Contact arc extinguishing system of circuit breaker

A circuit breaker and arc extinguishing technology, applied in the directions of circuit breaker contacts, circuit breaker parts, circuits, etc., can solve the problems that the air outlet cannot be in the arc movement, the discharge speed is not as fast as the generation speed, and the exhaust channel cannot be fully utilized. , to achieve the effect of accelerating the arc transfer speed, simplifying the equipment and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with specific embodiment, further illustrate the present invention.

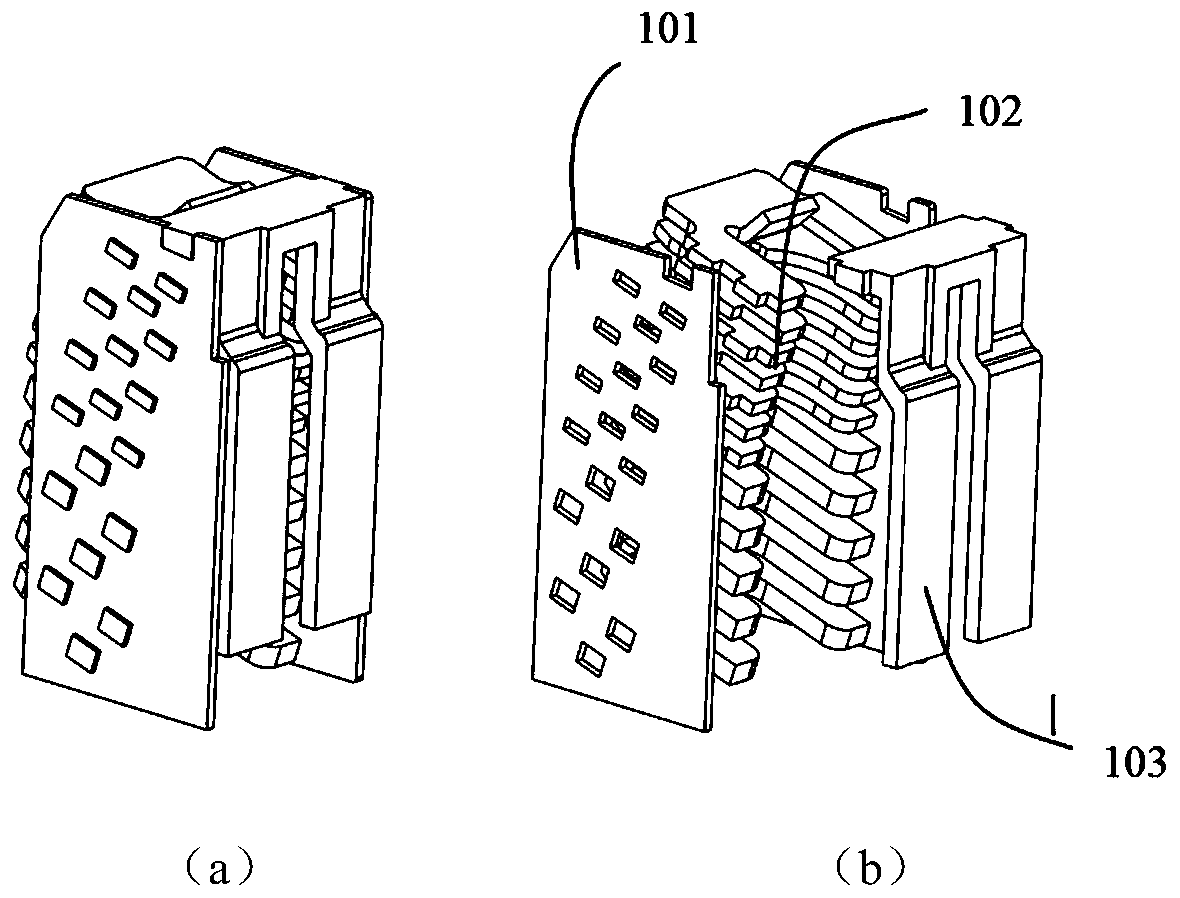

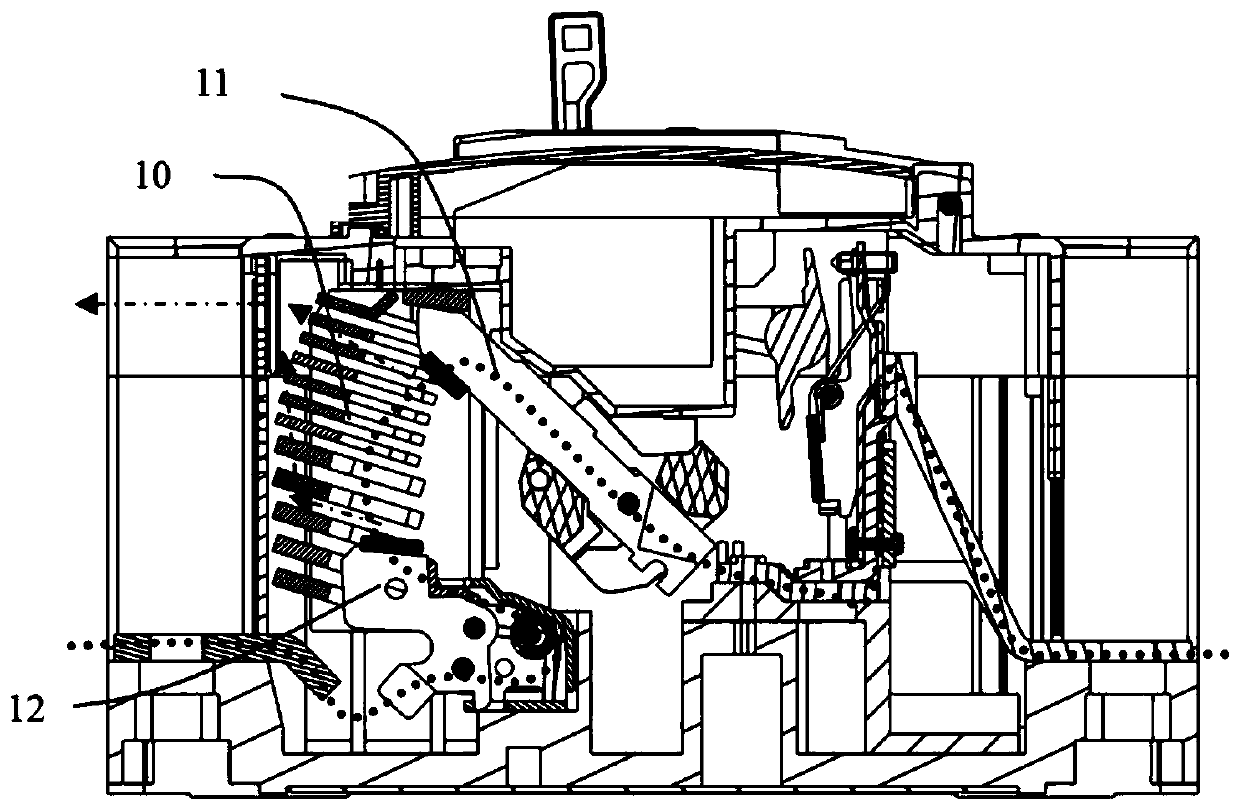

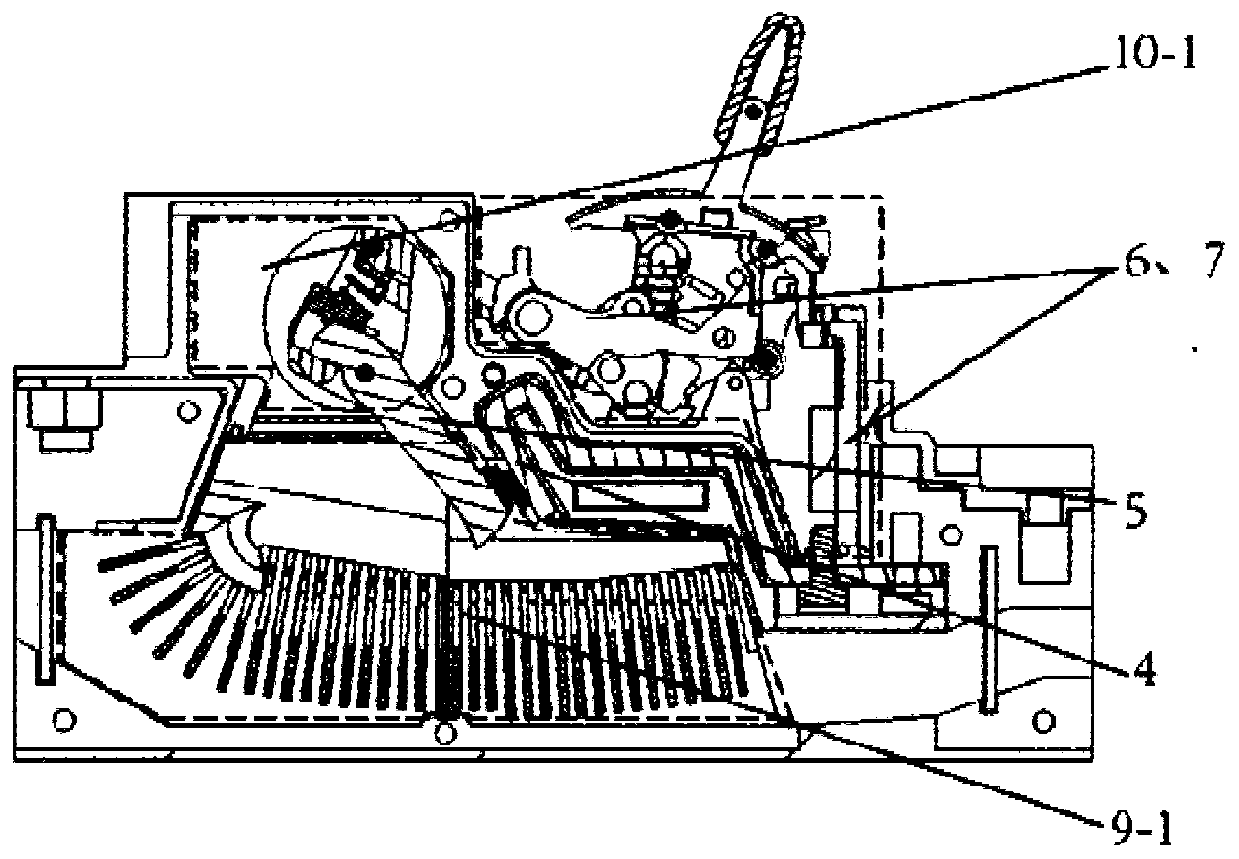

[0041] combine image 3 and Figure 4 , The present invention provides a contact arc extinguishing system of a circuit breaker, including an arc extinguishing system 20, a moving contact 22, a static contact 23 and the like. The moving contact 22 and the static contact 23 are arranged opposite to each other to form a contact system; the arc extinguishing system 20 is arranged under the contact system and is located at the bottom of the housing 25, and the arc extinguishing system 20 has a side with an arc strike groove Facing the contact system, the back of the arc extinguishing system 20 is facing the inner surface of the bottom surface of the housing 25. The left and right sides of the arc extinguishing system 20 are provided with exhaust ports 28. The arc extinguishing system 20 and the corresponding exhaust channels occupy the space of the housing 25. The lower space. A zer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com