Electric shock protection device for electric welding machine

A protection device, anti-electric shock technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of poor arc ignition effect, long time to start the main circuit output, high manufacturing cost, and eliminate human electric shock accidents. Hidden danger, good arc ignition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the embodiments of the present invention will be described in detail with reference to the drawings.

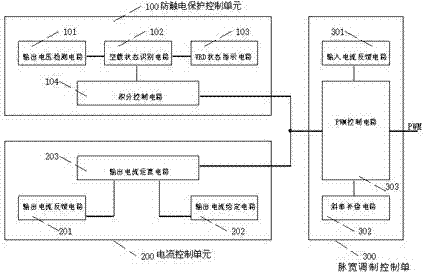

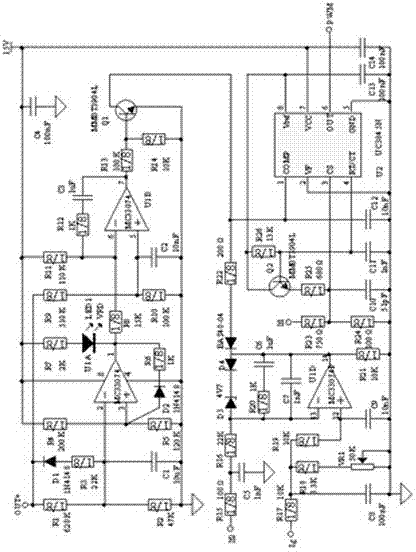

[0022] Such as figure 1 As shown, an electric shock protection device for an electric welding machine includes an electric shock protection control unit 100, a current control unit 200, and a pulse width modulation control unit (PWM control unit) 300. The electric shock protection control unit 100 and the current control unit 200 are respectively connected to the input end of the pulse width modulation control unit 300. The output end circuit of the pulse width modulation control unit 300 is connected to the main circuit of the inverter switch of the external welding machine, and the final output is The DC pulse with linearly adjustable air ratio is sent to the external inverter switch main circuit to drive the inverter switch main circuit. The electric shock protection control unit 100 samples the voltage at the output terminal of the electric welding machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com