Pulsation welding equipment and control method thereof

A pulse welding and control method technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of arc breaking and high noise, and achieve the effects of overcoming harsh noise, optimizing control, and improving arc ignition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

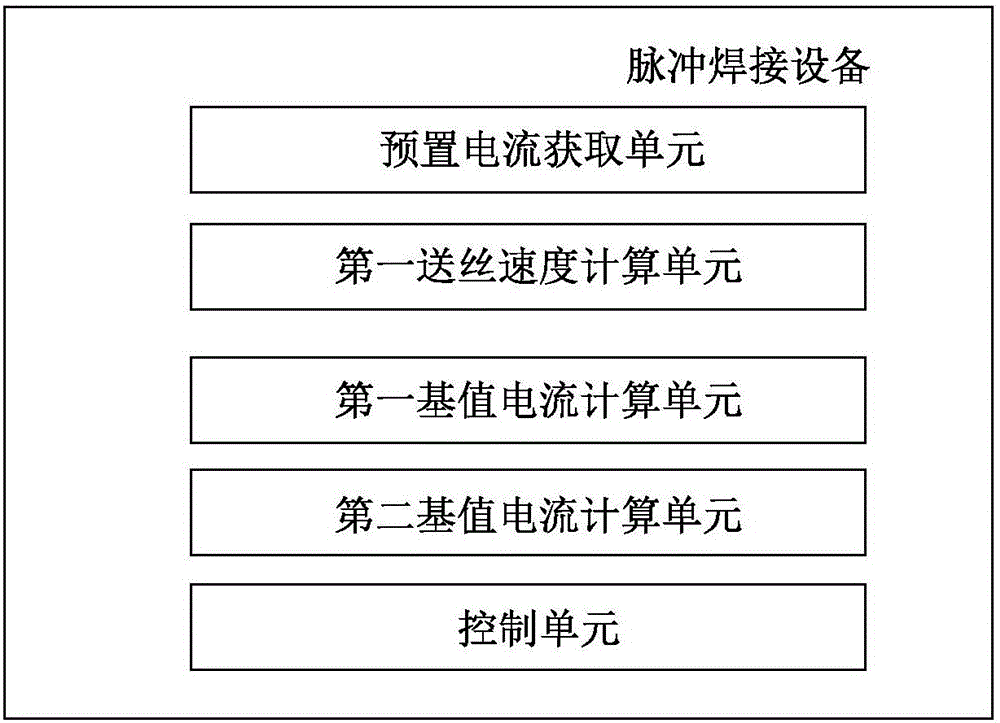

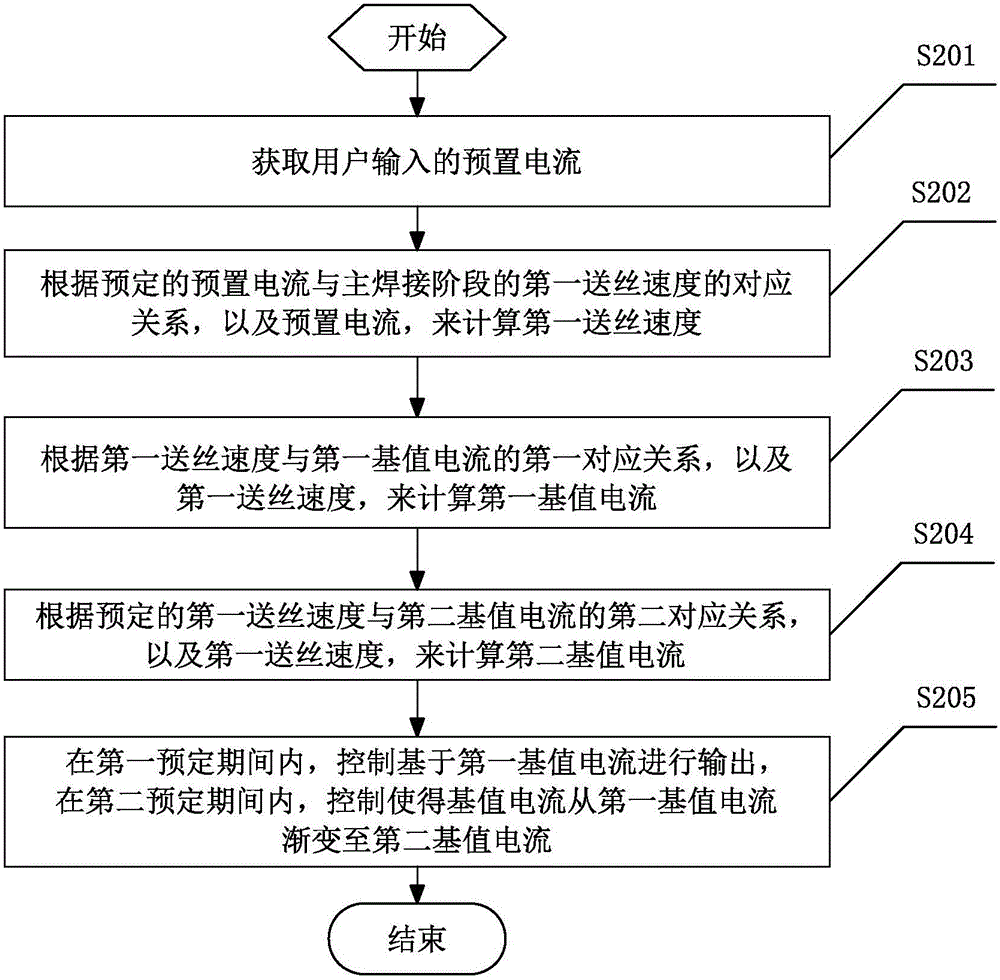

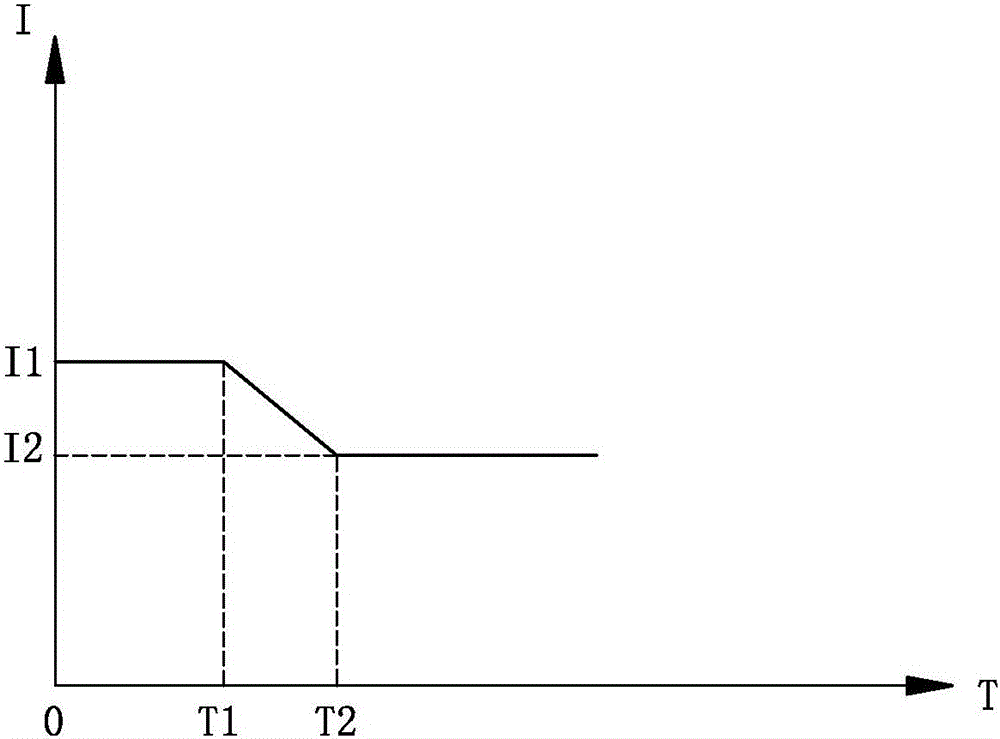

[0026] Refer below Figure 1 to Figure 4 A first embodiment of the present invention is described. In the first embodiment, the control when the pulse welding equipment uses small current welding is described. In this embodiment, the preset current not exceeding 100A is defined as a small current. figure 1 The software structure of the pulse welding apparatus of the first embodiment is shown.

[0027] Such as figure 1 As shown, the pulse welding equipment of the present invention includes: a preset current obtaining unit, which is used to obtain the preset current input by the user; a first wire feeding speed calculation unit, which is used to combine the preset current with the main welding The corresponding relationship of the first wire feeding speed of the stage, and the preset current, to calculate the first wire feeding speed; the first base value current calculation unit, which is used to calculate the first wire feeding speed and the predetermined first wire feedi...

no. 2 example

[0042] Refer below Figure 5 A second embodiment of the present invention is described. The second embodiment describes the control when the pulse welding equipment adopts high current welding. In this embodiment, a preset current exceeding 100A is defined as a large current.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com