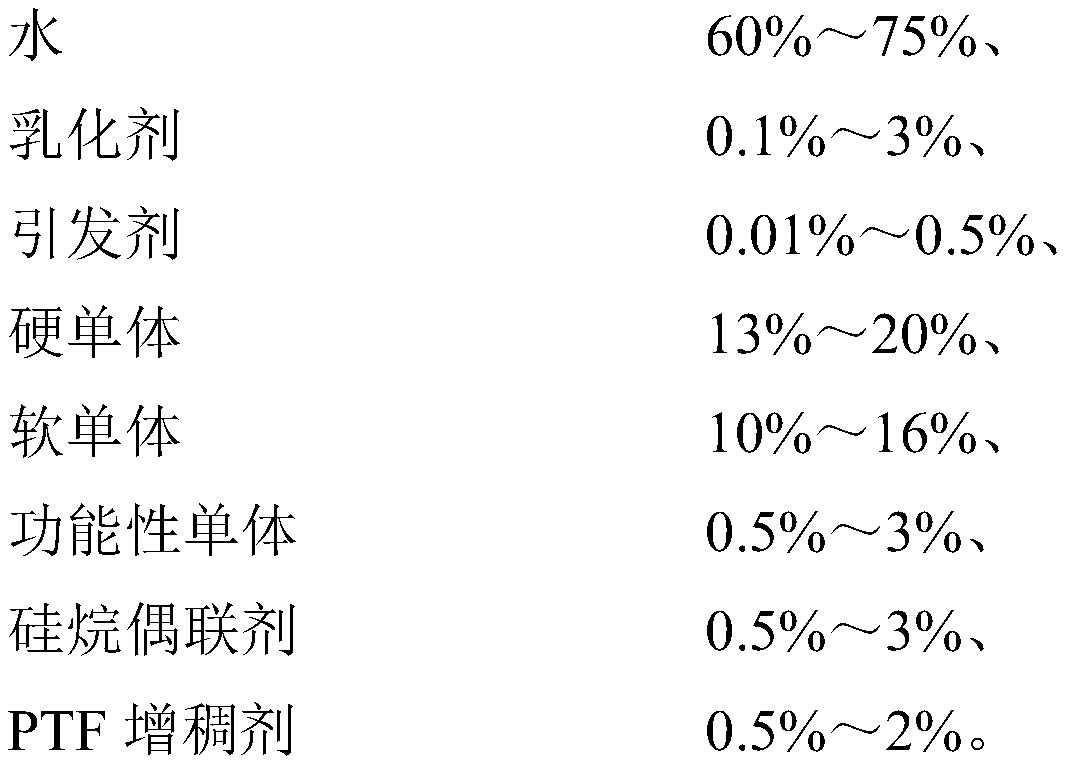

[0118] (1) The composition of acrylic emulsion is as follows:

[0119]

[0120] (2) Preparation of acrylic emulsion

[0121] Mix 83% of water, 50% of emulsifier SR-10, and PTF thickener, stir evenly, and heat up to 82°C to 85°C to obtain mixture A;

[0122] Dissolving 50% sodium persulfate with 2% water to obtain initiator solution 1, and set aside; and dissolving 50% sodium persulfate with 5% water to obtain initiator solution 2, set aside;

[0123] Mix 10% of water and the remaining 50% of emulsifier with methyl methacrylate, isooctyl acrylate, acrylic acid, acrylamide and silane coupling agent A-171, fully stir and emulsify to obtain mixture B, set aside;

[0124] Under the condition of 82°C to 85°C, add initiator solution 1 to mixture A, and after keeping it warm for 2 minutes, add part of initiator solution 2 and part of mixture B dropwise to the system at the same time, and the dropping time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com