Patents

Literature

44results about How to "Increase arc length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

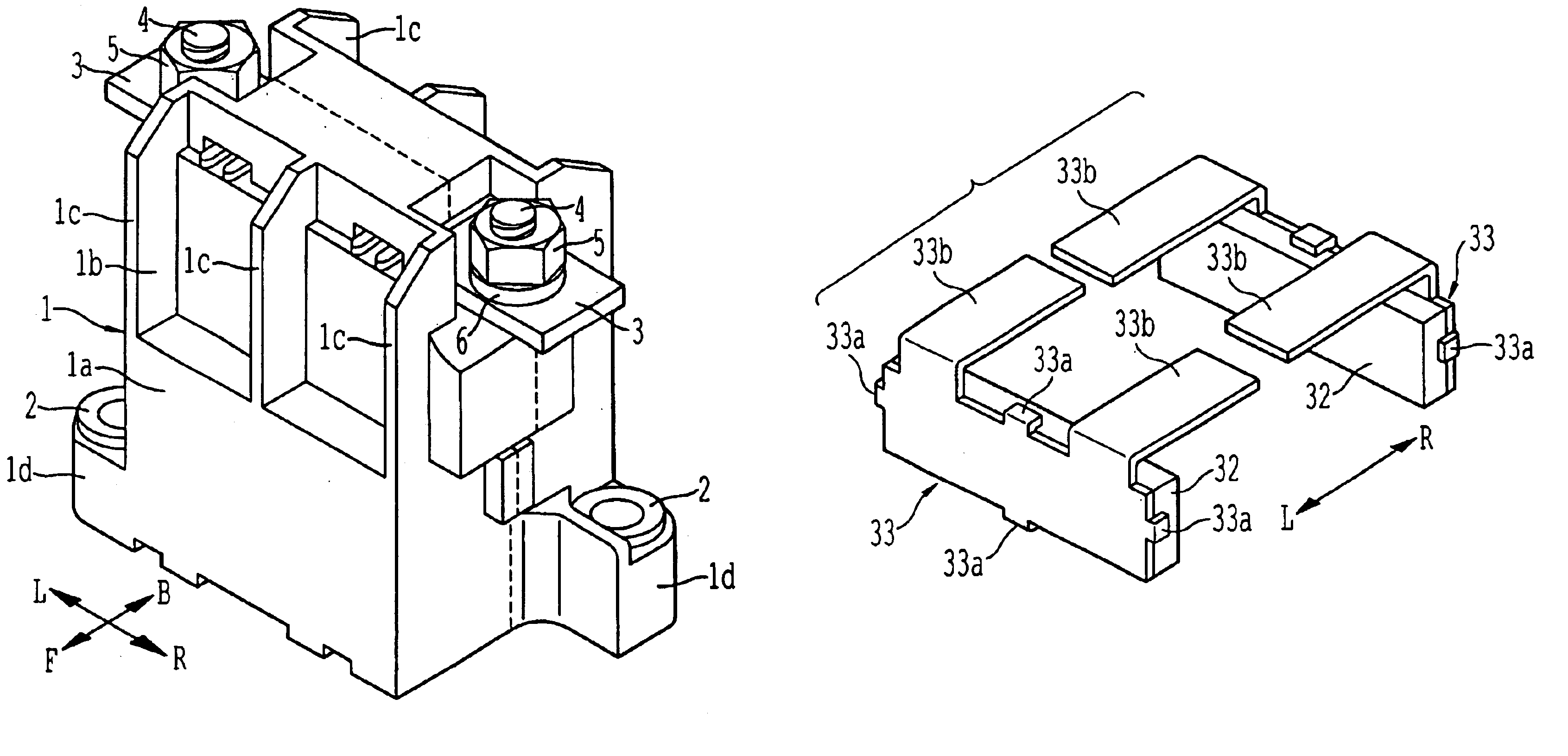

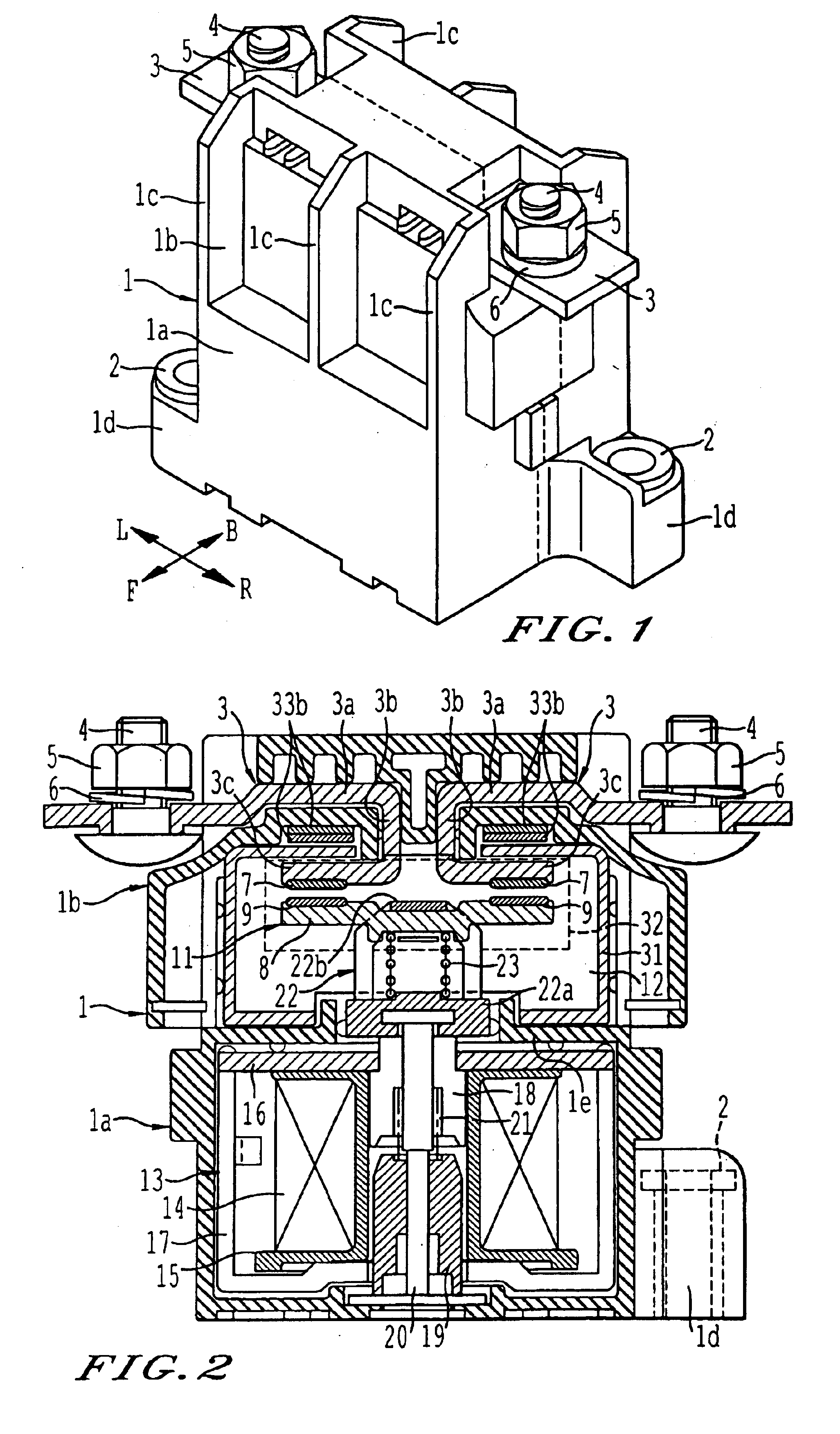

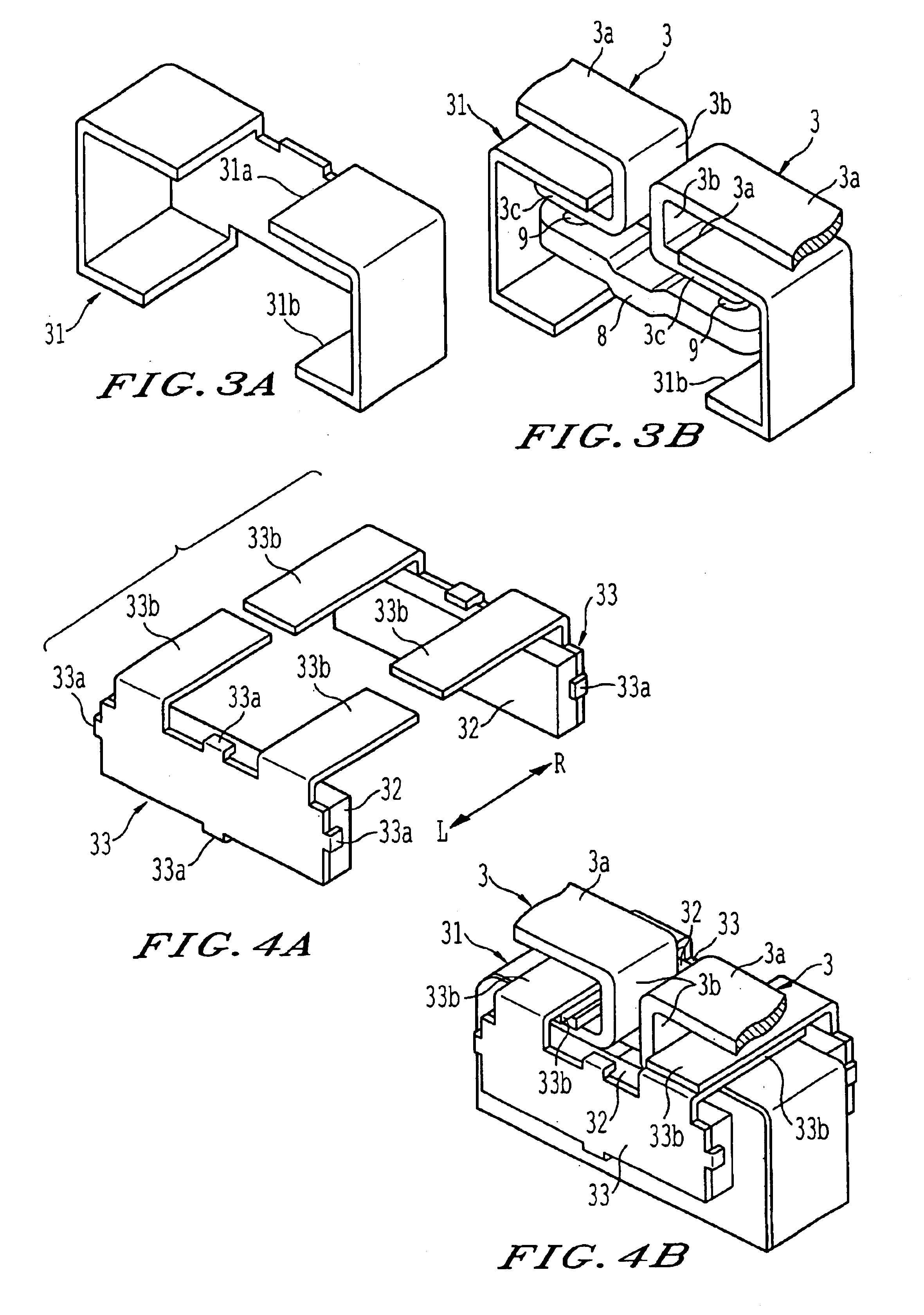

Contactor

InactiveUS6700466B1Increase arc lengthIncrease arc voltageHigh-tension/heavy-dress switchesAir-break switchesEngineeringMagnet

A contact apparatus is provided having a permanent magnet disposed in a region where a fixing contact point is mounted to a fixing contact and a movable contact to which a movable contact point is mounted. An arc generated between both the contact points is moved in a lateral direction by the magnetic force of the permanent magnet and stretched. An arc-extinguishing member which is heated by the arc for generating arc-extinguishing gas is provided such as to surround the fixing contact point and the movable contact point.

Owner:MATSUSHITA ELECTRIC WORKS LTD

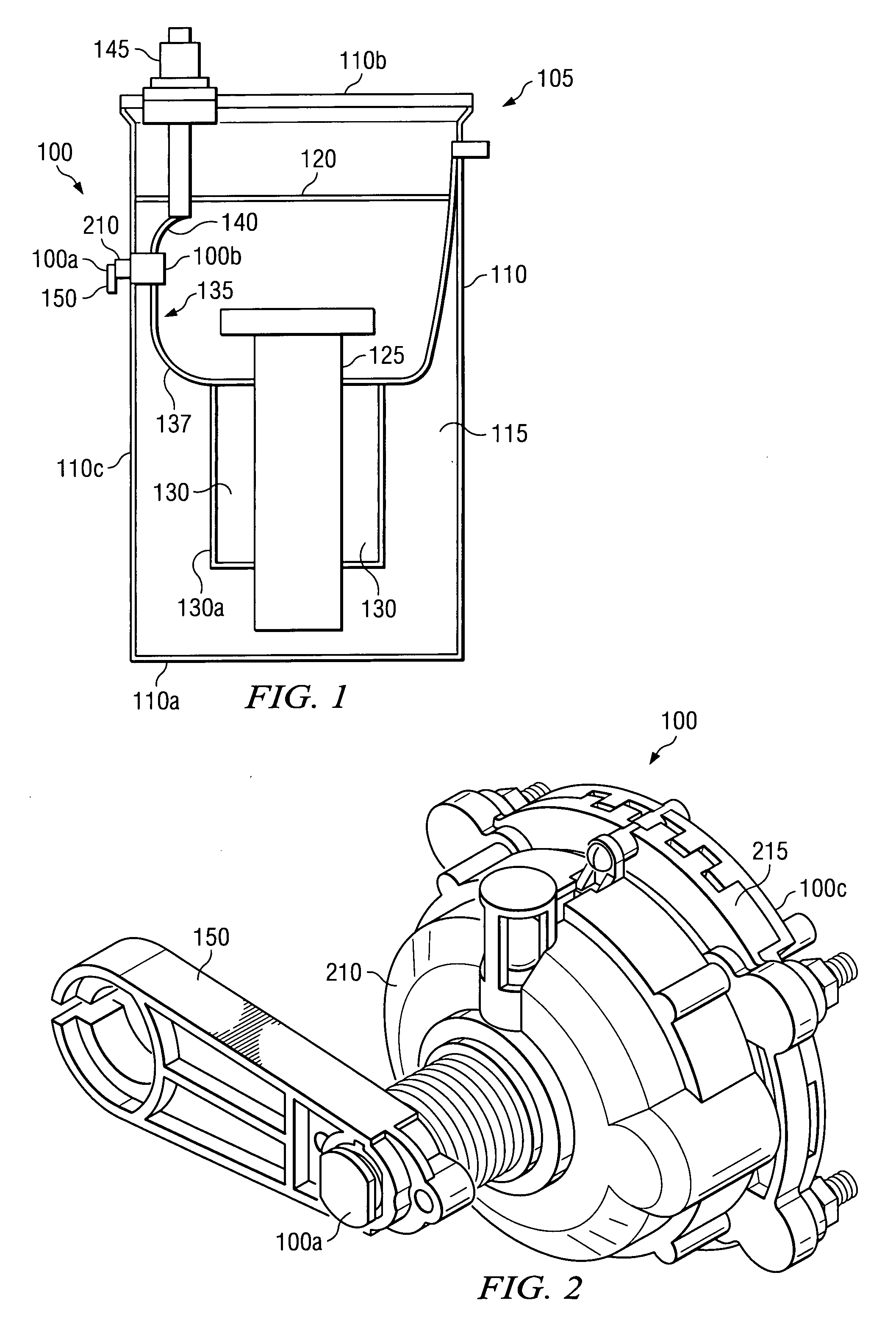

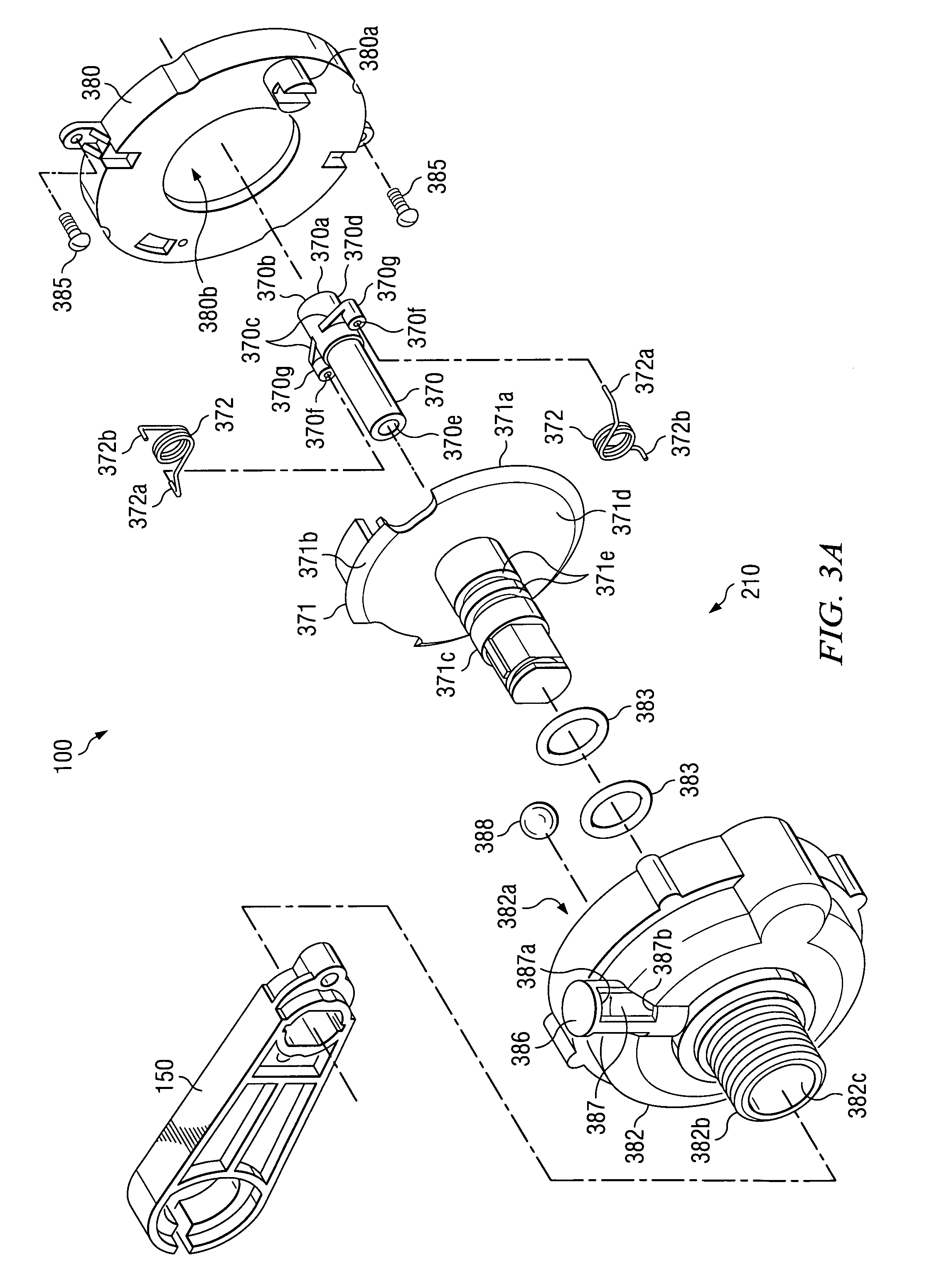

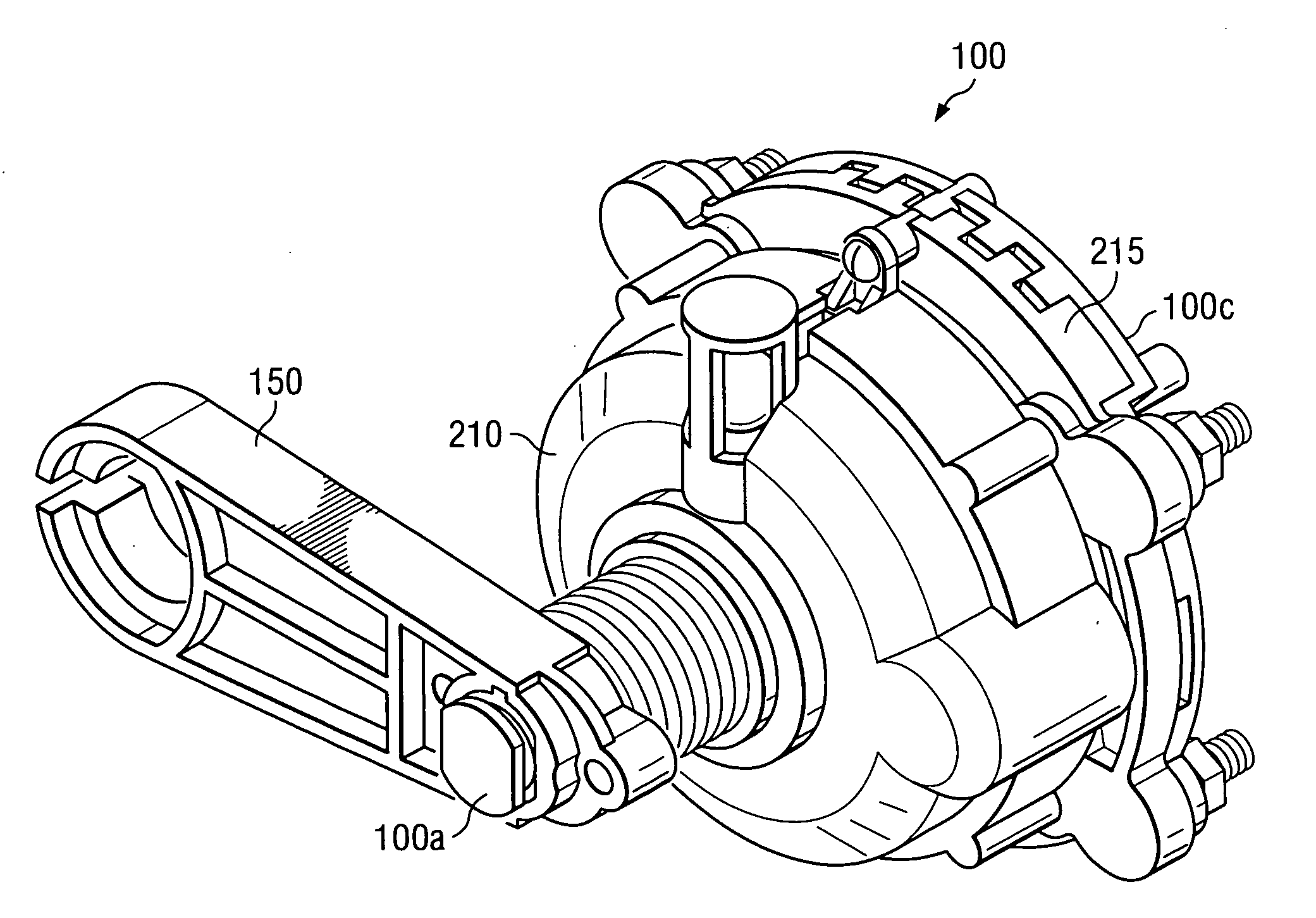

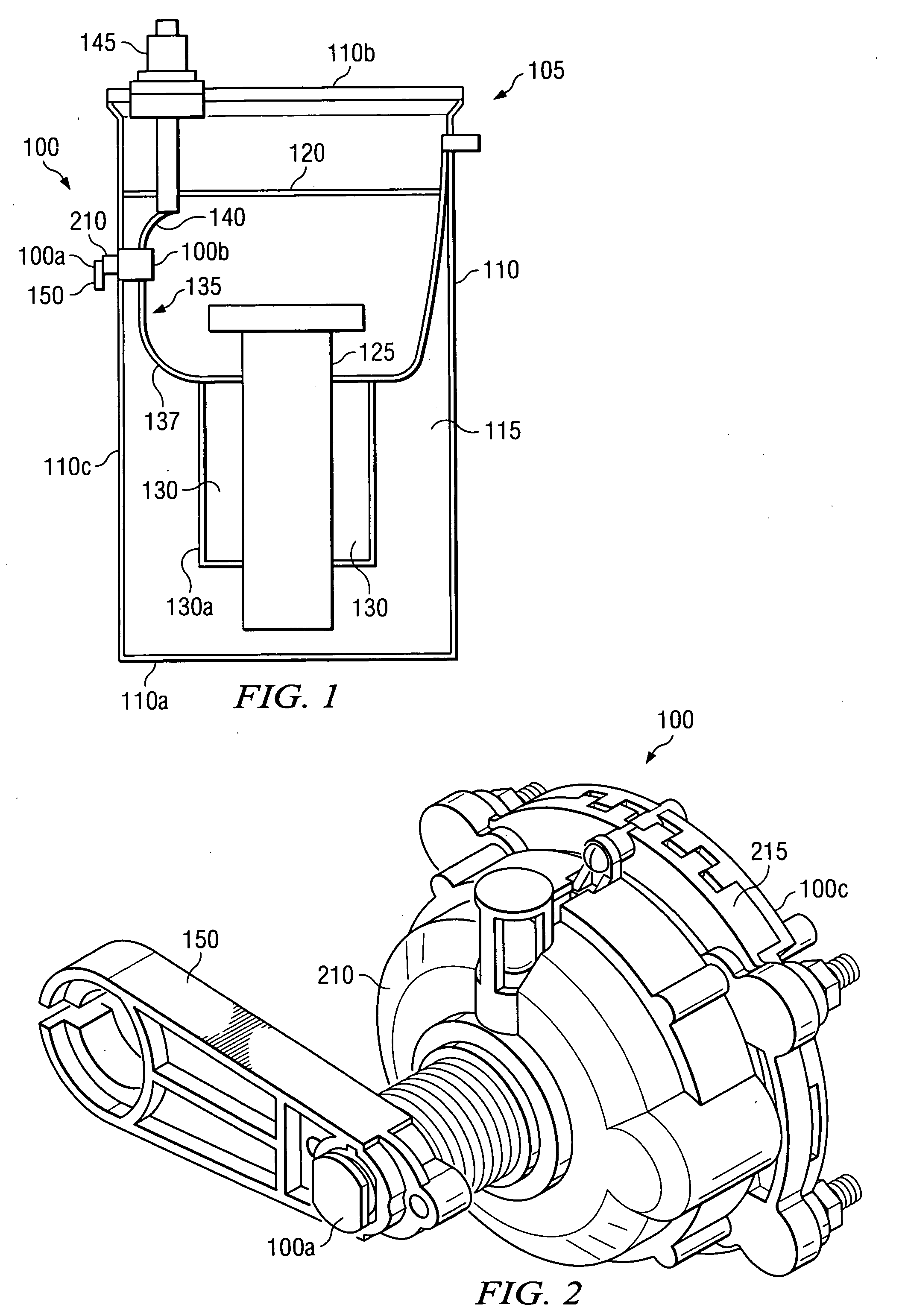

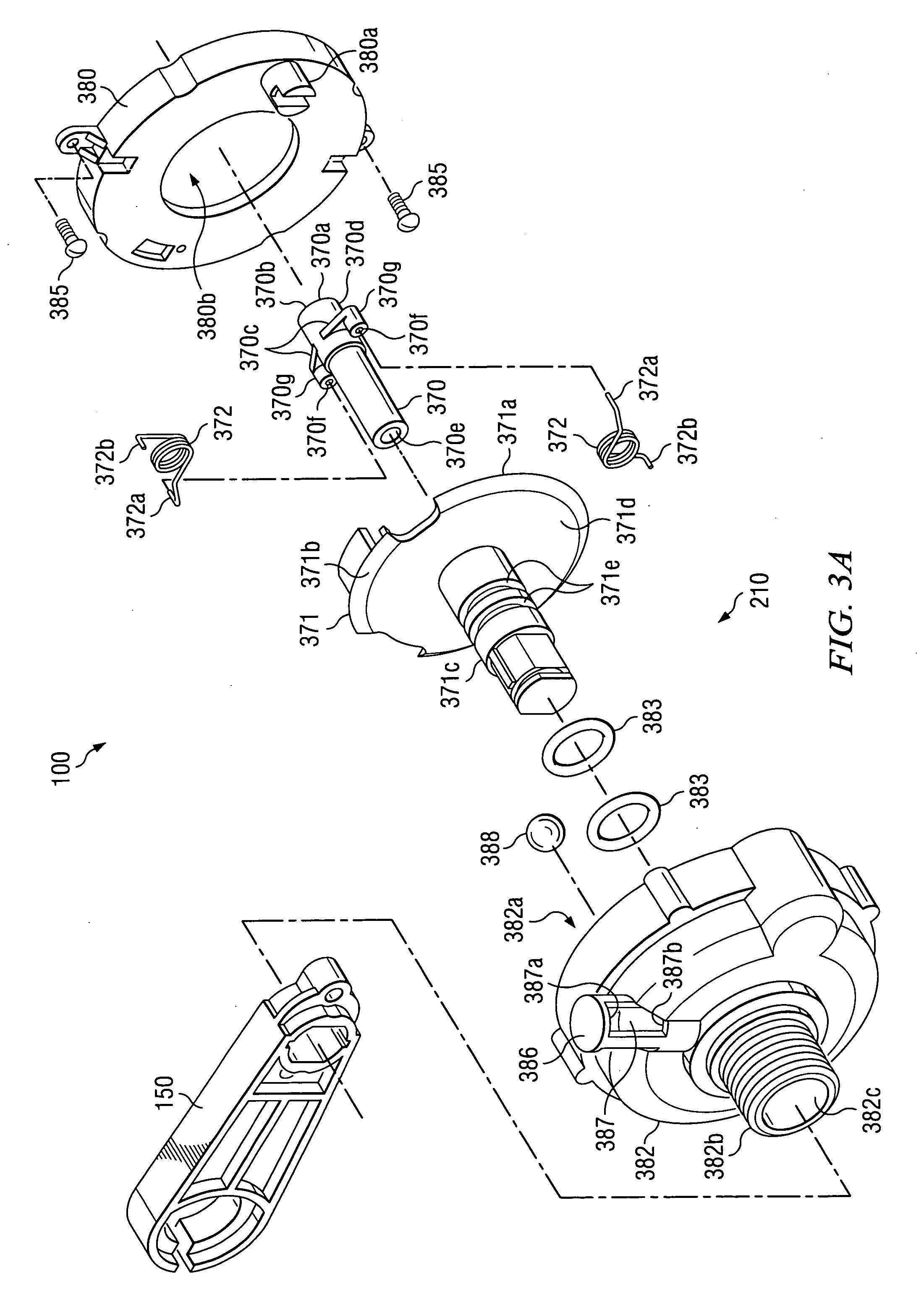

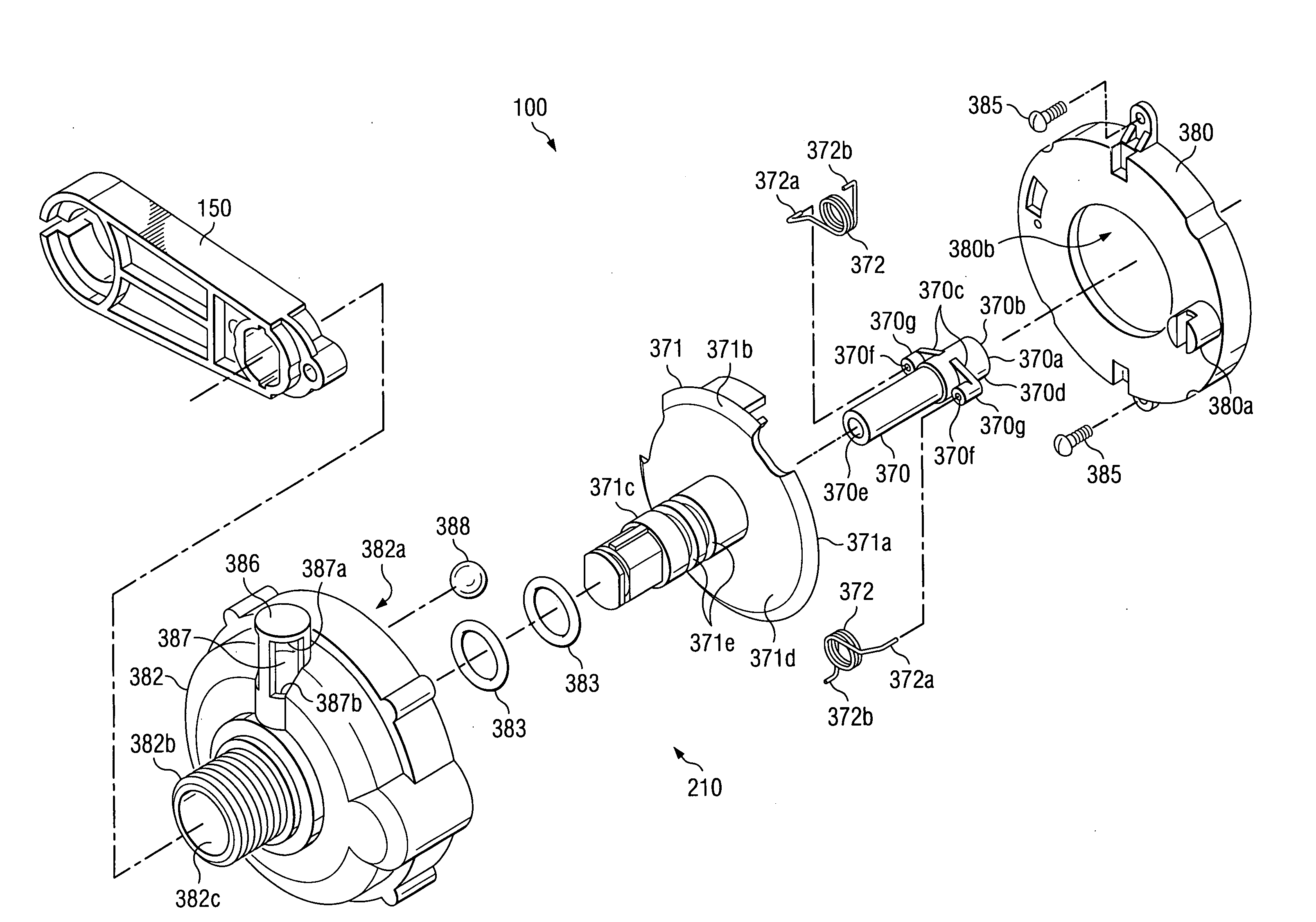

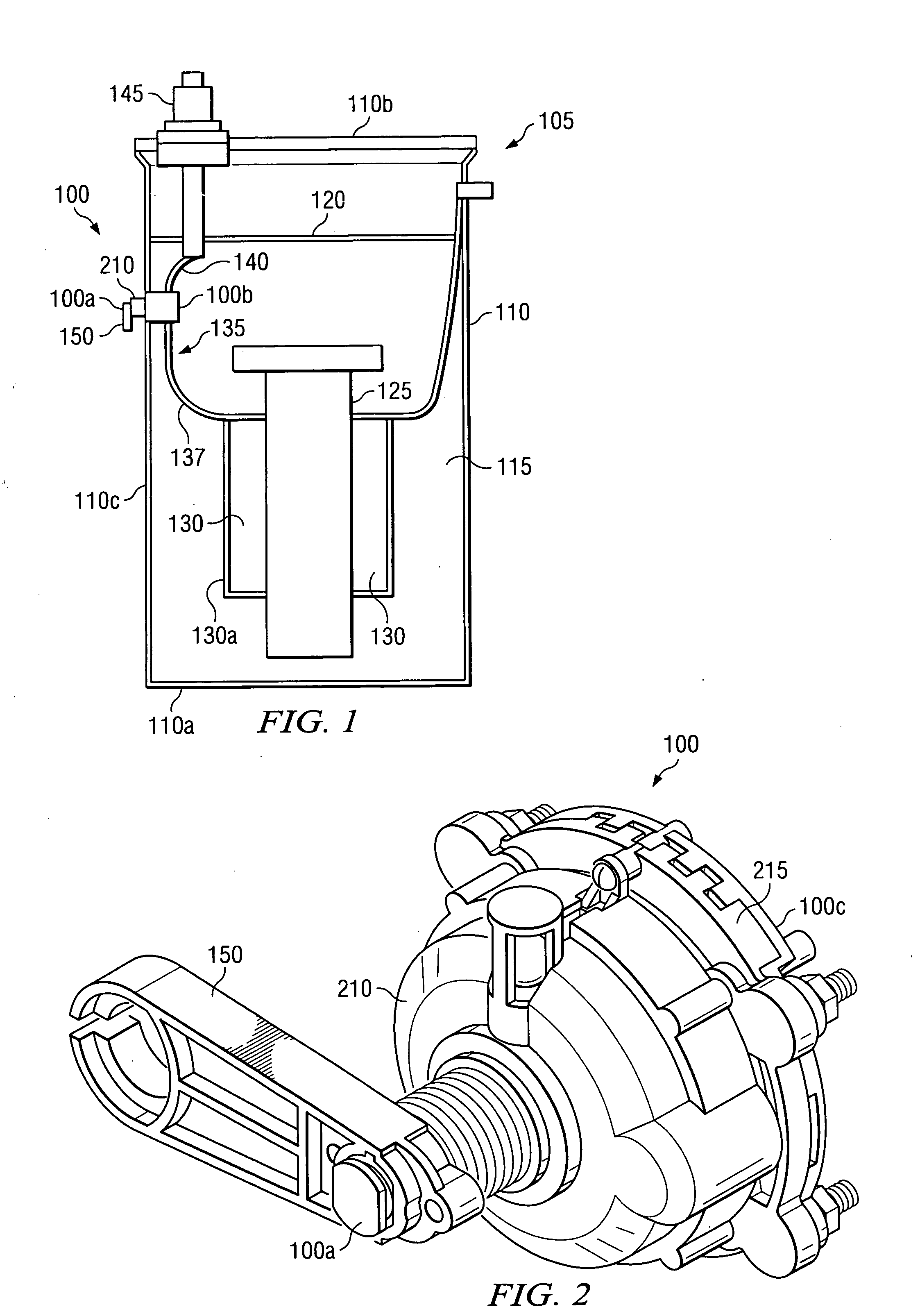

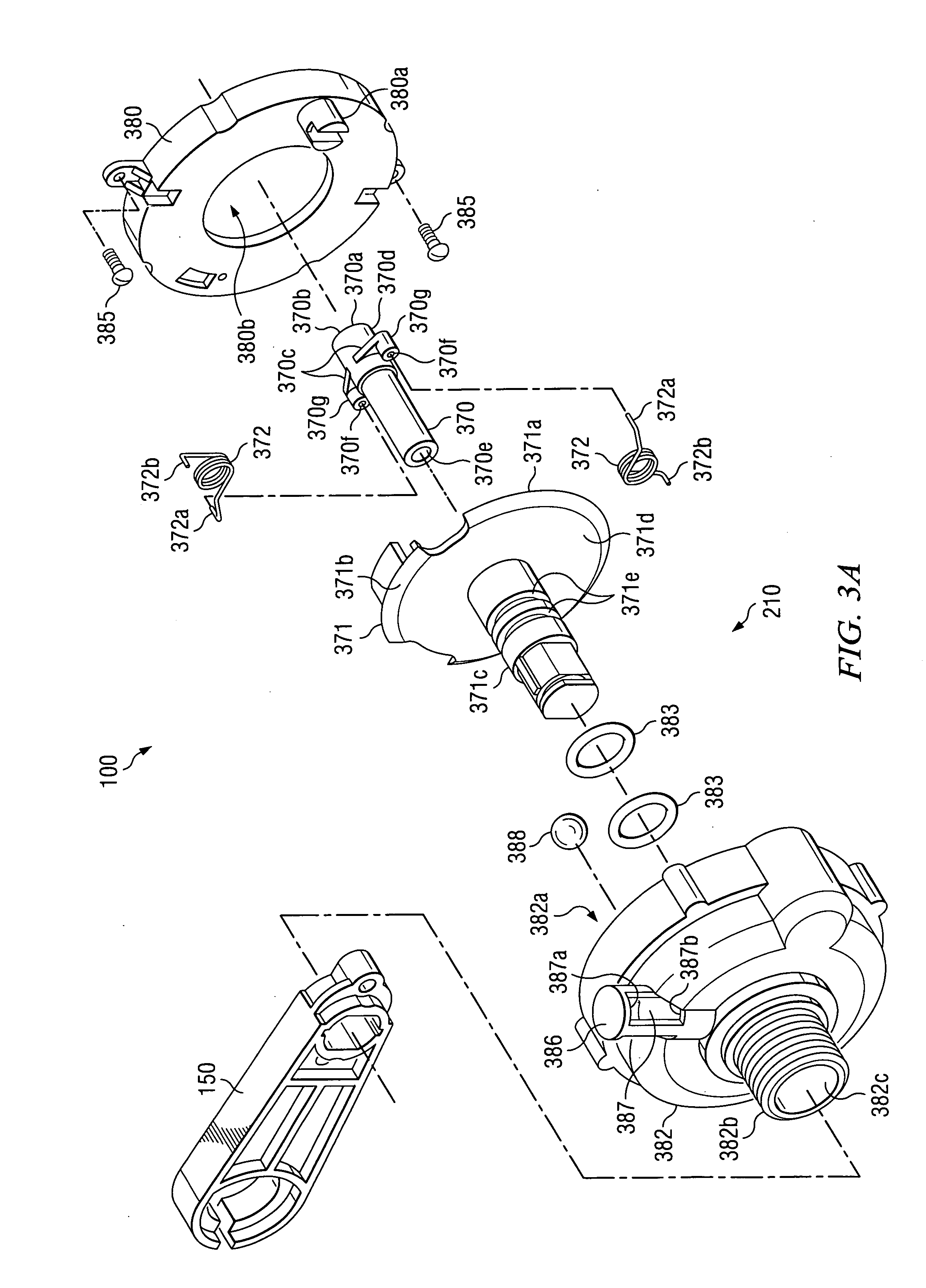

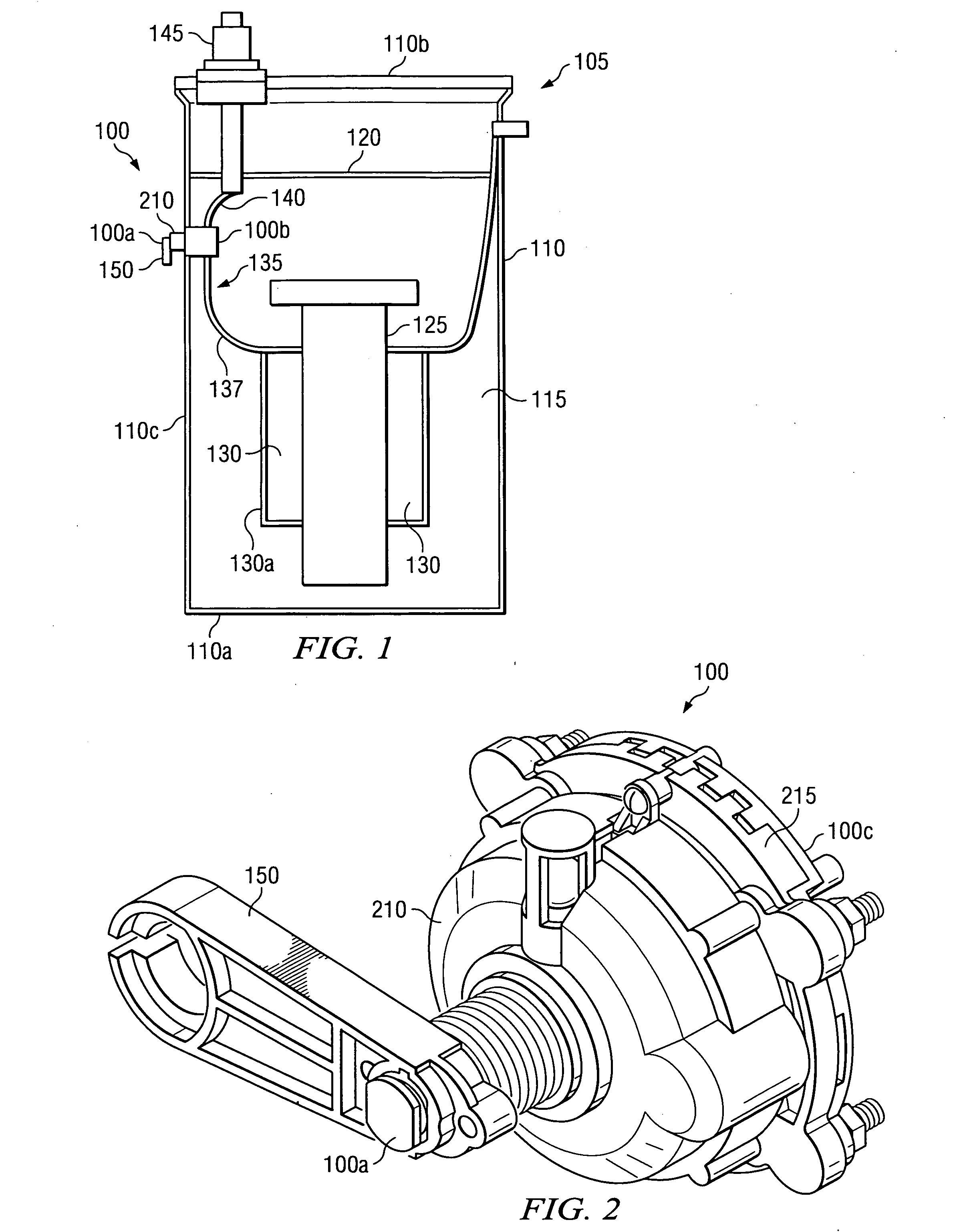

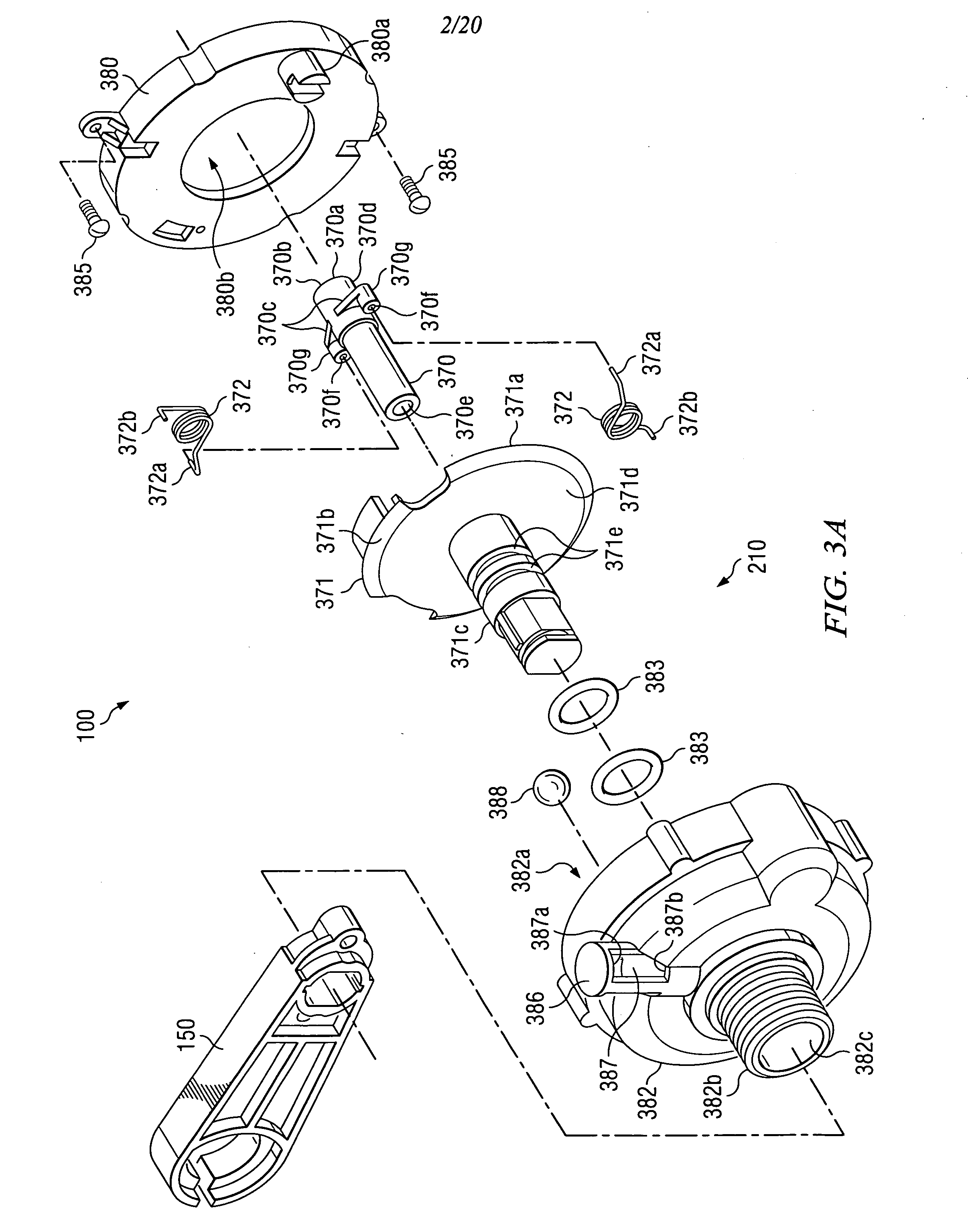

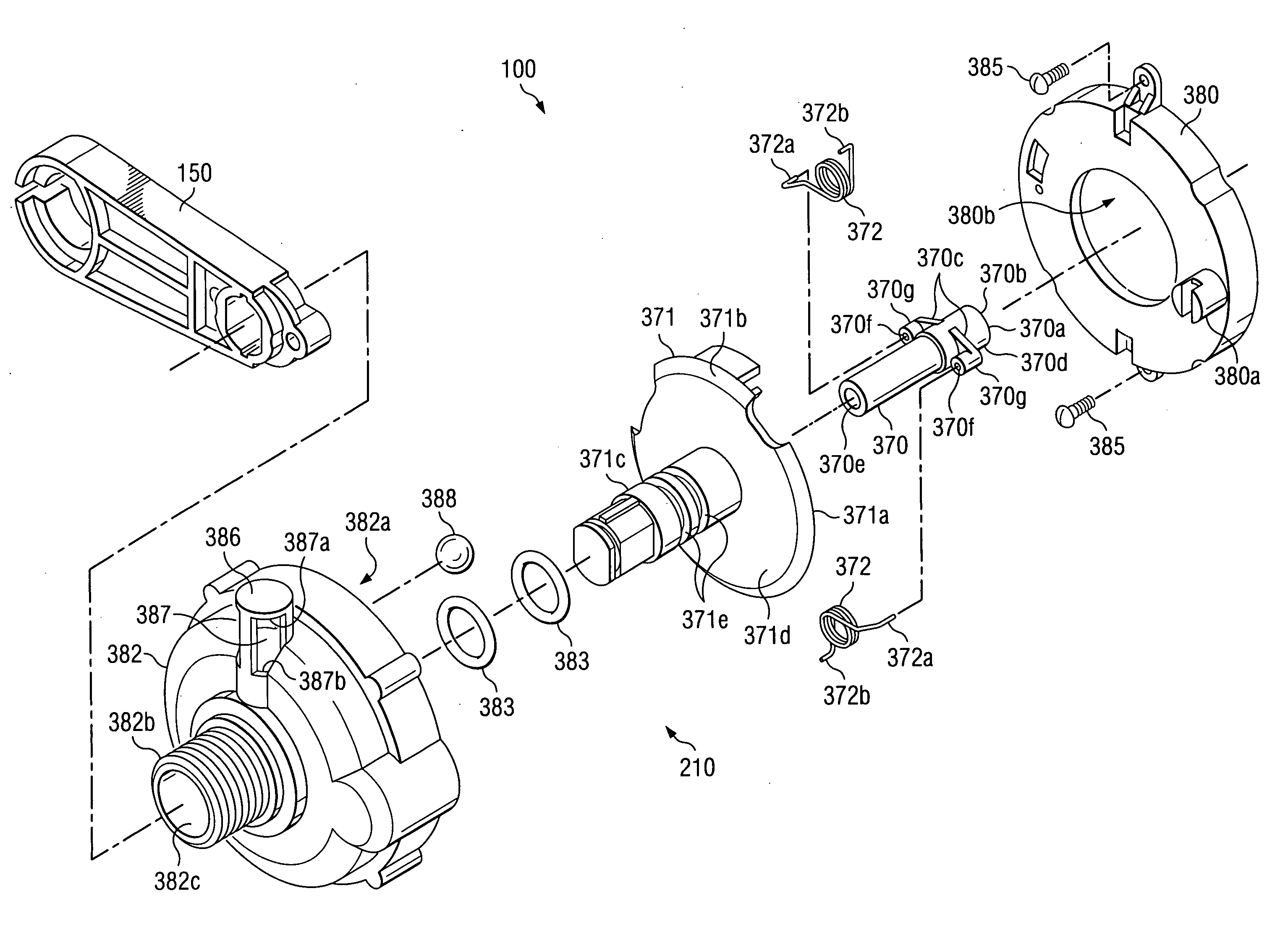

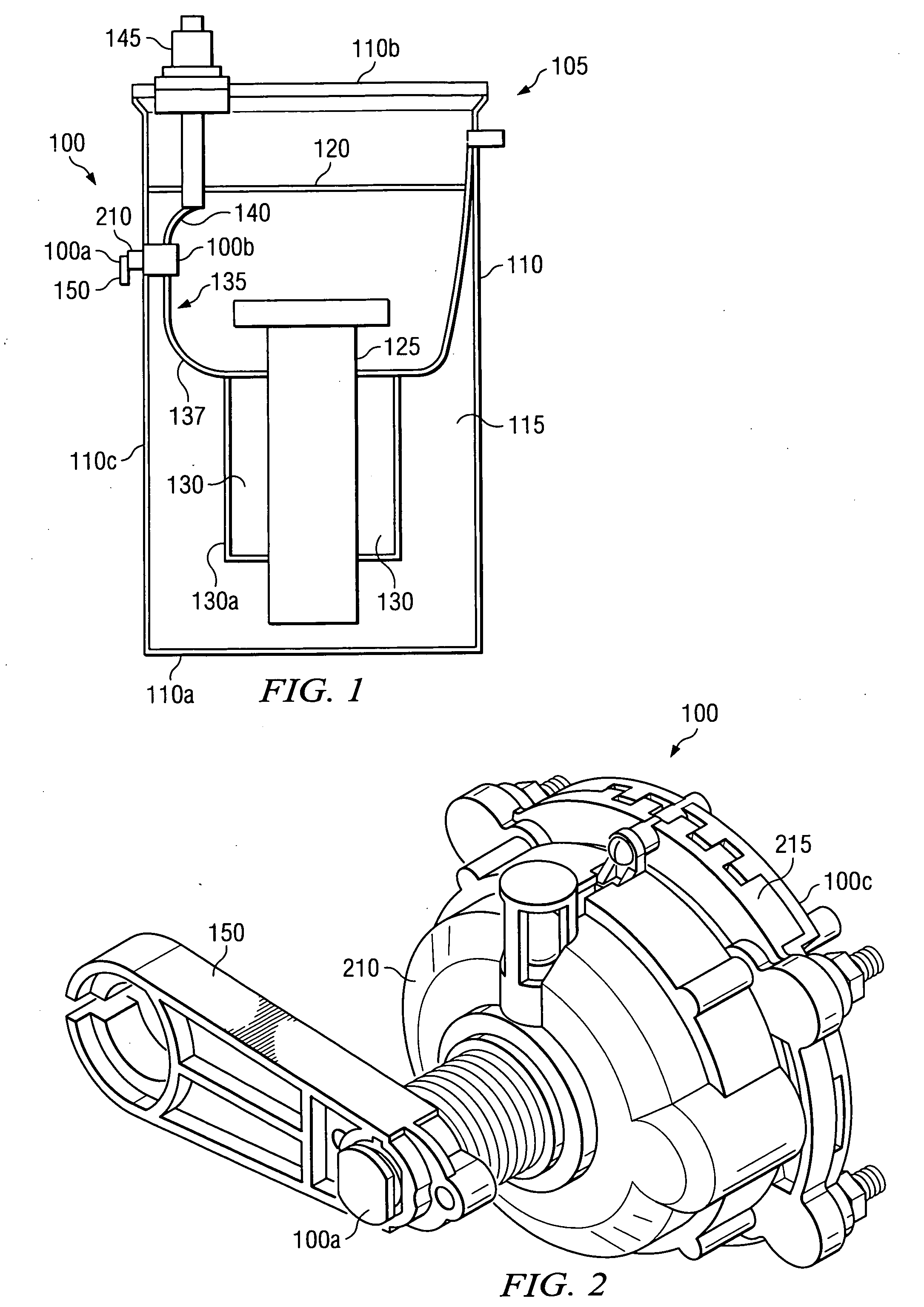

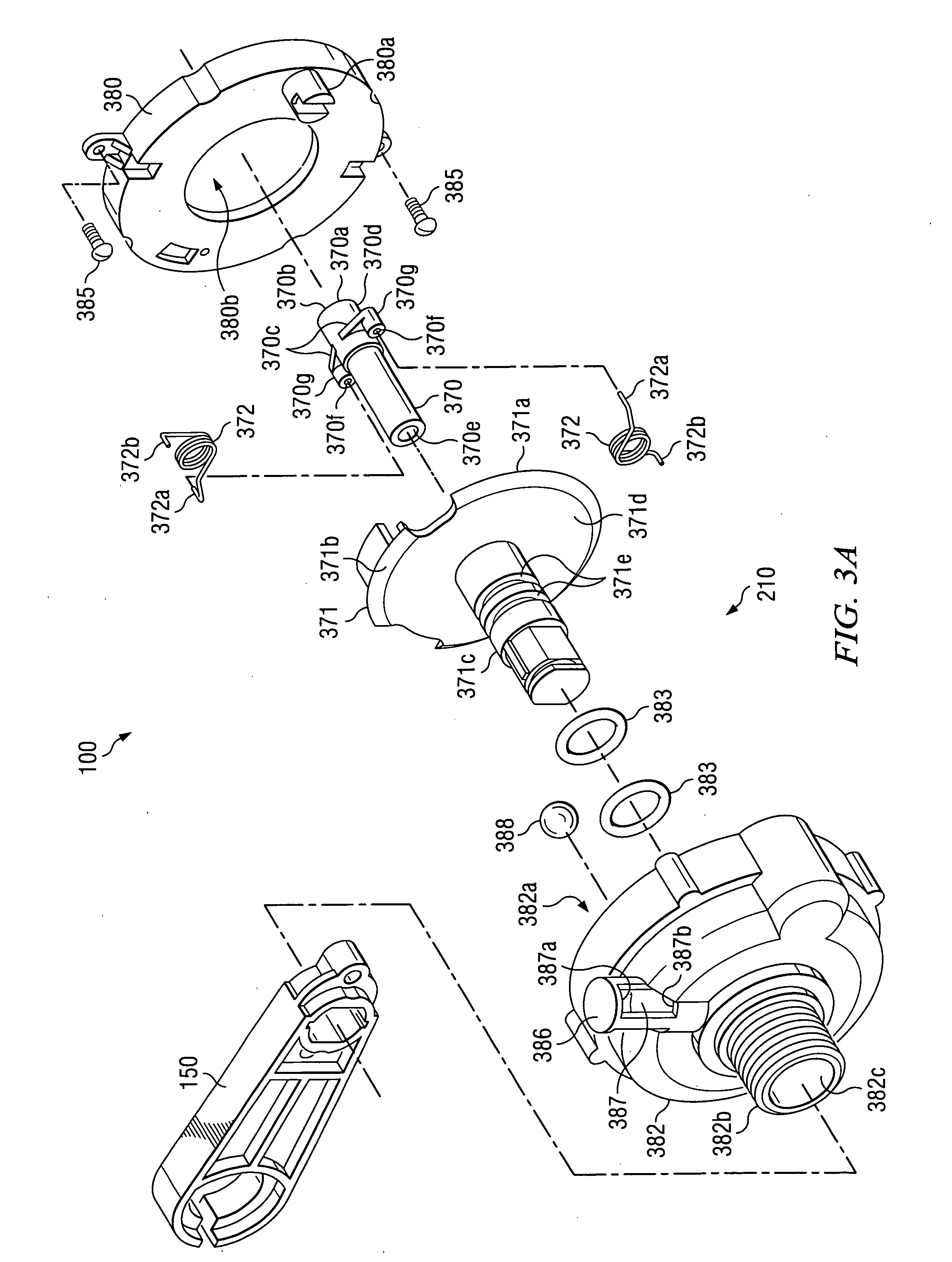

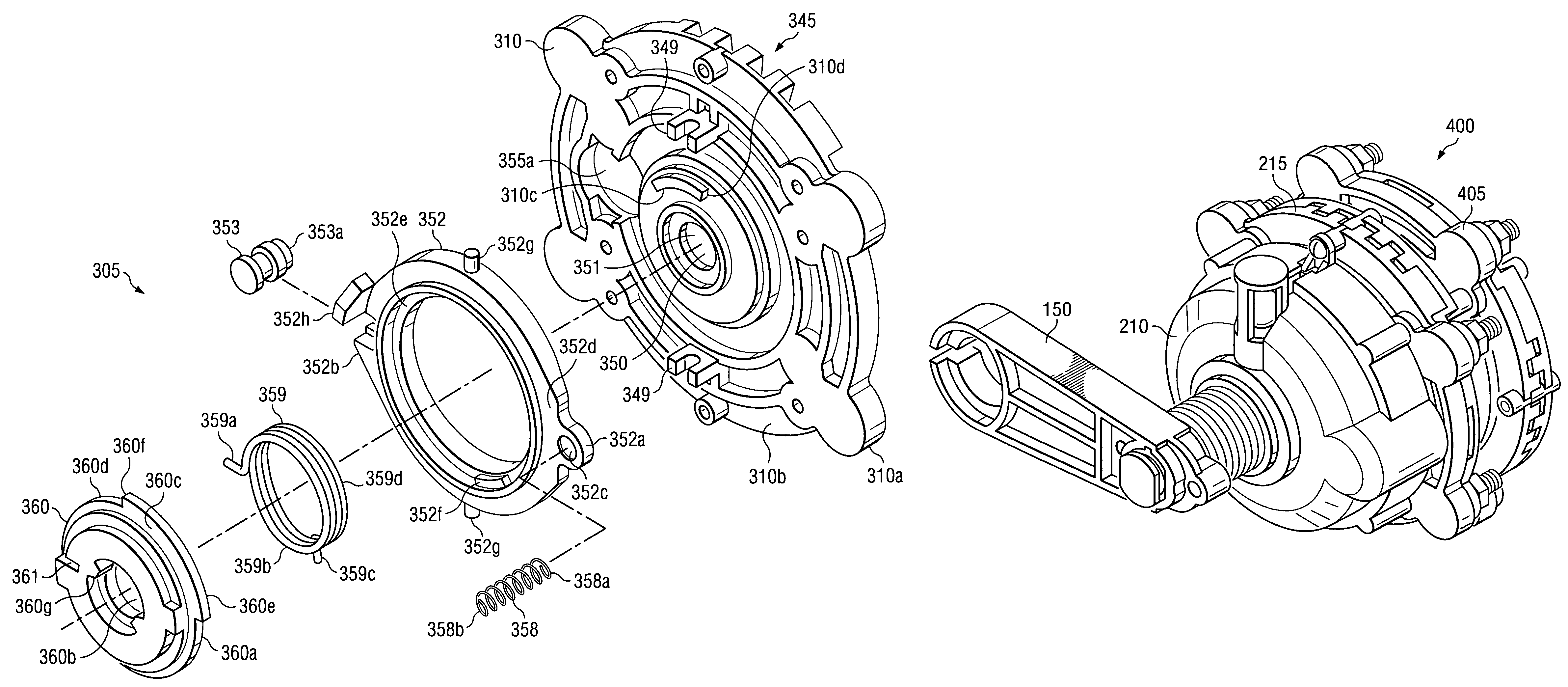

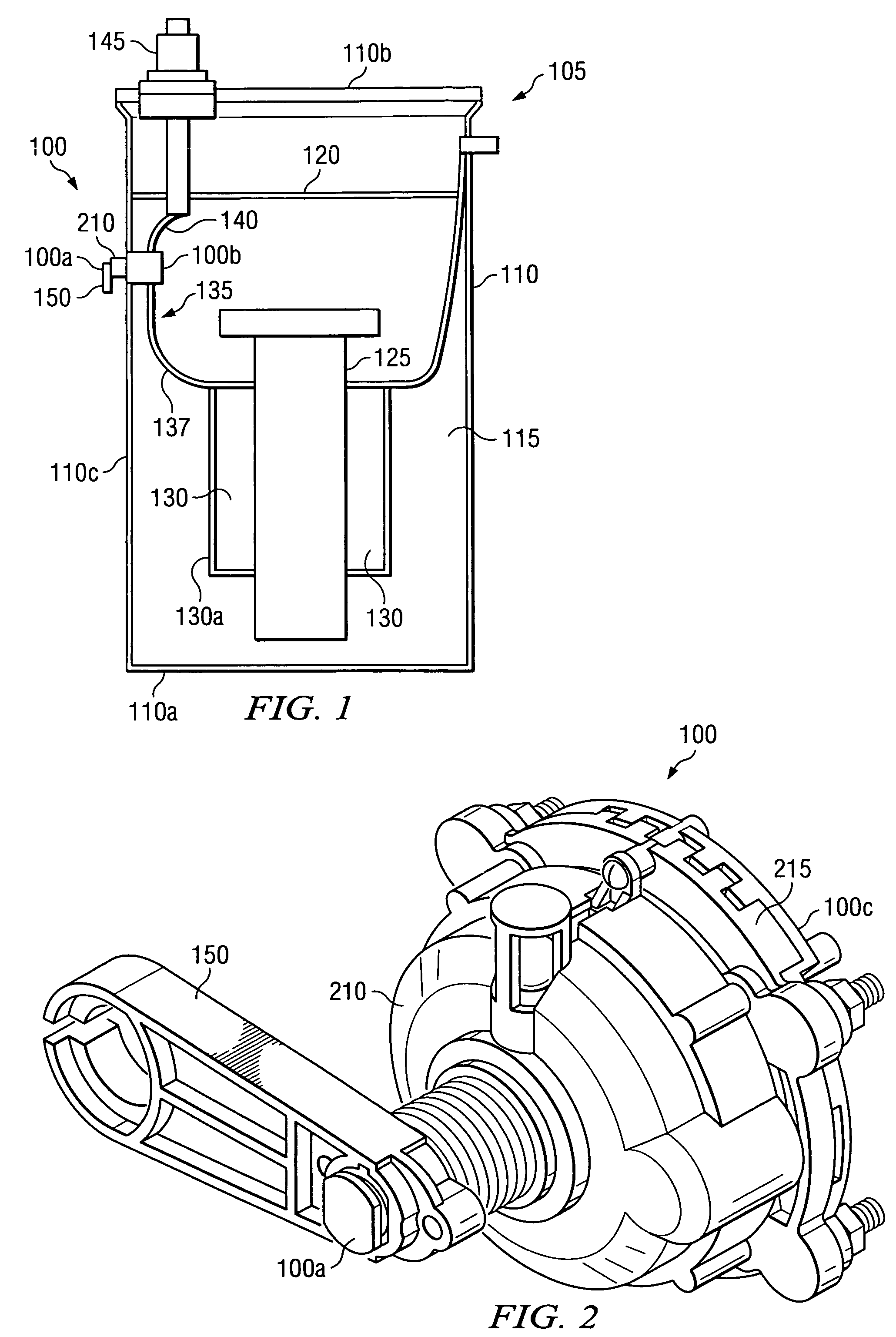

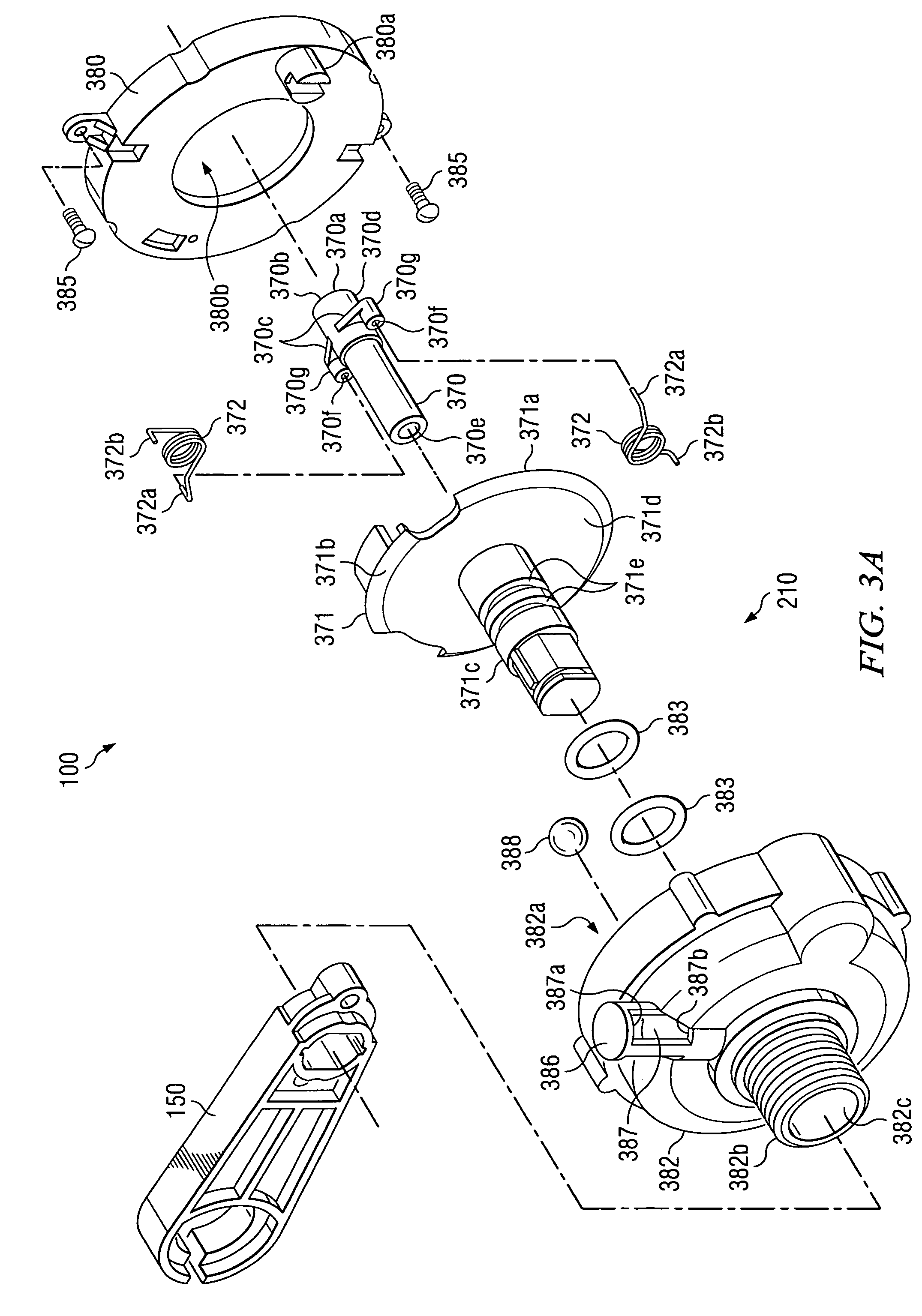

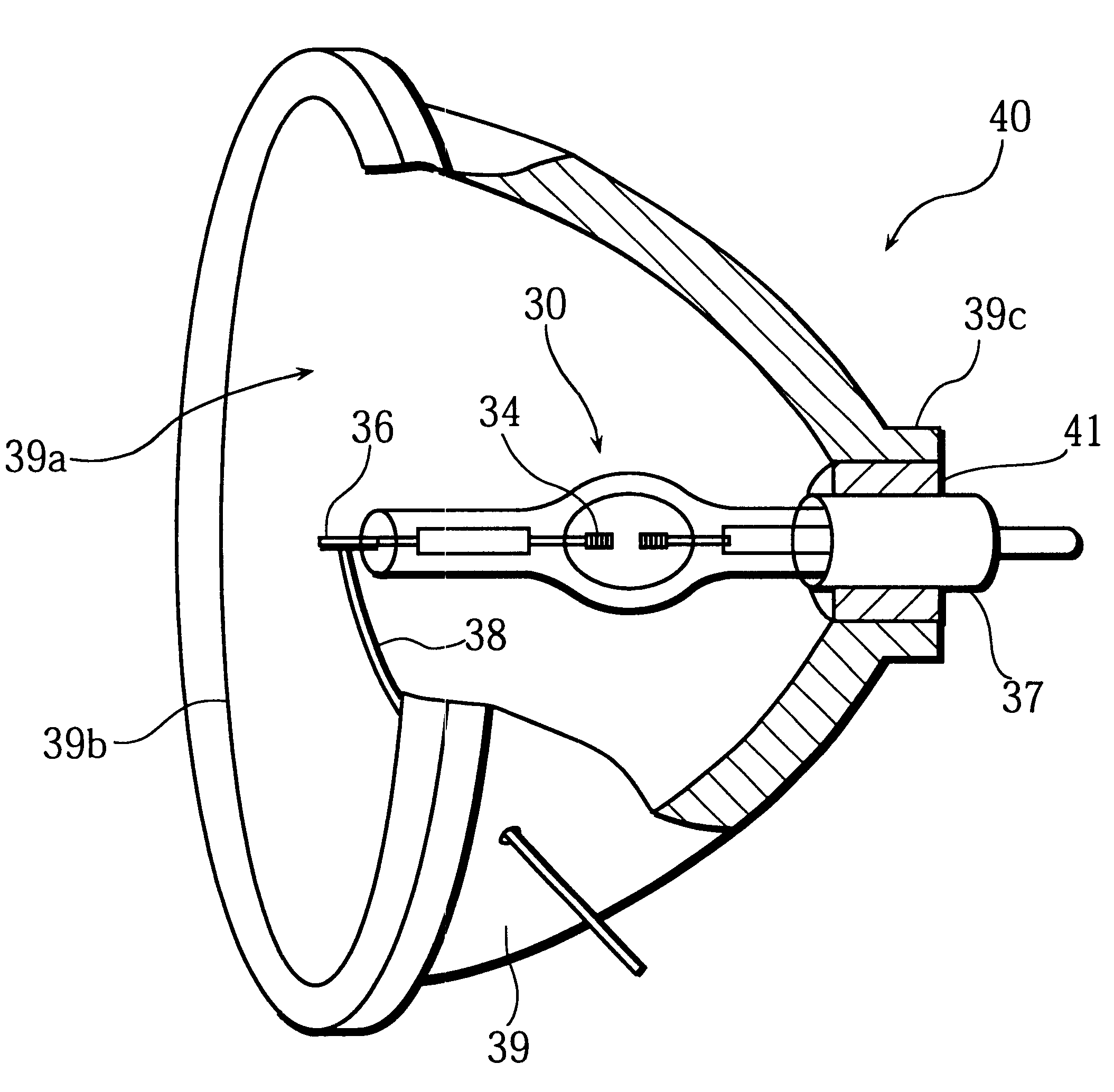

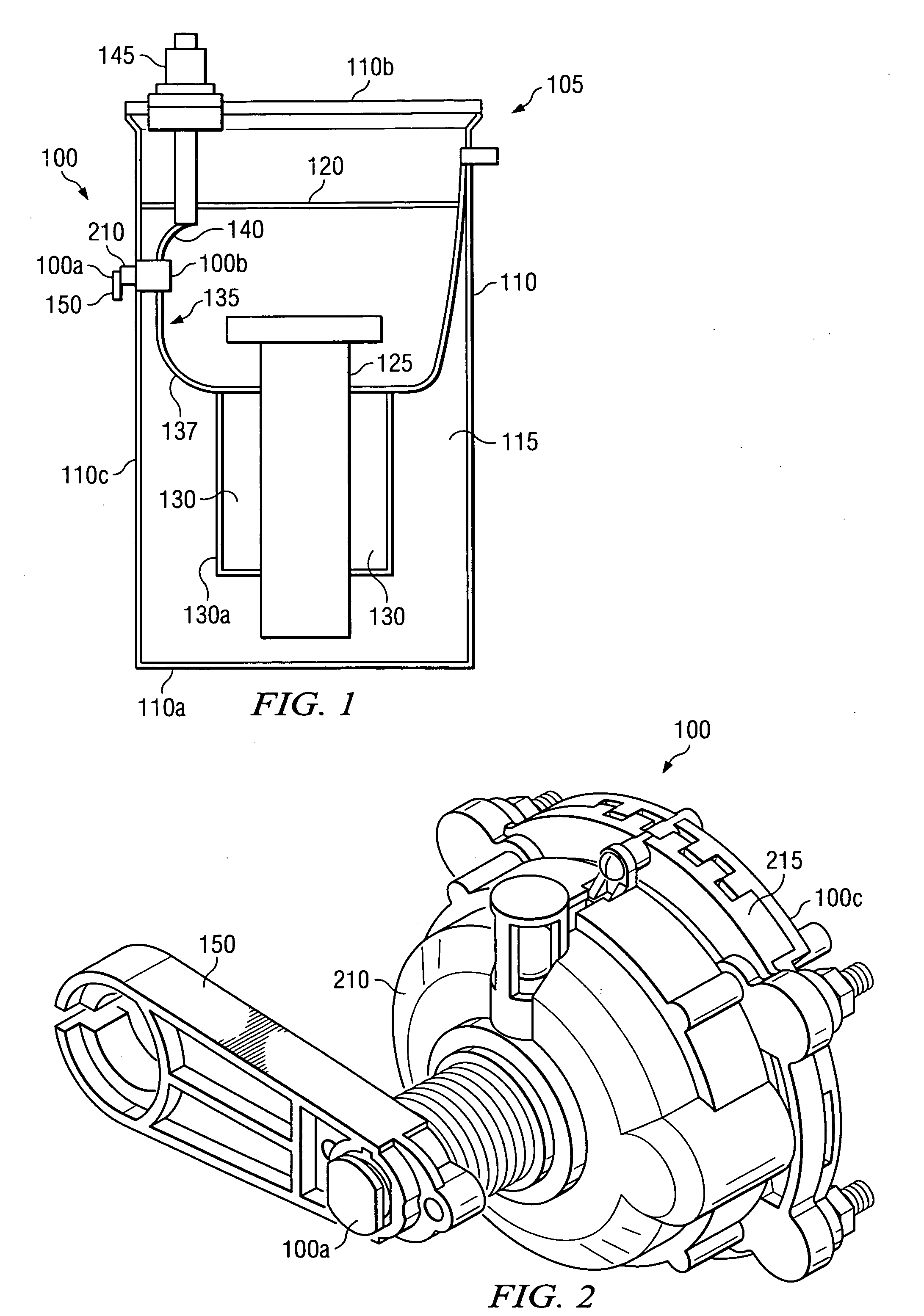

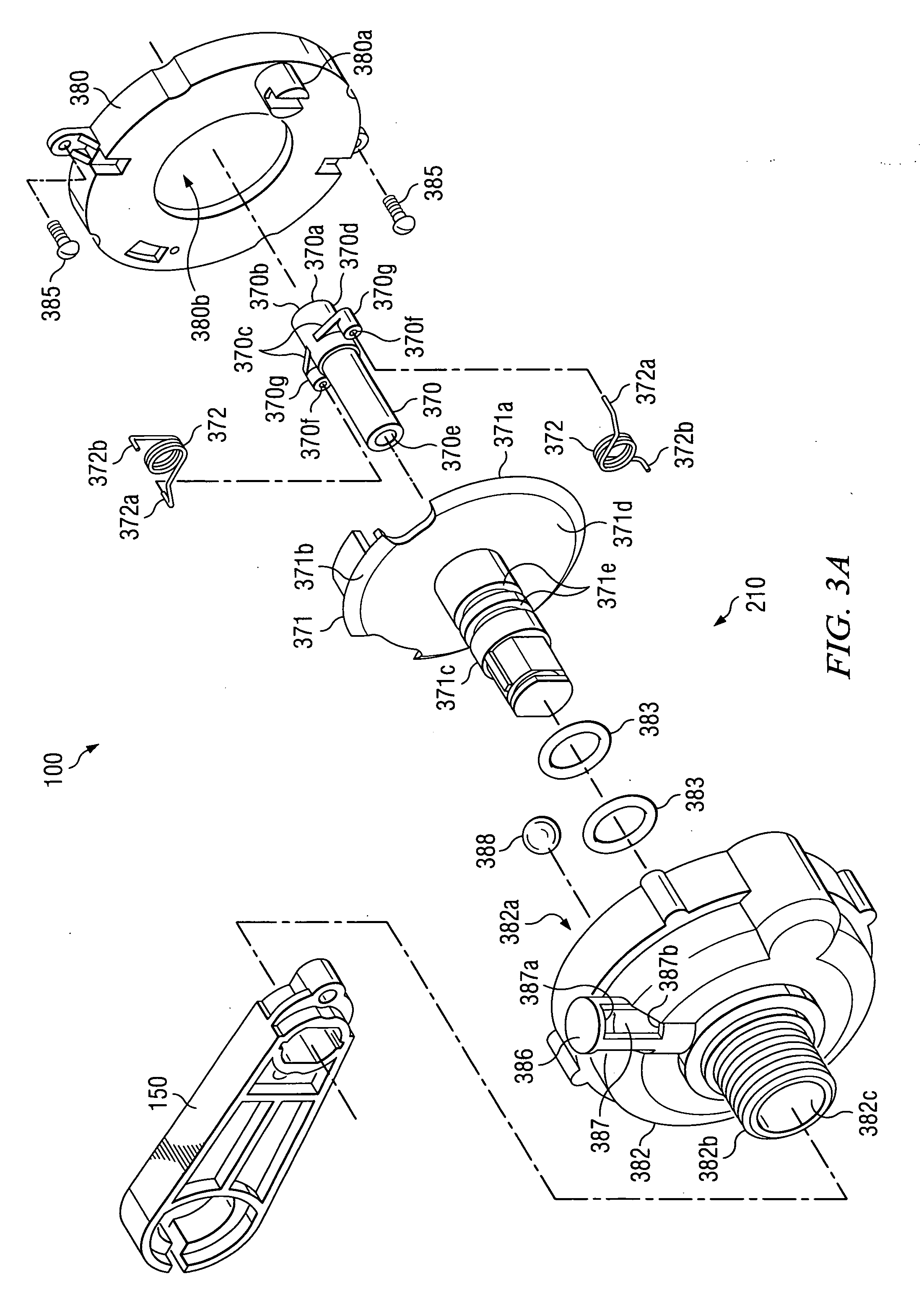

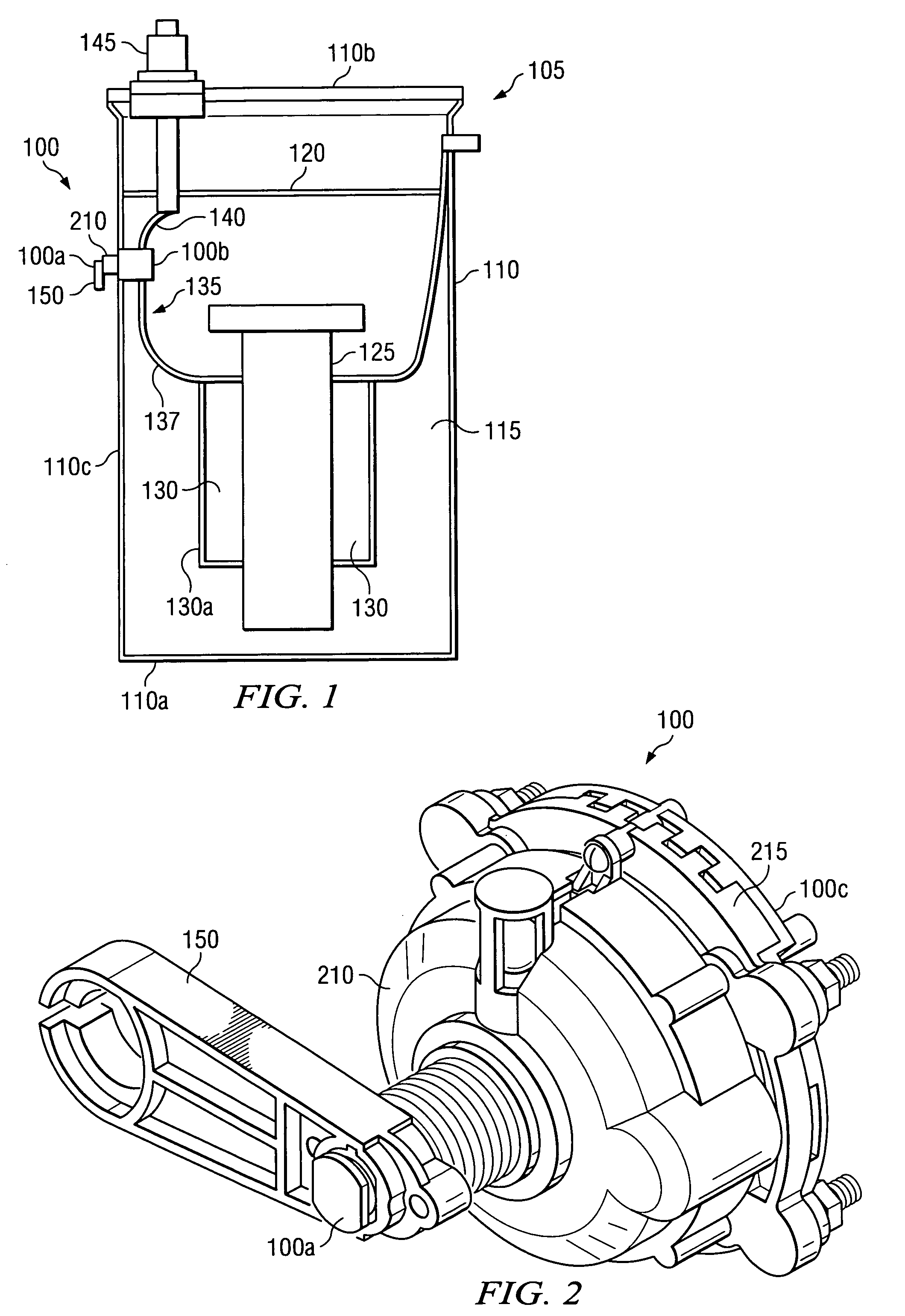

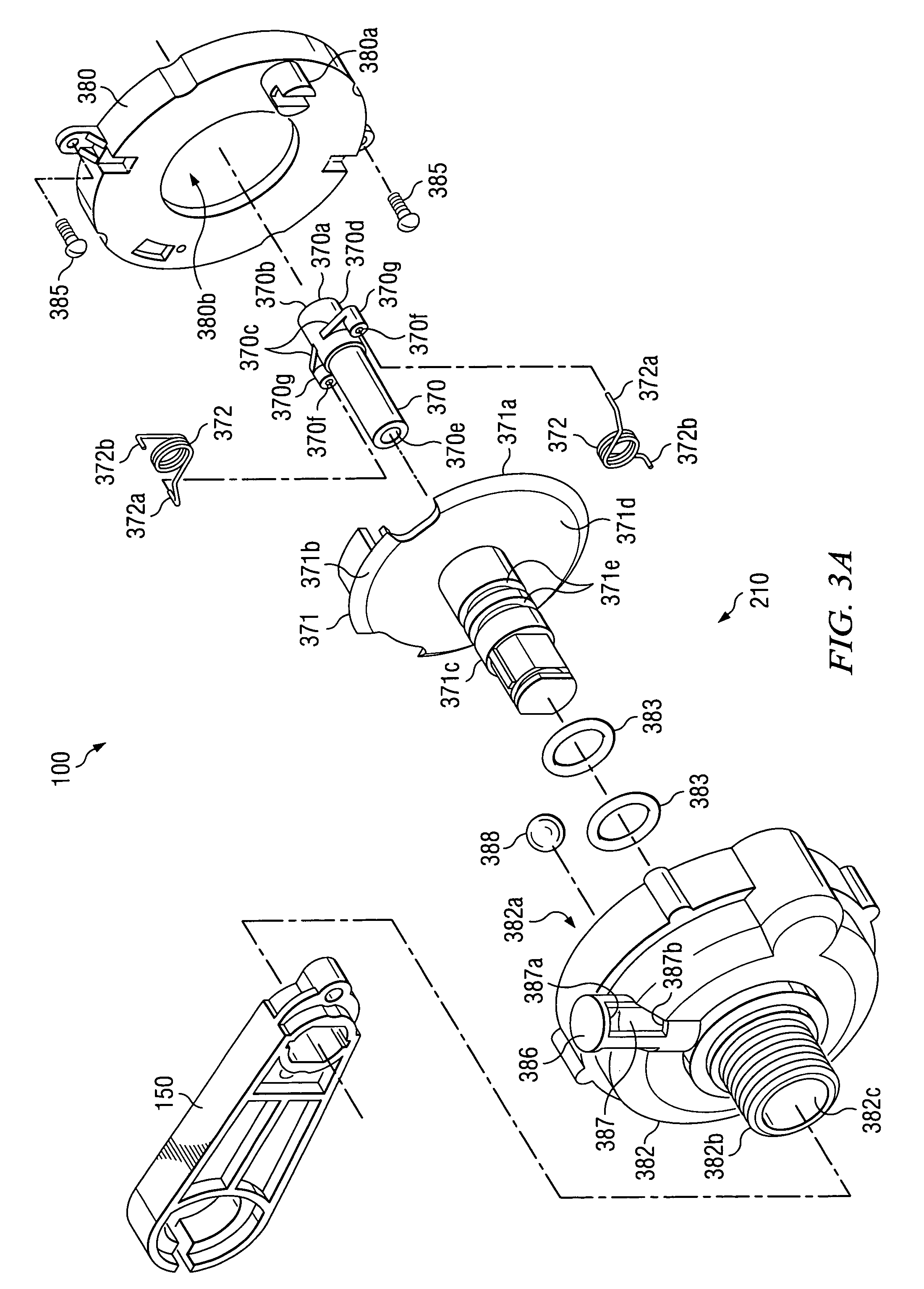

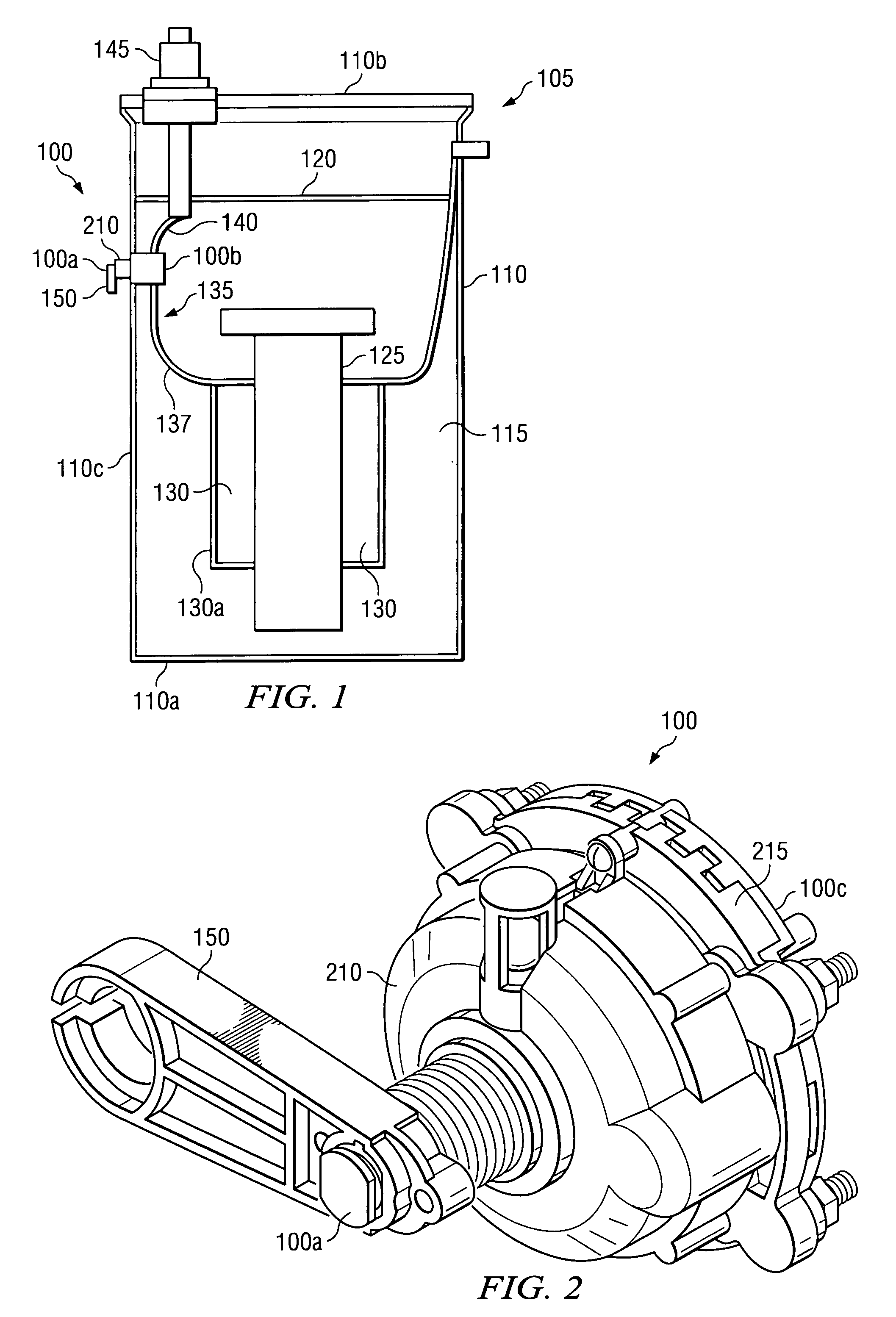

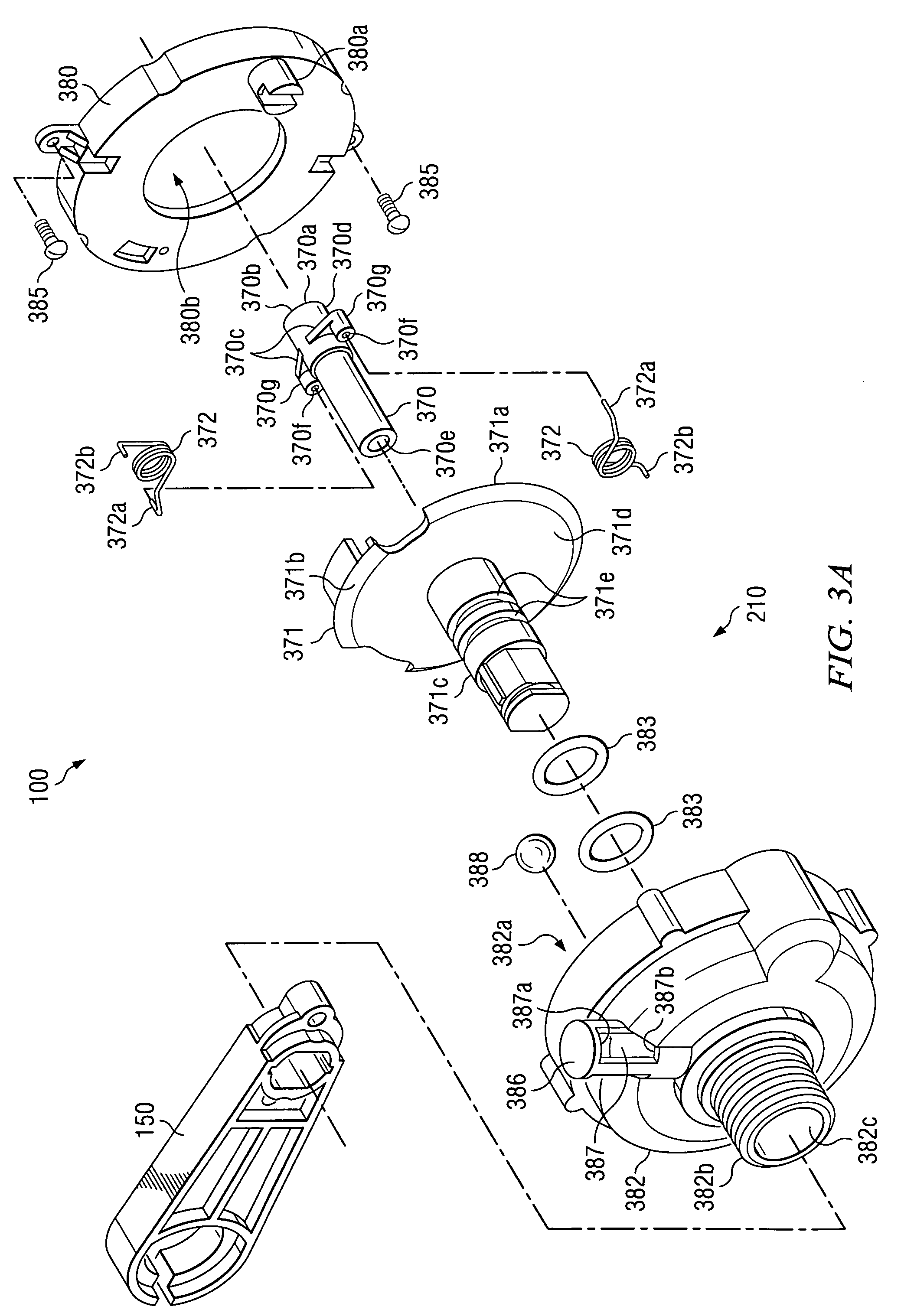

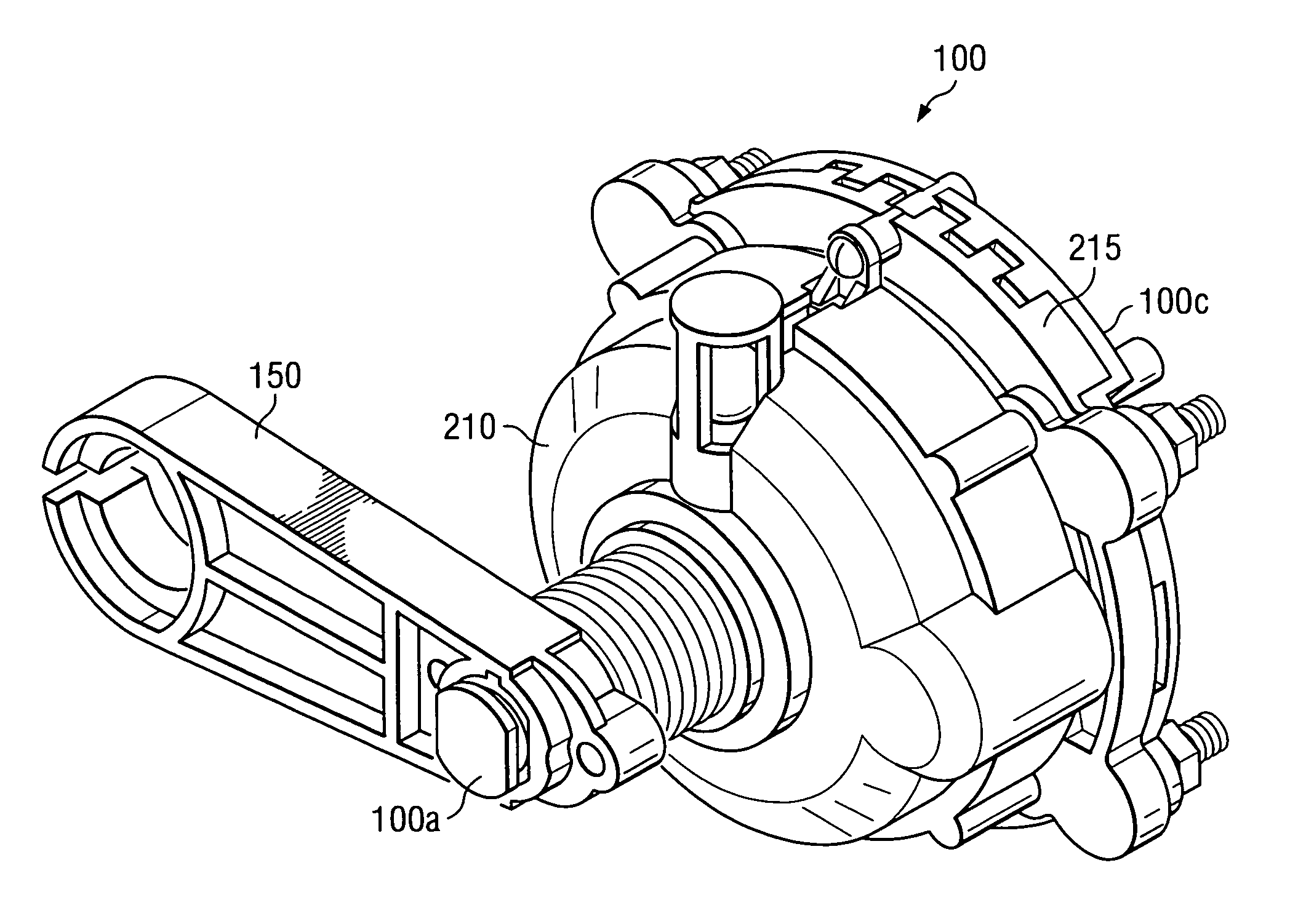

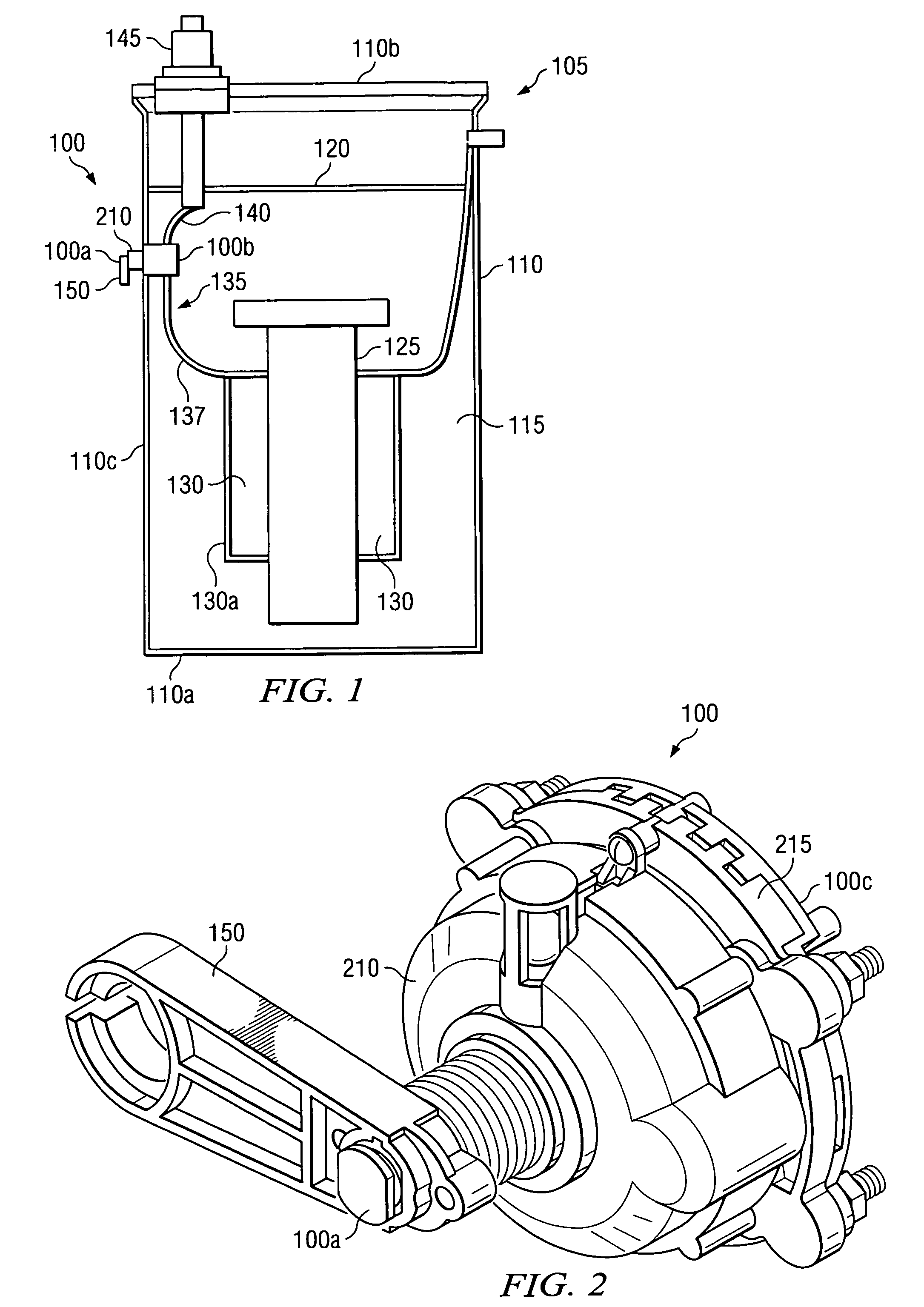

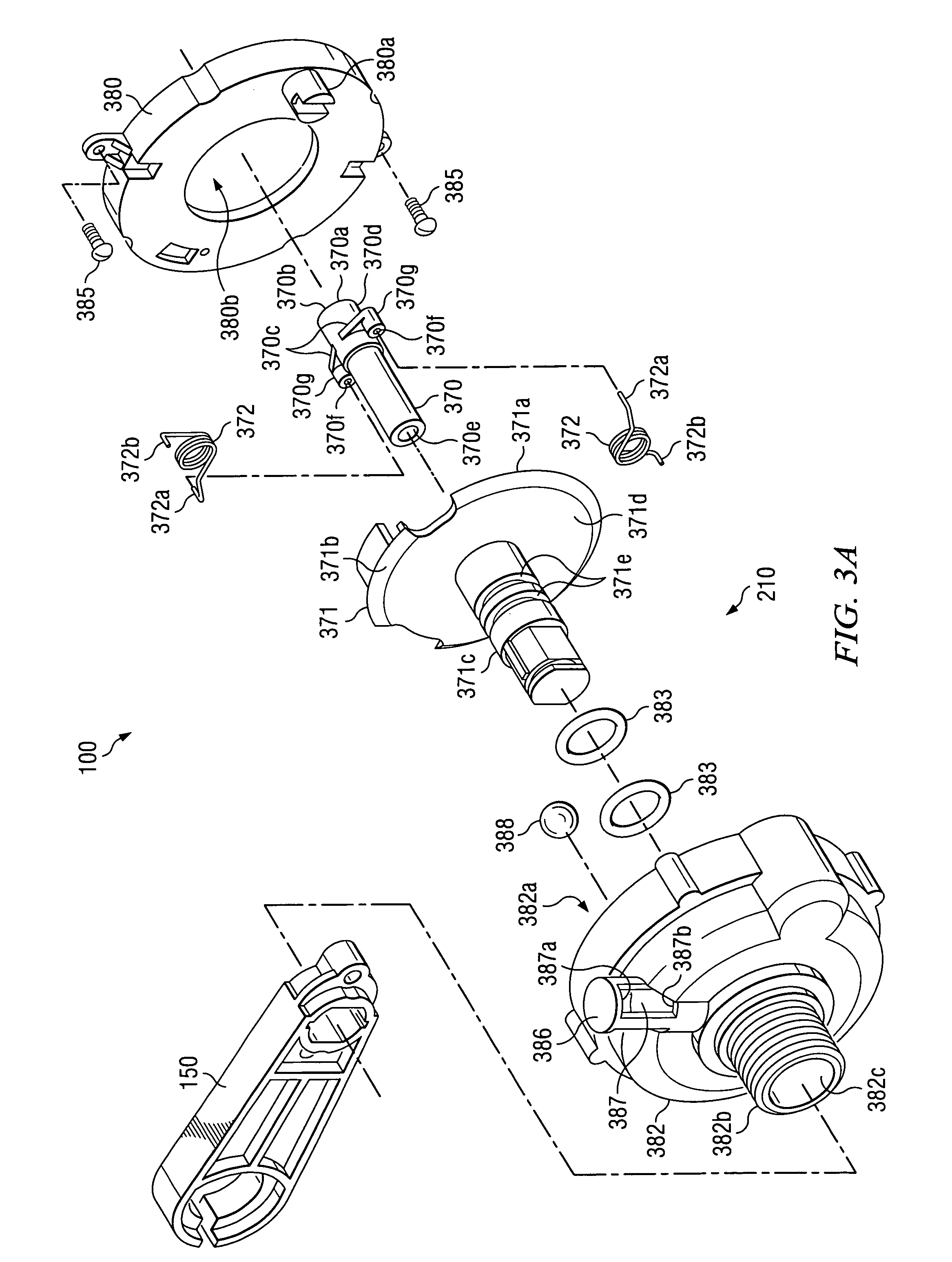

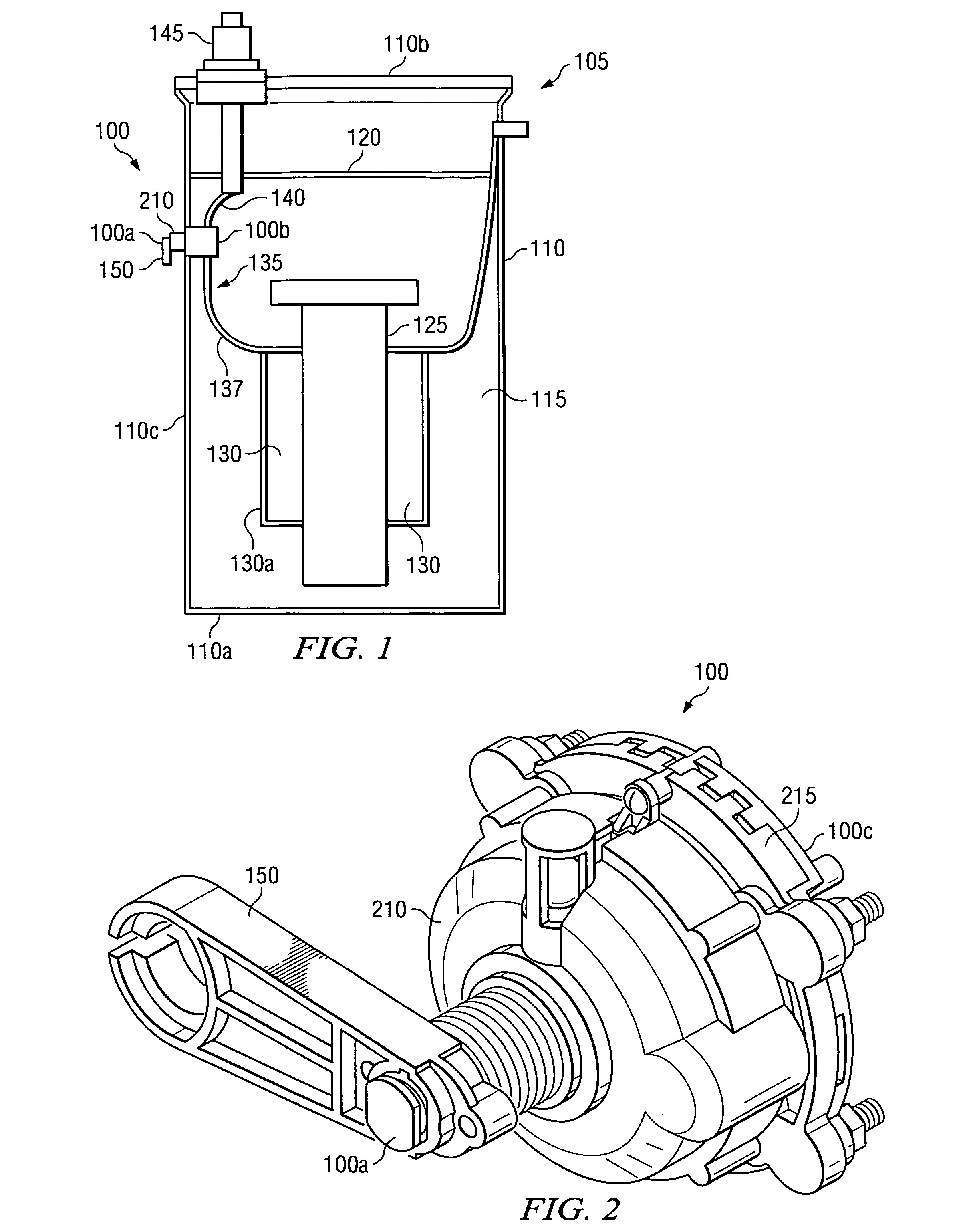

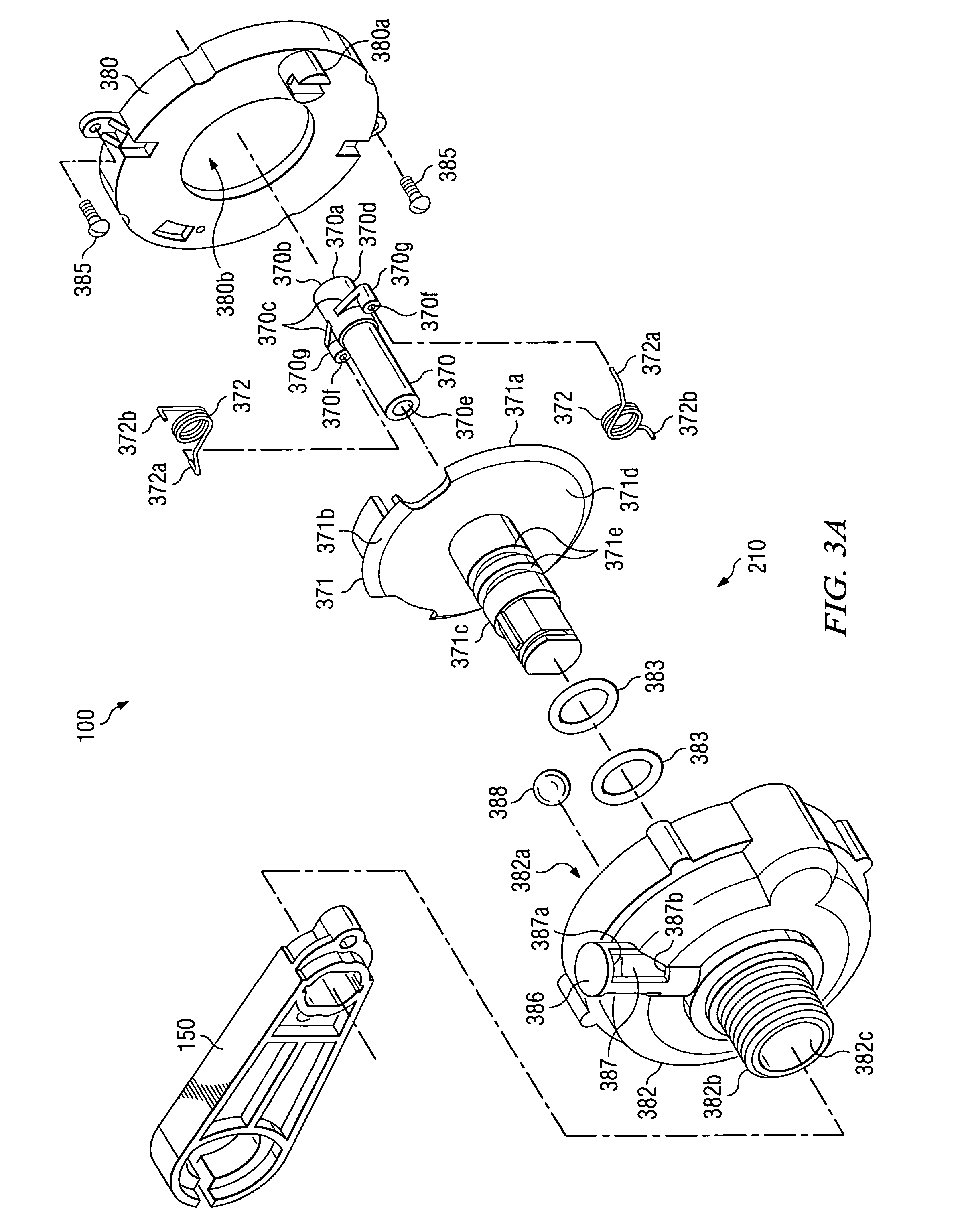

Fault Interrupter and Load Break Switch

ActiveUS20090278635A1Increases voltage capacityEasy to extinguishElectromagnetically operated protective switchesHigh-tension/heavy-dress switchesTransformerEngineering

A fault interrupter and load break switch includes a trip assembly configured to automatically open a transformer circuit electrically coupled to stationary contacts of the switch upon the occurrence of a fault condition. The fault condition causes a Curie metal element electrically coupled to at least one of the stationary contacts to release a magnetic latch. The release causes a trip rotor of the trip assembly to rotate a rotor assembly. This rotation causes ends of a movable contact of the rotor assembly to electrically disengage the stationary contacts, thereby opening the circuit. The switch also includes a handle for manually opening and closing the electrical circuit in fault and non-fault conditions. Actuation of the handle coupled to the rotor assembly via a spring-loaded rotor causes the movable contact ends to selectively engage or disengage the stationary contacts.

Owner:EATON INTELLIGENT POWER LIMITED

Indicator for a fault interrupter and load break switch

ActiveUS20090278636A1Increases voltage capacityEasy to extinguishElectronic circuit testingDirection of current indicationTransformerEngineering

A fault interrupter and load break switch includes a trip assembly configured to automatically open a transformer circuit electrically coupled to stationary contacts of the switch upon the occurrence of a fault condition. The fault condition causes a Curie metal element electrically coupled to at least one of the stationary contacts to release a magnetic latch. The release causes a trip rotor of the trip assembly to rotate a rotor assembly. This rotation causes ends of a movable contact of the rotor assembly to electrically disengage the stationary contacts, thereby opening the circuit. The switch also includes a handle for manually opening and closing the electrical circuit in fault and non-fault conditions. Actuation of the handle coupled to the rotor assembly via a spring-loaded rotor causes the movable contact ends to selectively engage or disengage the stationary contacts.

Owner:EATON INTELLIGENT POWER LIMITED

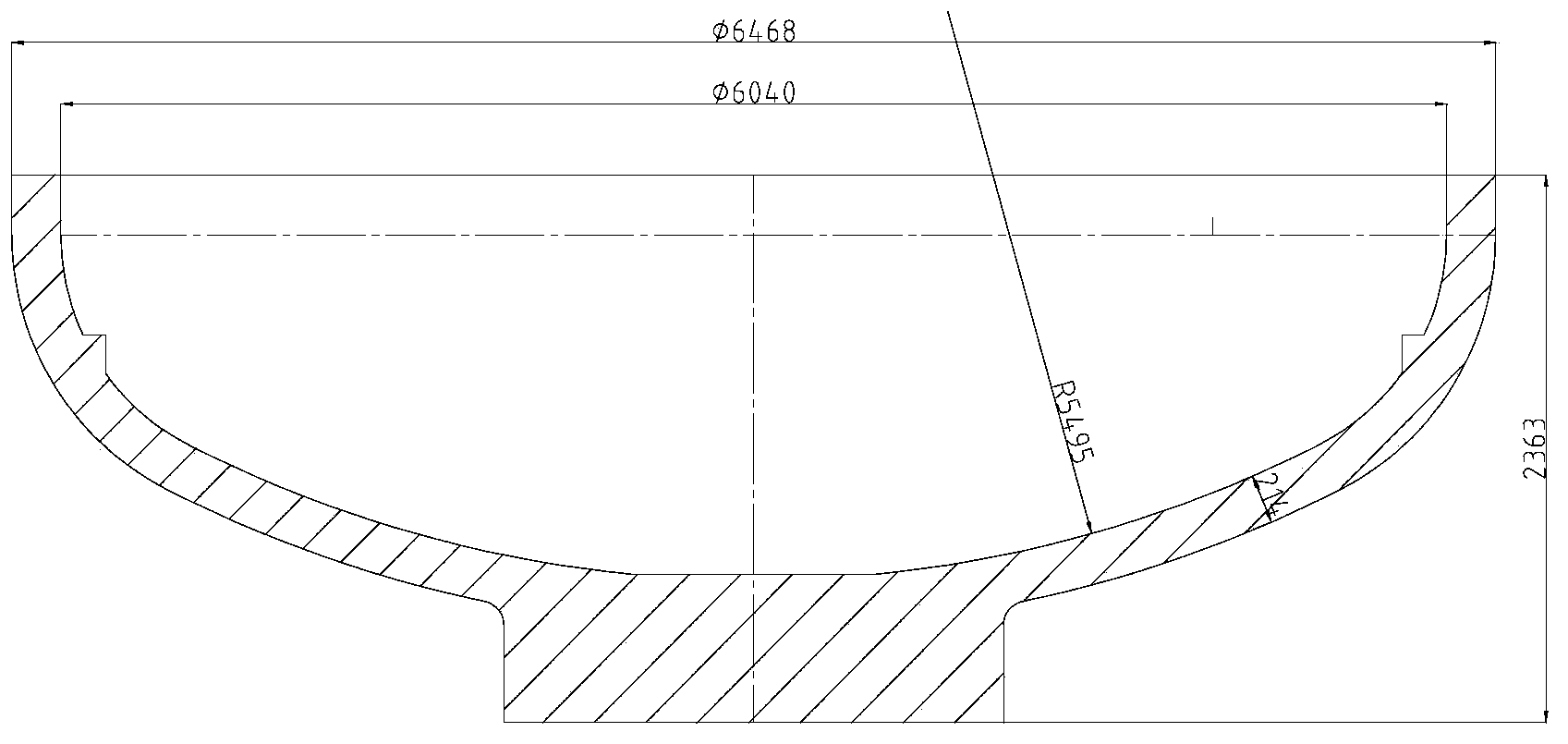

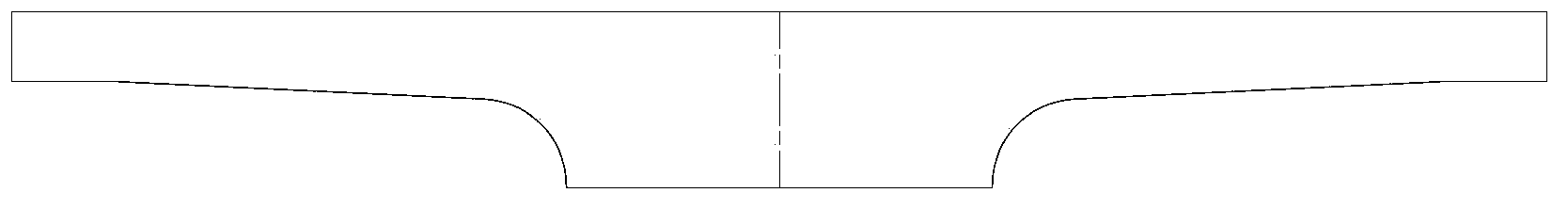

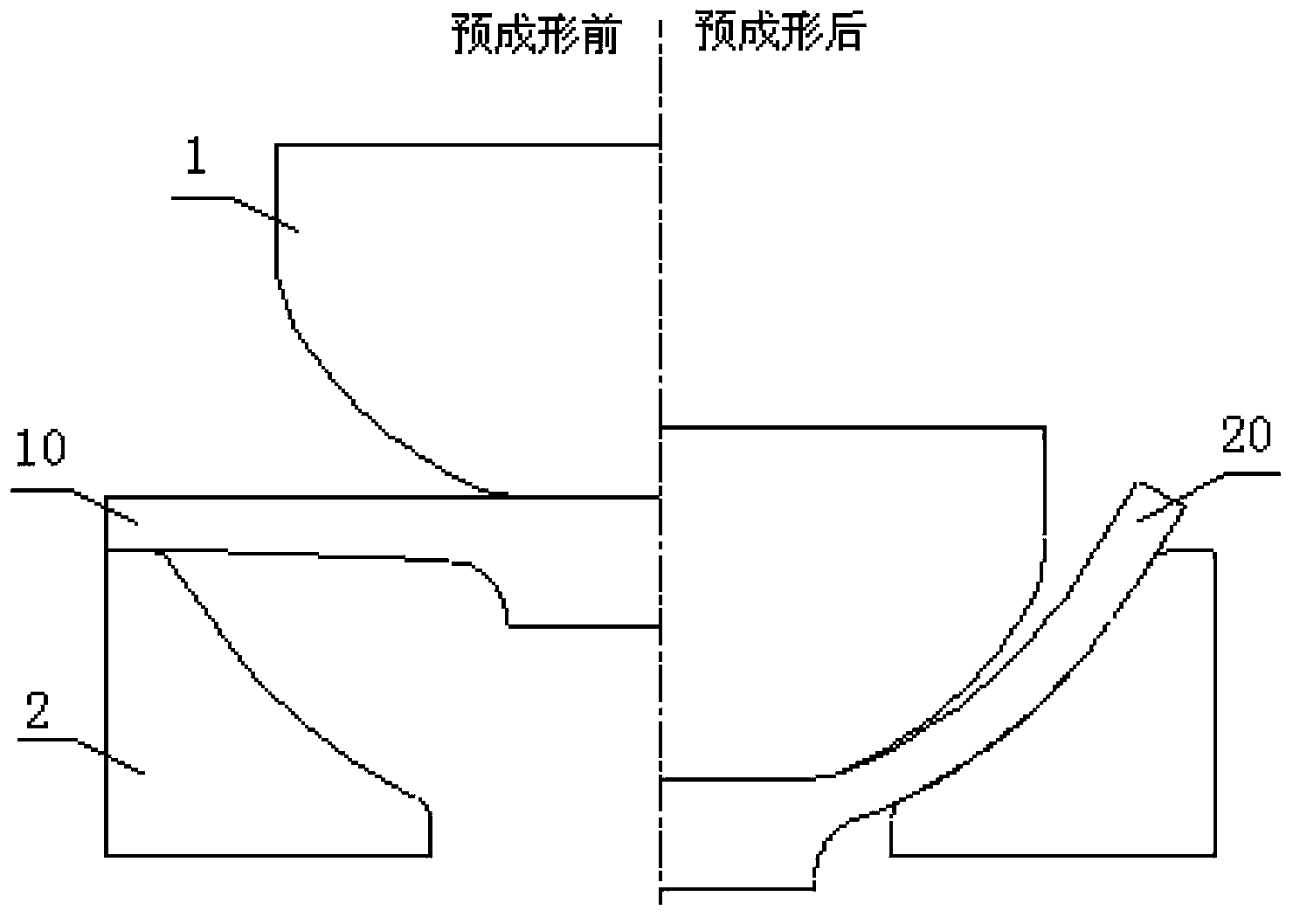

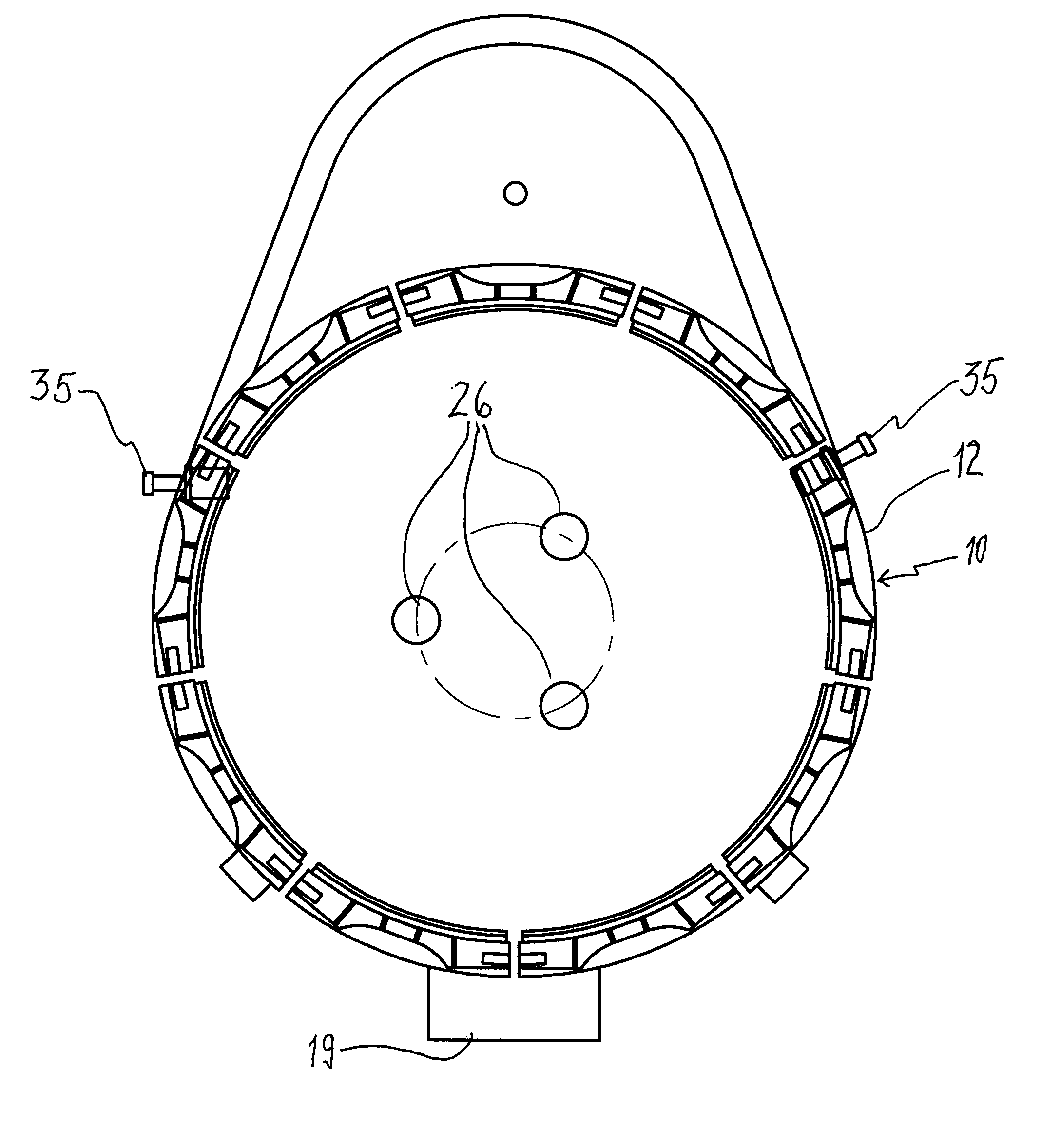

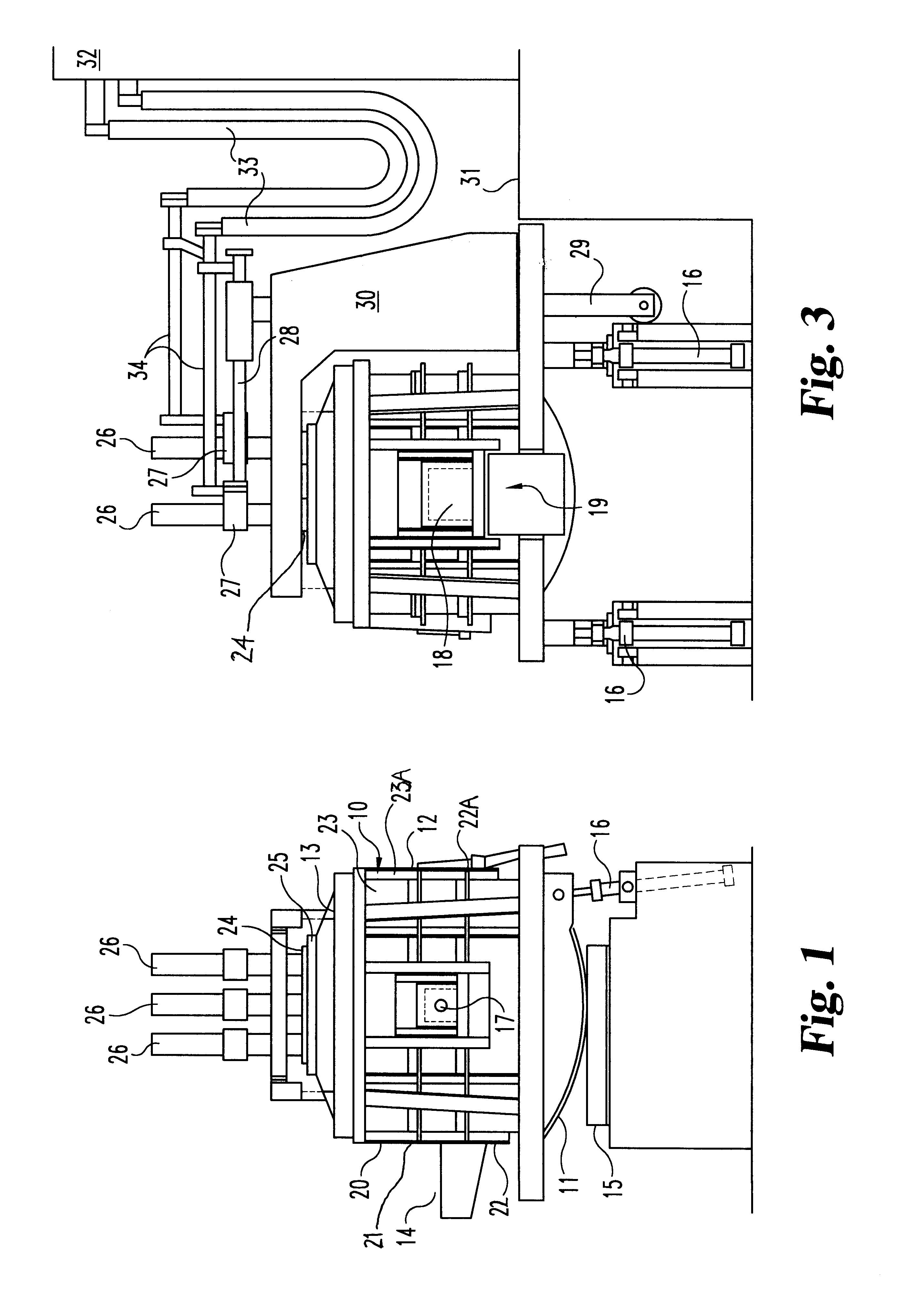

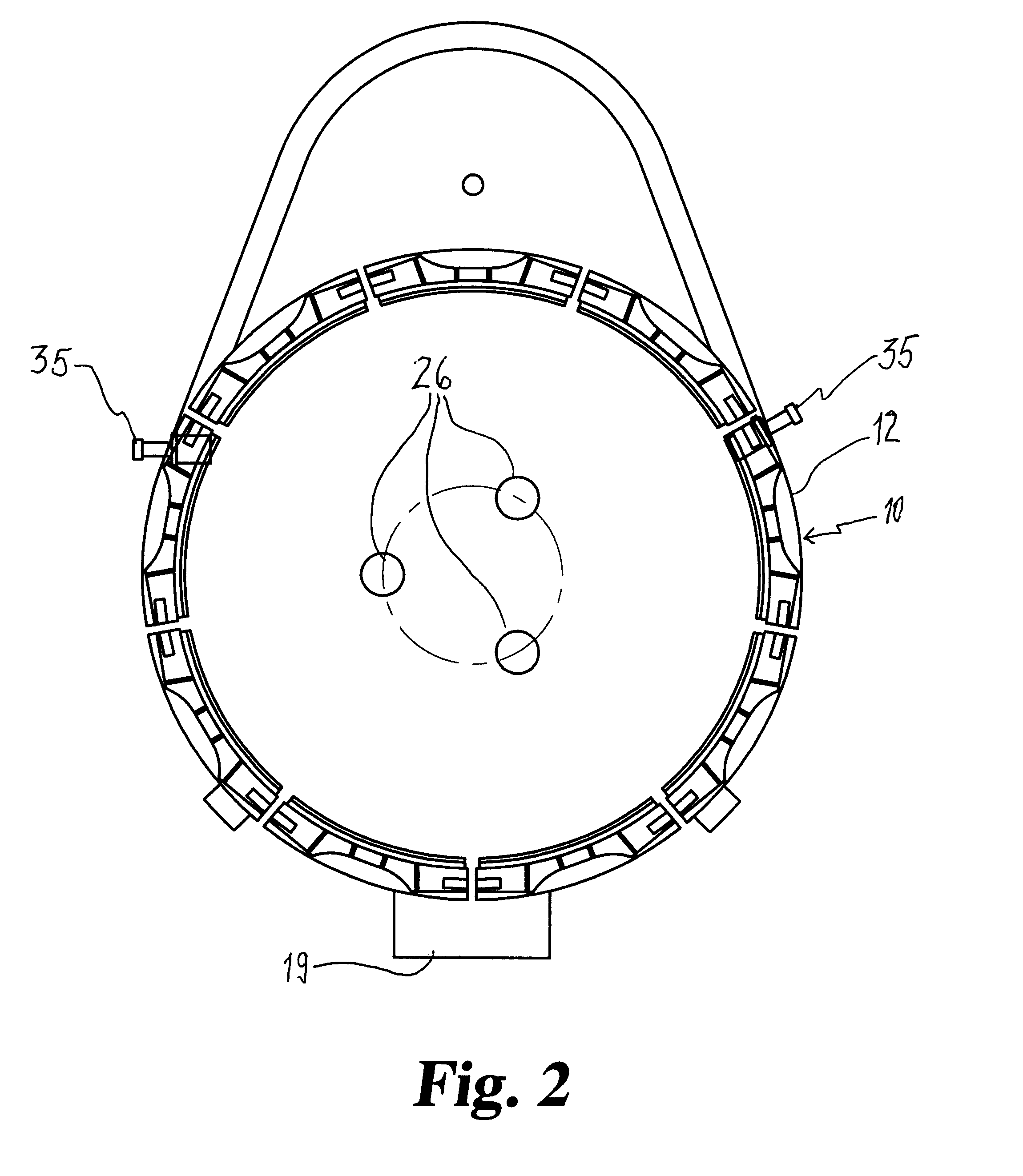

Forging method for elliptical seal head of CAP1400 steam generator

ActiveCN103567339ASolving Manufacturing ChallengesBloomMetal-working apparatusEngineeringMechanical engineering

The invention discloses a forging method for an elliptical seal head of a CAP1400 steam generator. The forging method comprises the steps of 1) manufacturing a blank; 2) heating; 3) assembling a die; 4) preforming; 5) stamping. By adopting the forging method, when the elliptical seal head with ultra-large size cannot be directly forged, firstly a circular plate blank with smaller diameter is preformed through a forging method of rotary drawing to increase the arc length of a workpiece and form an enough large circular-arc-shaped blank, and then the blank is stamped as a whole body to meet the requirement on the final size of the ultra-large size elliptical seal head. Therefore, the forging method for the elliptical seal head of the CAP1400 steam generator can effectively solve the problem that the large-sized and integrated forged piece of the elliptical seal head of the CAP1400 steam generator is difficult to manufacture.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

Low Oil Trip Assembly for a Fault Interrupter and Load Break Switch

InactiveUS20090277768A1Increases voltage capacityEasy to extinguishCircuit-breaking switches for excess currentsMachines/enginesTransformerInterrupter

A fault interrupter and load break switch includes a trip assembly configured to automatically open a transformer circuit electrically coupled to stationary contacts of the switch upon the occurrence of a fault condition. The fault condition causes a Curie metal element electrically coupled to at least one of the stationary contacts to release a magnetic latch. The release causes a trip rotor of the trip assembly to rotate a rotor assembly. This rotation causes ends of a movable contact of the rotor assembly to electrically disengage the stationary contacts, thereby opening the circuit. The switch also includes a handle for manually opening and closing the electrical circuit in fault and non-fault conditions. Actuation of the handle coupled to the rotor assembly via a spring-loaded rotor causes the movable contact ends to selectively engage or disengage the stationary contacts.

Owner:COOPER TECH CO

Sensor Element for a Fault Interrupter and Load Break Switch

ActiveUS20090279223A1Increases voltage capacityEasy to extinguishElectrothermal relaysEmergency protective arrangements for automatic disconnectionTransformerEngineering

A fault interrupter and load break switch includes a trip assembly configured to automatically open a transformer circuit electrically coupled to stationary contacts of the switch upon the occurrence of a fault condition. The fault condition causes a Curie metal element electrically coupled to at least one of the stationary contacts to release a magnetic latch. The release causes a trip rotor of the trip assembly to rotate a rotor assembly. This rotation causes ends of a movable contact of the rotor assembly to electrically disengage the stationary contacts, thereby opening the circuit. The switch also includes a handle for manually opening and closing the electrical circuit in fault and non-fault conditions. Actuation of the handle coupled to the rotor assembly via a spring-loaded rotor causes the movable contact ends to selectively engage or disengage the stationary contacts.

Owner:EATON INTELLIGENT POWER LIMITED

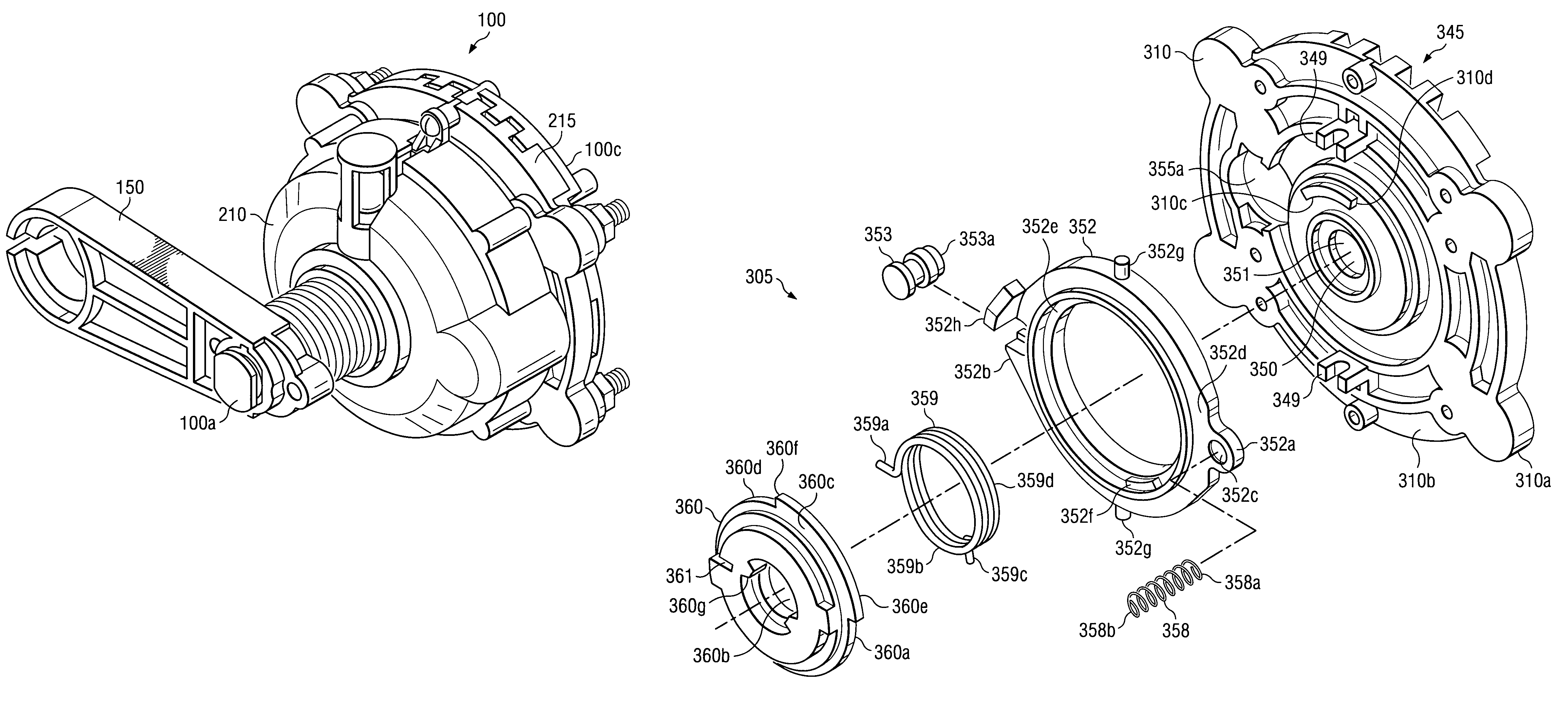

Adjustable Rating for a Fault Interrupter and Load Break Switch

ActiveUS20090279216A1Increases voltage capacityEasy to extinguishSwitches with electromagnetic openingElectromagnetically operated protective switchesTransformerEngineering

A fault interrupter and load break switch includes a trip assembly configured to automatically open a transformer circuit electrically coupled to stationary contacts of the switch upon the occurrence of a fault condition. The fault condition causes a Curie metal element electrically coupled to at least one of the stationary contacts to release a magnetic latch. The release causes a trip rotor of the trip assembly to rotate a rotor assembly. This rotation causes ends of a movable contact of the rotor assembly to electrically disengage the stationary contacts, thereby opening the circuit. The switch also includes a handle for manually opening and closing the electrical circuit in fault and non-fault conditions. Actuation of the handle coupled to the rotor assembly via a spring-loaded rotor causes the movable contact ends to selectively engage or disengage the stationary contacts.

Owner:EATON INTELLIGENT POWER LIMITED

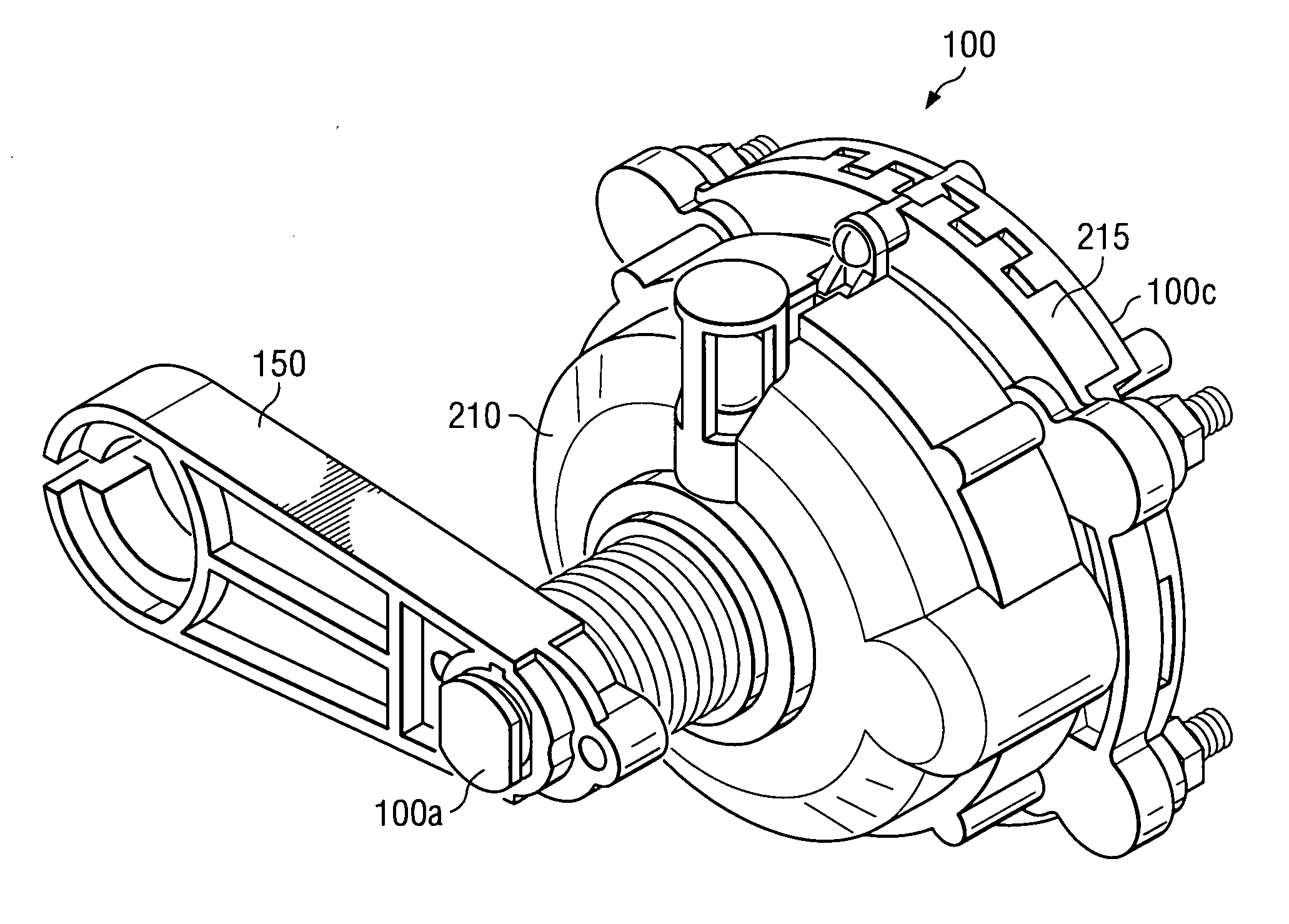

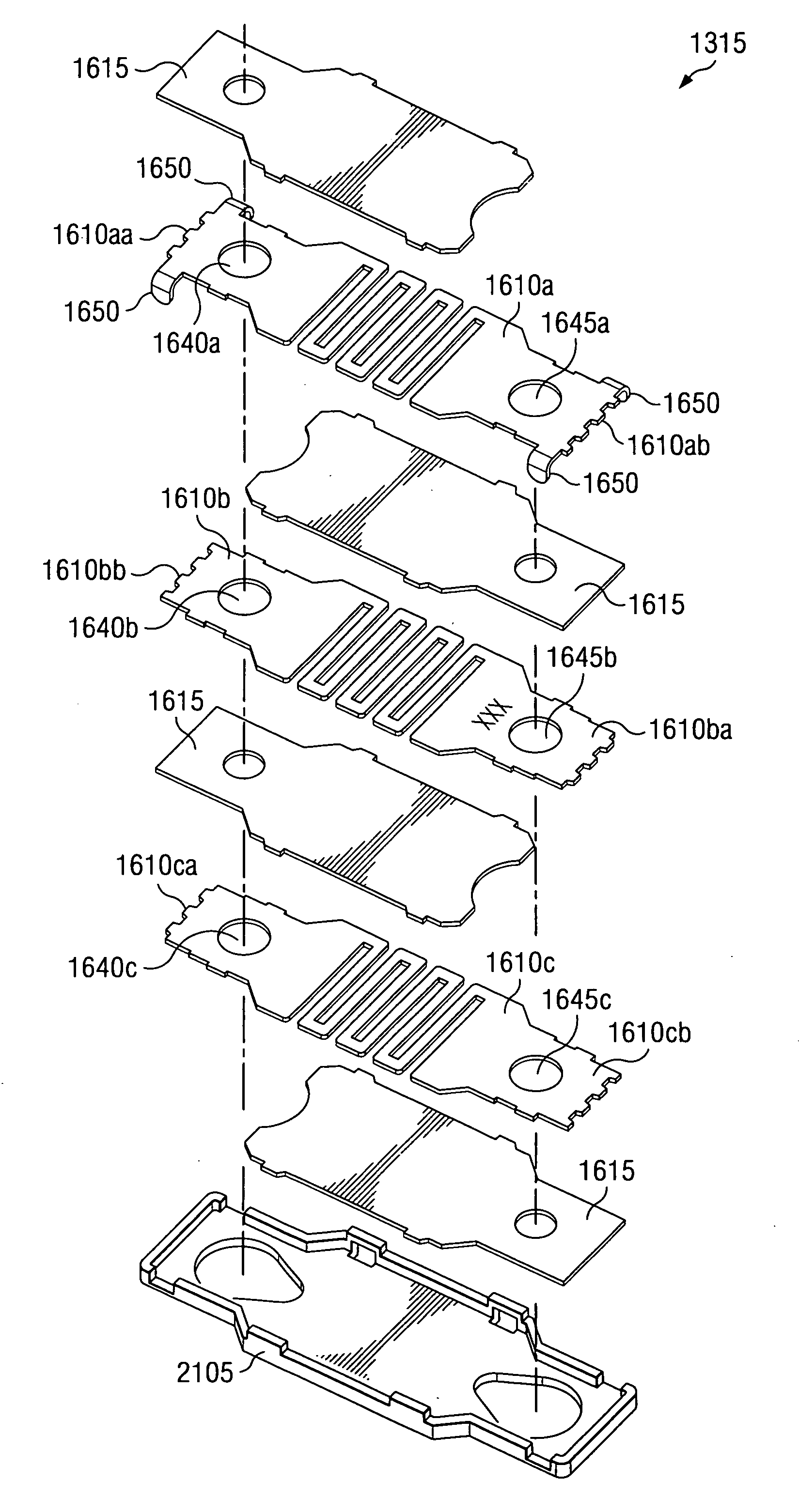

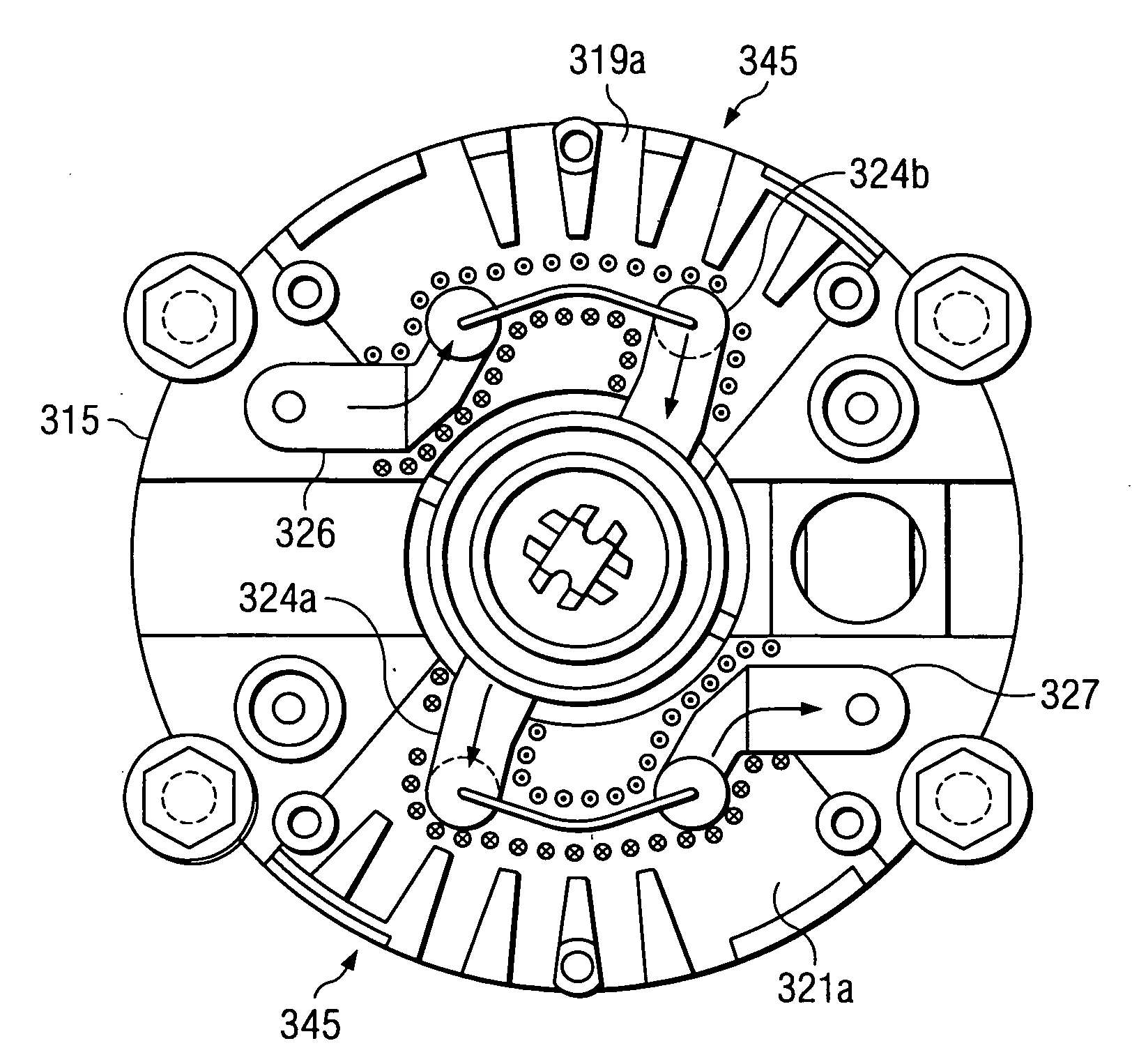

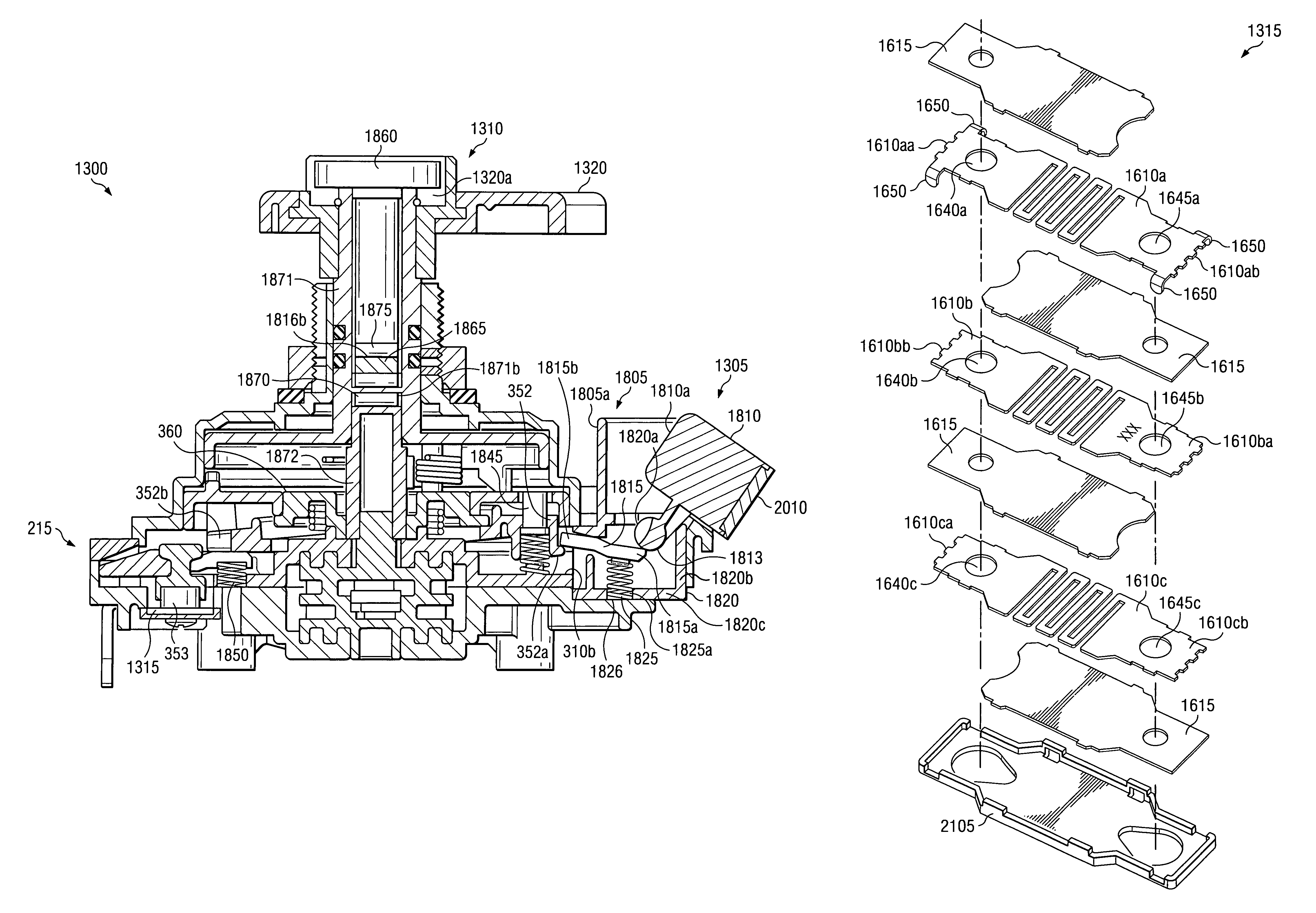

Multiple arc chamber assemblies for a fault interrupter and load break switch

ActiveUS7683287B2Easy to extinguishHigh voltageCircuit-breaking switches for excess currentsContact mechanismsTransformerEngineering

A fault interrupter and load break switch includes a trip assembly configured to automatically open a transformer circuit electrically coupled to stationary contacts of the switch upon the occurrence of a fault condition. The fault condition causes a Curie metal element electrically coupled to at least one of the stationary contacts to release a magnetic latch. The release causes a trip rotor of the trip assembly to rotate a rotor assembly. This rotation causes ends of a movable contact of the rotor assembly to electrically disengage the stationary contacts, thereby opening the circuit. The switch also includes a handle for manually opening and closing the electrical circuit in fault and non-fault conditions. Actuation of the handle coupled to the rotor assembly via a spring-loaded rotor causes the movable contact ends to selectively engage or disengage the stationary contacts.

Owner:EATON INTELLIGENT POWER LTD

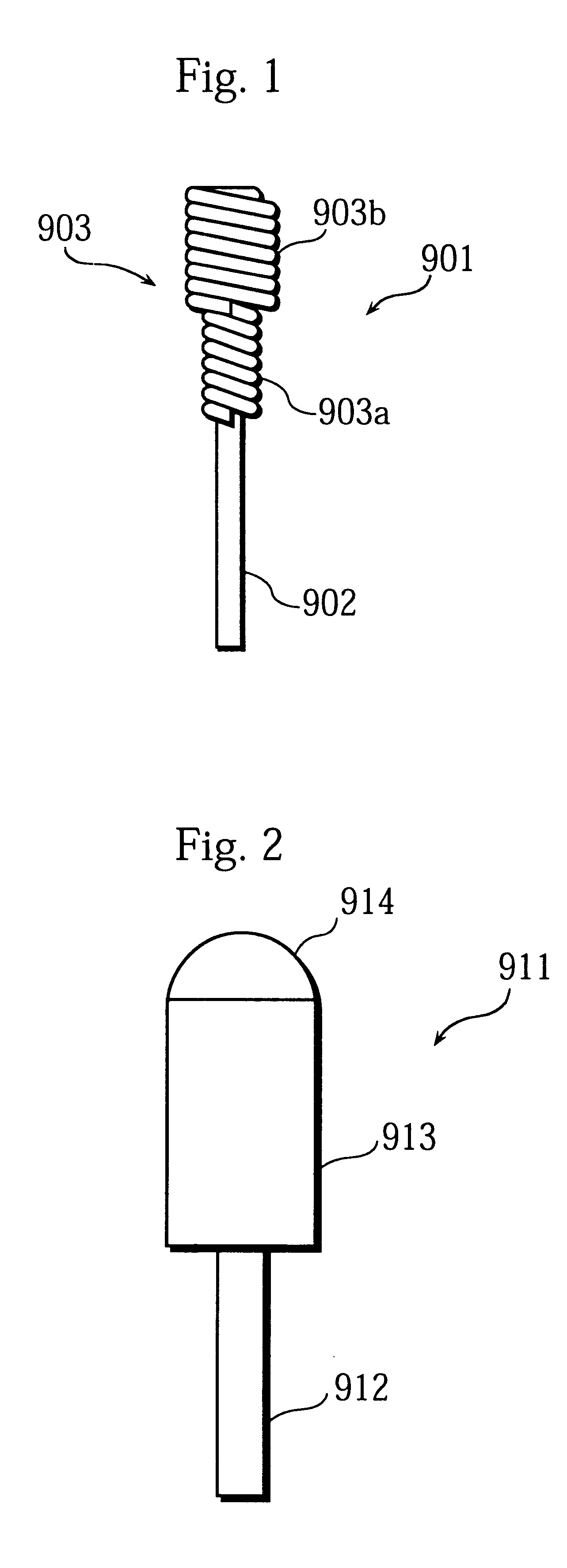

High pressure discharge lamp, high pressure discharge lamp electrode, method of producing the high pressure discharge lamp electrode, and illumination device and image display apparatus respectively using the high pressure discharge lamps

InactiveUS6492772B1Avoid darkeningIncrease arc lengthSolid cathode detailsGas discharge lamp detailsHigh pressureLaser

A high pressure discharge lamp has a pair of electrodes in a discharge tube. Each electrode includes a coil and an electrode rod with a tip, the coil being set around the electrode rod near the tip. The tip of the electrode rod and an adjacent portion of the coil are fused together during the initial discharge. To be more specific, the coil covers the electrode rod near the tip, with the tip of the electrode rod being left uncovered and a length of the tip being DELTAL that satisfies an inequality 1 / 50*R3<=DELTAL<=1 / 5*R3 where R3 is an outer diameter of the coil adjacent to the tip. Alternatively, the electrode can be first formed before being set in the discharge tube, by integrally melting the tip of the electrode rod and the adjacent portion of the coil using, for example, a plasma or laser.

Owner:PANASONIC CORP

Multiple Arc Chamber Assemblies for a Fault Interrupter and Load Break Switch

ActiveUS20090278634A1Increases voltage capacityEasy to extinguishCircuit-breaking switches for excess currentsContact mechanismsTransformerInterrupter

A fault interrupter and load break switch includes a trip assembly configured to automatically open a transformer circuit electrically coupled to stationary contacts of the switch upon the occurrence of a fault condition. The fault condition causes a Curie metal element electrically coupled to at least one of the stationary contacts to release a magnetic latch. The release causes a trip rotor of the trip assembly to rotate a rotor assembly. This rotation causes ends of a movable contact of the rotor assembly to electrically disengage the stationary contacts, thereby opening the circuit. The switch also includes a handle for manually opening and closing the electrical circuit in fault and non-fault conditions. Actuation of the handle coupled to the rotor assembly via a spring-loaded rotor causes the movable contact ends to selectively engage or disengage the stationary contacts.

Owner:EATON INTELLIGENT POWER LTD

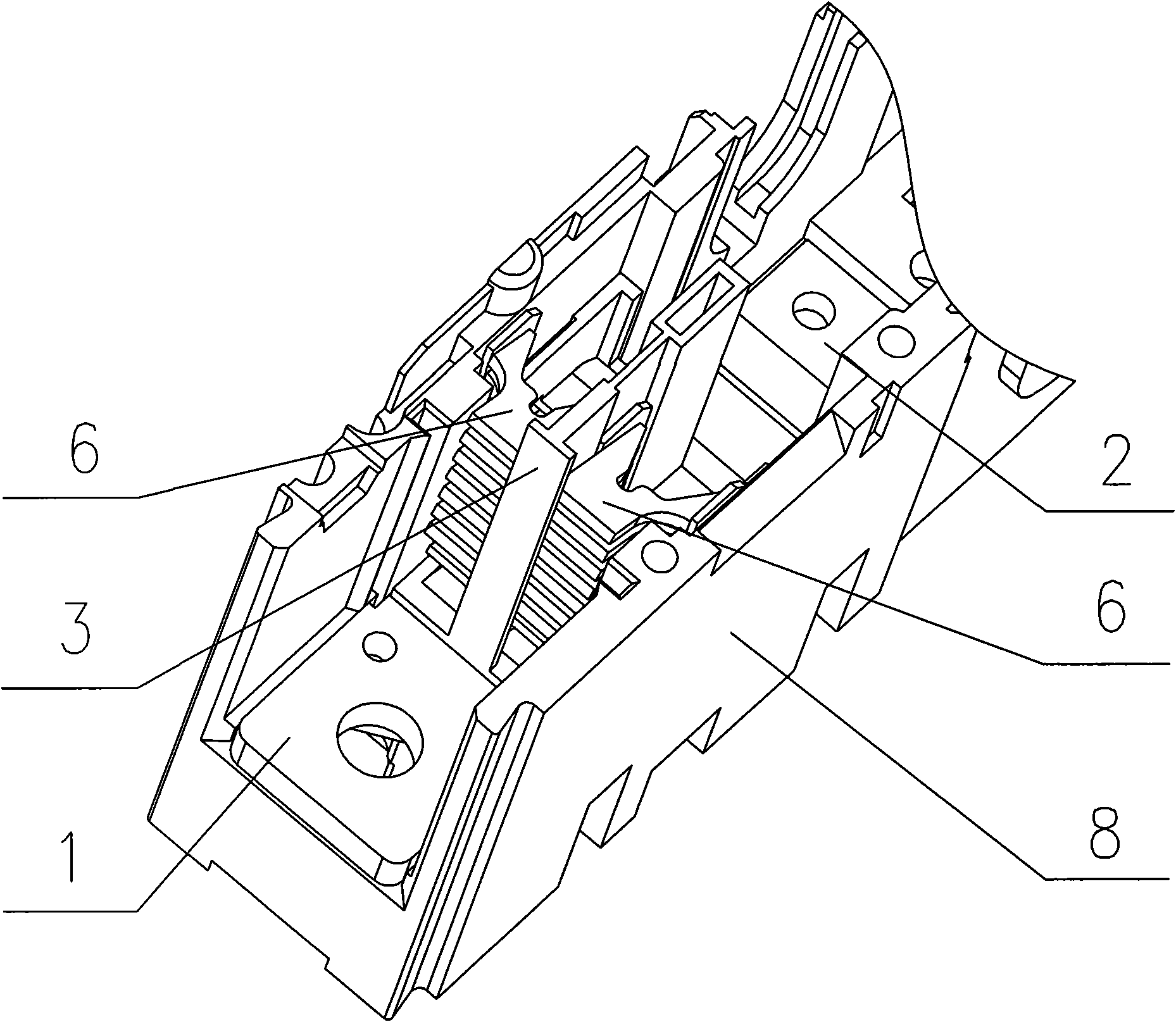

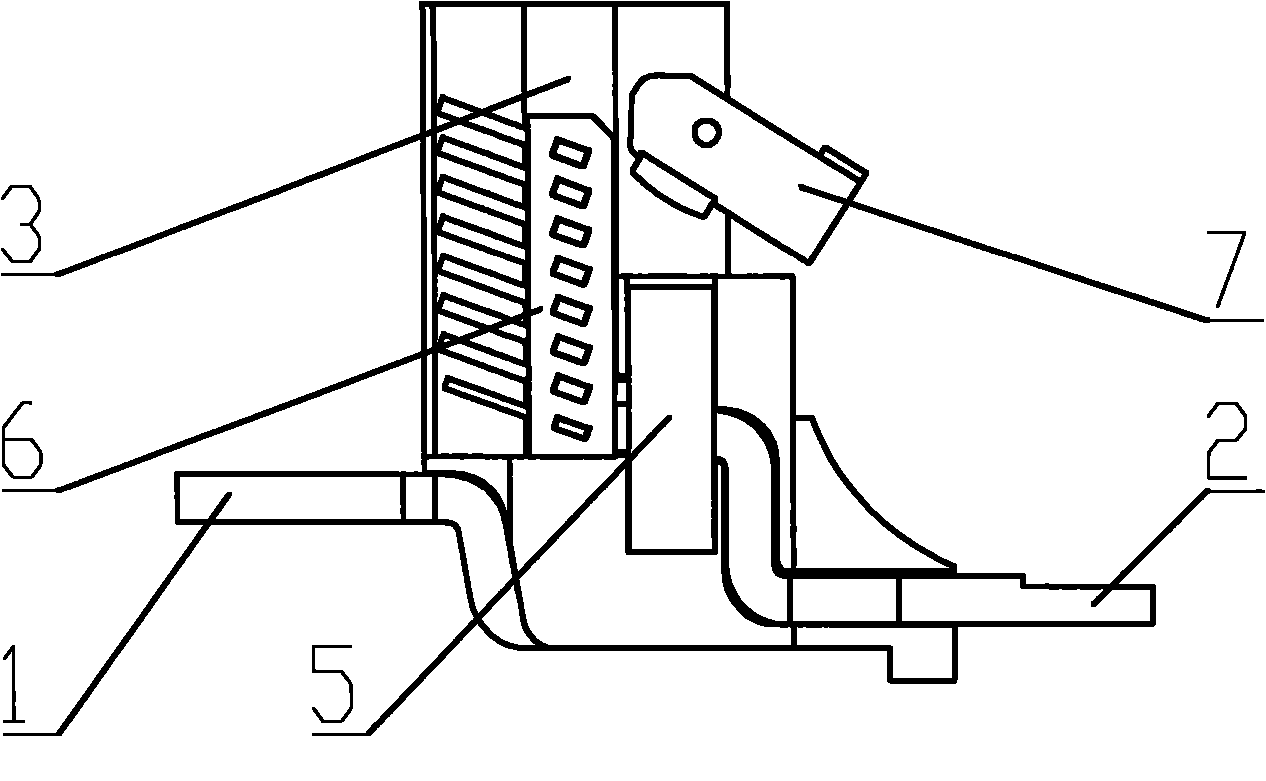

Combined magnetic-quenching device

ActiveCN102339691ASimple structureReduce the difficulty of processing and manufacturingProtective switch detailsCircuit-breaking switch detailsEngineeringQuenching

The invention relates to a combined magnetic-quenching device. The device comprises two fixed contacts, an insulation bracket, permanent magnet steel, a magnetic conduction board, a gate-chip type arc-extinguishing chamber and a moving contact. The combined magnetic-quenching device can fulfill the aims of speeding up an arc-extinguishing speed and improving the arc-extinguishing capacity in a simplest and easiest processing mode on the premise of not increasing the overall dimension of a breaker and reserving the structural form of a conventional breaker.

Owner:BEIJING JINGREN ELECTRICAL CO LTD

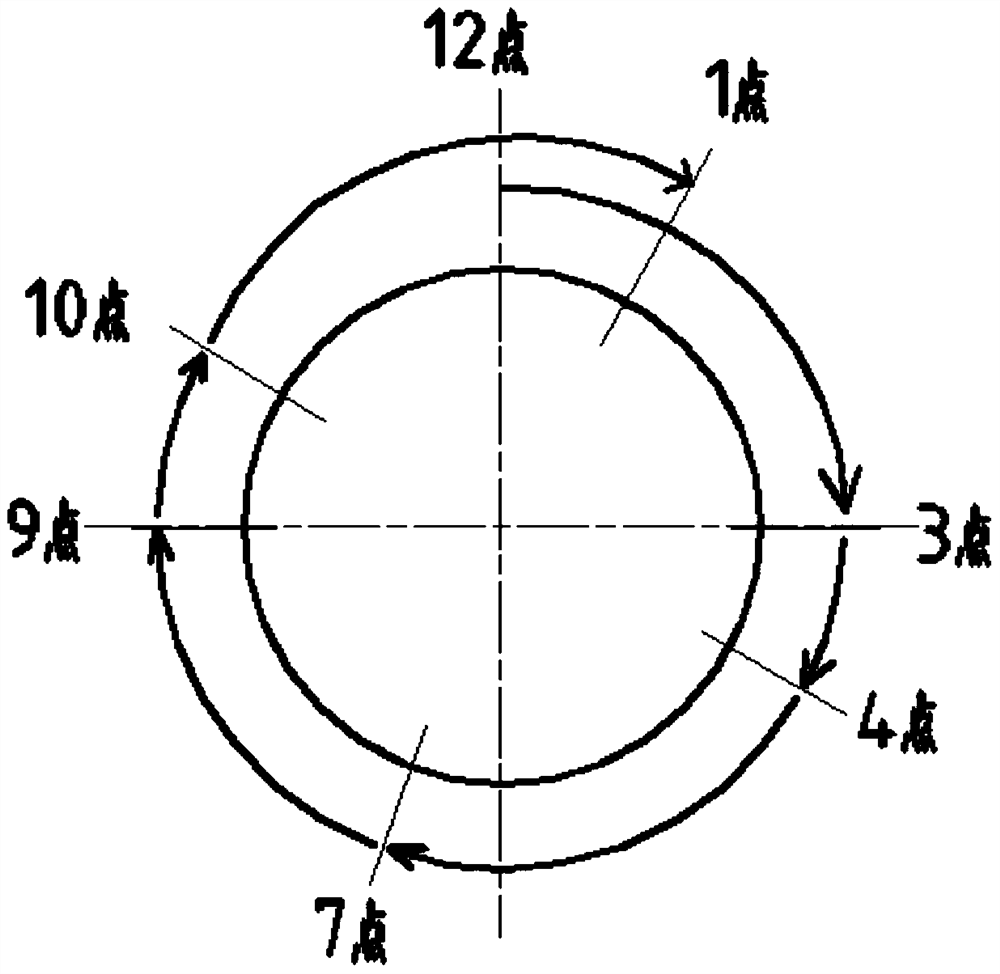

Rail TIG welding method for black-and-white pipes

The invention discloses a rail TIG welding method for black-and-white pipes, and belongs to the technical field of welding. When rail TIG welding is adopted for black-and-white pipe all-position welding, the difficulty lies in that smooth transition from welding materials in all directions (flat, downhill, uphill and the like) to a molten pool and stress balance in the molten pool crystallization process are guaranteed, otherwise, hot cracks are likely to appear on a base coat, inward concavities and the like are likely to appear on an overhead welding position, consequently, rail TIG welding cannot be successfully applied to butt joint of the black-and-white pipes, and wide application of rail TIG welding in boiler manufacturing is limited. According to the method, welding parameters are set in a partitioned manner, the welding rotating speed of the base coat is increased, the wire feeding amount and the welding current are reduced, and therefore the molten pool temperature at the overhead welding position at 4-7 o' clock is reduced, and generation of inward concavities of the base coat at the overhead welding position is effectively avoided; the welding rotating speed of a first filling layer at the overhead welding position is increased, the welding current is reduced, and the situation that when the first filling layer appears at the overhead welding position, inverse fusion is caused to the base coat, and consequently inward concavities are caused is effectively avoided; the welding parameters of the base coat are optimized, the arc extinguishing decay time and stroke are prolonged, the electric arc length is increased, and generation of arc extinguishing cracks of the base coat is effectively avoided; and the current and the wire feeding speed are changed in different areas, heat input of all the areas is accurately controlled, and generation of various poor fusion defects is effectively avoided.

Owner:WUHAN BOILER

Method for making steel with electric arc furnace

InactiveUS6584137B1Increase ratingsReduce probabilityElectric discharge heatingIncreasing energy efficiencyElectric arc furnaceMaterials science

A method of making steel in an electric arc furnace is provided. The method comprises the steps of measuring electrical current in at least two phases of electrical power supplied to electrodes in the furnace during a campaign, establishing a setpoint current level and an input time interval, and switching between modes of inputting exothermic energy into the steel melt when at least two phases have measured current levels below the setpoint for the input time interval.

Owner:NUCOR CORP

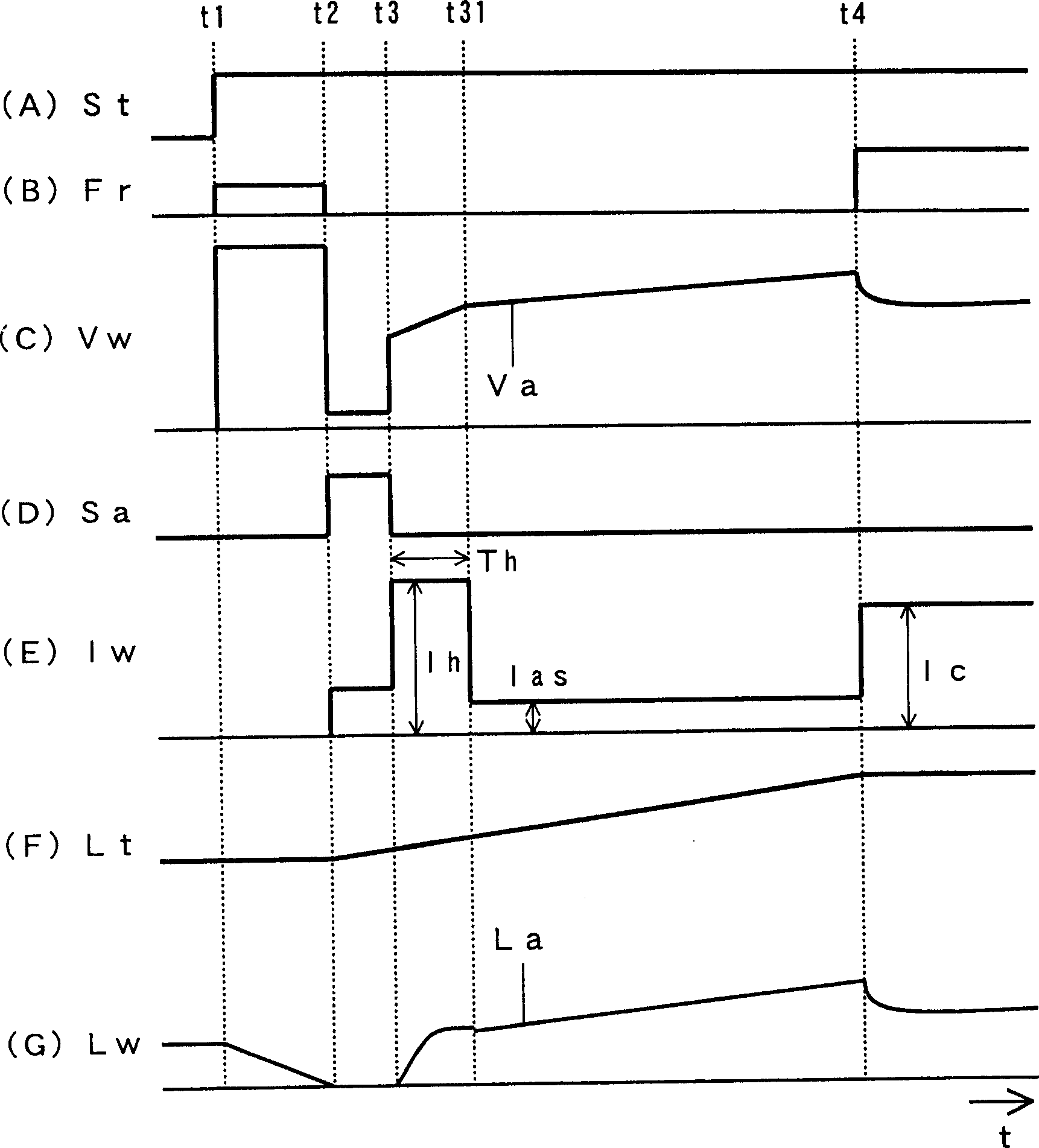

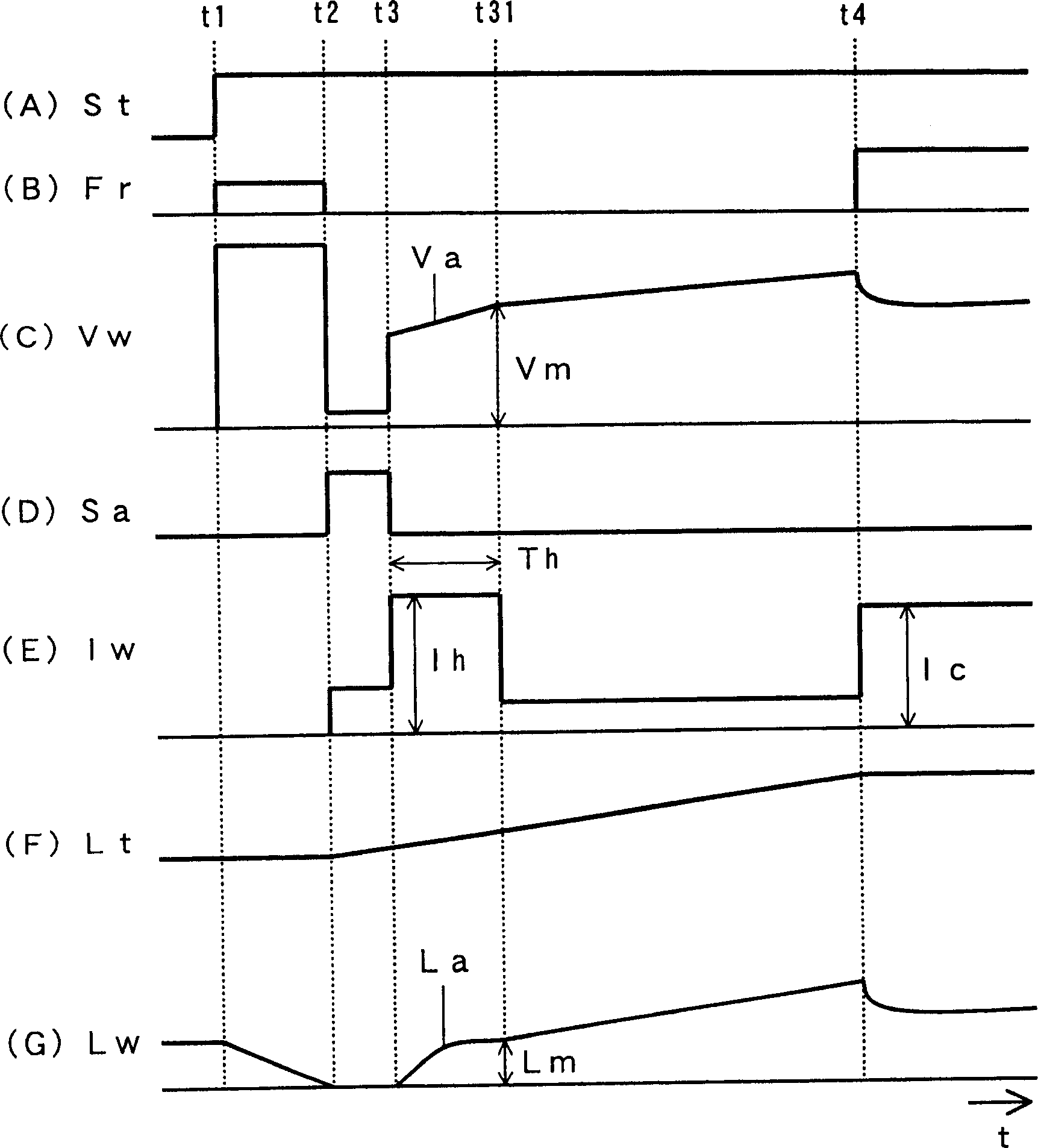

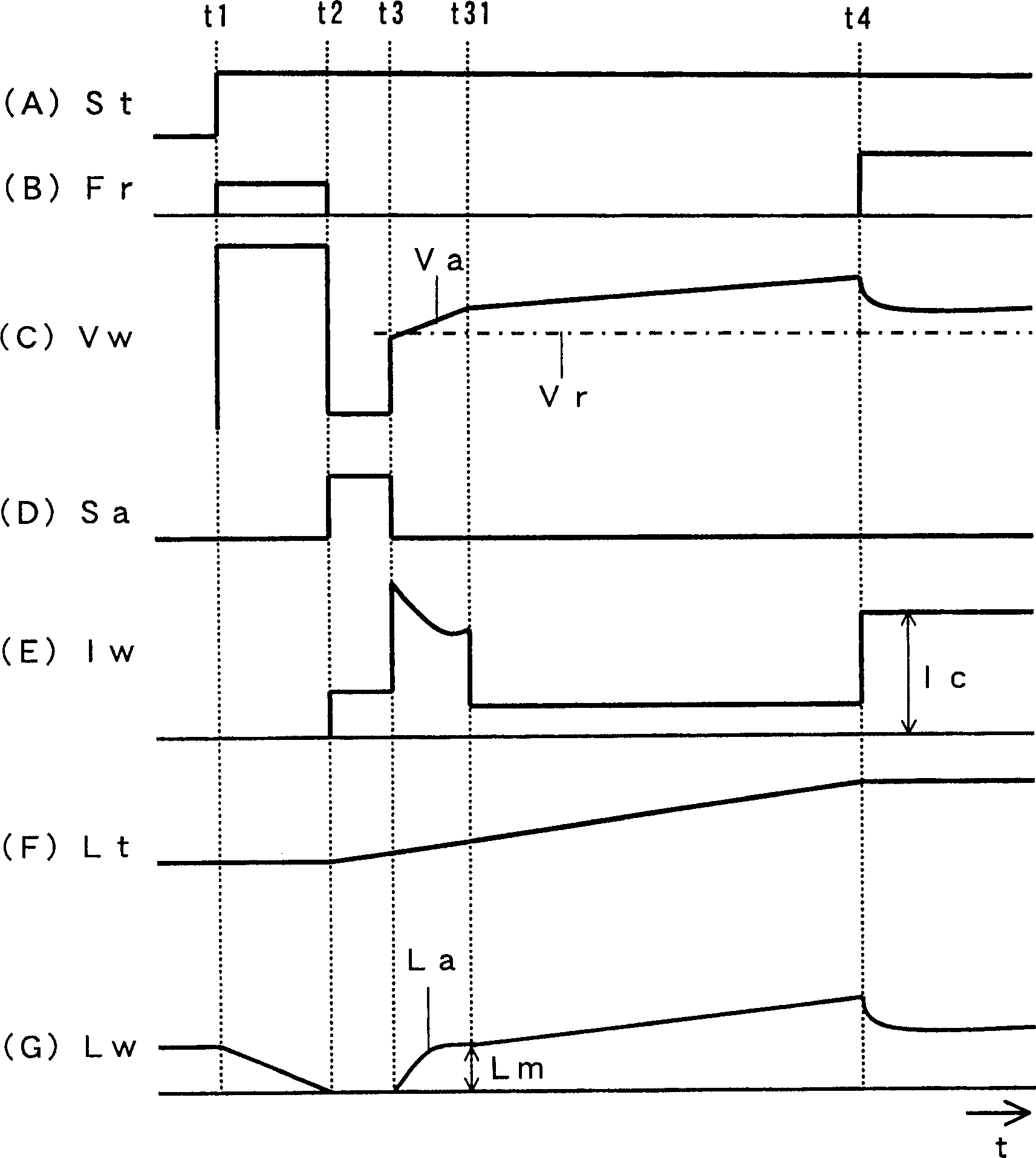

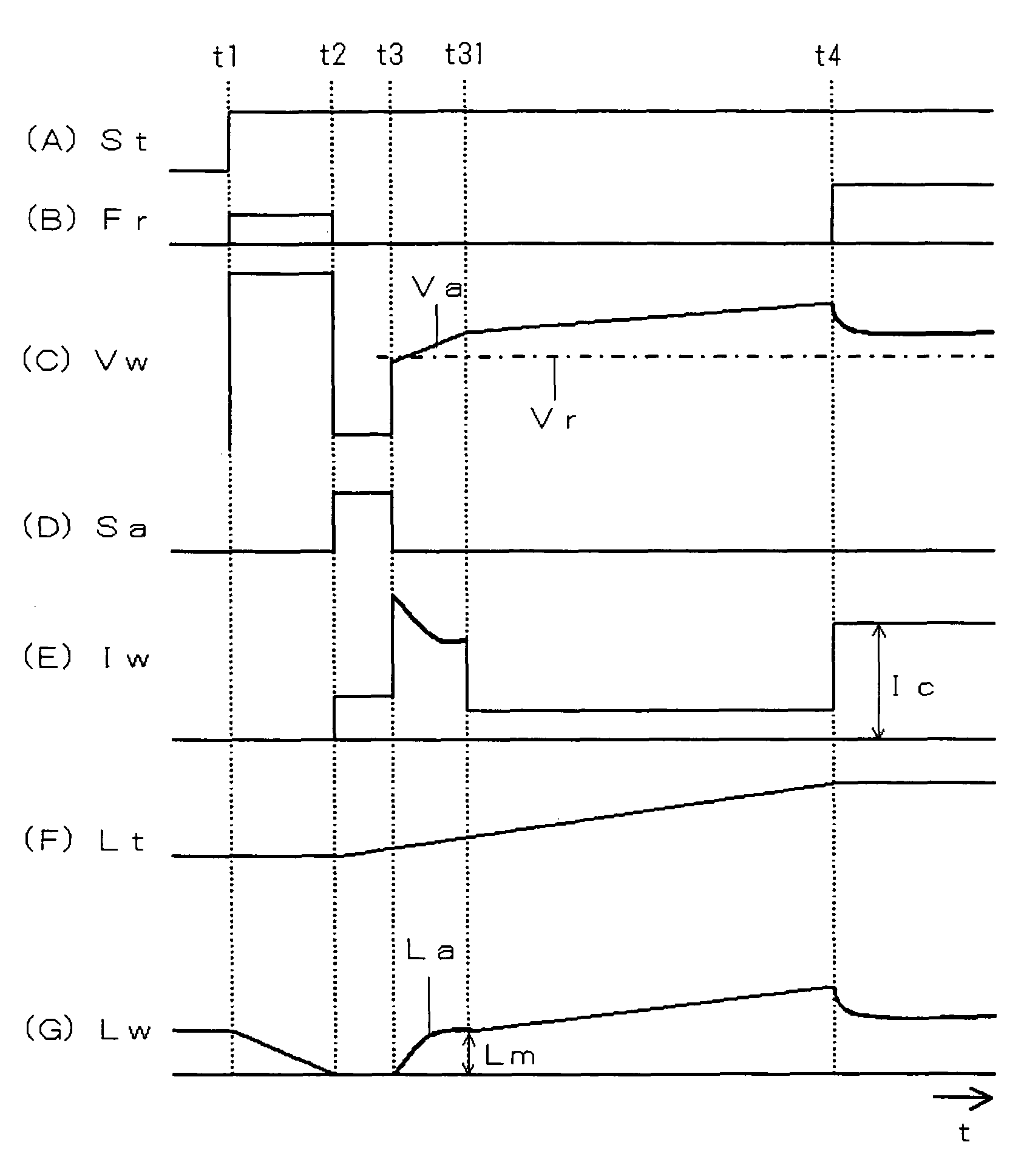

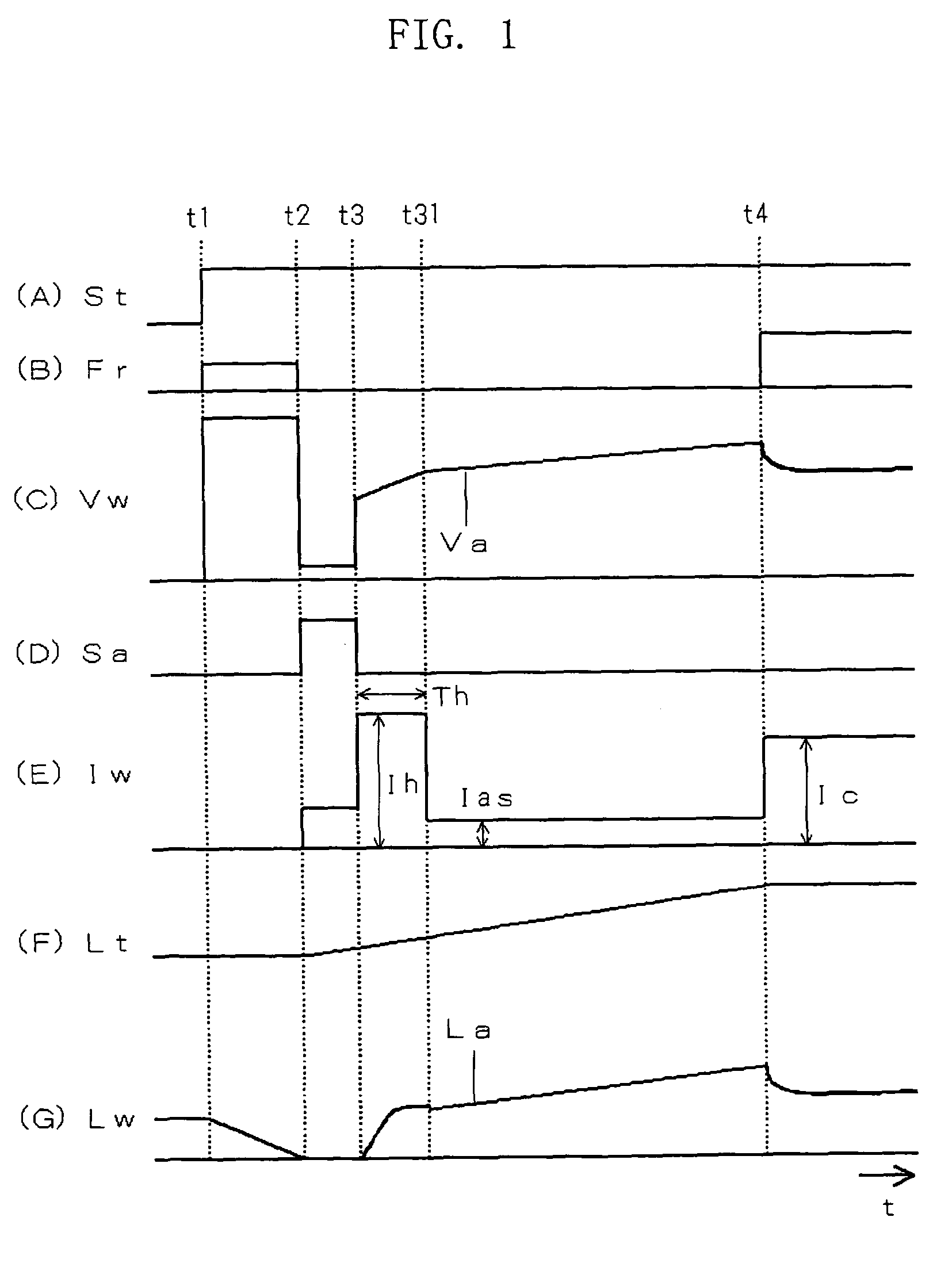

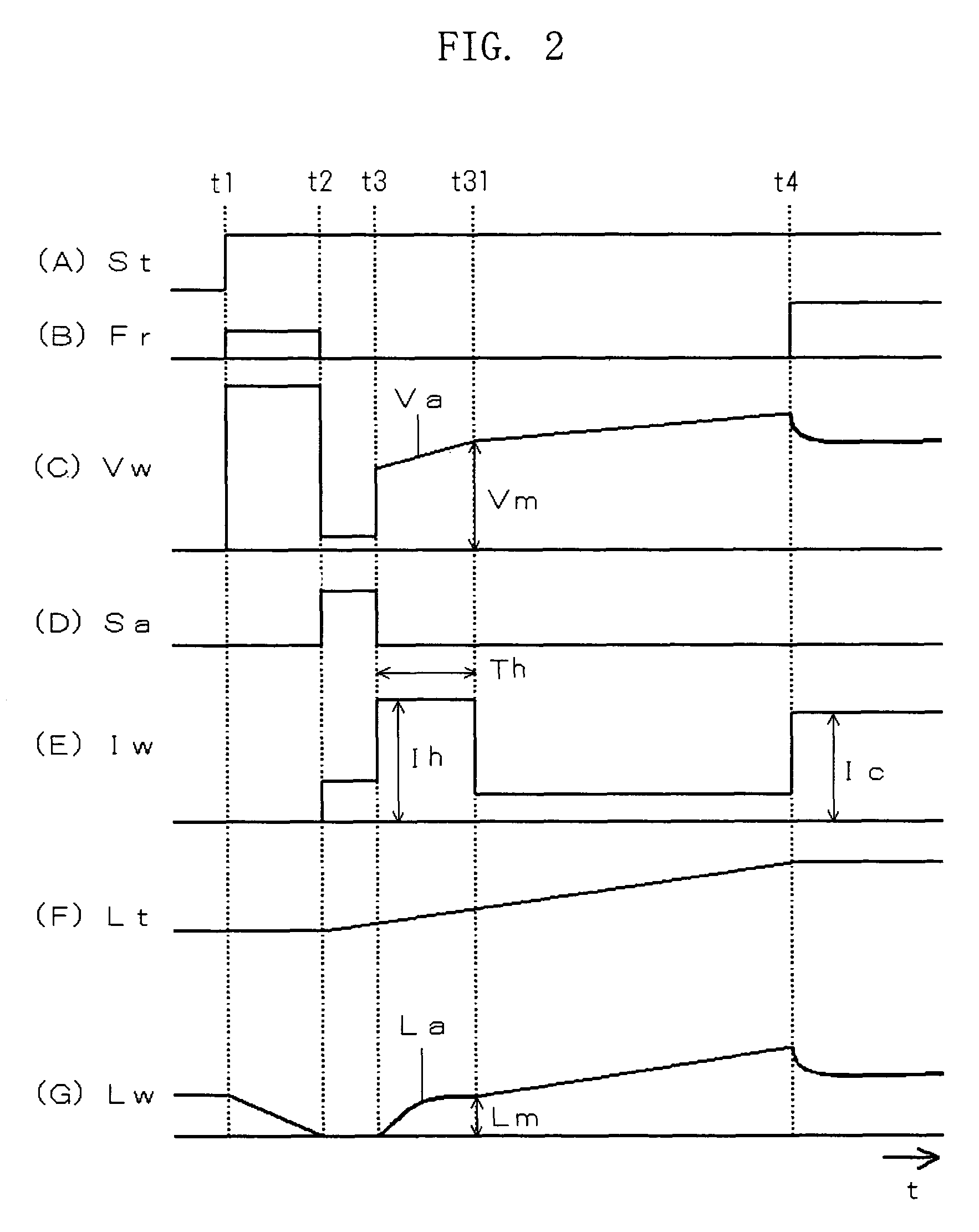

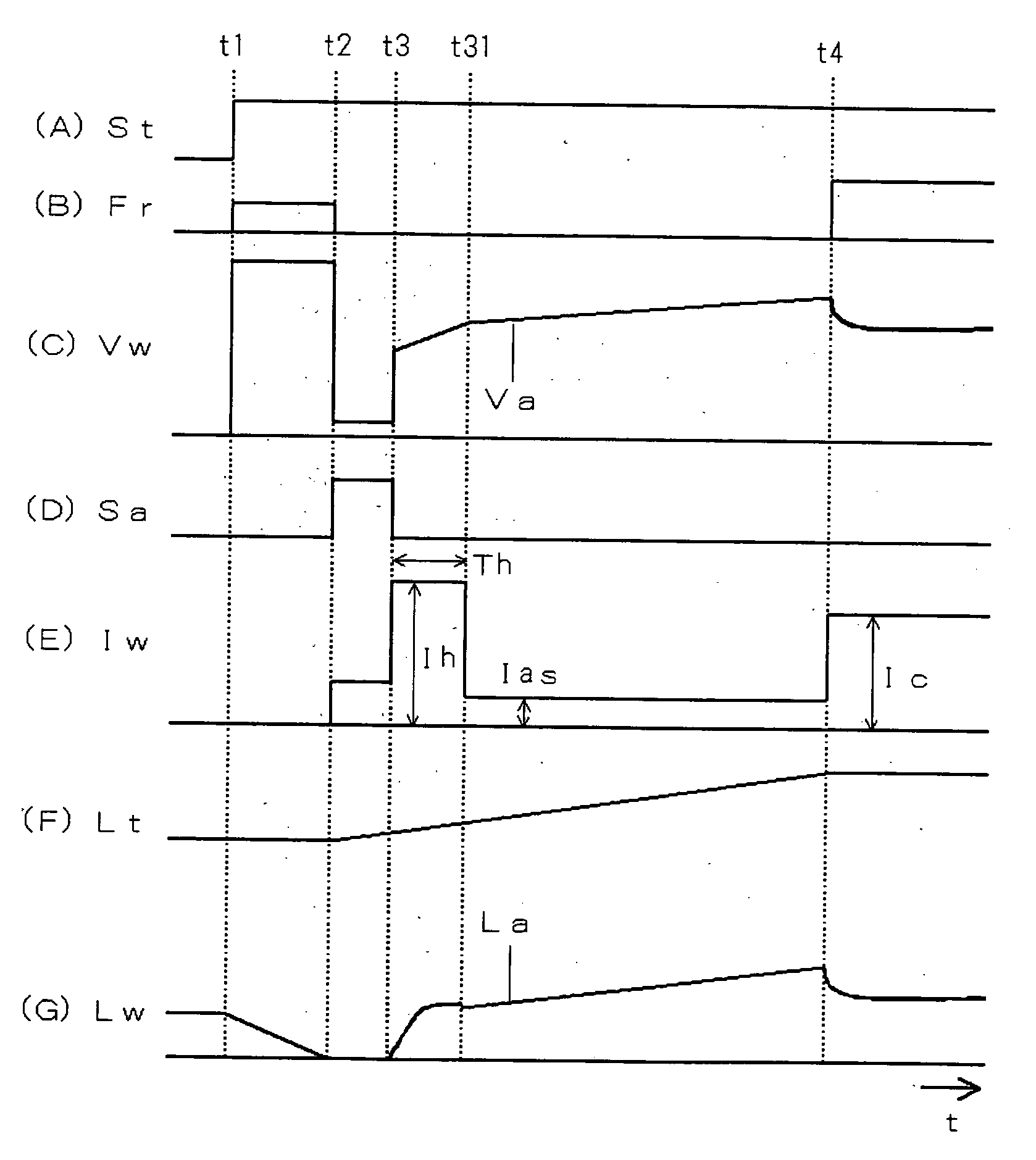

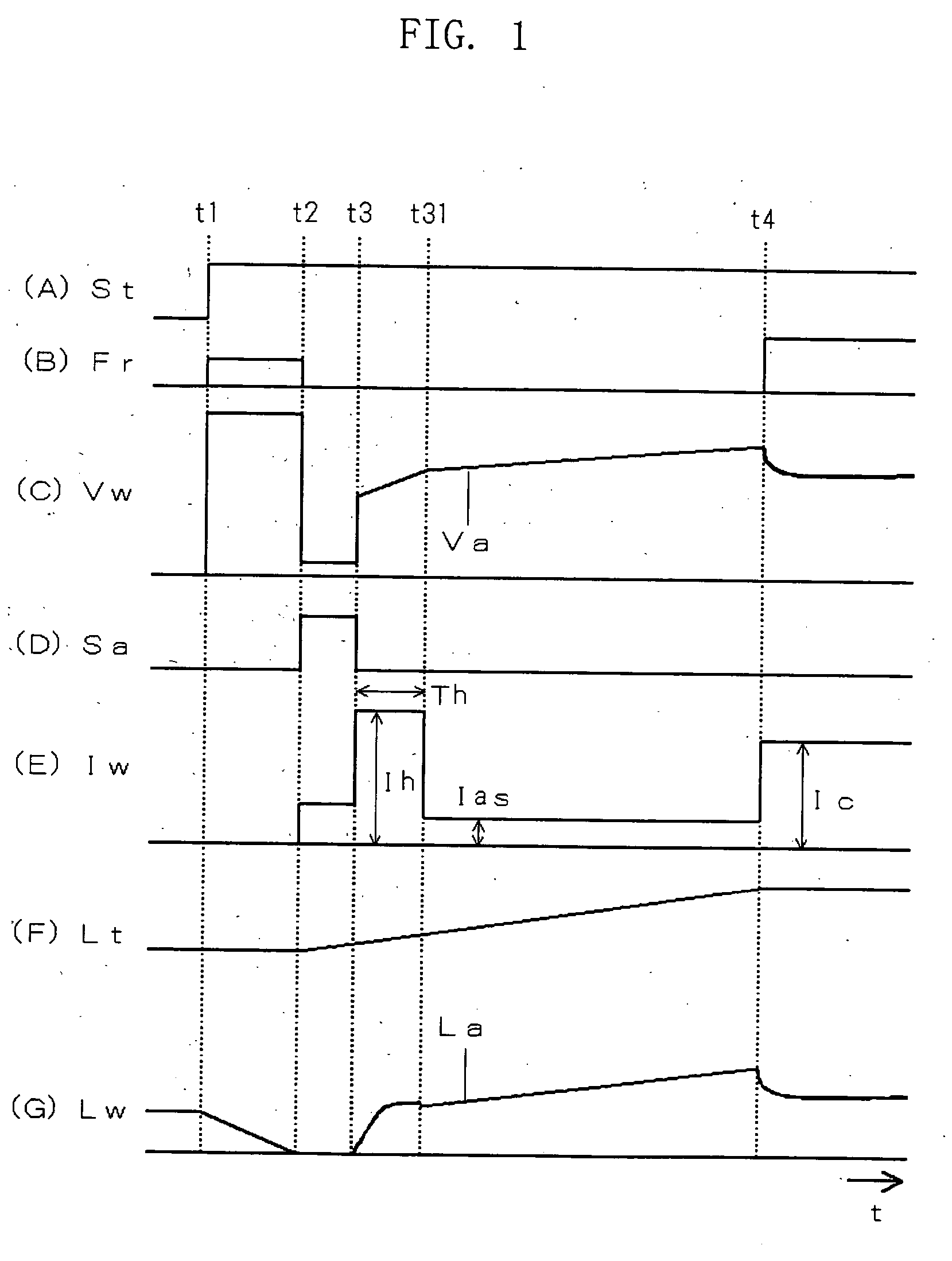

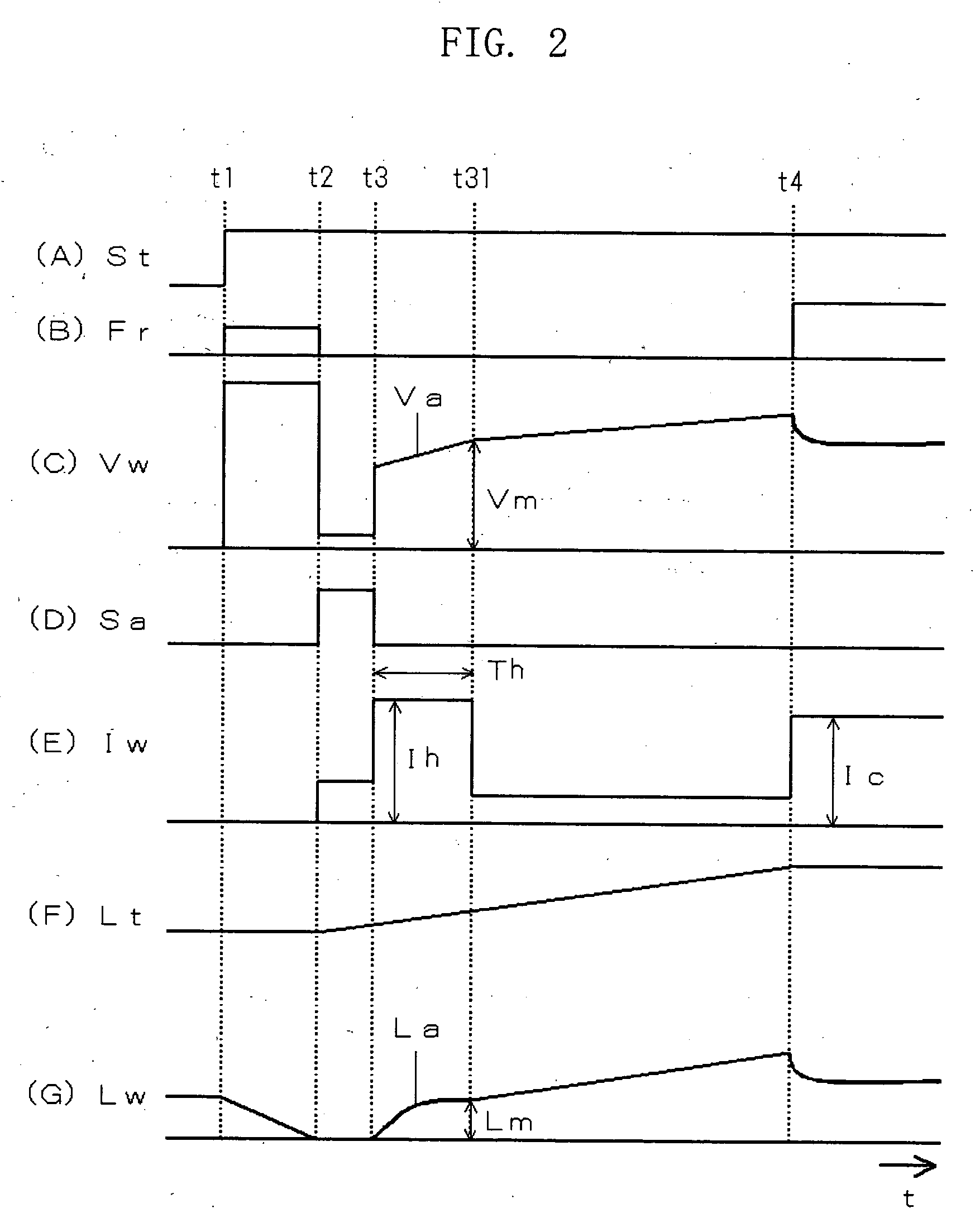

Arc start control method in robot welding

An arc start control method in robot welding includes the steps of shorting a welding wire with a base metal, retracting a welding torch by a welding robot (RM) for taking the welding wire off the base metal to generate an initial arc, retracting the welding torch to a predetermined position with maintaining the initial arc maintained while applying an initial arc current smaller than a steady welding current during an initial arc period, and starting to feed the welding wire steadily and to supply the steady welding current so as to make a transition from the initial arc to a steady arc as well as starting to move the welding torch along a welding line. During a re-shorting prevention period which starts from a beginning of the initial arc period, a re-shorting prevention current which is larger than the initial arc current is applied in order to prevent re-shortening between the tip of the wire and the base metal right after the initial arc is generated. Thereafter, the initial arc current is applied.

Owner:DAIHEN CORP

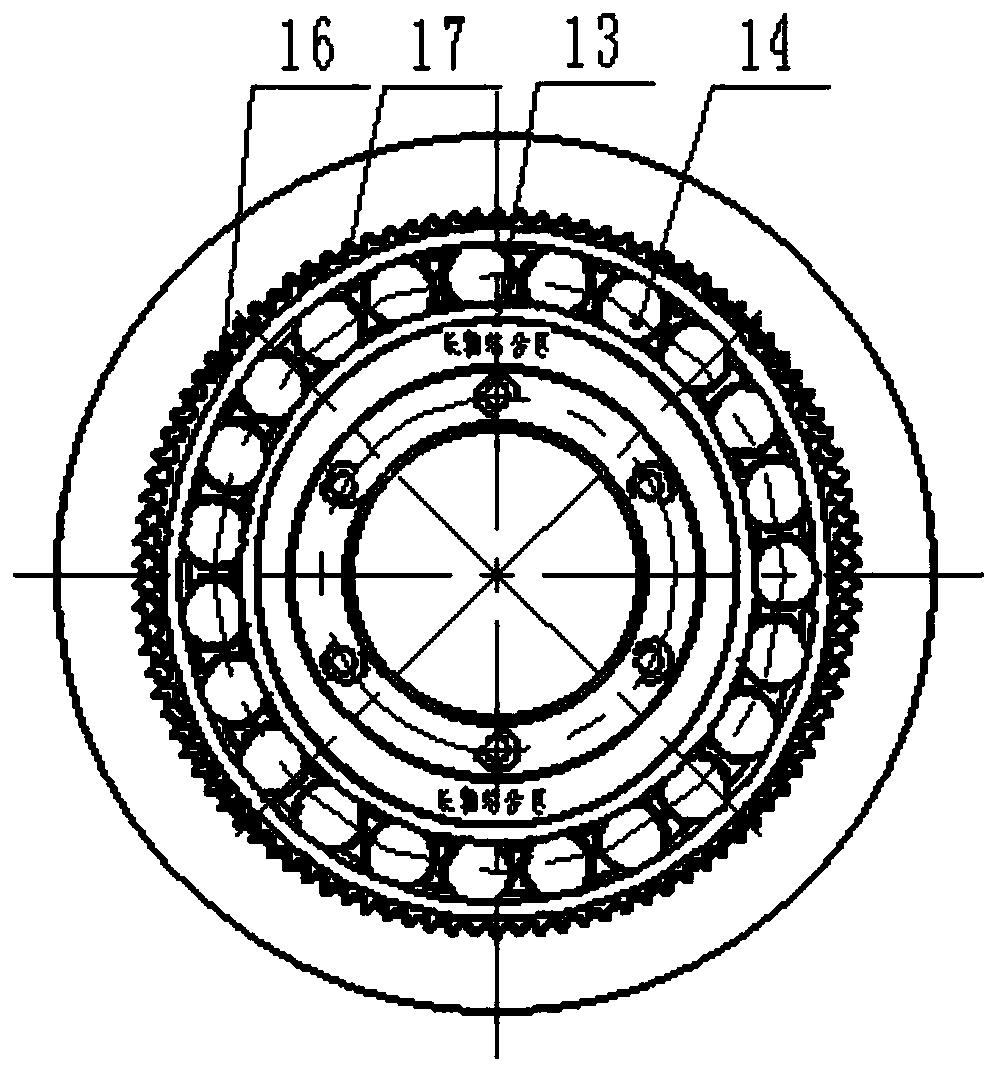

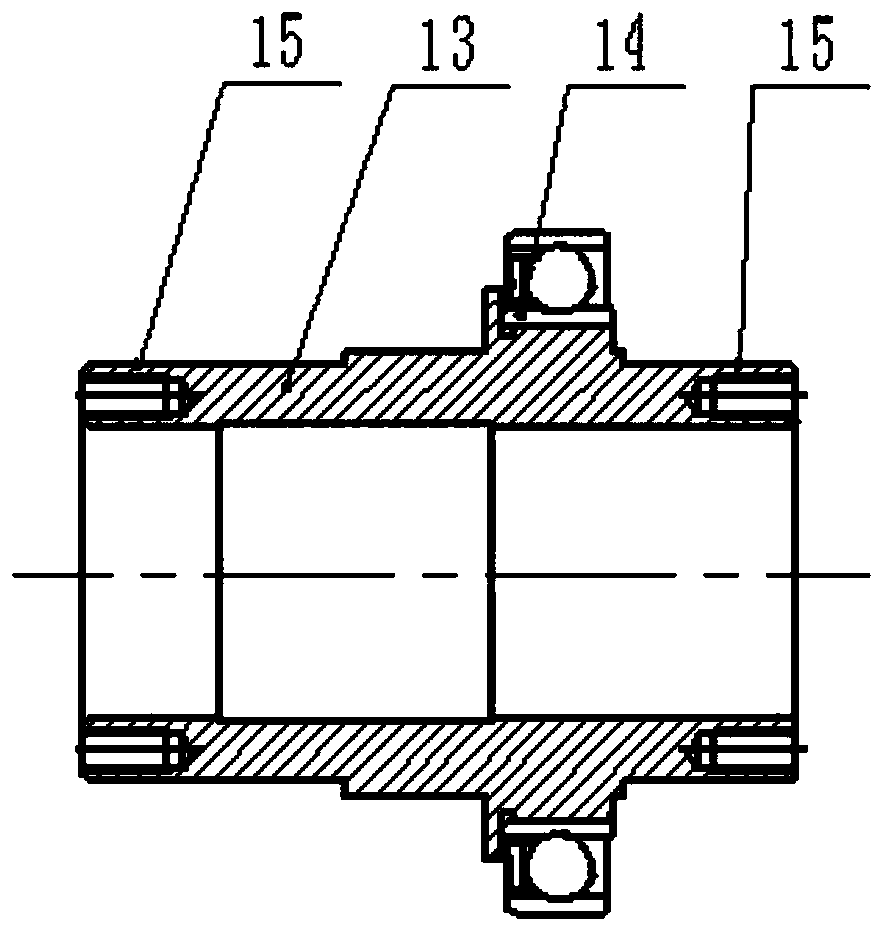

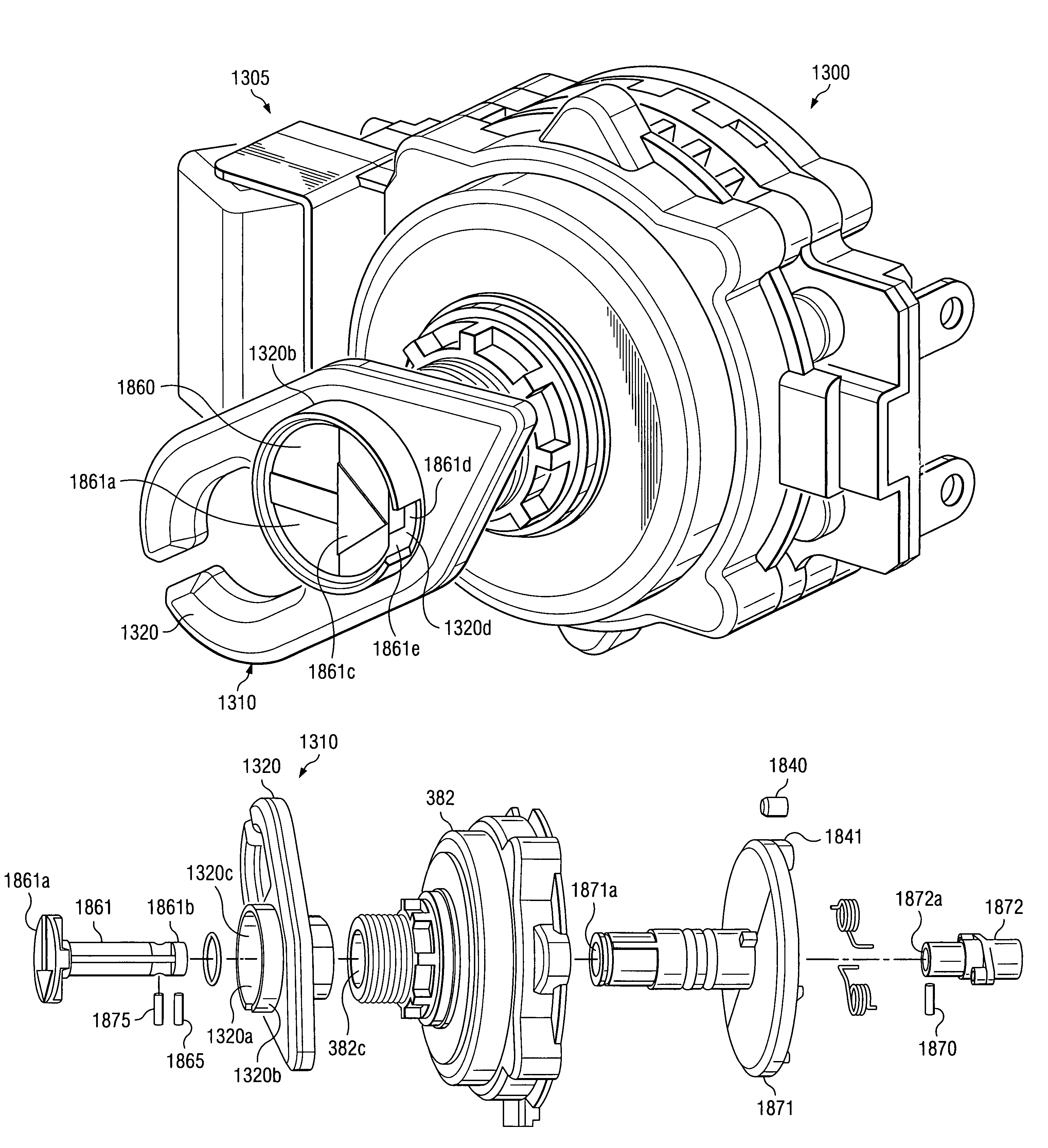

Wave generator and harmonic decelerator with wave generator

The invention relates to a wave generator and a harmonic decelerator with the wave generator, and belongs to the technical field of harmonic decelerators. The wave generator comprises a wave generatorcam, the shape expression of the elliptical cross-section of the wave generator cam is r=r1+2 / Lsin2theta, wherein r is the radial diameter of the elliptical cross-section of the wave generator cam, r1 is the base circle diameter of the elliptical cross-section of the wave generator cam, L equals to the length of a long shaft of the elliptical cross-section of the wave generator cam minus the length of a short shaft of the elliptical cross-section of the wave generator cam, theta is angle of the wave generator generation curve, and theta is no less than 0 degree and no less than 360 degrees. The wave generator is reasonable in structure, the specific expression of the shape curve of the wave generator cam is not only provided, but also the wave generator makes a flexible wheel and a rigidwheel better mesh, meanwhile, the tooth number of meshing is greater than 30%, the force distribution of a flexible bearing and gear meshing tooth face is improved, the force of the flexible wheel tooth bottom is reduced, and the service life is prolonged.

Owner:成都瑞迪智驱科技股份有限公司

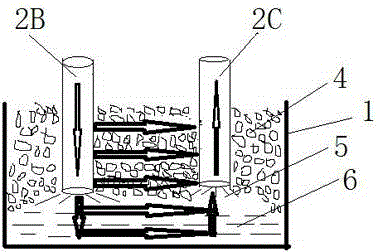

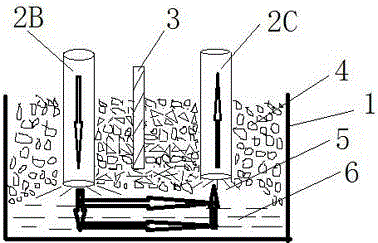

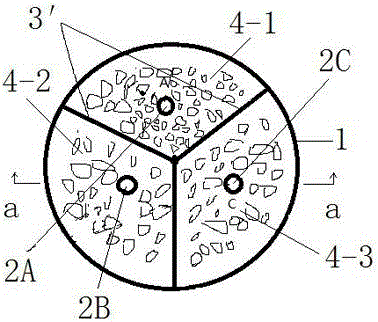

Three-phase alternating-current ore smelting furnace and method for controlling furnace condition thereof

ActiveCN103604292AImprove electricity efficiencyImprove power factorLighting and heating apparatusThree-phaseReaction zone

The invention discloses a method for controlling a furnace condition of a three-phase alternating-current ore smelting furnace. Electrodes are vertically arranged in a hearth of the three-phase alternating-current ore smelting furnace, a burden layer in the hearth is longitudinally divided into a plurality of smelting zones, the smelting zones are insulated from one another, and each smelting zone corresponds to one electrode. The invention further discloses the three-phase alternating-current ore smelting furnace which comprises the electrodes and high-temperature-resistant insulation devices. The electrodes are vertically arranged in the hearth of the three-phase alternating-current ore smelting furnace, the high-temperature-resistant insulation devices are arranged in the hearth, the corresponding burden layer of the hearth is longitudinally divided into the multiple smelting zones by the high-temperature-resistant insulation devices, accordingly, the smelting zones are insulated from one another, and each smelting zone corresponds to the corresponding single electrode. The method and the three-phase alternating-current ore smelting furnace have the advantages that the problem of influence of branch currents of a burden layer on running of an existing three-phase alternating-current ore smelting furnace can be solved by the method and the three-phase alternating-current ore smelting furnace, the stability of the furnace condition can be improved, secondary running voltages of the three-phase alternating-current ore smelting furnace can be increased, electric energy of reaction zones of lower ends of the electrodes can be greatly increased, unit energy consumption of products can be reduced, and the yield of the products can be increased.

Owner:勾武

Indicator for a fault interrupter and load break switch

ActiveUS8004377B2Easy to extinguishHigh voltageElectronic circuit testingDirection of current indicationTransformerEngineering

Owner:EATON INTELLIGENT POWER LTD

Fault interrupter and load break switch

ActiveUS7920037B2Easy to extinguishHigh voltageElectromagnetically operated protective switchesHigh-tension/heavy-dress switchesTransformerHemt circuits

A fault interrupter and load break switch includes a trip assembly configured to automatically open a transformer circuit electrically coupled to stationary contacts of the switch upon the occurrence of a fault condition. The fault condition causes a Curie metal element electrically coupled to at least one of the stationary contacts to release a magnetic latch. The release causes a trip rotor of the trip assembly to rotate a rotor assembly. This rotation causes ends of a movable contact of the rotor assembly to electrically disengage the stationary contacts, thereby opening the circuit. The switch also includes a handle for manually opening and closing the electrical circuit in fault and non-fault conditions. Actuation of the handle coupled to the rotor assembly via a spring-loaded rotor causes the movable contact ends to selectively engage or disengage the stationary contacts.

Owner:EATON INTELLIGENT POWER LTD

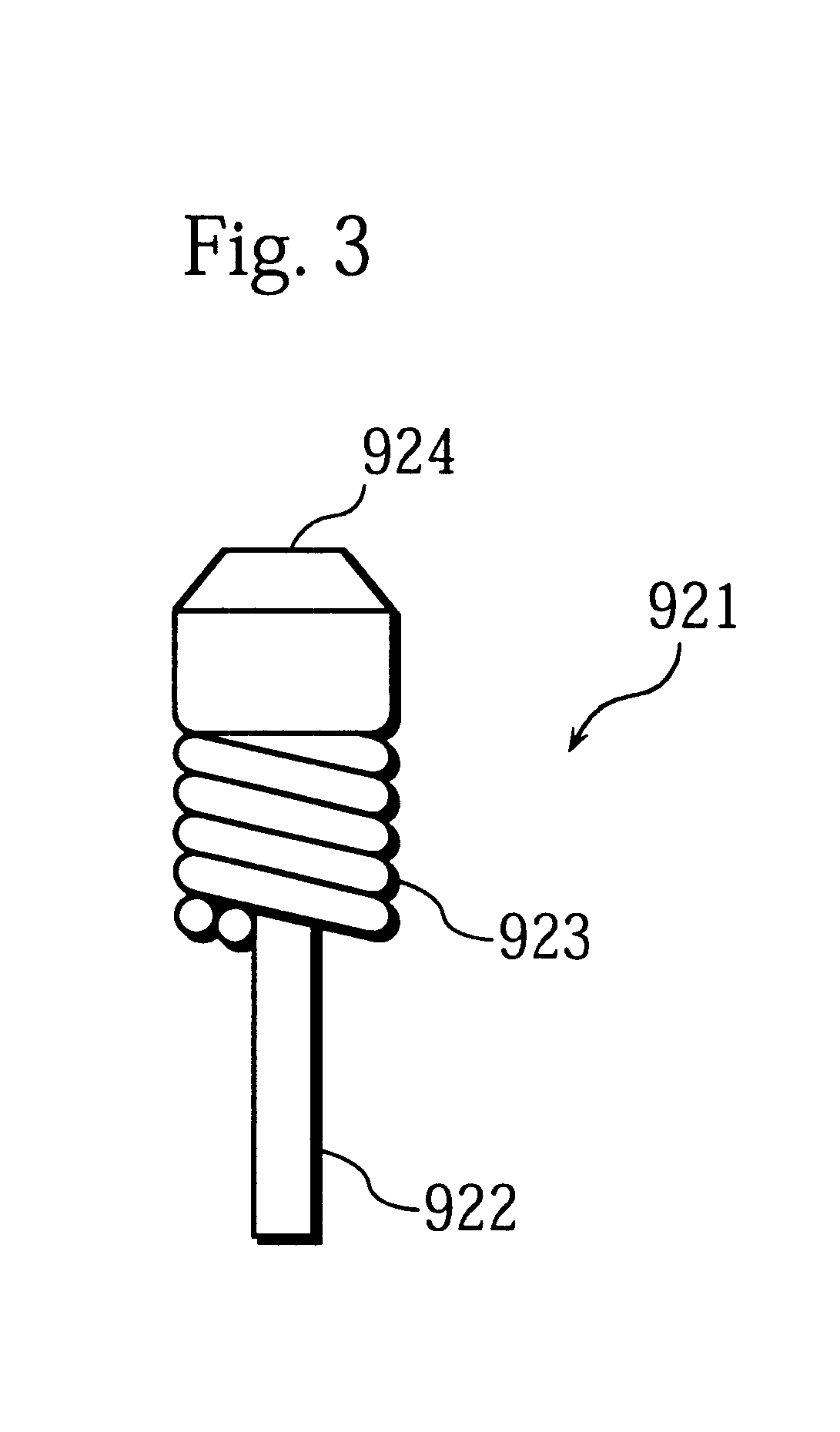

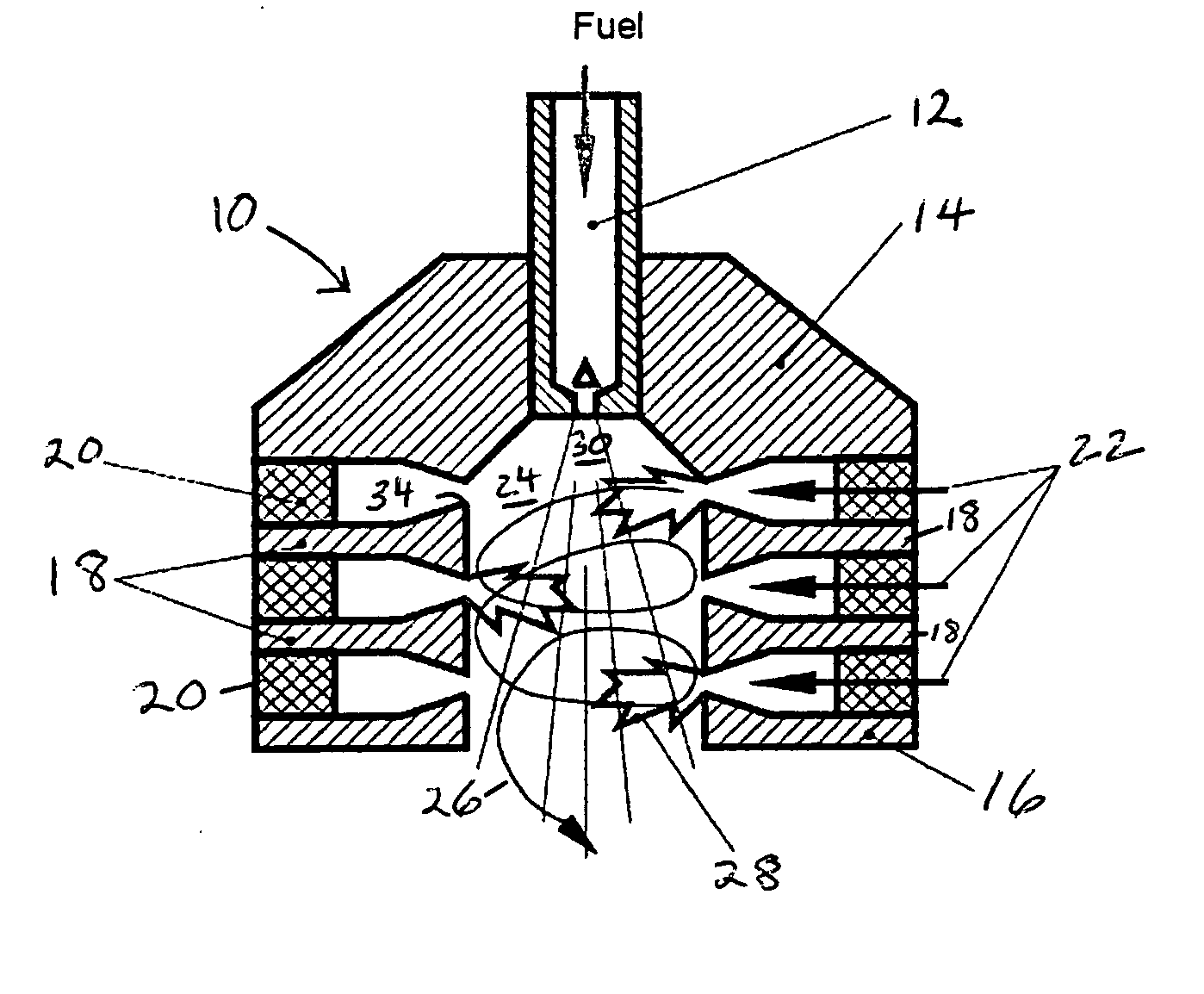

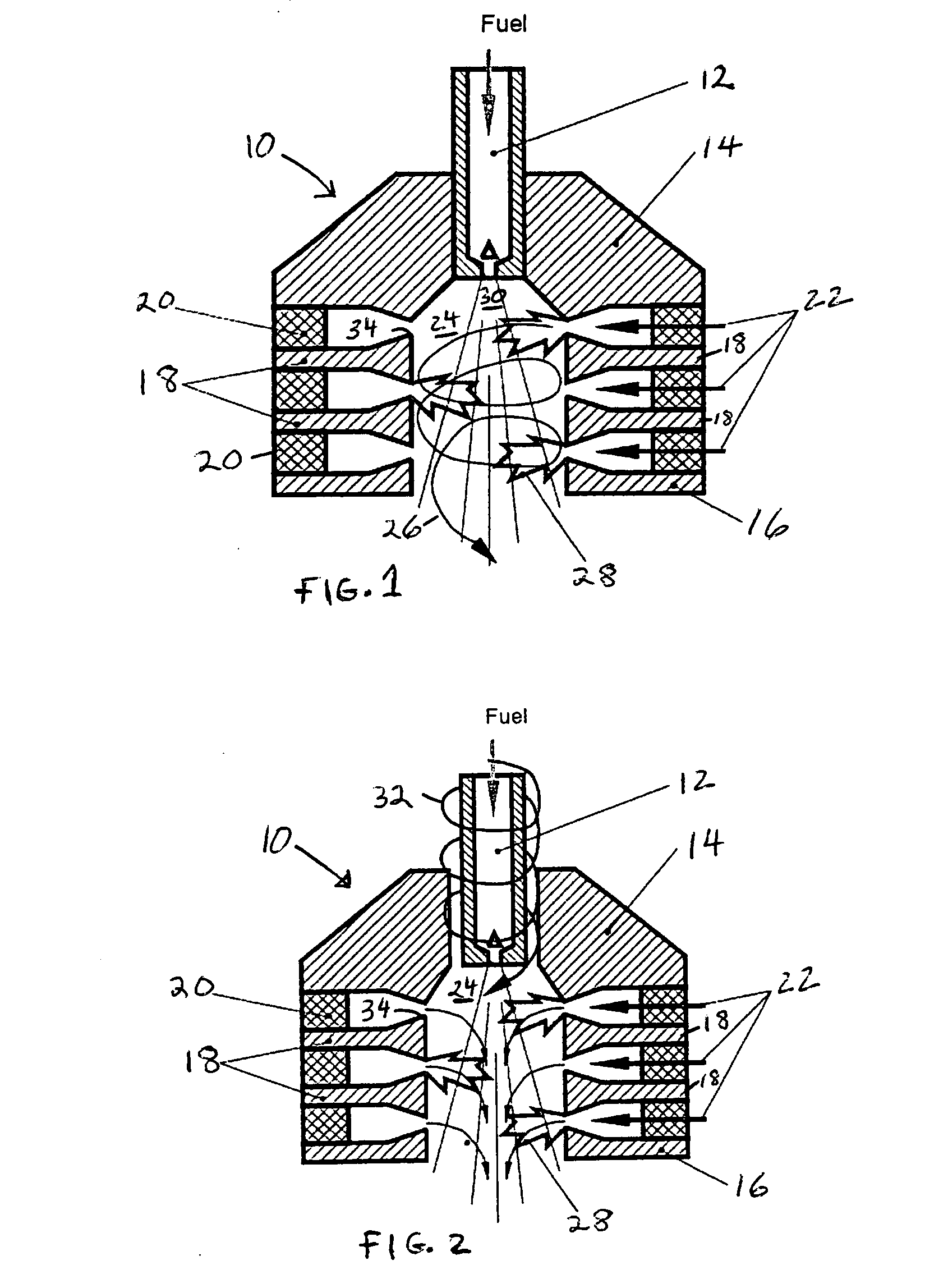

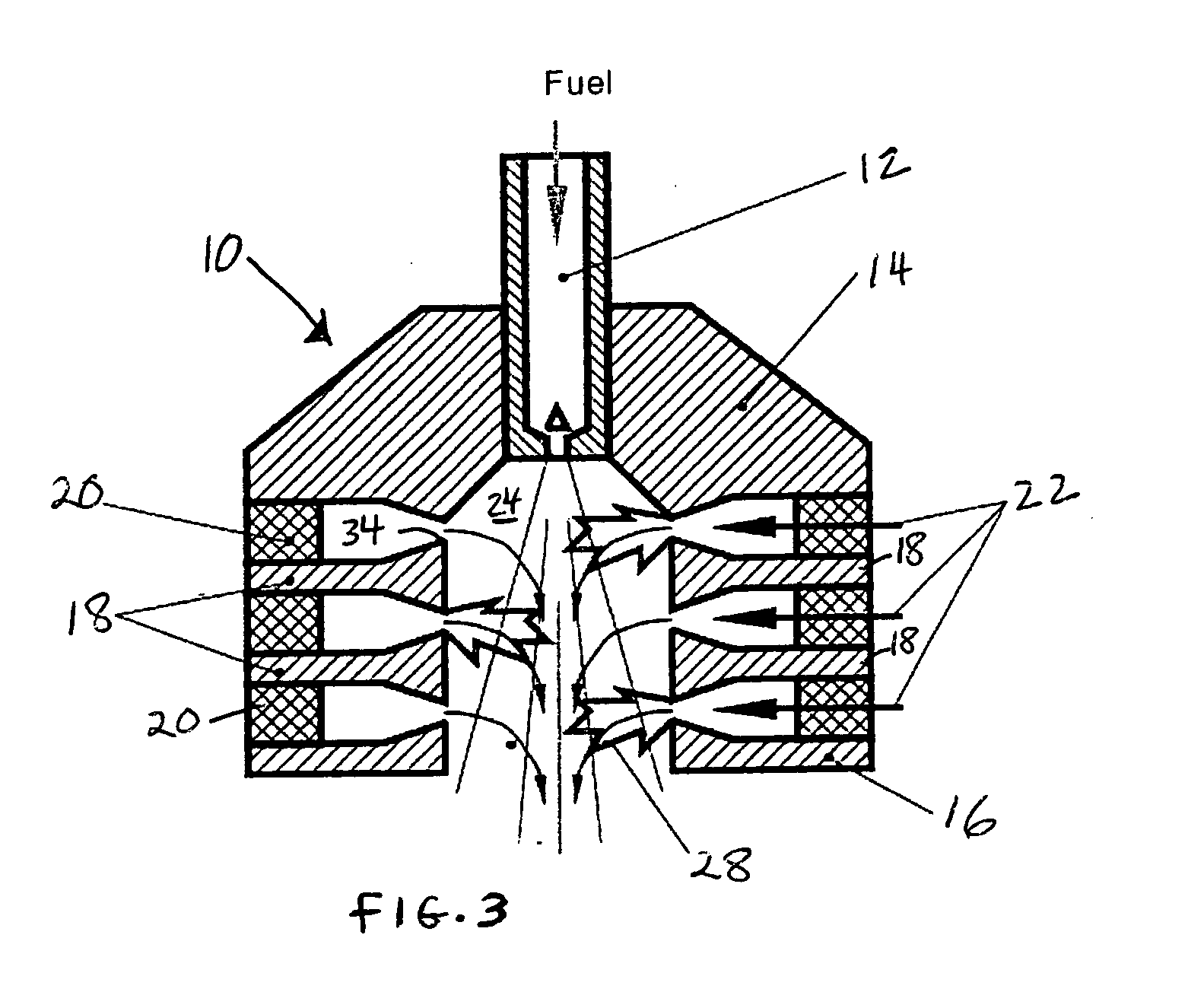

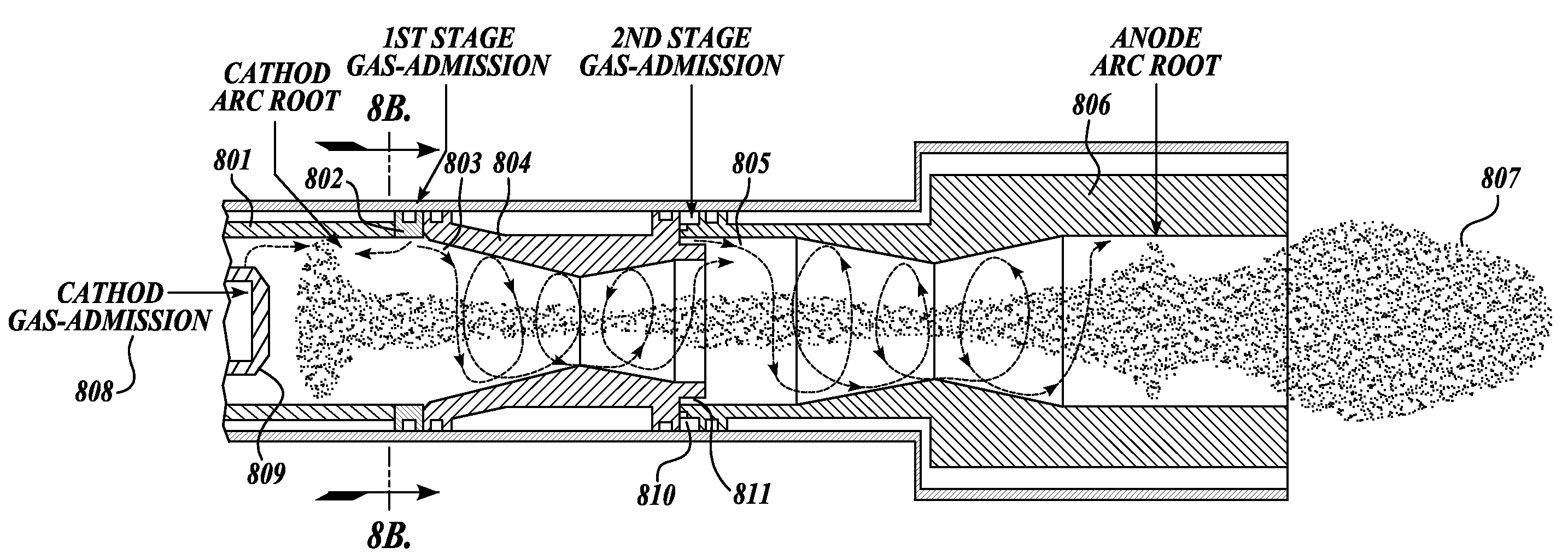

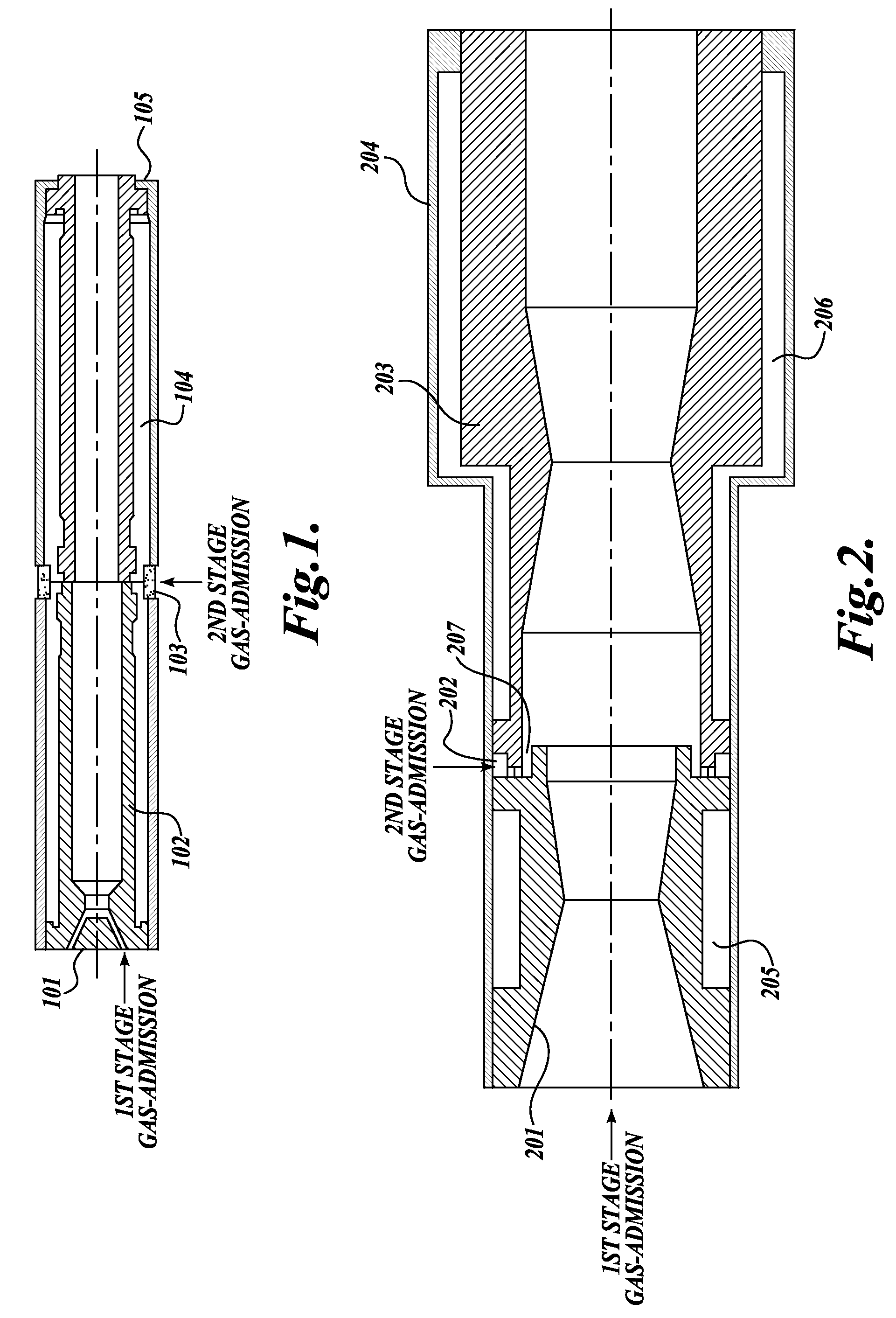

Plasma reformer with extended volume discharge

InactiveUS20070160511A1Increase arc lengthIncrease the discharge volumeHydrogenCombustion enginesElectricityContact time

Plasma reformer having a high voltage electrode spaced apart from a grounded electrode creating a volume therebetween. At least one electrically floating electrode is disposed between the high voltage electrode and the grounded electrode and a fuel atomizer is disposed to inject a hydrocarbon fuel into the volume. Structure is provided for introducing air into the volume and a high voltage source establishes a high voltage between the high voltage electrode and grounded electrode to create a cascade arc in the volume. The electrically floating electrodes increase the arc length and the discharge volume to create a cascade arc having a combined extended length and increased contact time with an air-fuel mixture for reforming a hydrocarbon fuel.

Owner:NANOENERGY GROUP UK

Arc start control method in robot welding

ActiveUS8383986B2Preventing re-shortingGood arc startingArc welding apparatusPower flowRobot welding

An arc start control method in robot welding includes the steps of shorting a welding wire with a base metal, retracting a welding torch by a welding robot for taking the welding wire off the base metal to generate an initial arc, retracting the welding torch to a predetermined position with maintaining the initial arc maintained while applying an initial arc current smaller than a steady welding current during this initial arc period, and starting to feed the welding wire steadily and to supply the steady welding current so as to make a transition from the initial arc to a steady arc as well as starting to move the welding torch along a welding line. During a re-shorting prevention period which starts from a beginning of the initial arc period, a re-shorting prevention current which is larger than the initial arc current is applied in order to prevent re-shortening between the wire tip and the base metal right after the initial arc was generated. Thereafter, the initial arc current is applied.

Owner:DAIHEN CORP

Adjustable rating for a fault interrupter and load break switch

ActiveUS7936541B2Easy to extinguishHigh voltageSwitches with electromagnetic openingElectromagnetically operated protective switchesTransformerInterrupter

A fault interrupter and load break switch includes a trip assembly configured to automatically open a transformer circuit electrically coupled to stationary contacts of the switch upon the occurrence of a fault condition. The fault condition causes a Curie metal element electrically coupled to at least one of the stationary contacts to release a magnetic latch. The release causes a trip rotor of the trip assembly to rotate a rotor assembly. This rotation causes ends of a movable contact of the rotor assembly to electrically disengage the stationary contacts, thereby opening the circuit. The switch also includes a handle for manually opening and closing the electrical circuit in fault and non-fault conditions. Actuation of the handle coupled to the rotor assembly via a spring-loaded rotor causes the movable contact ends to selectively engage or disengage the stationary contacts.

Owner:EATON INTELLIGENT POWER LTD

Arc start control method in robot welding

ActiveUS20070023407A1Preventing re-shortingGood arc startingArc welding apparatusWeld lineRobot welding

An arc start control method in robot welding includes the steps of shorting a welding wire with a base metal, retracting a welding torch by a welding robot for taking the welding wire off the base metal to generate an initial arc, retracting the welding torch to a predetermined position with maintaining the initial arc maintained while applying an initial arc current smaller than a steady welding current during this initial arc period, and starting to feed the welding wire steadily and to supply the steady welding current so as to make a transition from the initial arc to a steady arc as well as starting to move the welding torch along a welding line. During a re-shorting prevention period which starts from a beginning of the initial arc period, a re-shorting prevention current which is larger than the initial arc current is applied in order to prevent re-shortening between the wire tip and the base metal right after the initial arc was generated. Thereafter, the initial arc current is applied.

Owner:DAIHEN CORP

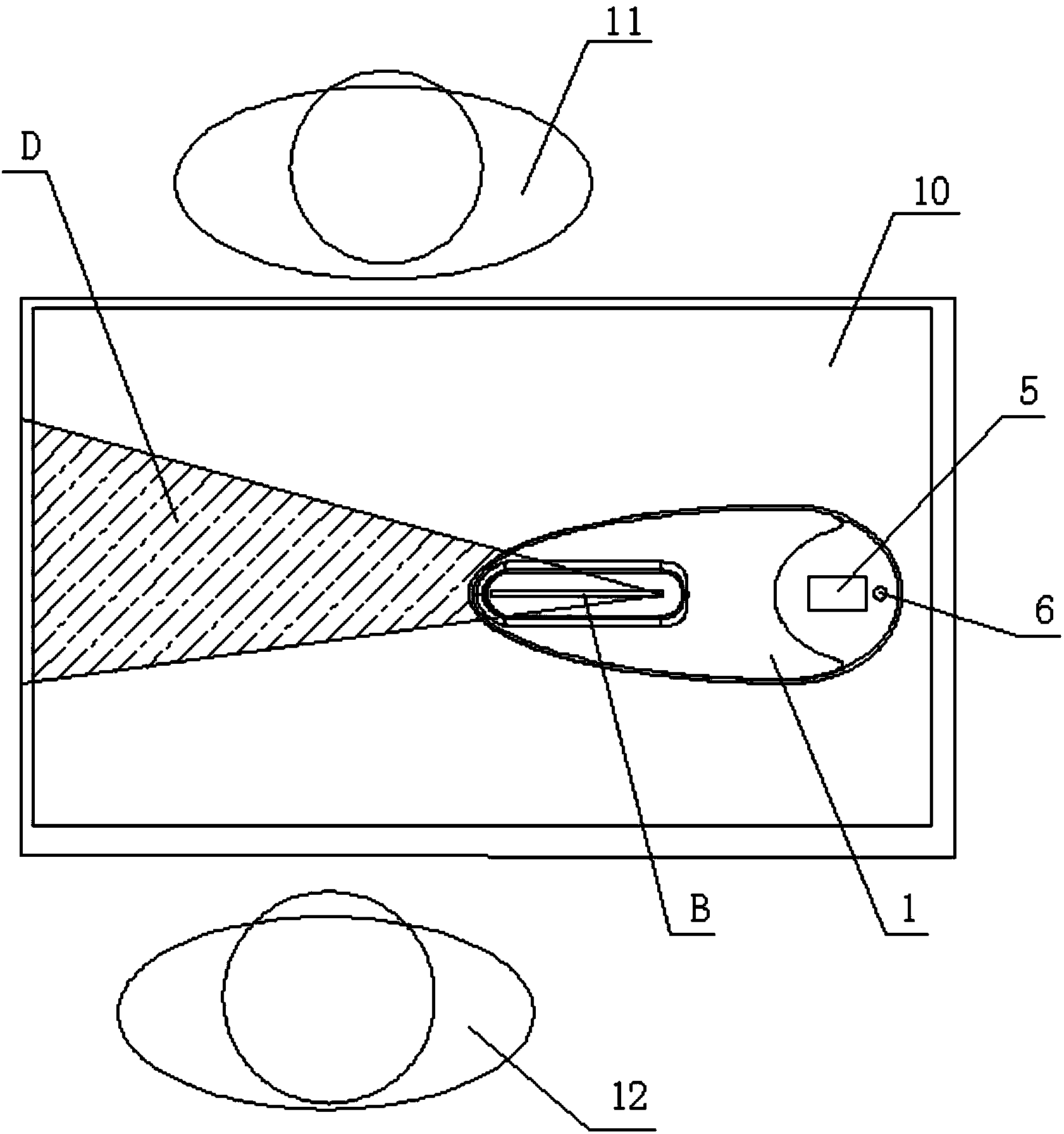

Portable air partitioning and generating device for doctor-patient separation

InactiveCN103953997APartition effectiveIncrease the areaLighting and heating apparatusSpace heating and ventilation detailsDoctor patientBlow out

The invention discloses a portable air partitioning and generating device for doctor-patient separation. The device includes a casing, as well as a fan, a drainage cover, an ultraviolet lamp tube, a filter net, an air outlet groove and a controller which are arranged in the casing, wherein the casing is fan-shaped, an air inlet is formed in the casing, the filter net is arranged on the inner side of the air inlet, the arc-shaped air outlet groove is formed in the arc-shaped surface of the fan-shaped casing, the ultraviolet lamp tube is arranged on the inner side of the air outlet groove, and the drainage cover is arranged between an air outlet of the fan and the air outlet groove of the casing. During the use, the device is usually placed on a working table in a consulting room or working station of a hospital and between a doctor and a patient, so that airflows generated by the fan pass through the drainage cover and are blown out through the air outlet groove to form an air partition between the doctor and the patient, which can separate the doctor from the patient and prevent viruses and bacteria from being spread through air.

Owner:喻安义

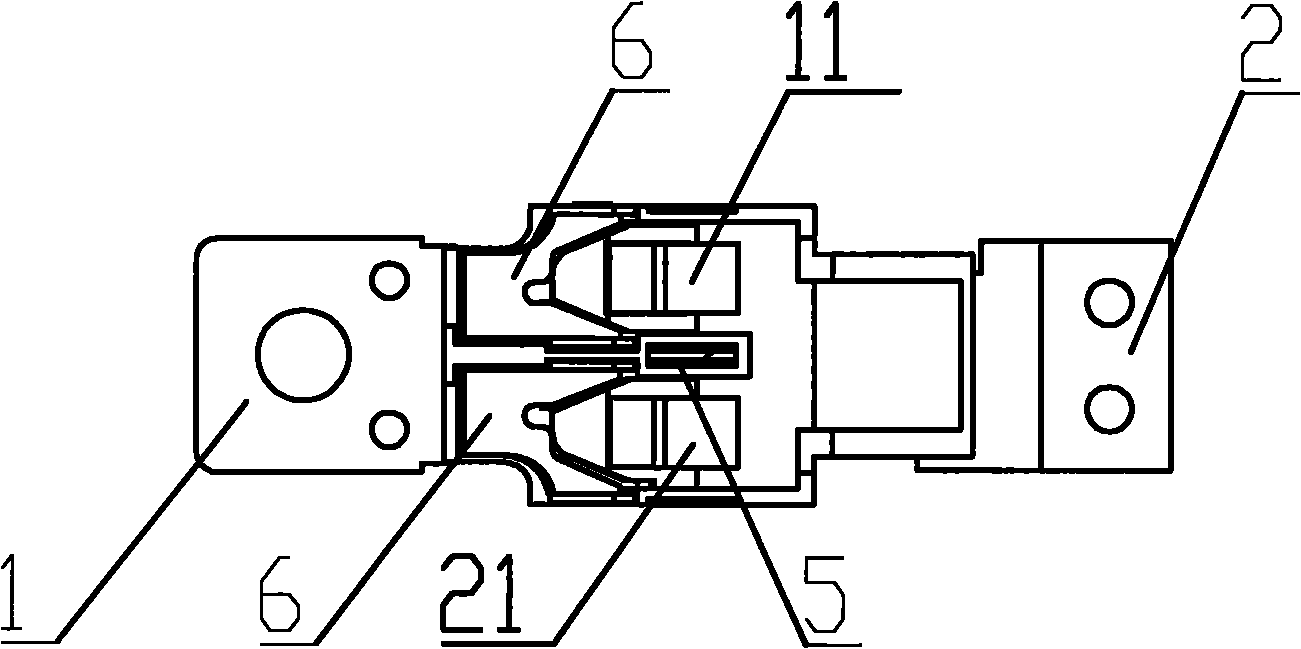

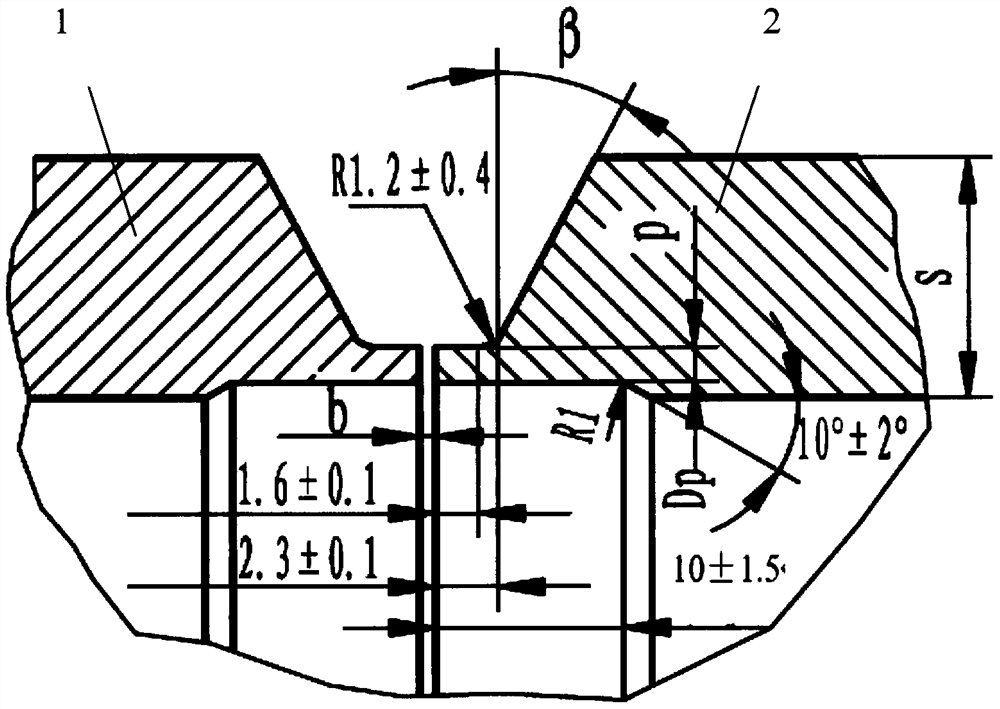

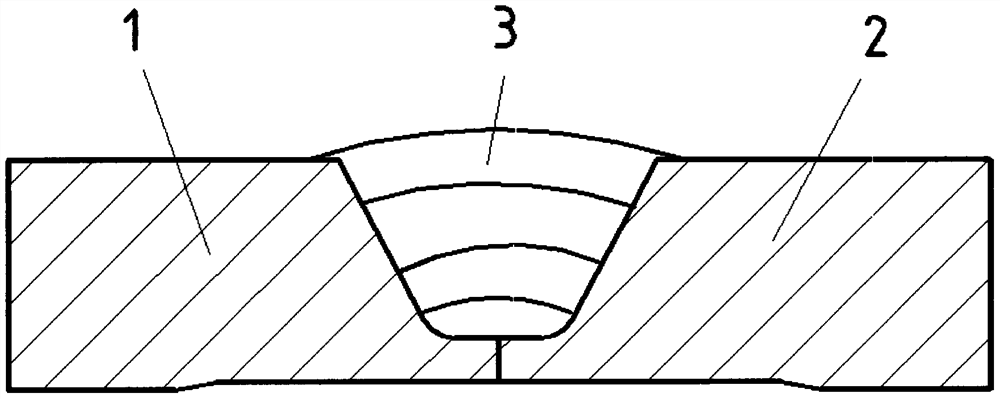

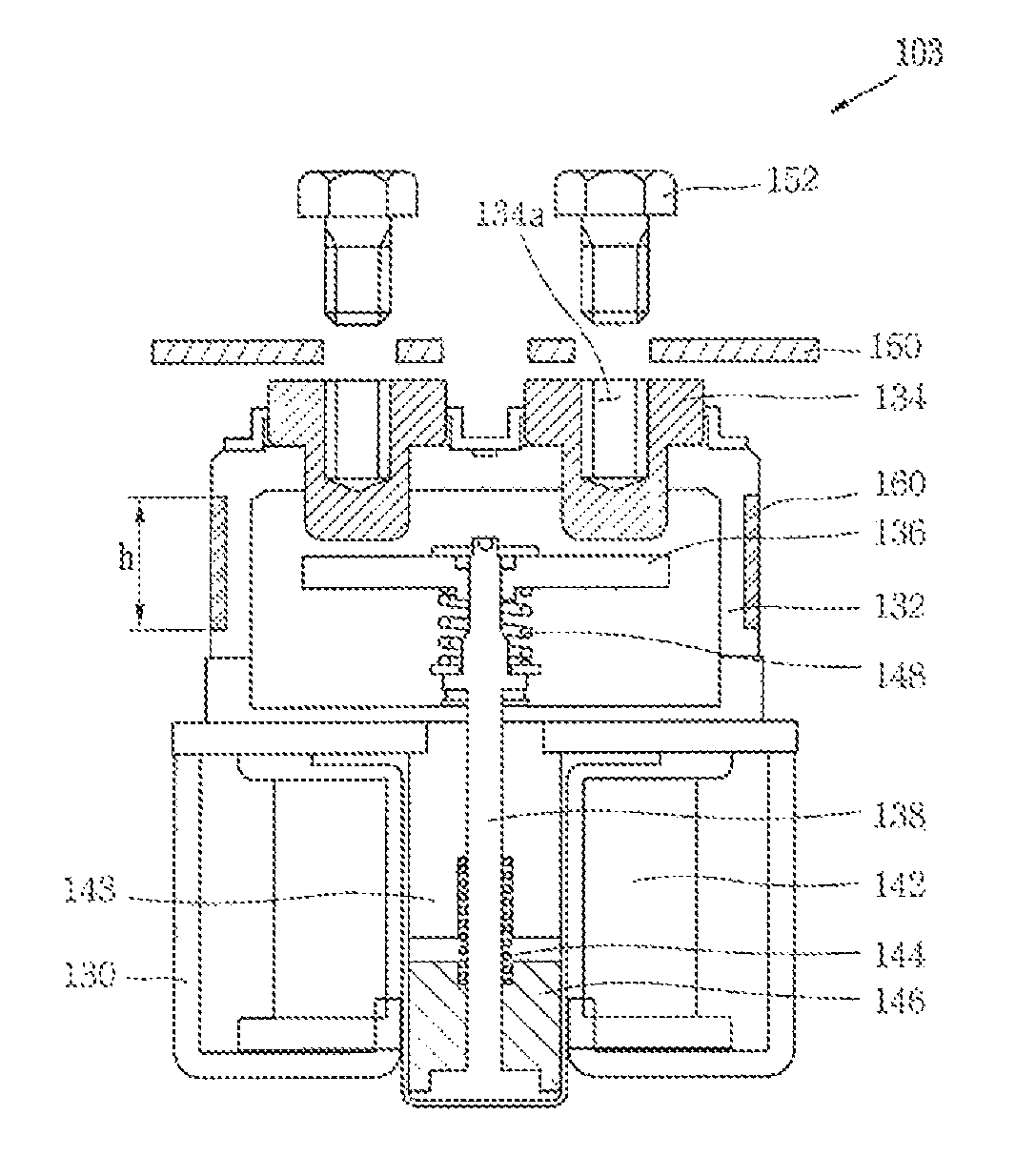

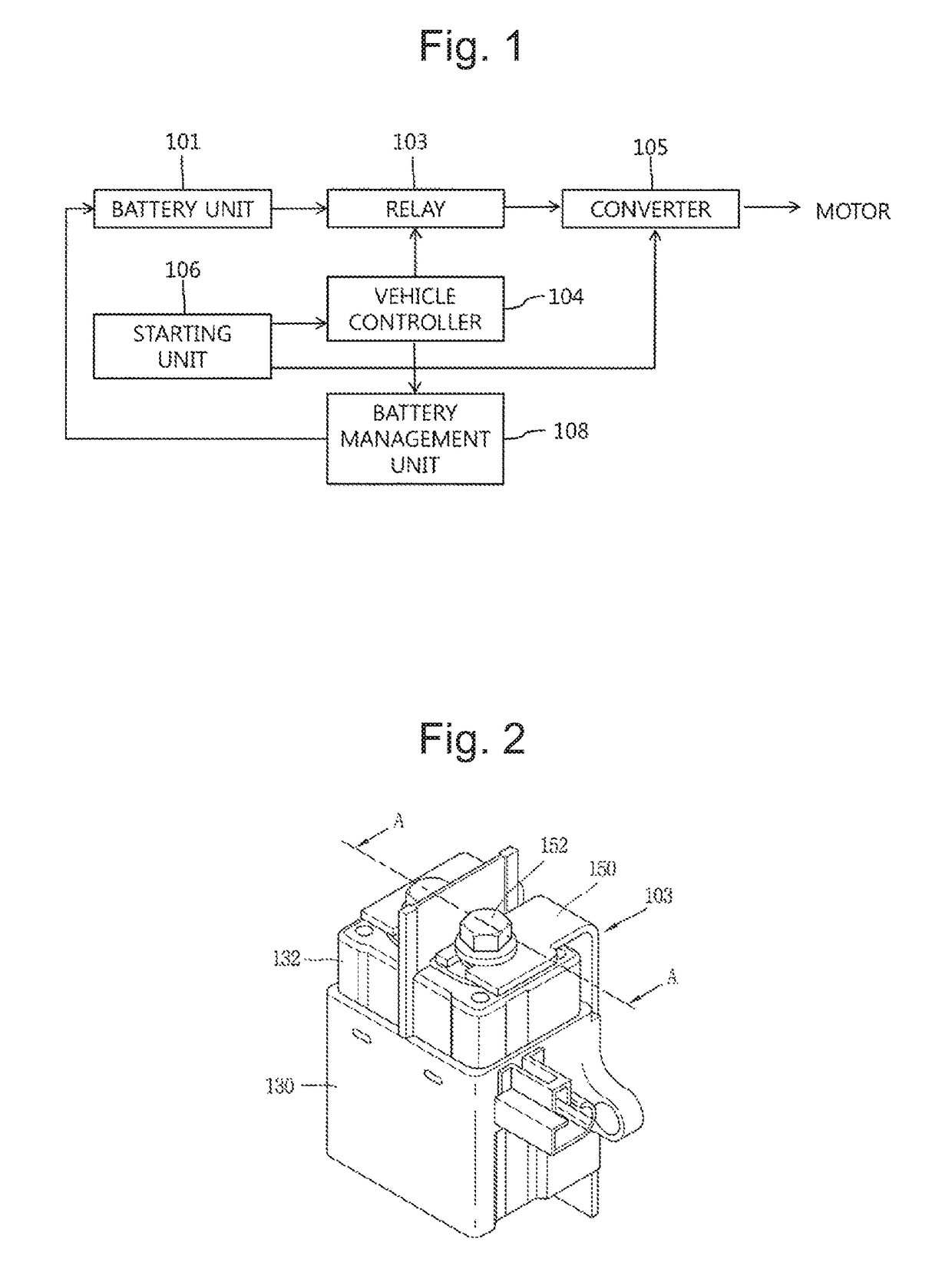

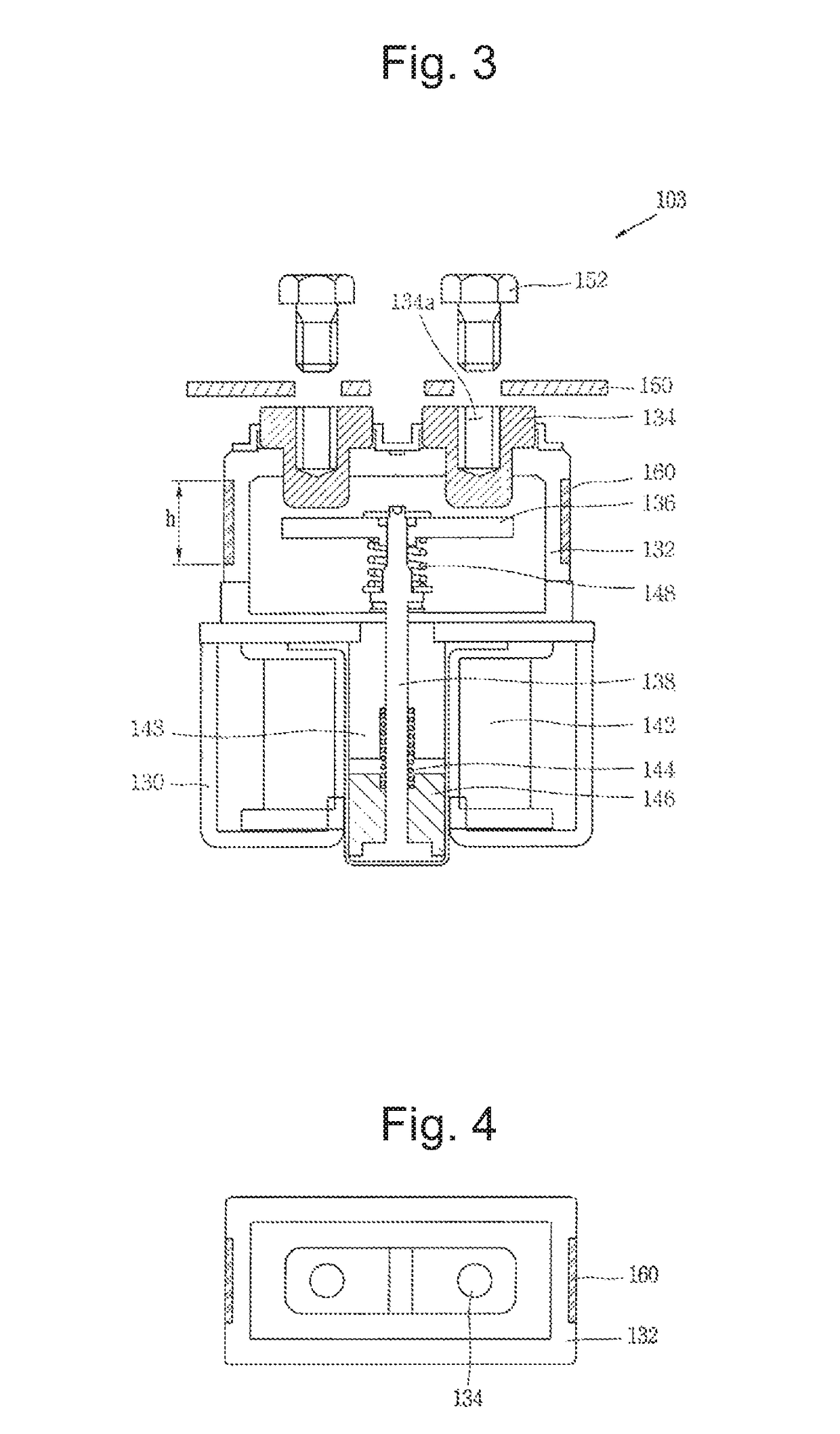

Method of fabricating a relay

ActiveUS9887056B2Fast executionIncrease arc lengthPermanent magnetsInorganic material magnetismEngineeringElectric vehicle

The present invention relates to a relay for an electric vehicle and a method of manufacturing the same, and more particularly, a relay for an electric vehicle where a permanent magnet is integrally formed with a housing formed of a ceramic chamber, and a method of manufacturing the same. The relay, capable of rapidly executing current interruption includes: a fixed contact; a movable contact formed to contact or to be separated from the fixed contact; a shaft connected to the movable contact, and configured to move the movable contact; a housing configured to accommodate therein the fixed contact and the movable contact; an actuator configured to drive the shaft; and a permanent magnet integrally formed with the housing, and configured to extend an arc generated between the fixed contact and the movable contact. The permanent magnet includes an alnico-based material or a neodymium-based material.

Owner:LSIS CO LTD

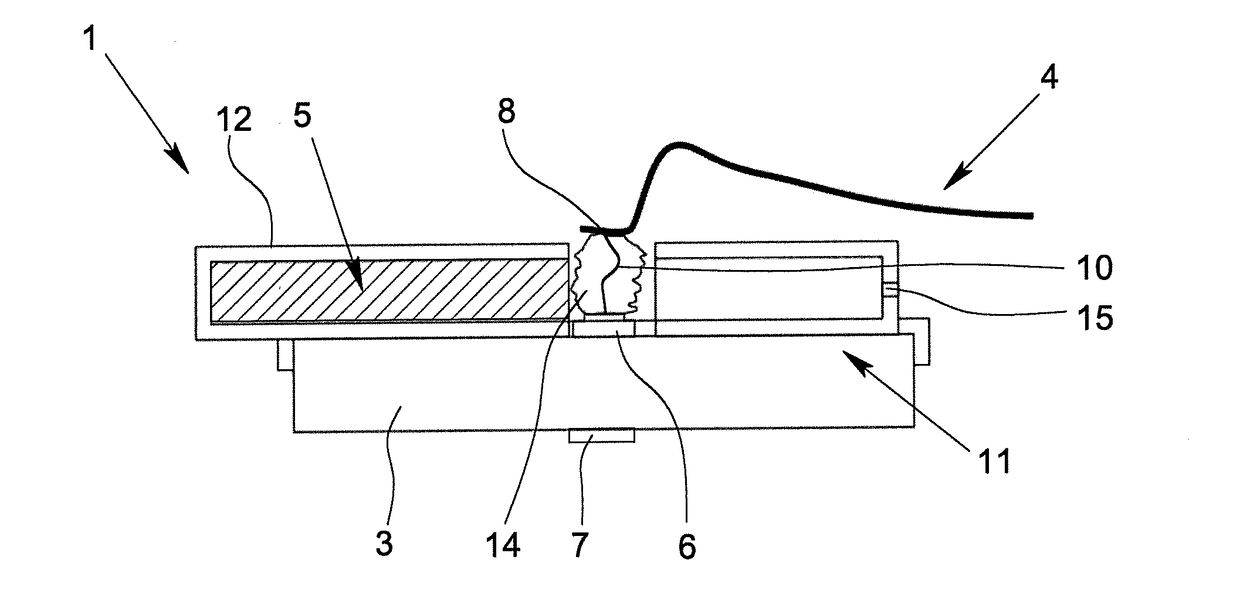

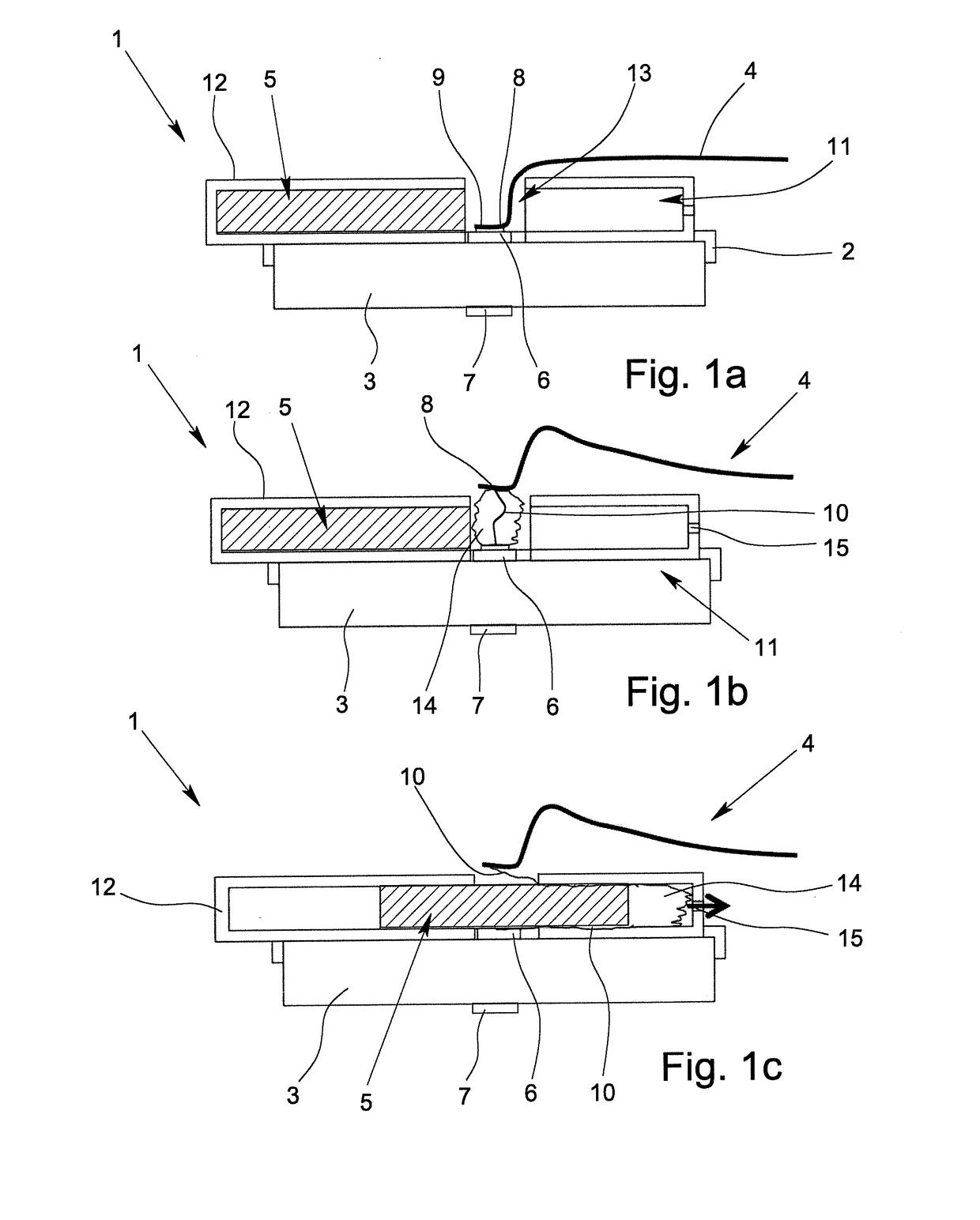

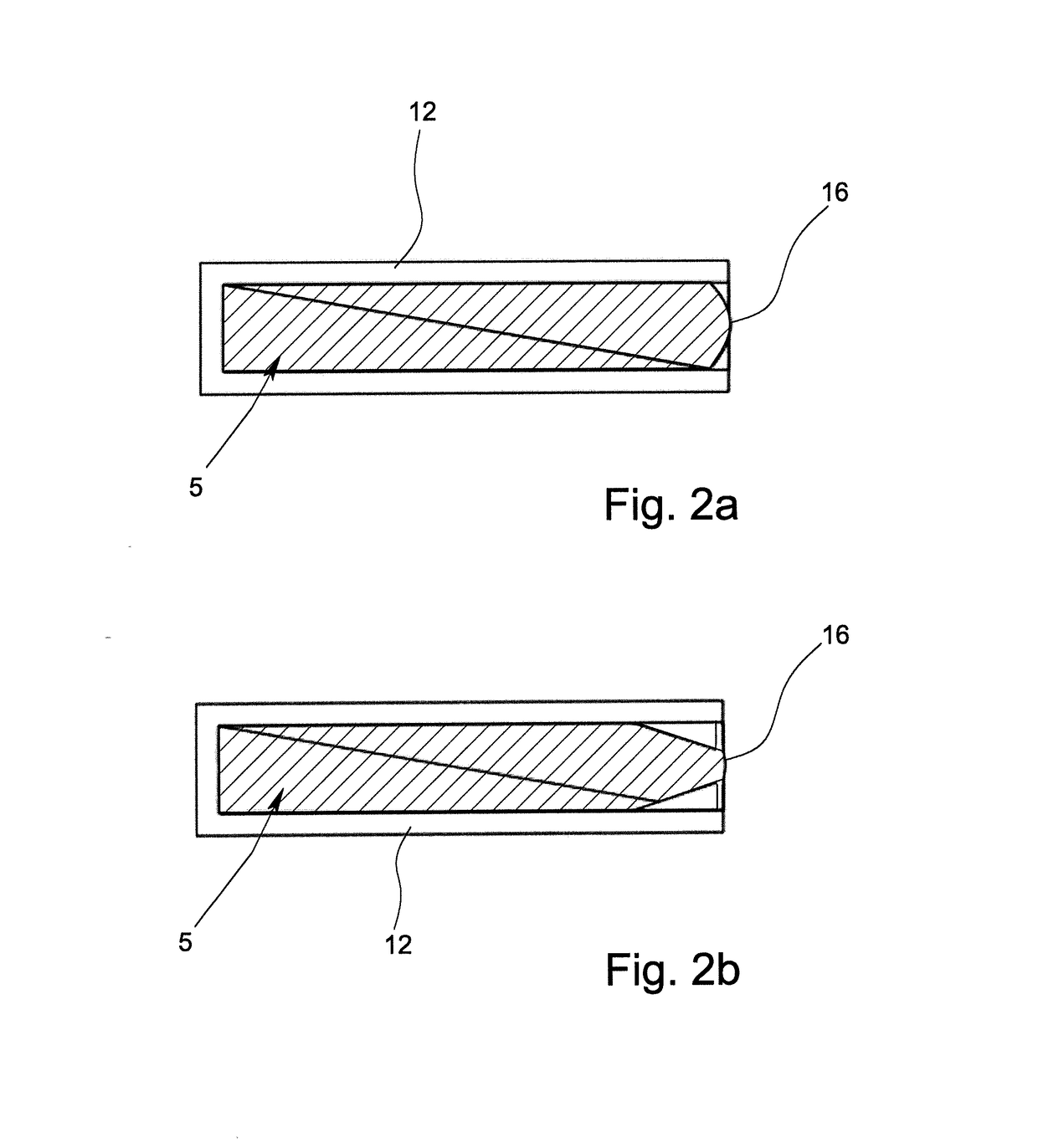

Surge suppressor

InactiveUS20180102637A1Avoid thermal damageReliable disconnectionSpark gap detailsHeating/cooling contact switchesSuppressorElectric power system

A surge suppressor with a housing, a varistor located in the housing, an electrically conductive connecting element and at least one isolating interrupter. The isolating interrupter is movable relative to a first terminal of the varistor out of a first position into a second position, in the normal state of the surge suppressor, a first end of the electrically conductive connecting element being connected to the first terminal of the varistor in an electrically conductive manner and the isolating interrupter being held in its first position. When a critical state of the varistor is reached, the isolating interrupter is moved into its second position in which a segment of the interrupter is located between the first end of the electrically conductive connecting element and the first terminal. Reliable disconnection from the power system is ensured by the arc formed being moved into at least one partially closed chamber.

Owner:PHOENIX CONTACT GMBH & CO KG

Sensor element for a fault interrupter and load break switch

ActiveUS7952461B2Easy to extinguishHigh voltageElectrothermal relaysEmergency protective arrangements for automatic disconnectionTransformerEngineering

A fault interrupter and load break switch includes a trip assembly configured to automatically open a transformer circuit electrically coupled to stationary contacts of the switch upon the occurrence of a fault condition. The fault condition causes a Curie metal element electrically coupled to at least one of the stationary contacts to release a magnetic latch. The release causes a trip rotor of the trip assembly to rotate a rotor assembly. This rotation causes ends of a movable contact of the rotor assembly to electrically disengage the stationary contacts, thereby opening the circuit. The switch also includes a handle for manually opening and closing the electrical circuit in fault and non-fault conditions. Actuation of the handle coupled to the rotor assembly via a spring-loaded rotor causes the movable contact ends to selectively engage or disengage the stationary contacts.

Owner:EATON INTELLIGENT POWER LTD

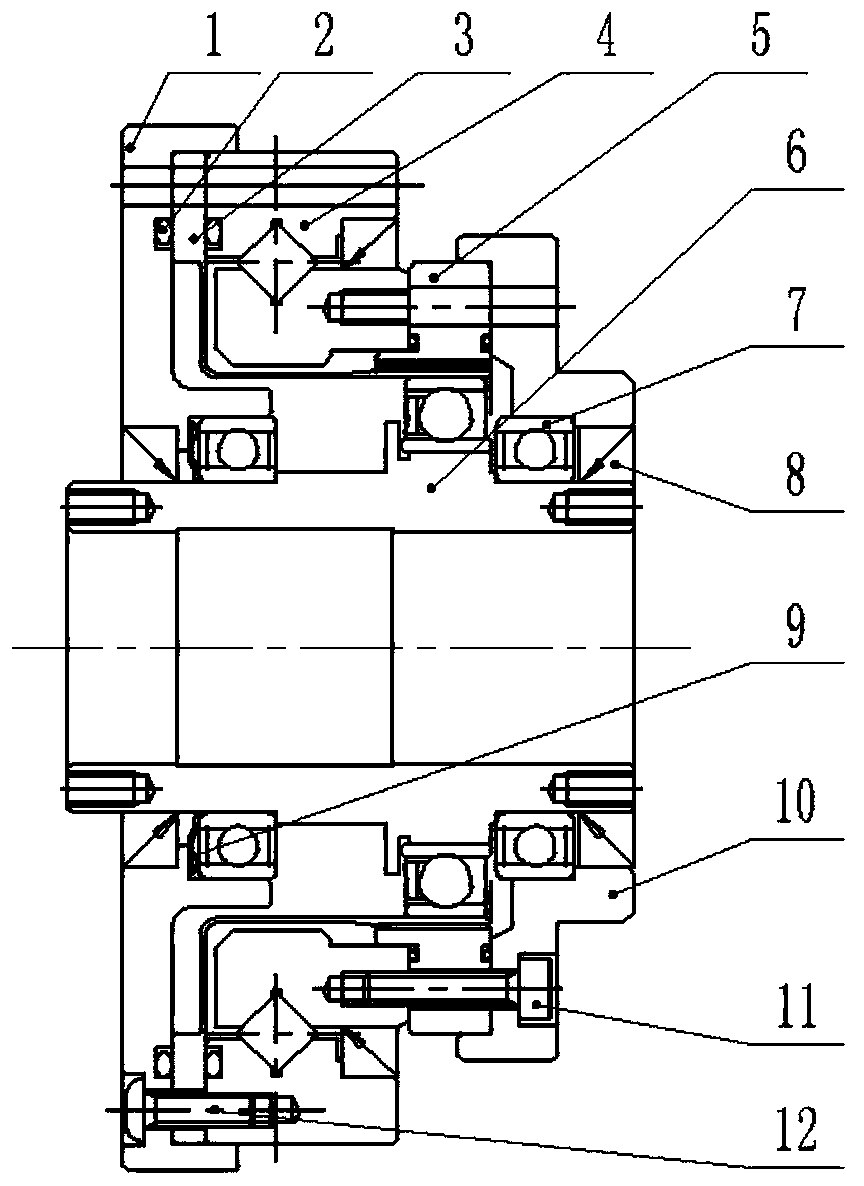

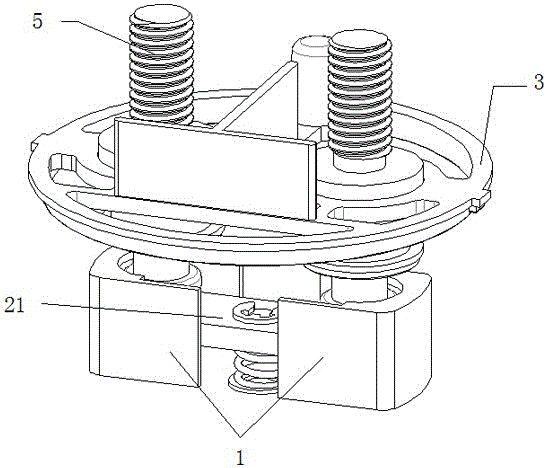

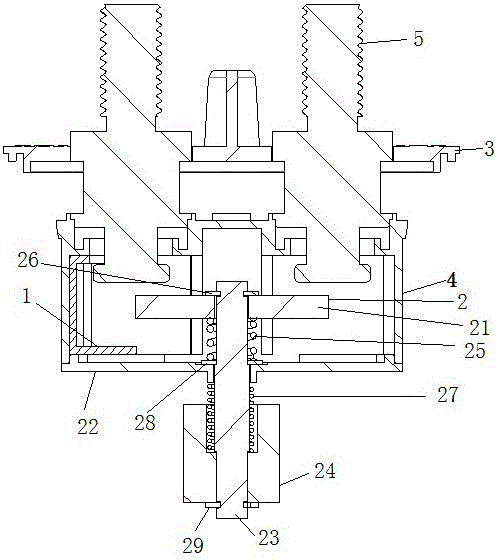

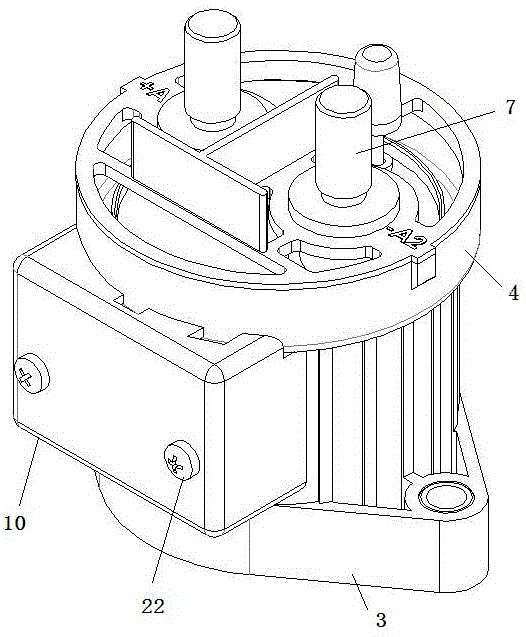

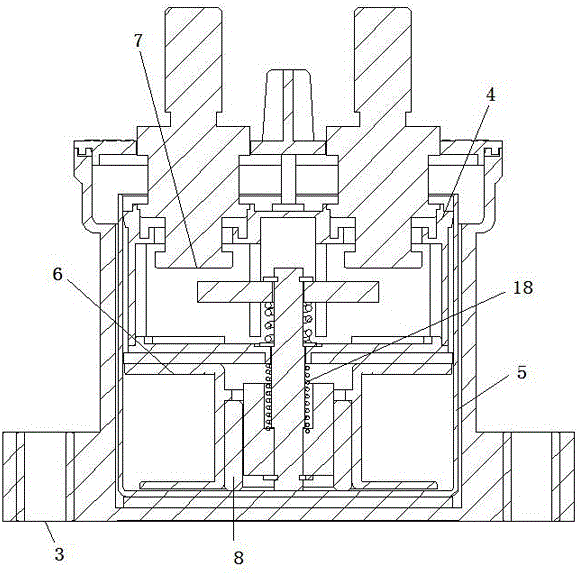

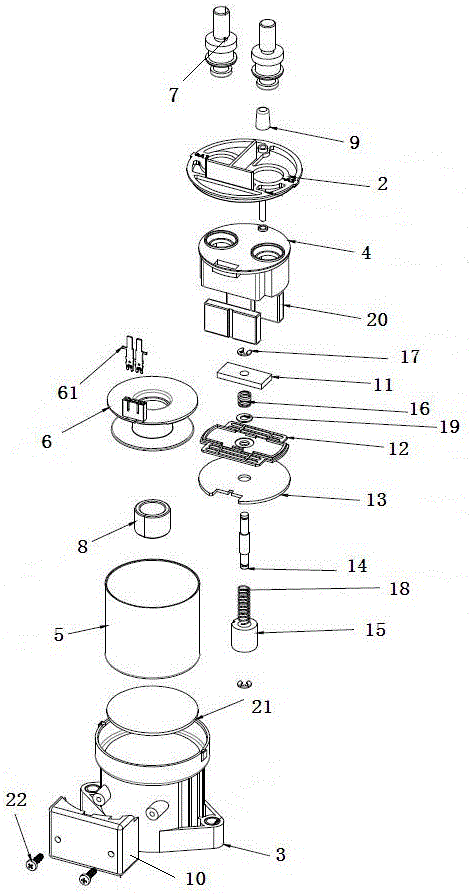

Relay

InactiveCN106653493ASimple structureIncrease arc lengthContacts enclosures/screensElectromagnetic relay detailsEngineeringMechanical engineering

The invention relates to a relay, and belongs to the technical field of relays. The relay comprises an upper press cover, a contact bin, main contacts, a movable contact assembly and porcelain covers, wherein the upper press cover is arranged on the contact bin, the movable contact assembly and the contact bin are fixed, the main contacts are in contact with the movable contact assembly, the porcelain covers are arranged in the contact bin, the movable contact assembly comprises a movable contact, an insulation support seat, a stainless steel connection rod and a movable iron core, one end of the stainless steel connection rod sequentially penetrates through the insulation support seat and the movable contact, the other end of the stainless steel connection rod is connected with the movable iron core in a penetrating way, the insulation support seat is matched with the contact bin, and the main contacts are in contact with the movable contact. The relay is reasonable in structure, low in production, simple in process, cheap in equipment cost and short in production period, and is safe and reliable.

Owner:ZHEJIANG ZHONGXIN NEW ENERGY TECH CO LTD

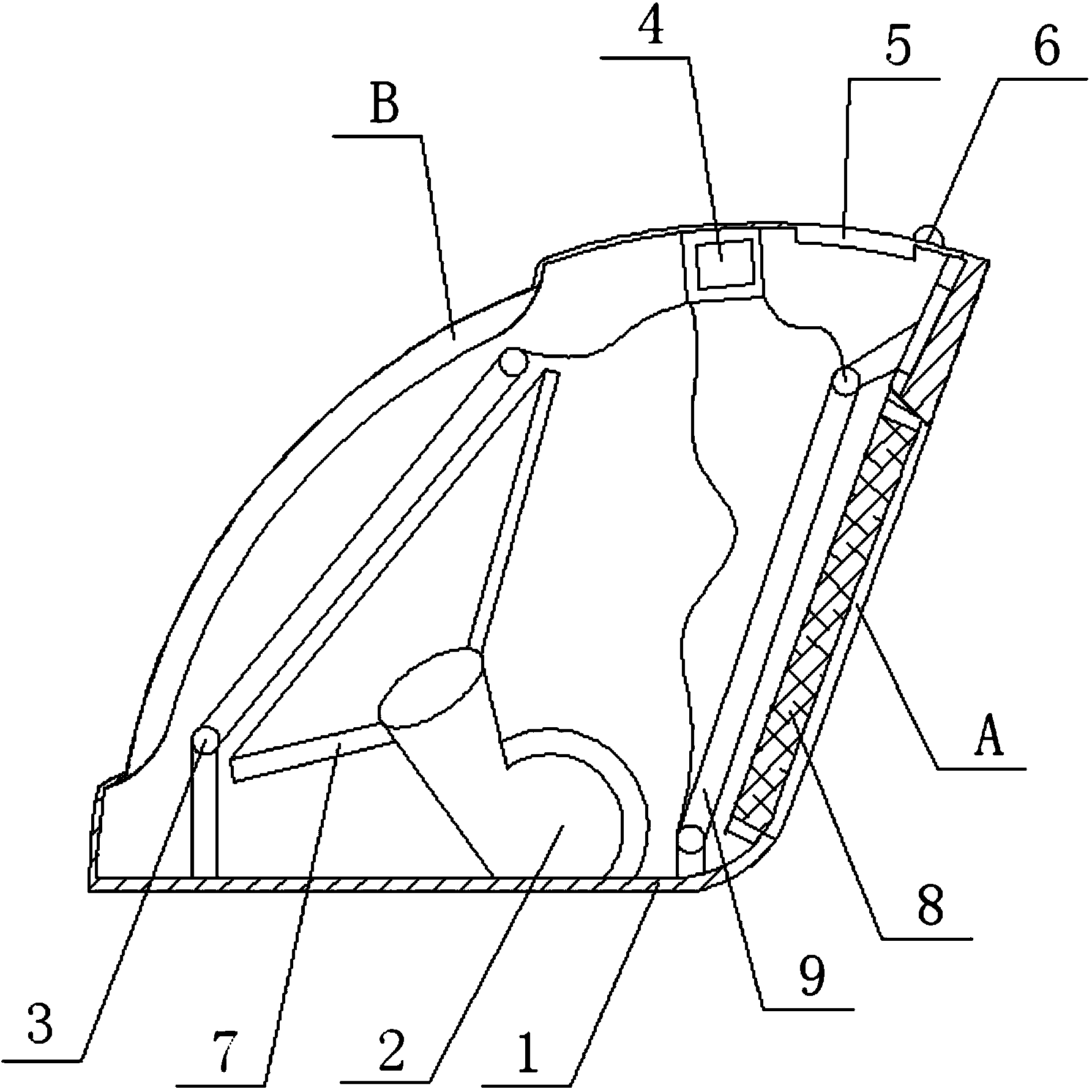

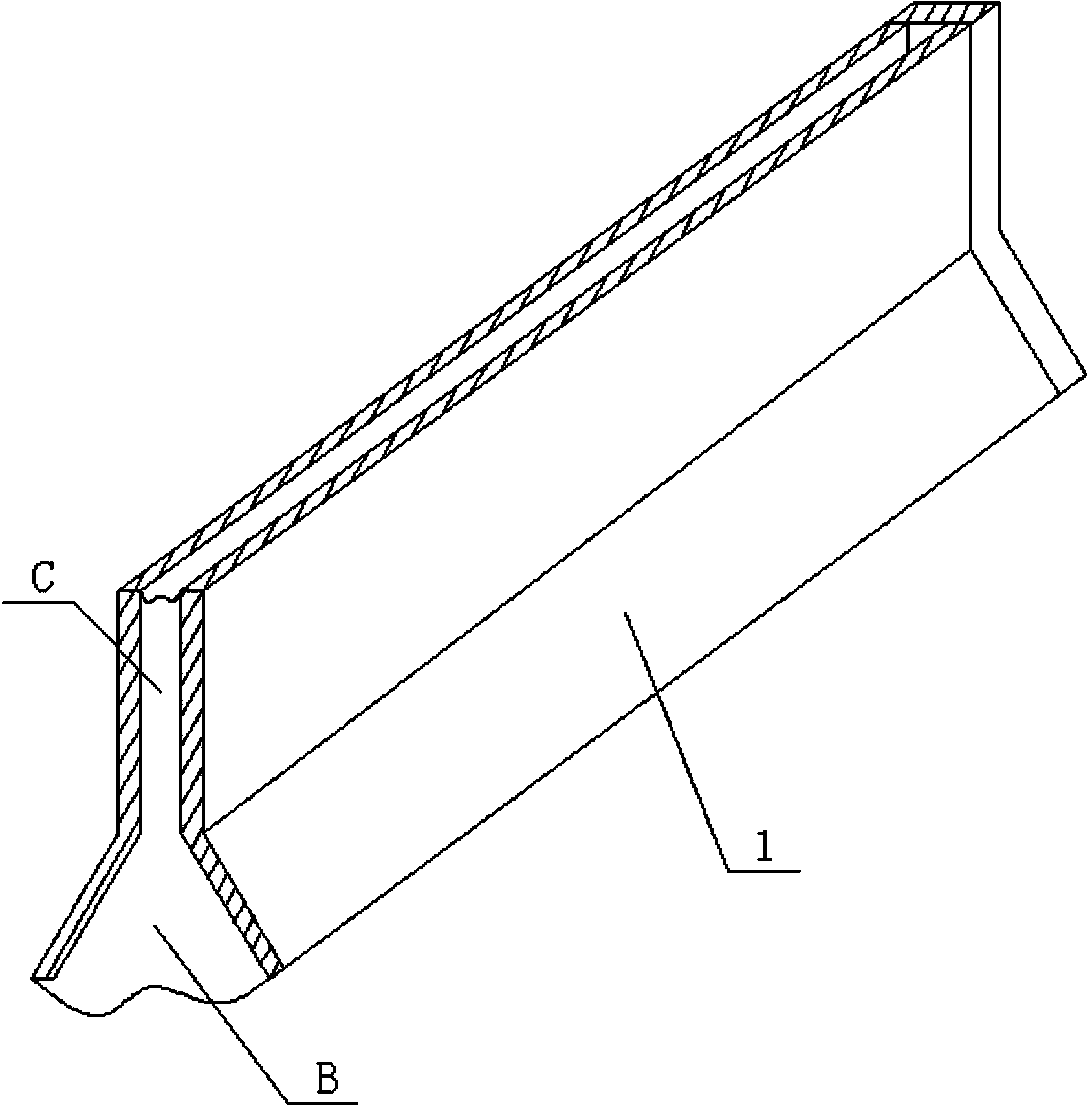

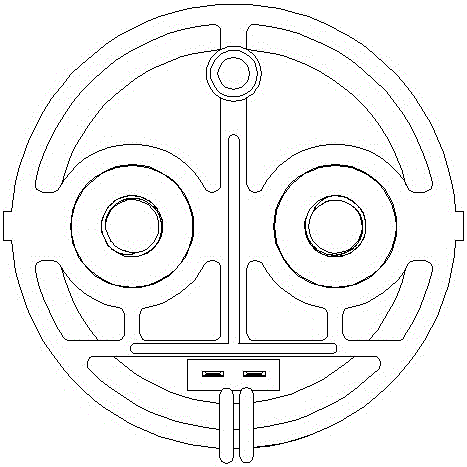

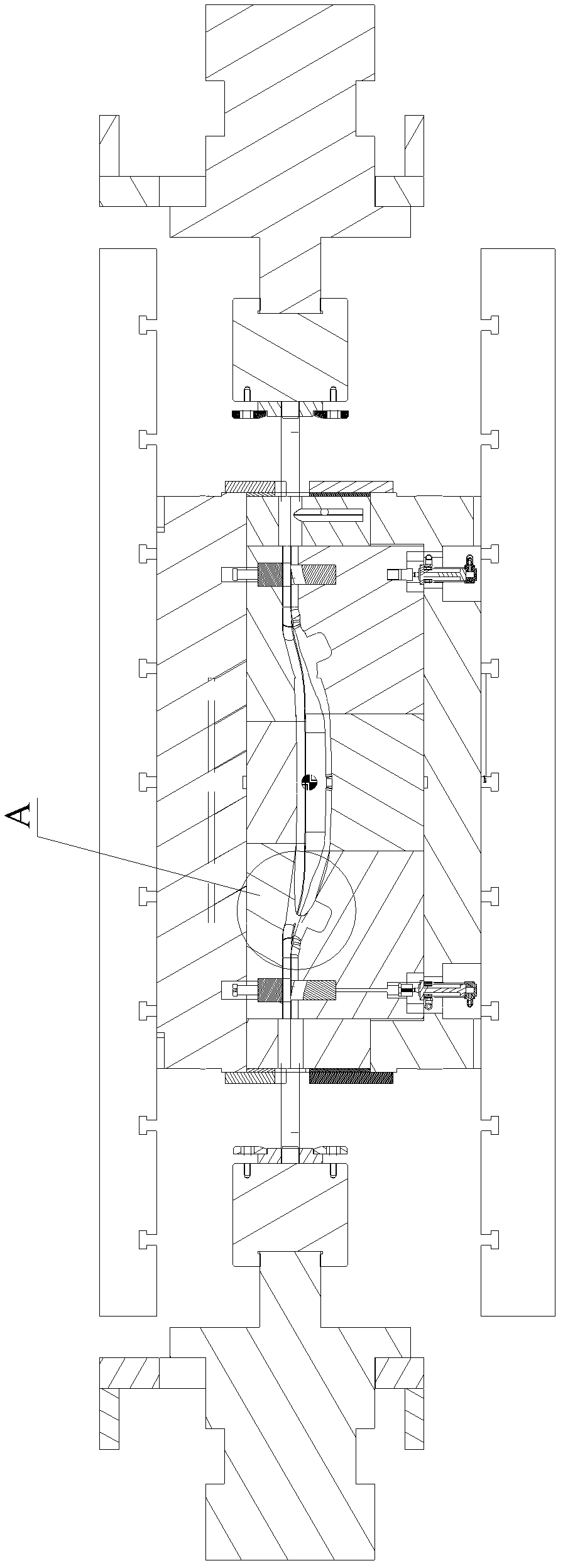

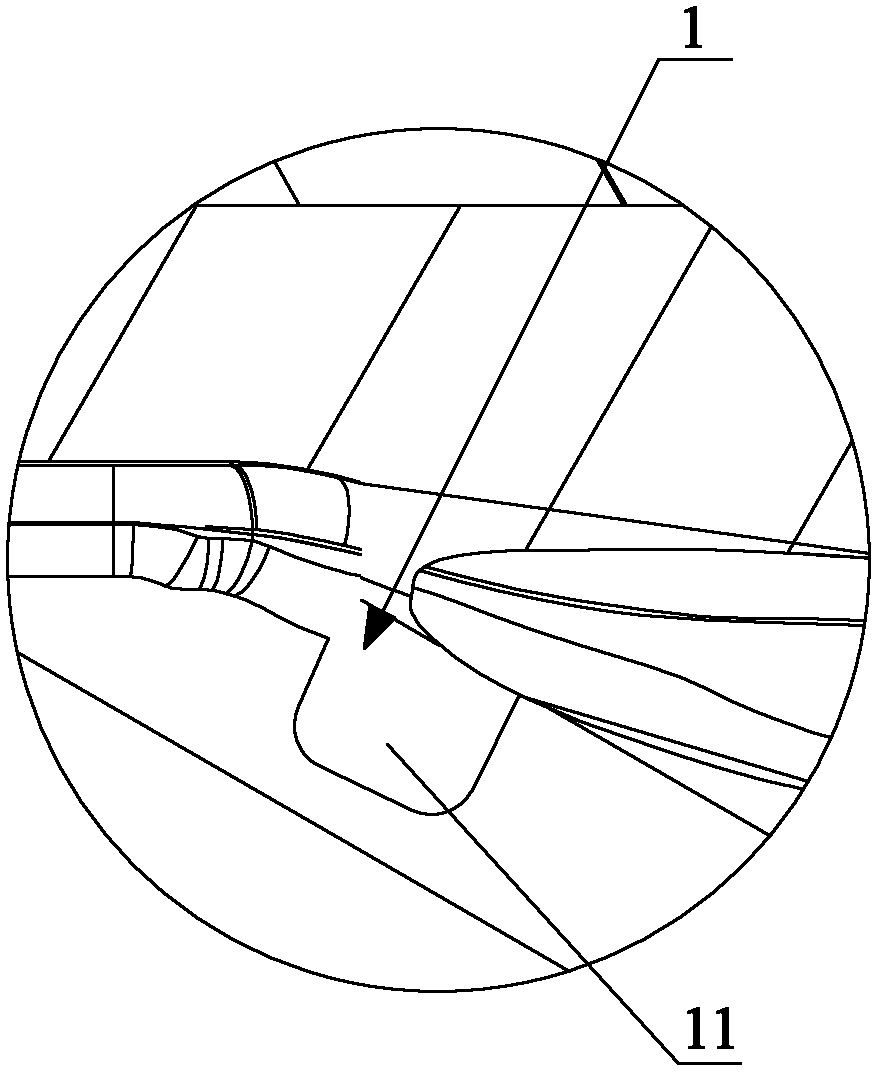

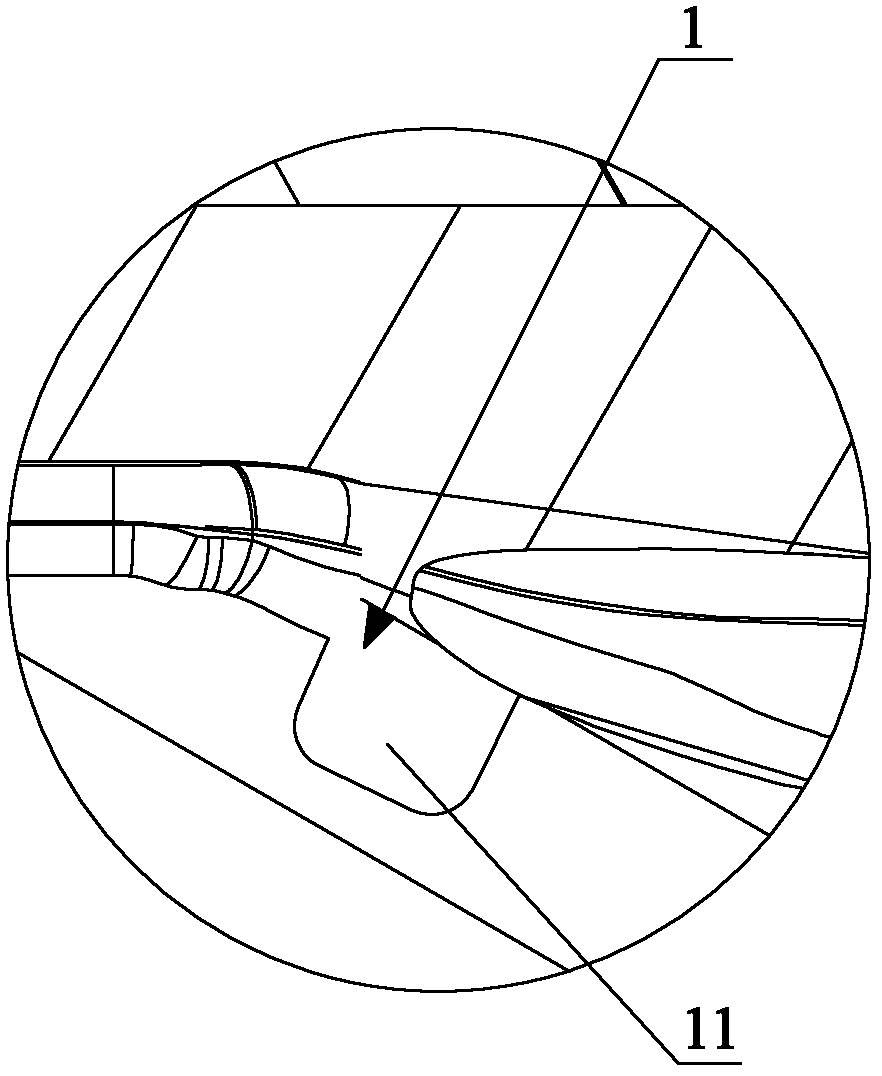

Internal high pressure forming die

The invention provides an internal high pressure forming die. The shape of a cavity (1) of the die is matched with that of a formed pipe, and grooves (11) are arranged on the inner wall of the cavity (1) and correspond to bent positions of the pipe. When the internal high pressure forming die is used for manufacturing the pipe, as the grooves (11) are arranged on the inner wall of the cavity (1) and correspond to the bent positions of the pipe, projections are arranged at the bent positions of the formed pipe, the arc length of the bent positions of the pipe is increased by the aid of the protections, and further the yield point of the bent positions is improved. Therefore, cracking, creasing and rebounding of the bent positions of the pipe caused by incapability of completely plastically deforming due to non-uniform stress on the pipe are decreased.

Owner:吉林省元隆达工装设备有限公司

High-voltage DC relay

InactiveCN105719907AHigh speedLow calorific valueElectromagnetic relay detailsHigh pressureMechanical engineering

The invention relates to a high-voltage DC relay, belonging to the technical field of a relay. The high-voltage DC relay comprises an upper press cover, a shell body, a contact bin, an outer shell, a static contact, a fixed iron core, a movable contact assembly and a framework, wherein the upper press cover is matched with the shell, the contact bin is assembled with the outer shell, the movable contact assembly is arranged on the framework, the contact bin is assembled on the movable contact assembly, and the fixed iron core is arranged in the framework. The high-voltage DC relay has the advantages of reasonable structure, simplicity in production process, high working voltage, long service lifetime, safety and reliability.

Owner:ZHEJIANG ZHONGXIN NEW ENERGY TECH CO LTD

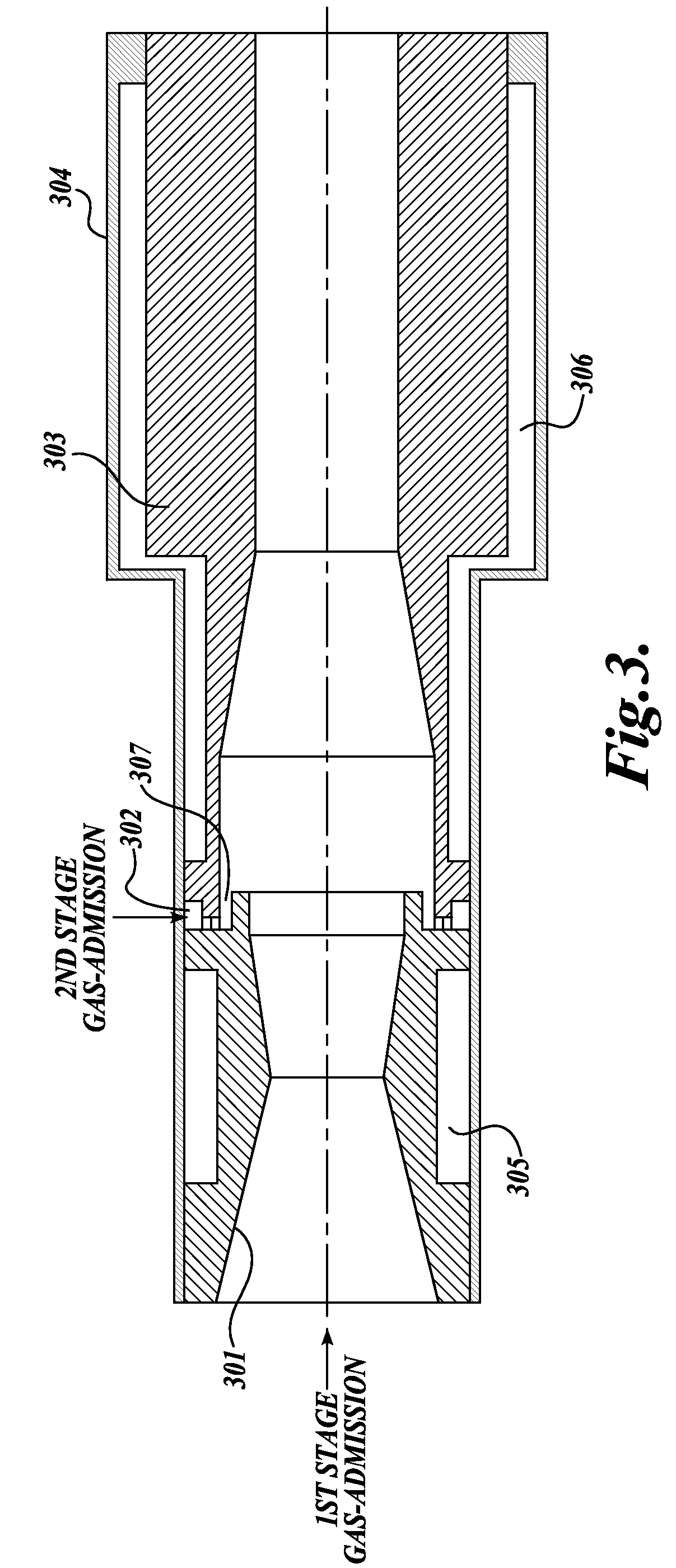

Anode of an arc plasma generator and the arc plasma generator

ActiveUS8698383B2Convenient amountHigh voltageLamp incadescent bodiesDischarge tube/lamp detailsPlasma generatorAtomic physics

An anode of an arc plasma generator and the arc plasma generator are disclosed. The plasma generator is a multi-stage gas admission type arc plasma generator, and the plasma generator includes a cathode and an anode. The anode comprises at least two portions (201, 203), wherein any two adjacent portions of the anode are connected electrically with one another.

Owner:YANTAI LONGYUAN POWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com