Patents

Literature

48results about How to "Improve fade resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound cathode slurry of graphene high-power lithium batteries and preparation method of compound cathode slurry

ActiveCN107528054AHigh discharge specific capacityImprove fade resistanceCell electrodesSecondary cellsUltrasound attenuationSlurry

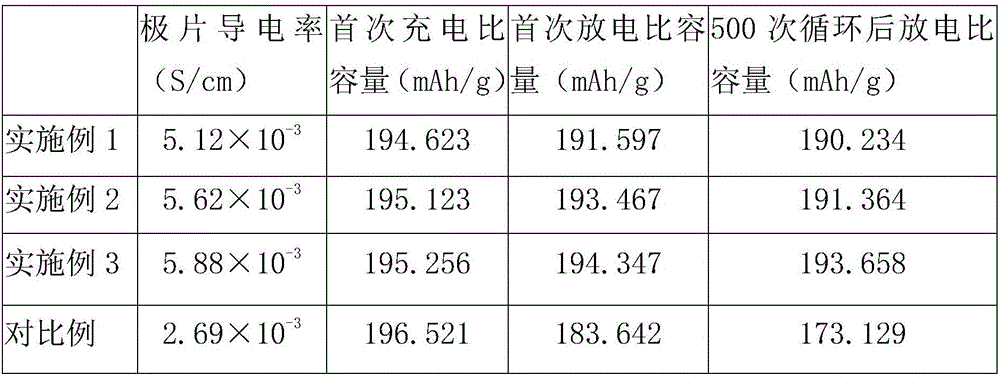

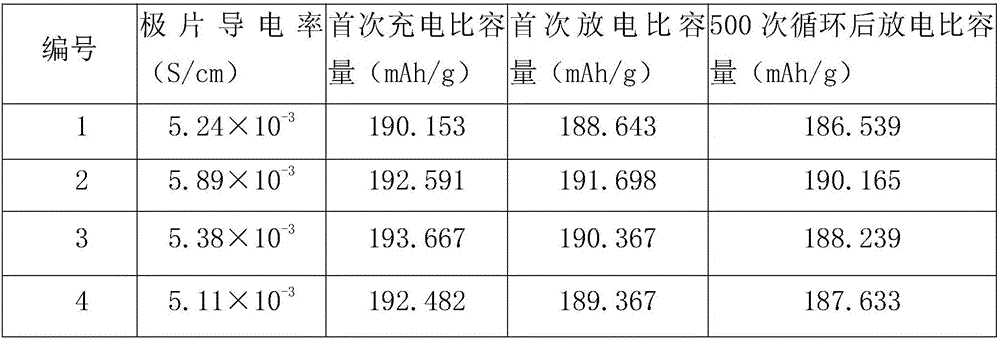

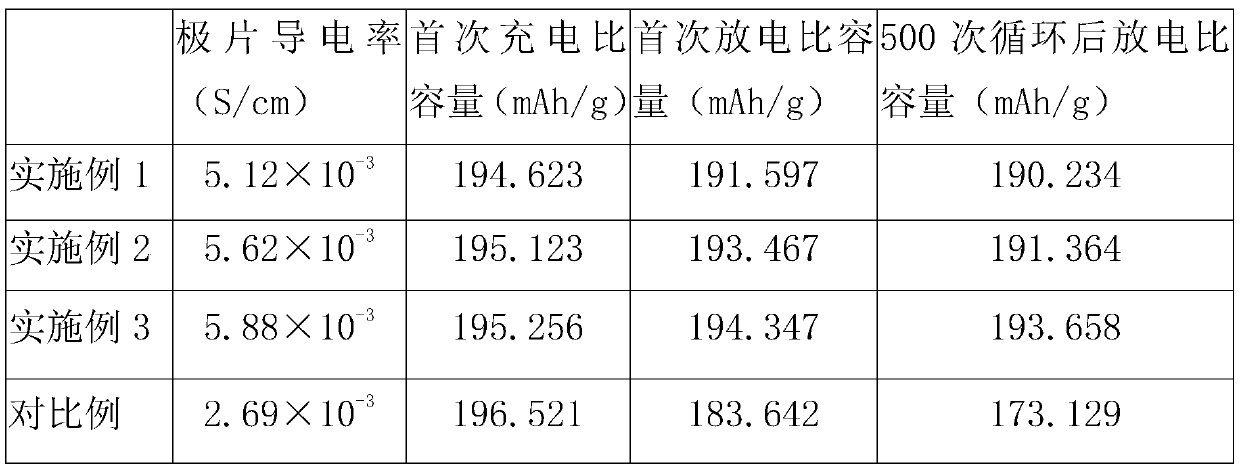

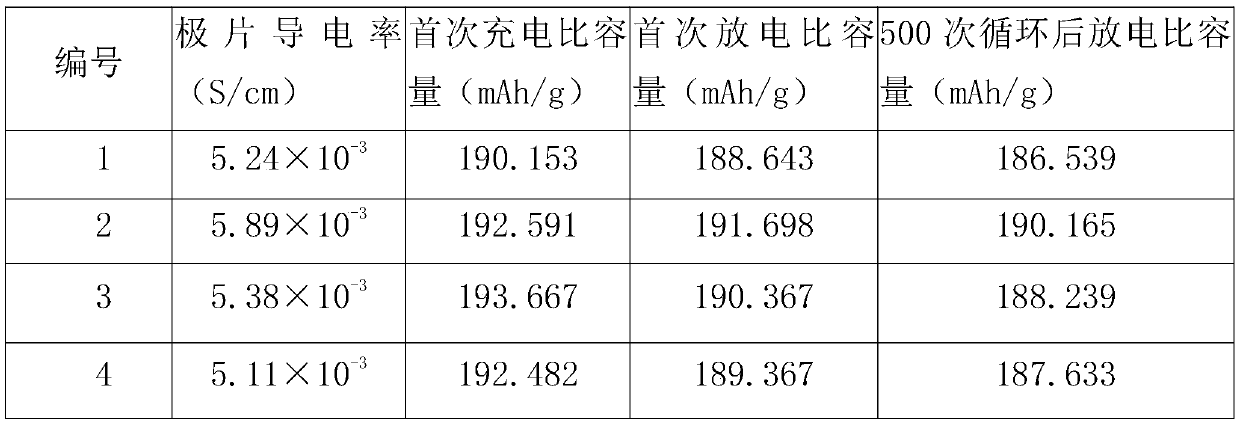

The invention provides compound cathode slurry of graphene high-power lithium batteries, relates to the technical field of cathode slurry of lithium batteries and aims to solve the technical problems that cathode slurry used in the prior art causes reduced energy storage capacity and poor cycle performance and stability of the lithium batteries, as a result, the lithium batteries easily heat and are short in service life and low in utilization rate during usage. Thus, the invention provides the compound cathode slurry of graphene high-power lithium batteries. Compared with traditional cathode slurry for the lithium batteries, the prepared compound cathode slurry has the battery capacity reduced from 195.256 mAh / g to 193.658 mAh / g and the capacity retention rate up to 99.18% under the conditions that the temperature is 35 DGE C and 1C charge and 6C discharge are circulated 500 times, the discharge specific capacity and attenuation resistance are improved, and the high cycle life and high capacity stability are realized.

Owner:上海玖银电子科技有限公司

Printing and dyeing auxiliary

The invention discloses a printing and dyeing auxiliary, and relates to the technical field of spinning dyeing. The printing and dyeing auxiliary comprises, by weight, 10-15 parts of guar gum, 7-9.5 parts of poly alkyl acrylate, 15-20 parts of sodium carboxymethylcellulose, 5-8 parts of octadecyl dimethyl benzyl ammonium chloride, 2-3 parts of tannin and 10-15 parts of barium chloride. A preparing method comprises the steps that the raw materials are weighed according to the weight part, the poly alkyl acrylate, the sodium carboxymethylcellulose and the octadecyl dimethyl benzyl ammonium chloride are added into a reaction kettle to be heated and stirred until reaction is thorough, and cooling is carried out; the tannin and the barium chloride are added, stirred and heated, the guar gum is added, and stirring is even. The printing and dyeing auxiliary has the advantages of being high color fastness, good in color protecting performance and fading proof.

Owner:江苏中诚印染股份有限公司

Printing and dyeing auxiliary and preparation method thereof

InactiveCN106120392AHigh color fastnessReduce usageDyeing processChemistrySodium carboxymethylcellulose

The invention discloses a printing and dyeing auxiliary and a preparation method thereof and relates to the technical field of textile printing and dyeing. The printing and dyeing auxiliary comprises the following raw materials in parts by weight: 8-10 parts of guar gum, 15-17 parts of sodium dioctylsulfosuccinate, 4-6 parts of sodium sulfite, 4-10 parts of polyethylene glycol laurate, 5-7 parts of polyalkyl acrylate, 5-8 parts of sodium carboxymethyl cellulose, 9-11 parts of octadecyl dimethyl benzyl ammonium chloride and 6-9 parts of barium chloride. The printing and dyeing auxiliary disclosed by the invention has good efficacies of improving color fastness, protecting color and preventing color fading, simultaneously can reduce the consumption of dyes, is green, environment-friendly and nontoxic and reduces the cost, thereby having wide industrialization prospect and market value.

Owner:WUHU SHZ IND FABRIC

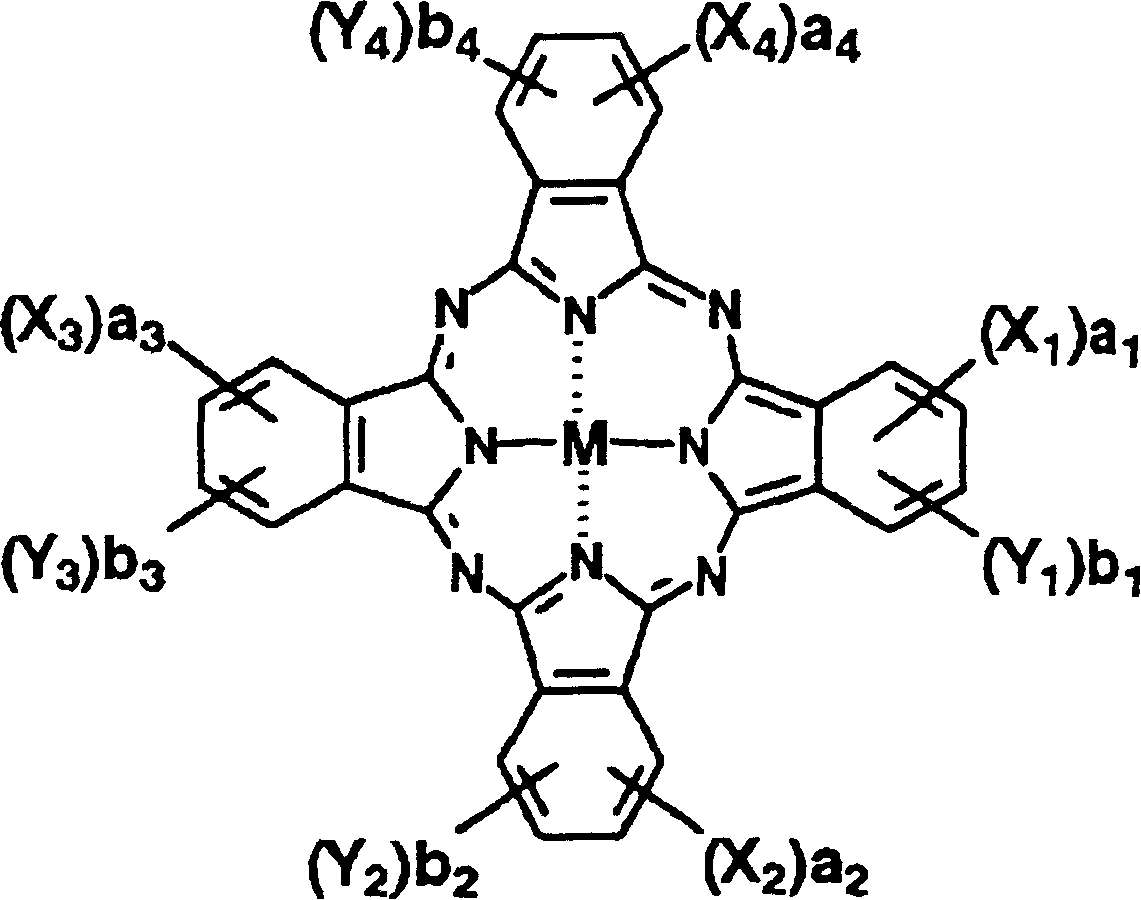

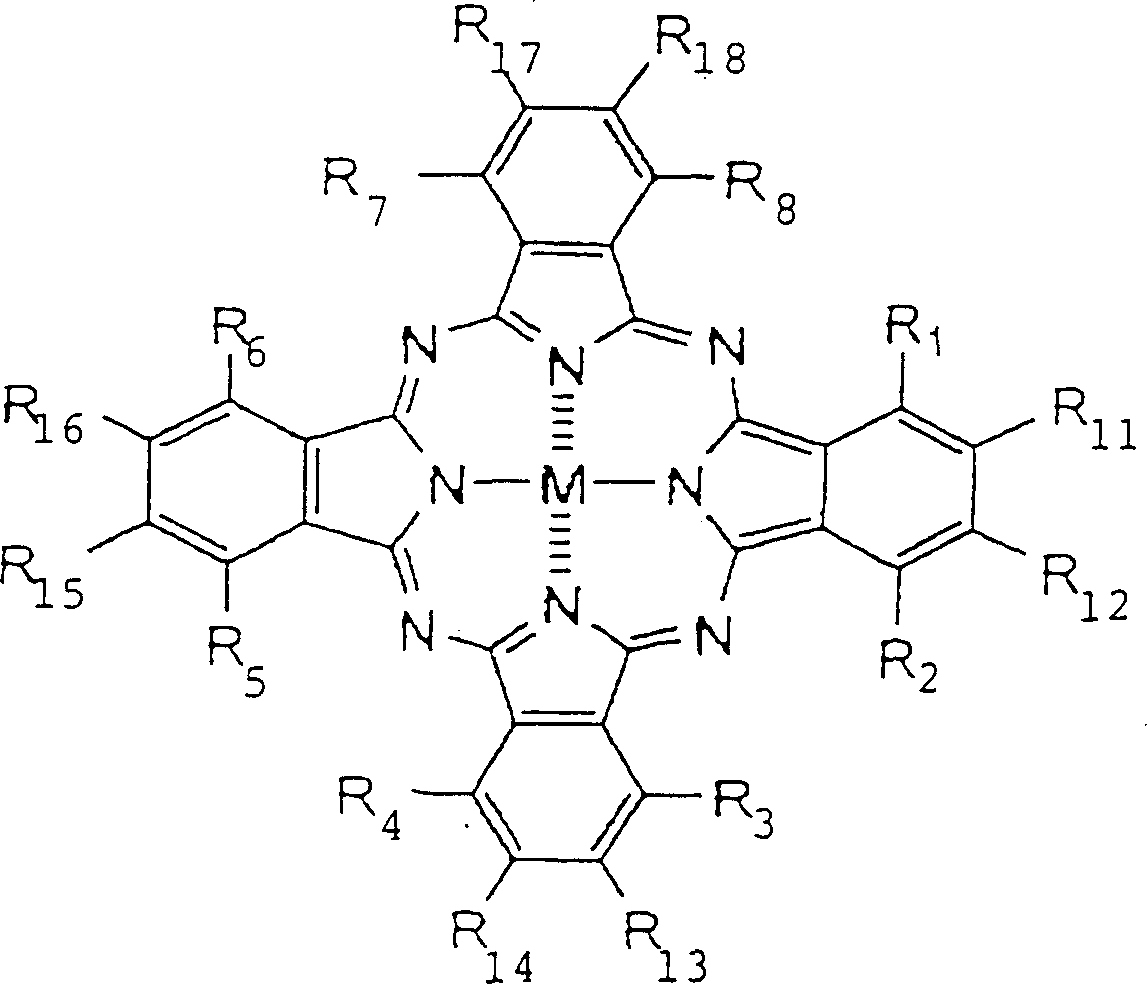

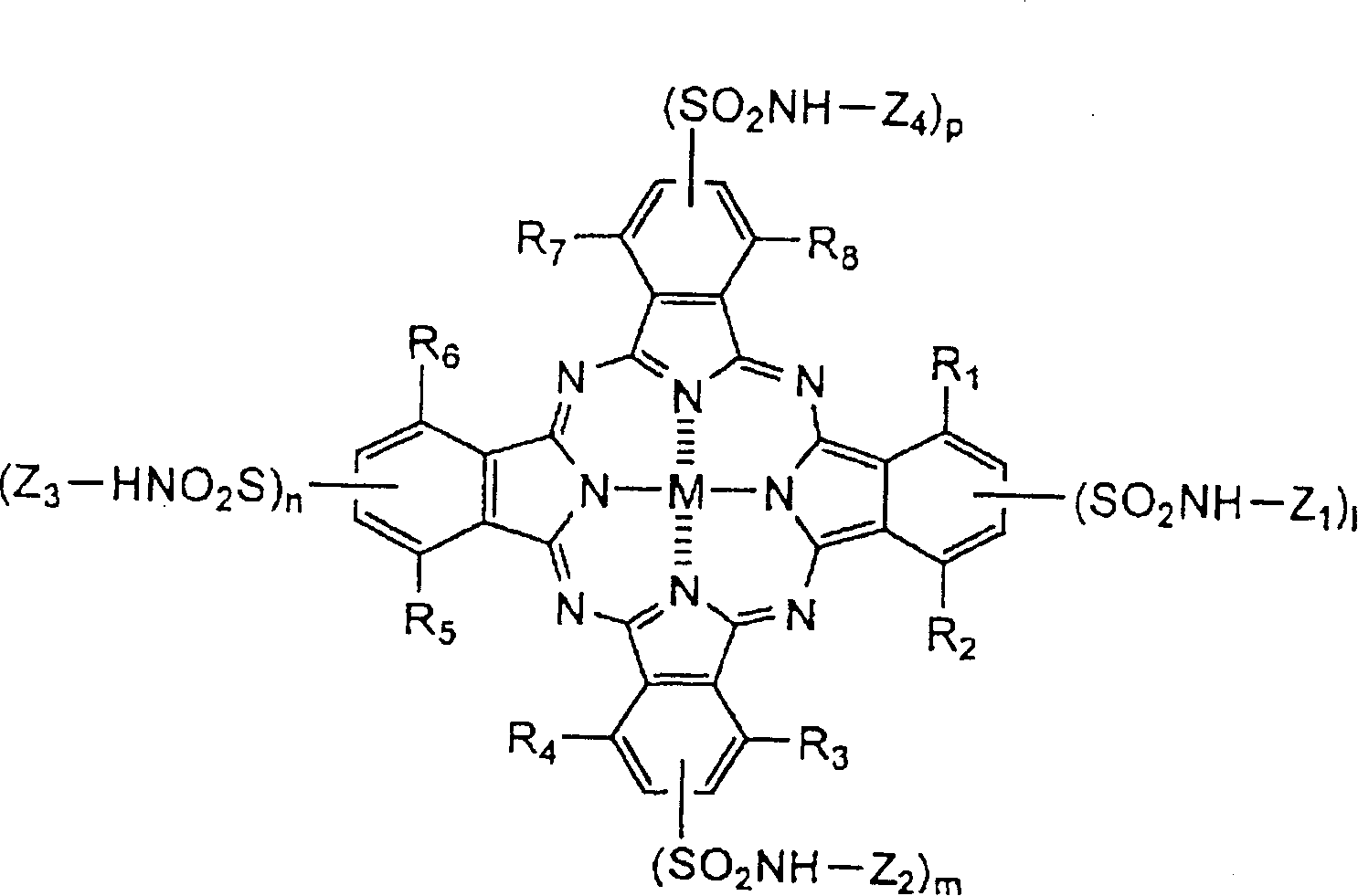

Colored image-forming composition containing phthalocyanine compound, inks, inkjet inks, inkjet recording method and method of improving tolerance to decoloration due to ozone gas

Inks characterized by containing at least one compound selected from among phthalocyanine compounds represented by the general formulae (I), (II), (III) and (IV) have absorption properties with an excellent color reproducibility as a primary color colorant and sufficient fatness against light, heat, moisture and active gases in the surroundings. Thus, these inks can provide colored images and colored materials being excellent in color hue and fastness. They are usable in, for example, printing ink compositions for inkjetting and the like, ink sheets to be used in thermal transfer image-forming materials, electrophotographic toners, various coloring compositions such as coloring compositions for color filters to be used in LCD, PDP and CCD and liquid dyes for various fibers, etc.

Owner:FUJIFILM CORP

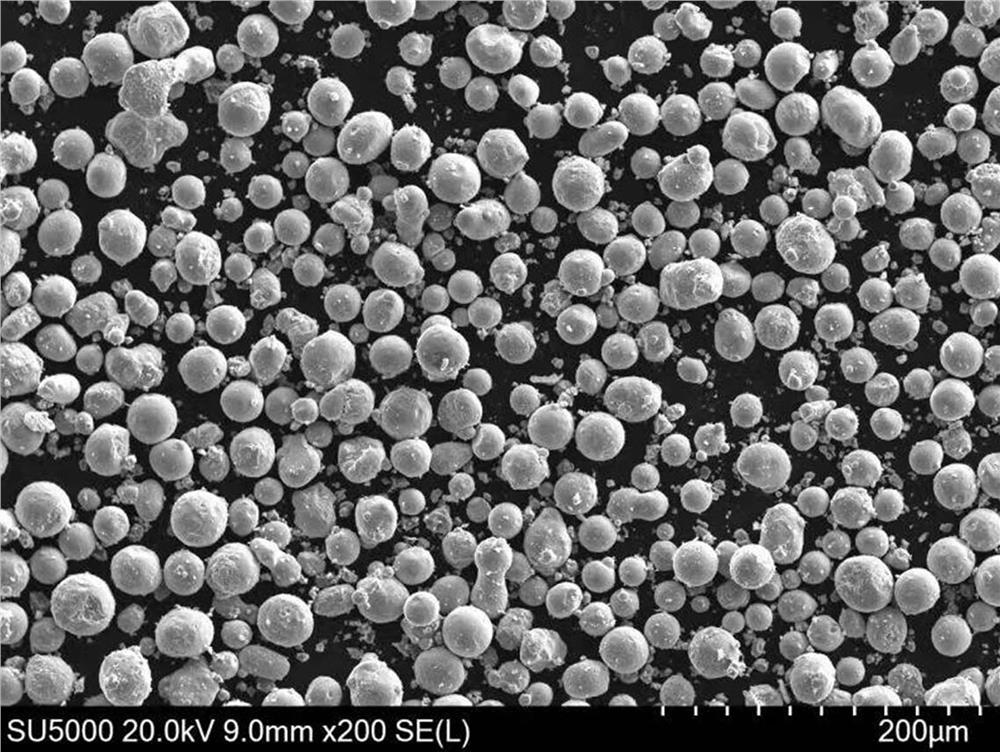

Application by using carbon nanotube/urea formaldehyde resin carbon-coated spherical microcrystalline graphite as negative electrode material of lithium ion battery

InactiveCN107959028AImprove processing efficiencyImprove crushing precisionCell electrodesArgon atmosphereCarbon nanotube

The invention relates to application by using carbon nanotube / urea formaldehyde resin carbon-coated spherical microcrystalline graphite as negative electrode material of a lithium ion battery. Spherical microcrystalline graphite material is adopted as the lithium ion negative-electrode material to prepare the lithium ion battery, wherein the weight ratio of the negative electrode material, SBR (50% of solid content), CMC to Super-p is 97.5: 1.5: 2: 1, then moderate deionized water is added to mix to be syrup-like liquid, copper foil is coated with the liquid and dried in a vacuum drying oven for 12 h to prepare a negative electrode plate, an electrolyte of the lithium ion battery adopts 1MLiPF6 / EC+DEC+DMC=1: 1: 1, a separator is microporous polypropylene membrane, a counter electrode is alithium tablet, and the battery is assembled in a glove box with an airtight argon atmosphere. When the lithium ion battery is charged and discharged at the ratio of 0.1 C, a first charging and discharging cycle charging capacity is 390 mAh / g, and when the lithium ion battery is charged and discharged at the ratio of 5 C, after 500 times of cycles, the capacity retention ratio is 97.2%.

Owner:林荣铨

Printing and dyeing auxiliary agent, and preparation method and application thereof

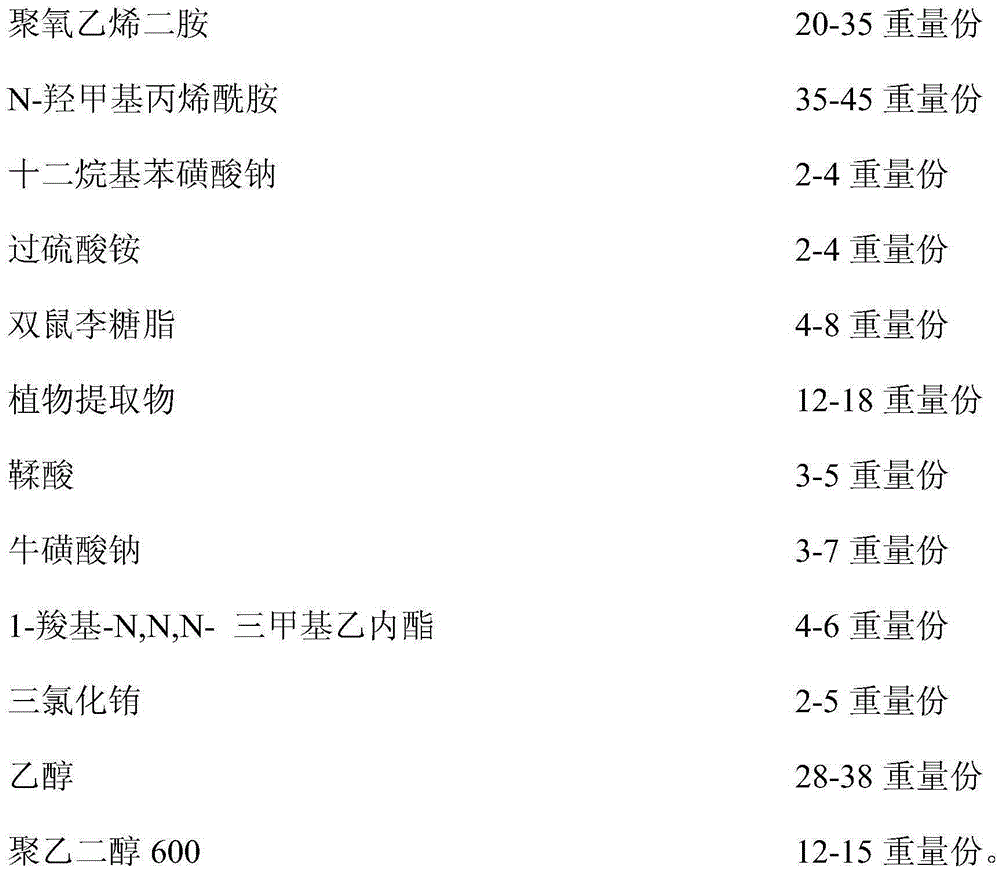

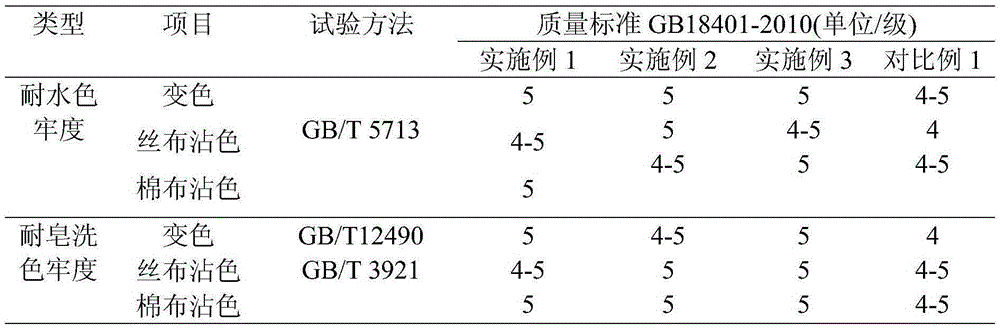

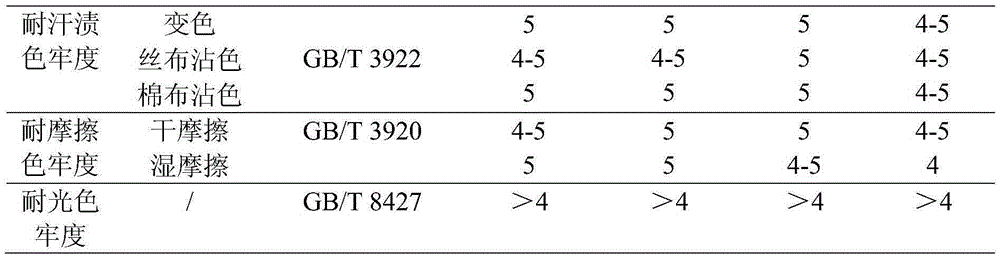

InactiveCN105256613AHigh color fastnessGood color protectionDyeing processPolyethylene glycolEuropium

The invention provides a printing and dyeing auxiliary agent. The printing and dyeing auxiliary agent is prepared from the following raw materials: 20 to 35 parts by weight of polyethylene glycol diamine, 35 to 45 weight parts of N-hydroxymethyl acrylamide, 2 to 4 weight parts of sodium dodecylbenzene sulfonate, 2 to 4 weight parts of ammonium persulfate, 4 to 8 weight parts of di-rhamnolipid, 12 to 18 parts by weight off plant extract, 3 to 5 weight parts of tannin, 3 to 7 weight parts of sodium taurate, 4 to 6 weight parts of 1-carboxy-N,N,N-trimethylmethanaminium inner salt, 2 to 5 weight parts of europium chloride, 28 to 38 weight parts of ethyl alcohol and 12 to 15 weight parts of polyethylene glycol 600. The printing and dyeing auxiliary agent prepared by the preparation method has good effects on improving color fastness, protecting color, and preventing color fading, and also has the functions of resisting bacteria and preventing static electricity.

Owner:朱忠良

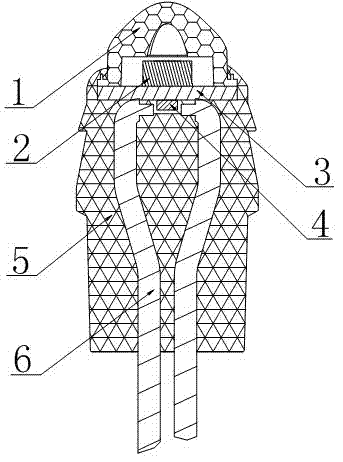

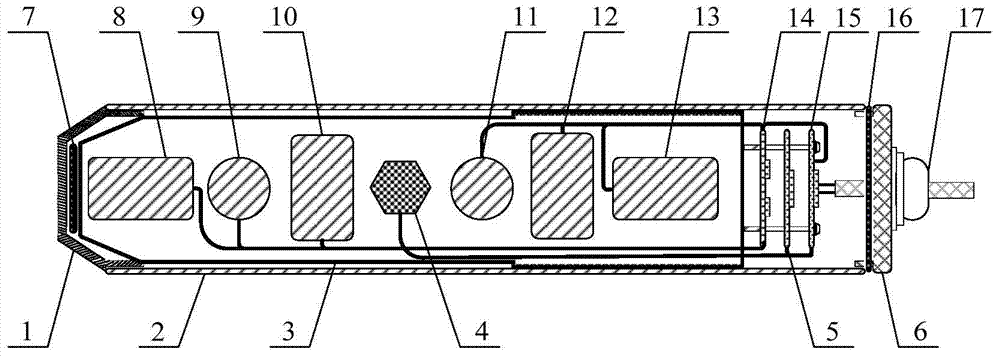

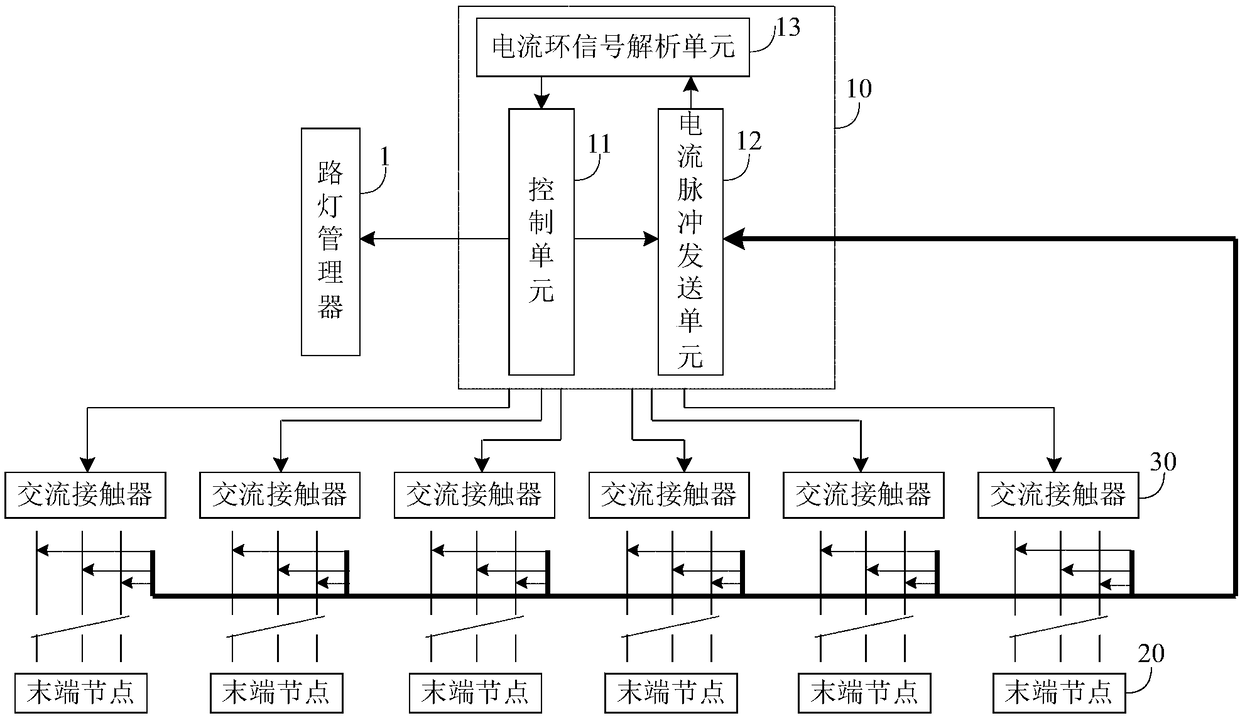

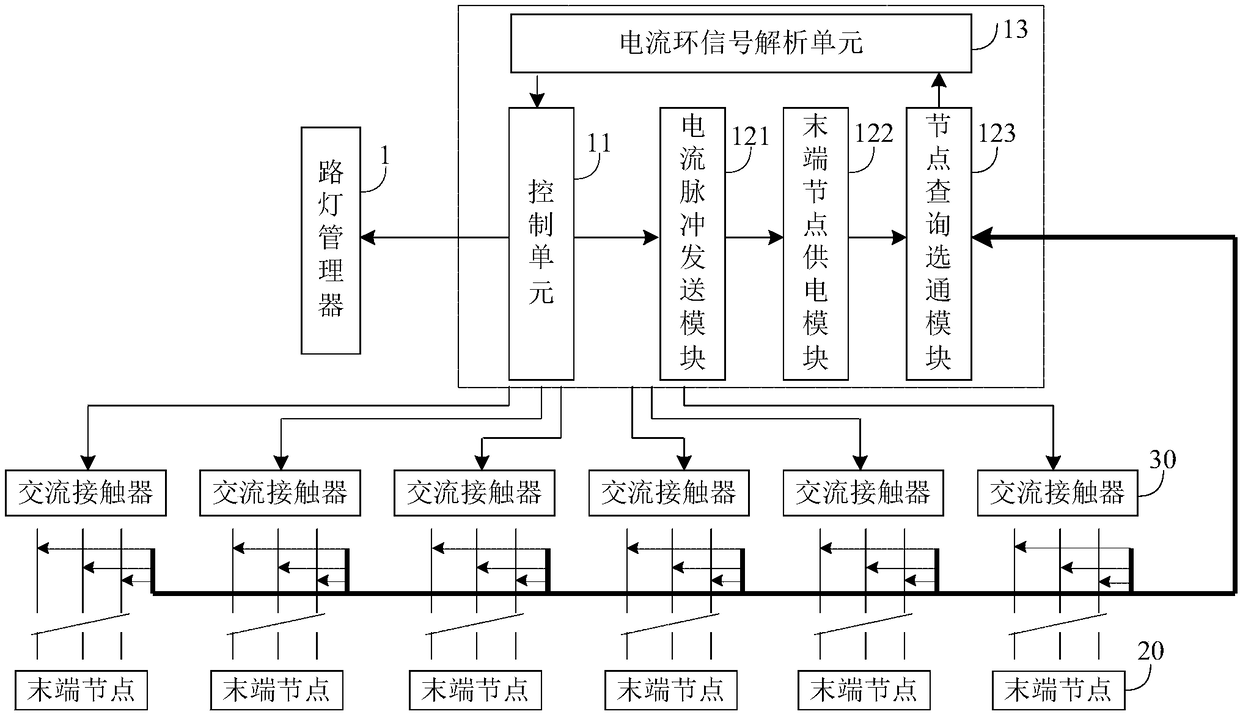

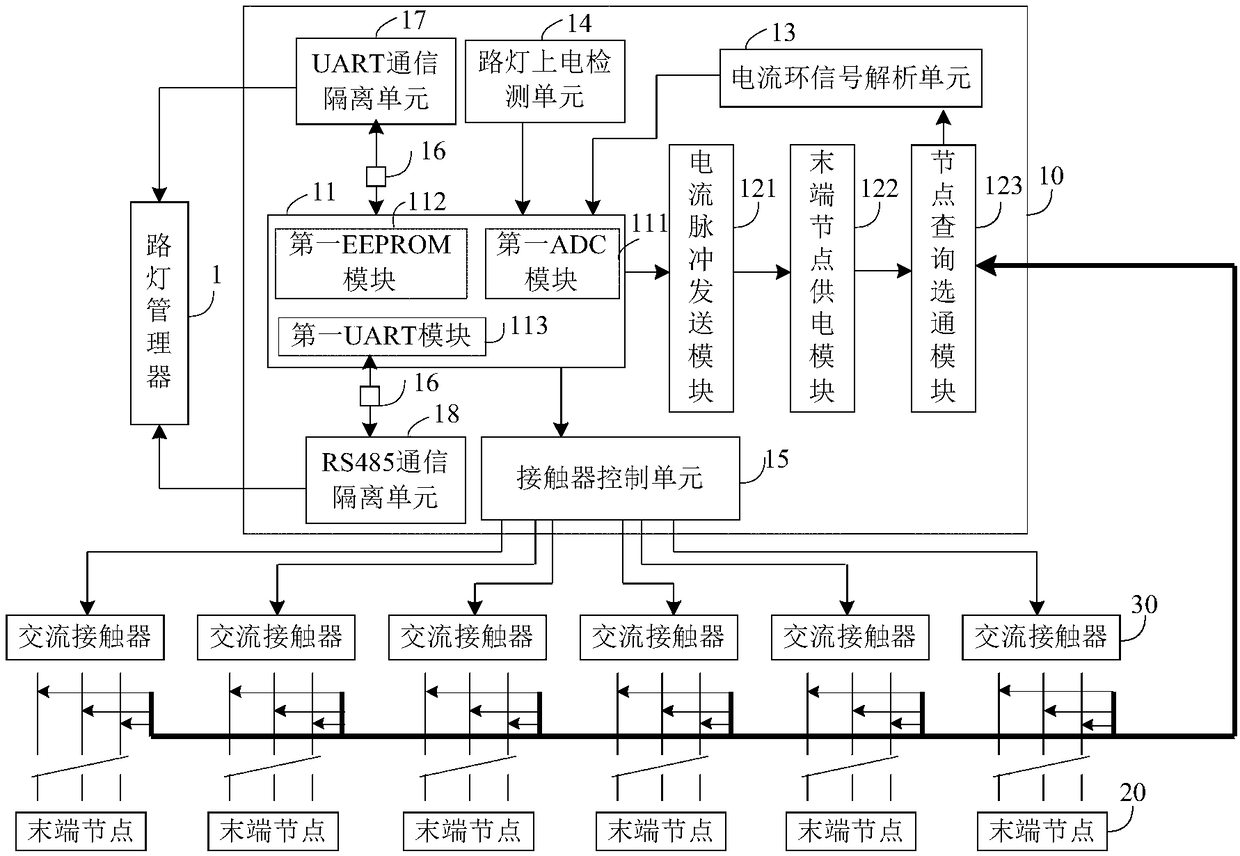

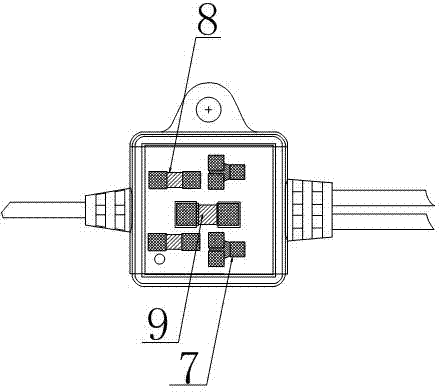

Cable anti-theft device

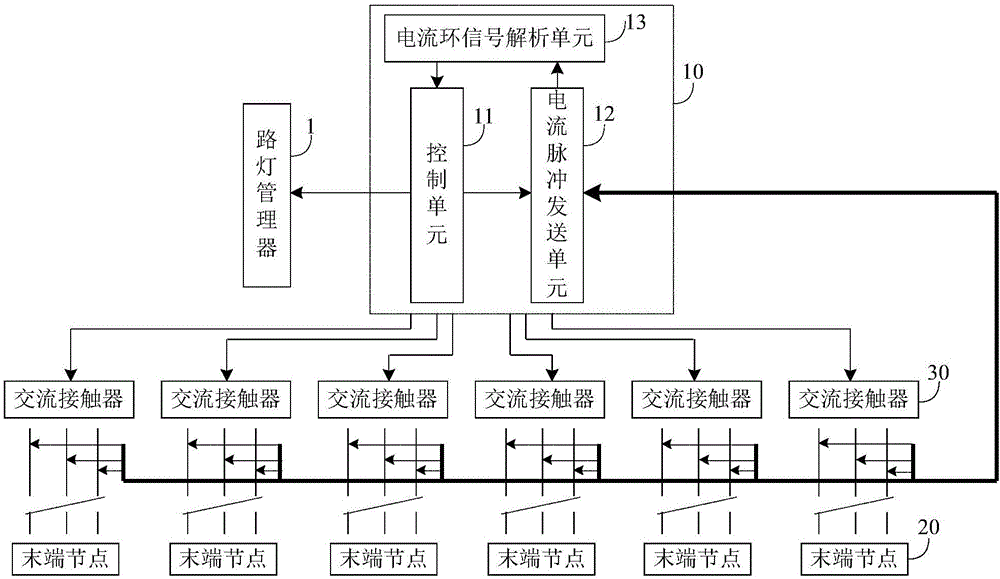

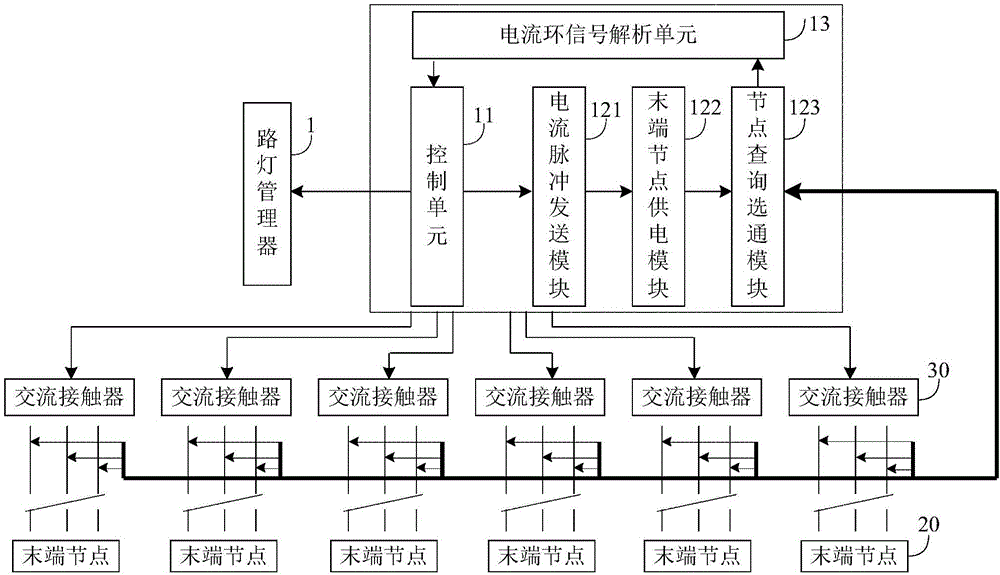

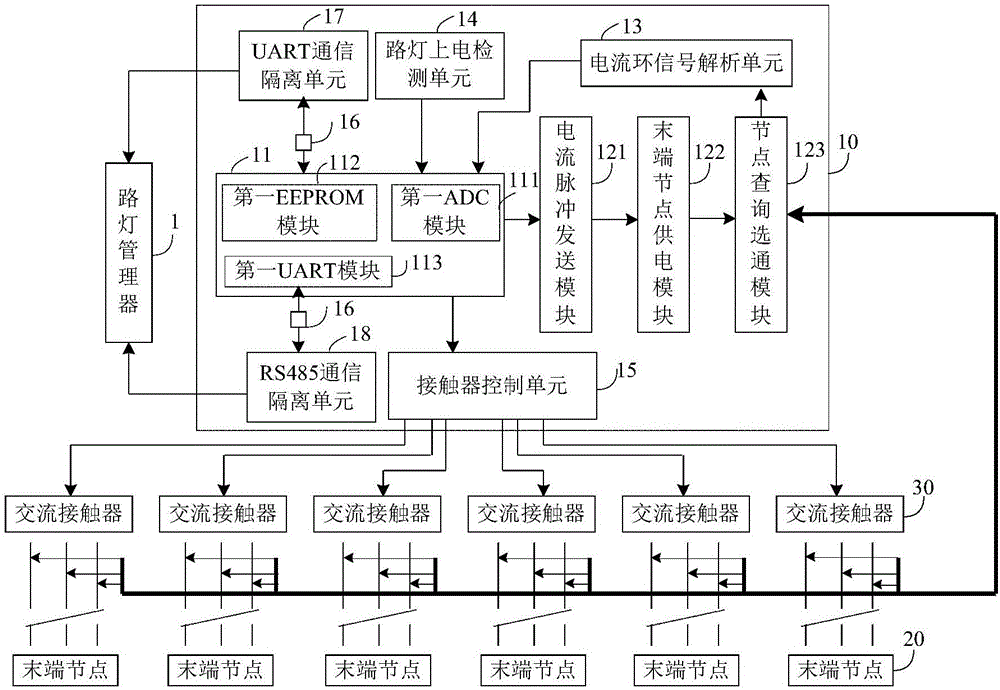

ActiveCN106157509AImprove noise marginImprove fade resistanceBurglar alarm electric actuationPower flowEngineering

The invention discloses a cable anti-theft device, and belongs to the technical field of anti-theft of street lamp cables. The anti-theft device comprises a detecting host and a terminal node, wherein the detecting host comprises a control unit, a current pulse sending unit and a current loop signal resolving unit, and the control unit controls the current pulse sending unit to send current pulse signals to the terminal node; the terminal node resolves the current pulse signals and sends response current pulse signals to the current loop signal resolving unit of the detecting host according to the resolution result, and the current loop signal resolving unit of the detecting host resolves the response current pulse signals and transmits the resolution result to the control unit; the control unit calculates the terminal node address information according to the resolution result and judges whether the terminal node is lost or not according to the address information and uploads the lost information to a street lamp manager when the terminal node is lost. The current is used as a carrier to transmit data to ensure the quality of communication and achieve longer-distance signal transmission, so that the cable anti-theft device has the advantages of accurate detection and efficient operation.

Owner:HEFEI DAMING ENERGY SAVING TECH

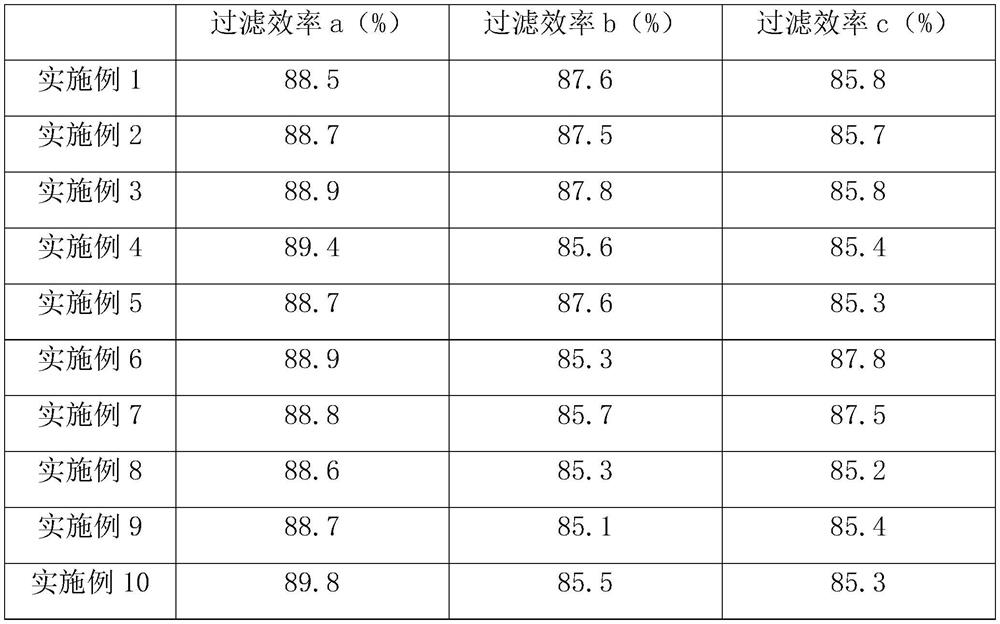

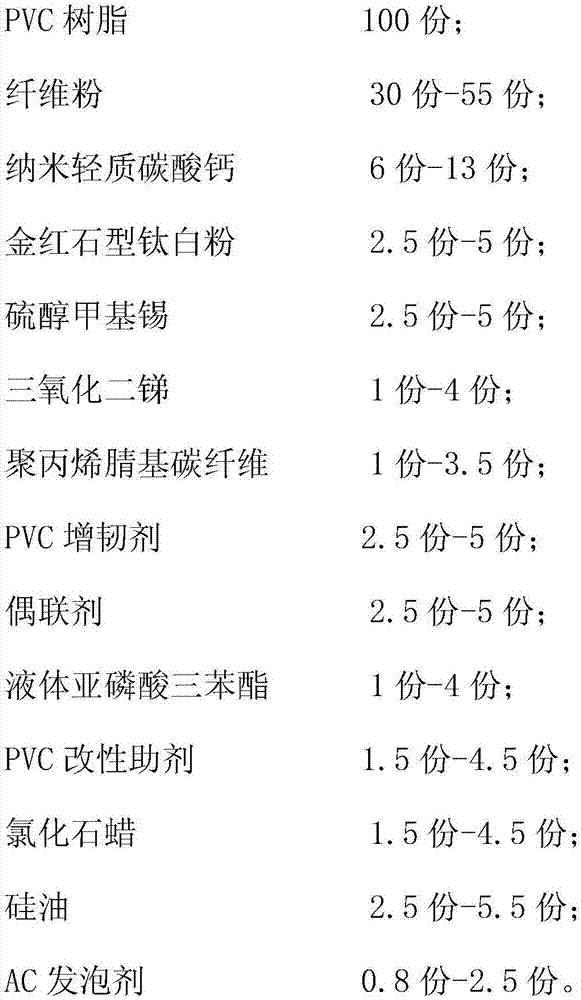

Processing method of water electret melt-blown fabric

PendingCN113337964AEvenly dispersedReduce surface tensionFibre typesNon-woven fabricsPolymer scienceMoisture resistance

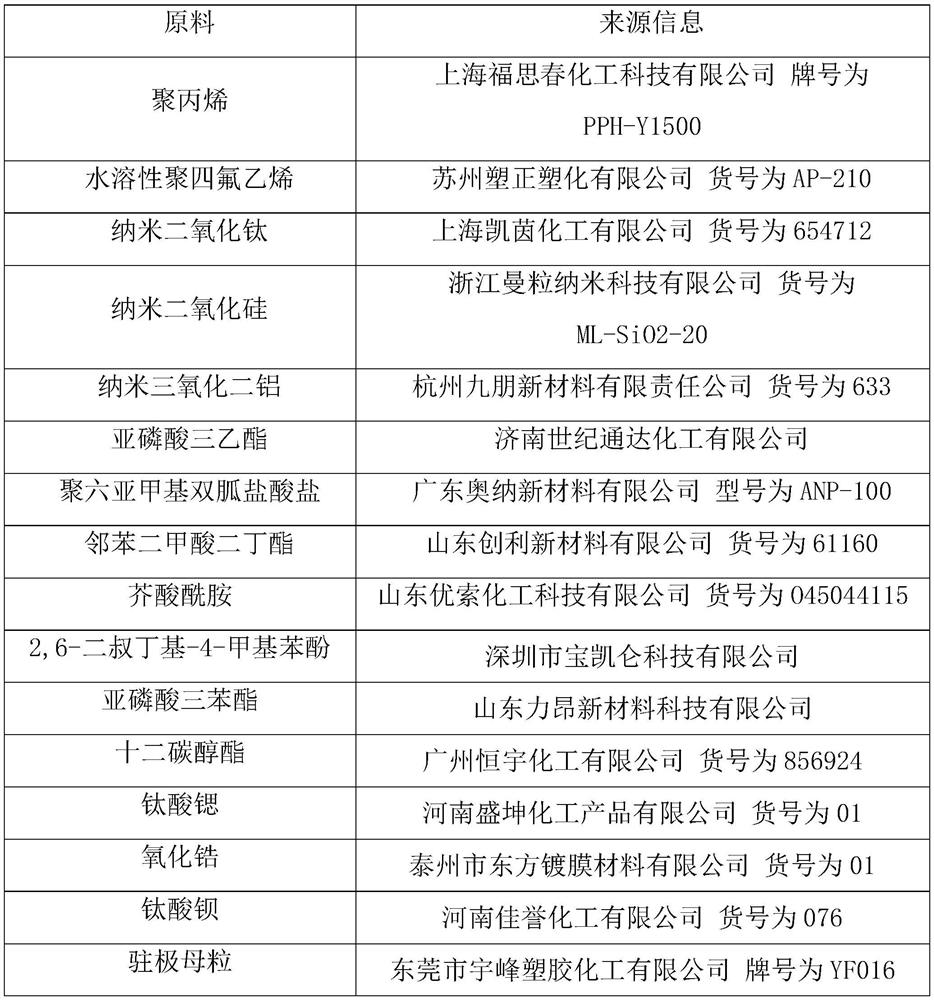

The invention relates to the technical field of melt-blown fabric processing, and particularly discloses a processing method of water electret melt-blown fabric. The processing method of the water electret melt-blown fabric comprises the following steps of 1) preparing modified polypropylene melt-blown fabric: mixing polypropylene, soluble polytetrafluoroethylene, nano titanium dioxide, nano silicon dioxide and nano aluminum oxide to obtain a mixture, adding an antioxidant and an auxiliary agent in the step 1-2), blending with the mixture, melting, extruding, converging, stretching and cooling to obtain the modified polypropylene melt-blown fabric; 2) preparation of pure water, 3) electret process and 4) drying process, and obtaining the water electret melt-blown fabric. The water electret melt-blown fabric has better filtering performance and meanwhile has the advantages of being relatively good in moisture resistance and high temperature resistance.

Owner:上海盈兹无纺布有限公司

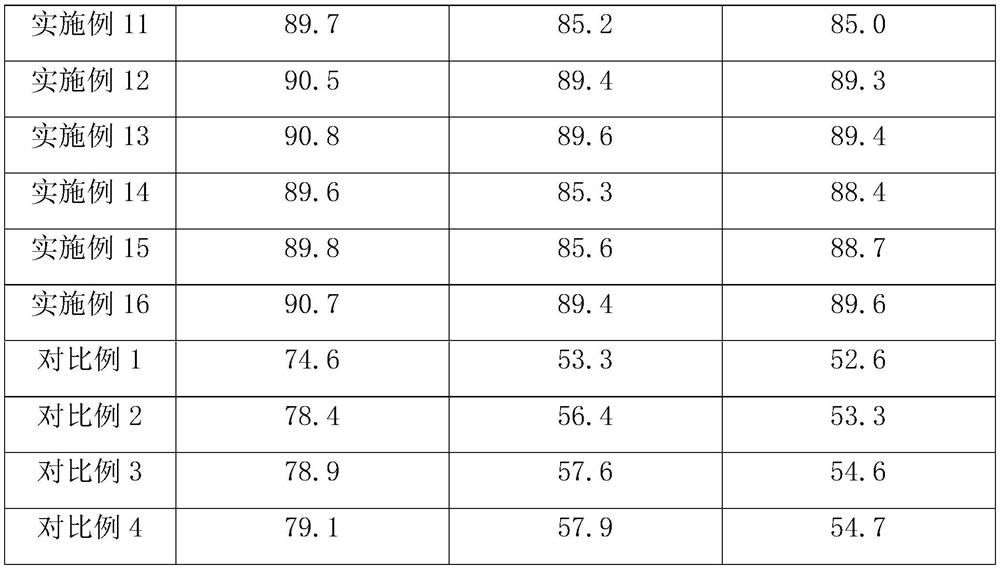

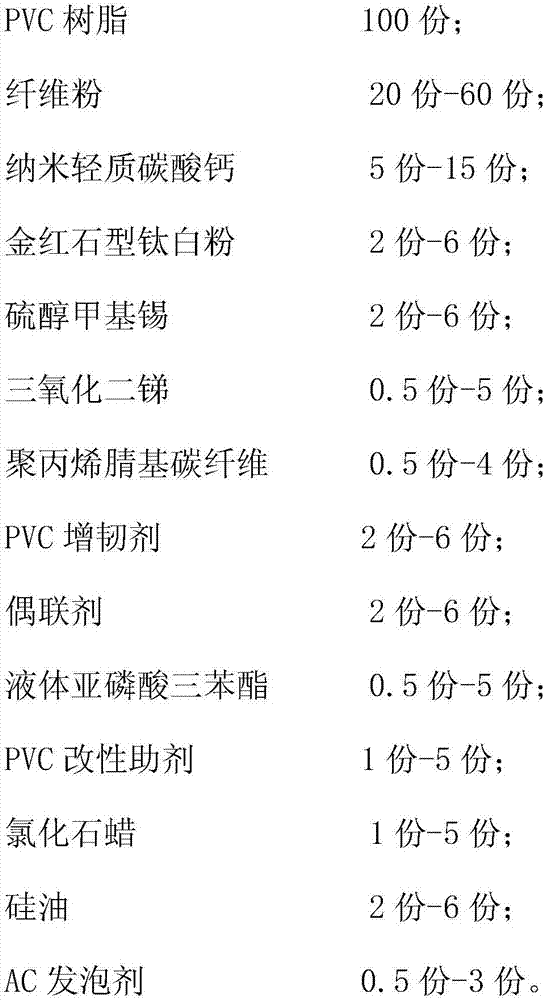

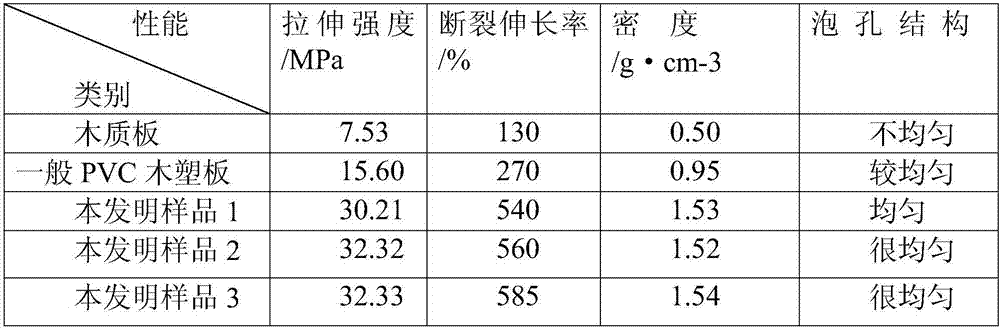

High-toughness flame-retardant foamed PVC wood-plastic board and preparation method thereof

InactiveCN107099103ADoes not affect curing speedDoes not affect molding speedCarbon fibersChlorinated paraffins

The invention discloses a high-toughness flame-retardant foamed PVC wood-plastic board. The high-toughness flame-retardant foamed PVC wood-plastic board comprises PVC resin, fiber powder, nanometer light calcium carbonate, rutile titanium dioxide, methyltin mercaptide, antimony trioxide, polyacrylonitrile-based carbon fibers, a PVC flexibilizer, a coupling agent, liquid triphenyl phosphite, a PVC modification aid, chlorinated paraffin, silicone oil and an AC foaming agent. The invention also discloses a preparation method for the PVC wood-plastic board. The preparation method for PVC wood-plastic board in the invention is simple in process and easy to operate; and the prepared PVC wood-plastic board has a plurality of advantages like good thermal stability, good ageing resistance, good anti-oxidizability, good impact resistance, good wear resistance, good insulating properties and good flame resistance.

Owner:程艳青

Novel carbon-carbon nanotube lithium ion battery cathode material and preparation method thereof

InactiveCN103137954AHigh gram capacityLow rate characteristicsCell electrodesCarbon nanotubeSodium-ion battery

The invention discloses a novel carbon-carbon nanotube lithium ion battery cathode material and a preparation method thereof, and belongs to the technical field of lithium ion batteries and the nanometer technology field. The novel carbon-carbon nanotube lithium ion battery cathode material is characterized in that the novel carbon-carbon nanotube lithium ion battery cathode material is formed by spherical graphite and a cladding material wrapped on the surface of the spherical graphite, and the cladding material accounts for 8-12% of the total weight of the spherical graphite and the cladding material; and the cladding material is prepared through mixing carbon nanotubes with organic carbon powder, and the weight ratio of the carbon nanotubes to the organic carbon powder is 3:7. The novel carbon-carbon nanotube lithium ion battery cathode material prepared in the invention can well solve the carbon nanotube agglomeration phenomenon through multi-time grading diffusion, the cladding material is wrapped on the surface of the spherical graphite, and the carbon nanotubes generate a pompon-like grid structure on the surface of the spherical graphite, so the surface strength is enhanced, the conductive performance and the anti-damping performance are substantially improved, and the first discharge capacity is substantially improved.

Owner:YANGZHOU YET NEW ENERGY MATERIAL TECH

Dyeing and printing auxiliary agent containing sodium carboxymethyl cellulose

InactiveCN106884345AGood color fastnessHigh color fastnessDyeing processDodecylsulfonic acidGuar gum

The invention provides a dyeing and printing auxiliary agent containing sodium carboxymethyl cellulose. The dyeing and printing auxiliary agent is prepared from the following raw materials in parts by weight: 6 to 8 parts of guar gum, 13 to 15 parts of polyethylene glycol laurate, 8 to 10 parts of polyalkyl acrylate, 12 to 13 parts of the sodium carboxymethyl cellulose, 8 to 10 parts of sodium dodecyl sulfonate, 7 to 8 parts of polyalkyl acrylate, 9 to 10 parts of stearyl dimethylbenzyl ammonium chloride, 6 to 7 parts of fatty alcohol, 5 to 7 parts of ethylene oxide, 2 to 3 parts of acetic acid and 9 to 24 parts of barium chloride. Compared with the prior art, the dyeing and printing auxiliary agent has the beneficial benefits that the dyeing and printing auxiliary agent has good effects of improving the color fastness, protecting color and preventing fading; meanwhile, the utilization amount of dyestuff can be reduced; the dyeing and printing auxiliary agent is green, environment-friendly and non-toxic, and the cost is reduced, so that the dyeing and printing auxiliary agent has wide industrial prospect and wide market value.

Owner:ZHONGSHAN LVLANG ADDITIVES CO LTD

Method for preparing ultraviolet excited or vacuum ultraviolet excited green emitting phosphor

InactiveCN102888224AHigh luminous intensityHigh retention rateLuminescent compositionsMass ratioPhosphor

The invention discloses a method for preparing ultraviolet excited or vacuum ultraviolet excited green emitting phosphor. The method comprises the following steps of: weighing Al2O3, MgO, Tb3O4 and CeO2 in a mass ratio, sieving all raw materials by using a 100-mesh sieve, mixing by a dry method, introducing one or more of BaCO3, MgCl2, AlF3, MgF2, BaF2 and H3BO3 into the uniformly mixed raw materials, and fully mixing; loading the mixed powder into an alumina crucible; firing at high temperature at reducing atmosphere; crushing the fired fluorescent powder blocks, and sieving by using the 100-mesh sieve; dispersing by a wet method to obtain slurry; controlling the particle size to be 2 to 12 mu m; sieving the slurry which is obtained by wet-method dispersing by using a 500-mesh sieve; removing the sieving residues on the 500-mesh sieve; washing with water; and suction-filtering, drying and screening to obtain the green emitting phosphor. The green emitting phosphor has the characteristics of controllable particle size, high brightness, light failure, color development and low color bleaching.

Owner:CAIHONG GRP ELECTRONICS CO LTD

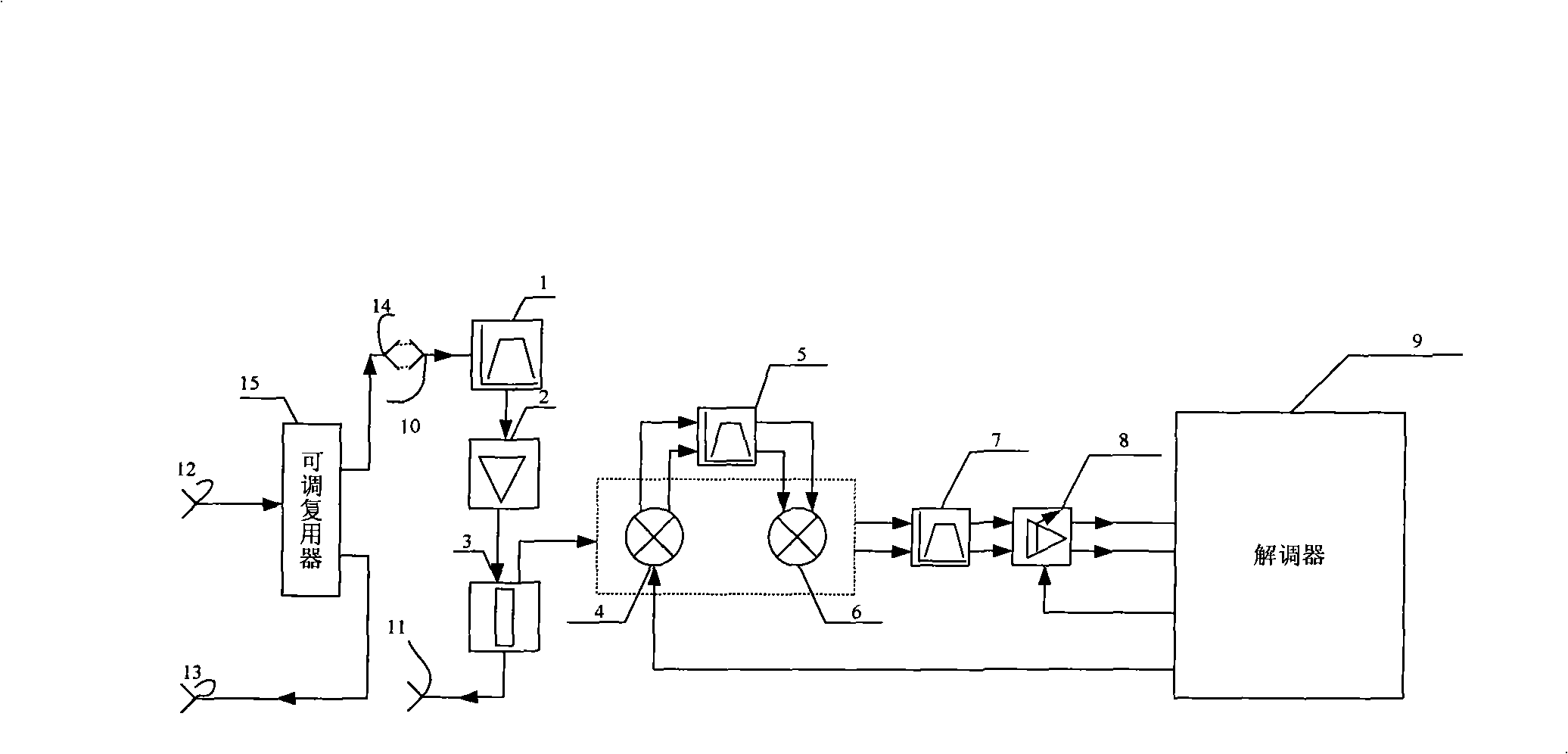

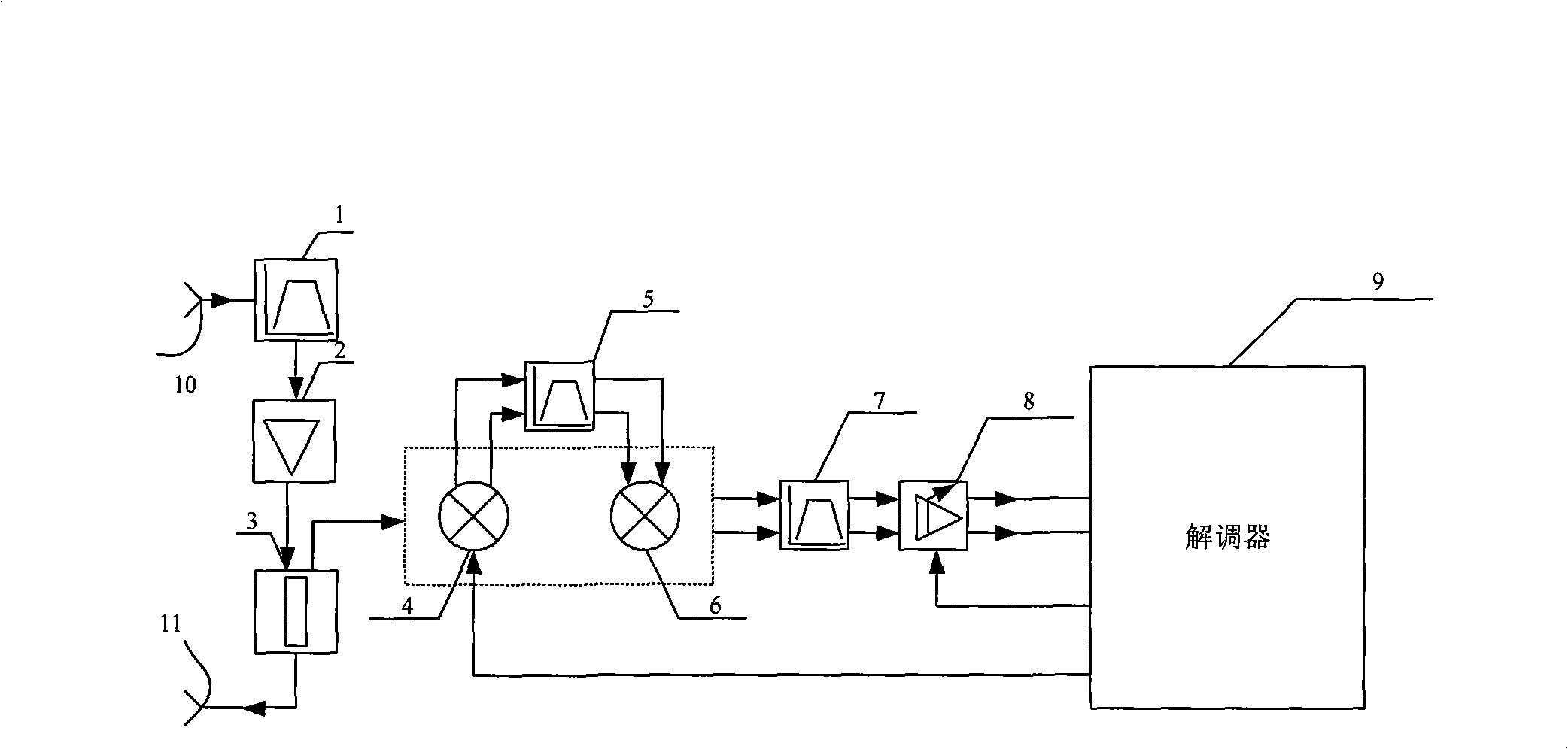

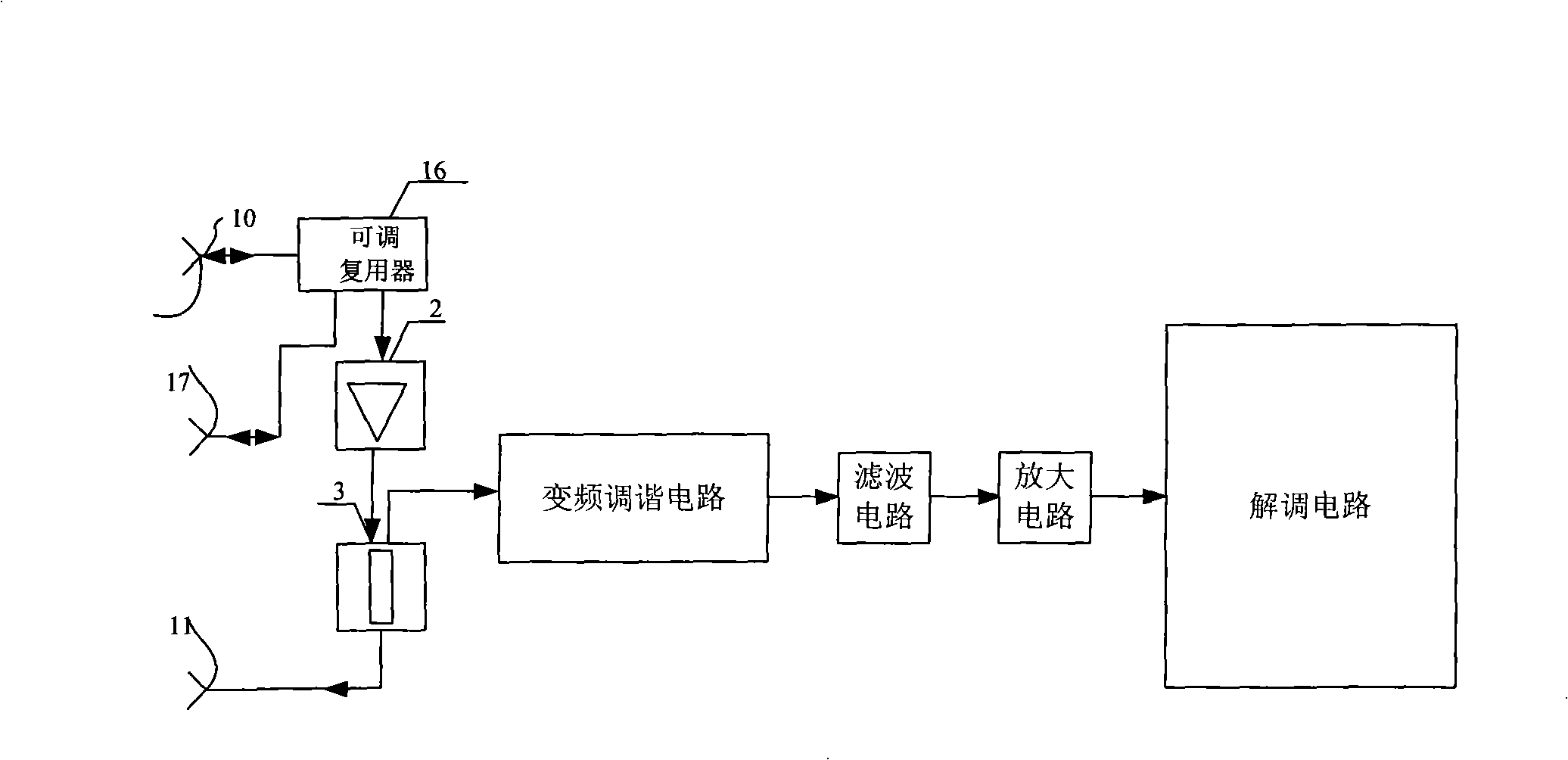

Novel integrated bidirectional tuner

InactiveCN101287077AReduce incrementImprove fade resistanceTelevision system detailsColor television detailsMultiplexerBand-pass filter

The invention provides a novel integrated bidirectional tuner which comprises a tuner input port, a variable frequency tuning circuit, a filter circuit, an amplification circuit and a demodulation circuit which are connected in the way that the output end of the variable frequency tuning circuit is connected with the input end of the filter circuit, the output end of which is connected with the input end of the amplification circuit; and the output end of the amplification circuit is connected with the input end of the demodulation circuit. The novel integrated bidirectional tuner is characterized in that an adjustable multiplexer also is connected between the variable frequency tuning circuit and the tuner input port. The adjustable multiplexer is embedded into a tuner which can not only separate data signals and cable television signals, but also function as a band-pass filter; therefore, compared with the original method that the adjustable multiplexer is arranged outside the tuner, elements, such as cable components or an adapter and a band-pass filter, etc., are reduced, thus not only saving cost, but also reducing extra insertion loss caused by the adding of the cable components or introduced by the adapter.

Owner:雷科通技术(杭州)有限公司

Liquid phenolic resin with high solid content and special for resin grinding tool and preparation method thereof

The invention aims at providing liquid phenolic resin with a high solid content and special for resin grinding tools and a preparation method thereof. The liquid phenolic resin is appropriate in molarratio, high in solid content and stable in technical index, and the resin grinding tools made of the liquid phenolic resin have excellent performance. The phenolic resin is prepared from, by mass, 100 parts of phenol, 94-170 parts of formaldehyde, 5-15 parts of composite alkali metal oxides, 1-10 parts of formaldehyde catching agent, 1.2-3.0 parts of basic catalysts and 0.1-2 parts of lactic acid, wherein the concentration of formaldehyde is 37%. The preparation method of the phenolic resin includes the following steps of adding phenol and formaldehyde; adding the basic catalysts; conductingheating by three steps, and then conducting vacuum dewatering; introducing icy water for fast cooling, adding composite alkali metal oxides, and then conducting depressurization and dewatering; addinga formaldehyde catching agent and lactic acid, and conducting stirring; detecting corresponding technical indexes, and if the indexes reach standards, obtaining a product. The liquid phenolic resin with the high solid content and special for the resin grinding tools and the preparation method thereof are applied to the field of phenolic resin.

Owner:ZHUHAI BONDRIGHT SYNTHETIC MATERIAL

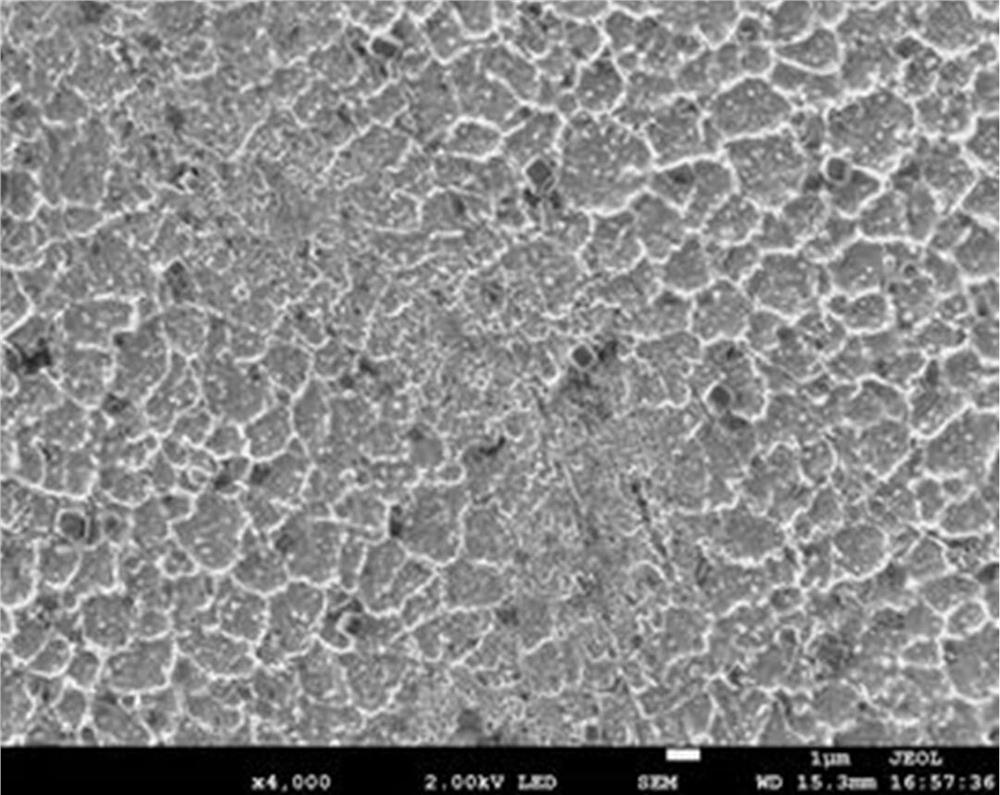

A kind of preparation method of graphene-lithium battery cathode composite material

InactiveCN103500826BIncrease volume capacityImprove fade resistanceCell electrodesLi-accumulatorsMass ratioHydrogen-Ion Concentrations

The invention discloses a preparation method of a positive composite material of a graphene-lithium battery. The preparation method comprises the following steps of (1) performing coprecipitation-loading on graphene, a graphene precursor, graphene powder or graphene dispersion and a positive material of a lithium battery, namely adding the graphene, the graphene precursor, the graphene powder or the graphene dispersion and the positive material of the lithium battery in the mass ratio of 1:8 to 1:100 into a solvent to keep the concentration at 1-120 g / L, then adding auxiliaries which is 1-10 mass percent of the grapheme, adjusting the hydrogen ion concentration to be 1.0*10<-5> to 1.0*10<2> mol / L through a pH value adjustment agent, and mixing at the temperature of 10-80 DEG C for 1-96 hours to obtain a loaded product; (2) performing centrifugal separation on the loaded product, wherein one product is a solid sample; (3) roasting the separated solid sample at the temperature of 400-700 DEG C for 0.5-4 hours, and performing activation to obtain the positive composite material of the graphene-lithium battery. The preparation method disclosed by the invention has the beneficial effects that the volume specific capacity and the attenuation resistance are improved, the cycle life is long, and the capacity stability is high.

Owner:LUXI GRP

Novel carbon-carbon nanotube lithium ion battery cathode material and preparation method thereof

InactiveCN103137954BHigh gram capacityLow rate characteristicsCell electrodesCarbon nanotubeSodium-ion battery

The invention discloses a novel carbon-carbon nanotube lithium ion battery cathode material and a preparation method thereof, and belongs to the technical field of lithium ion batteries and the nanometer technology field. The novel carbon-carbon nanotube lithium ion battery cathode material is characterized in that the novel carbon-carbon nanotube lithium ion battery cathode material is formed by spherical graphite and a cladding material wrapped on the surface of the spherical graphite, and the cladding material accounts for 8-12% of the total weight of the spherical graphite and the cladding material; and the cladding material is prepared through mixing carbon nanotubes with organic carbon powder, and the weight ratio of the carbon nanotubes to the organic carbon powder is 3:7. The novel carbon-carbon nanotube lithium ion battery cathode material prepared in the invention can well solve the carbon nanotube agglomeration phenomenon through multi-time grading diffusion, the cladding material is wrapped on the surface of the spherical graphite, and the carbon nanotubes generate a pompon-like grid structure on the surface of the spherical graphite, so the surface strength is enhanced, the conductive performance and the anti-damping performance are substantially improved, and the first discharge capacity is substantially improved.

Owner:YANGZHOU YET NEW ENERGY MATERIAL TECH

Printing and dyeing auxiliaries

The invention discloses a printing and dyeing auxiliary, and relates to the technical field of spinning dyeing. The printing and dyeing auxiliary comprises, by weight, 10-15 parts of guar gum, 7-9.5 parts of poly alkyl acrylate, 15-20 parts of sodium carboxymethylcellulose, 5-8 parts of octadecyl dimethyl benzyl ammonium chloride, 2-3 parts of tannin and 10-15 parts of barium chloride. A preparing method comprises the steps that the raw materials are weighed according to the weight part, the poly alkyl acrylate, the sodium carboxymethylcellulose and the octadecyl dimethyl benzyl ammonium chloride are added into a reaction kettle to be heated and stirred until reaction is thorough, and cooling is carried out; the tannin and the barium chloride are added, stirred and heated, the guar gum is added, and stirring is even. The printing and dyeing auxiliary has the advantages of being high color fastness, good in color protecting performance and fading proof.

Owner:江苏中诚印染股份有限公司

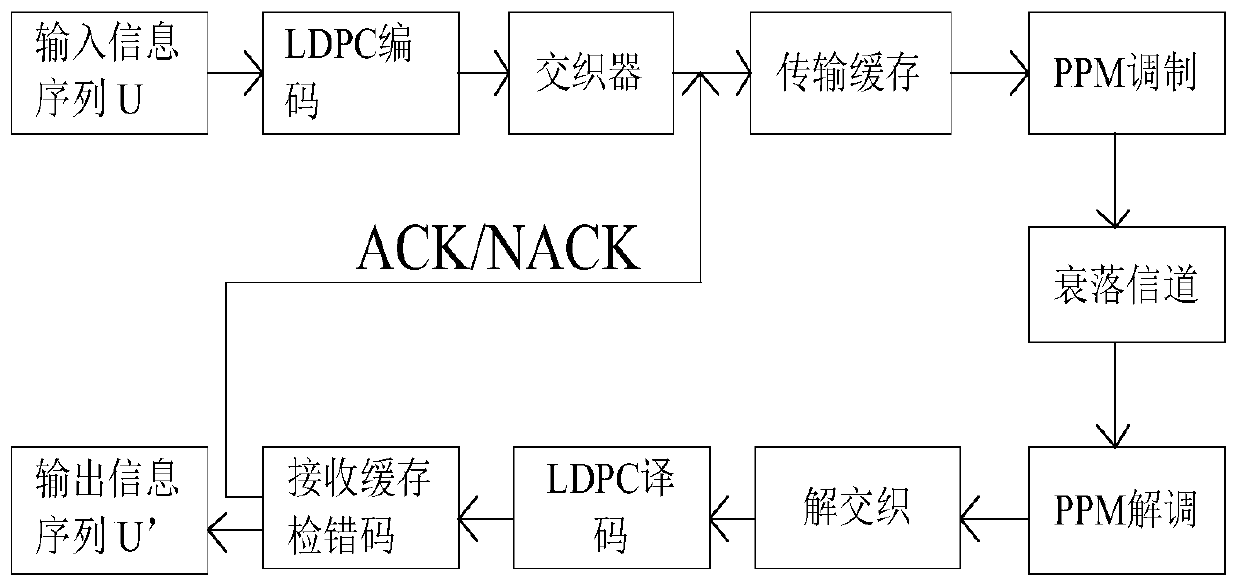

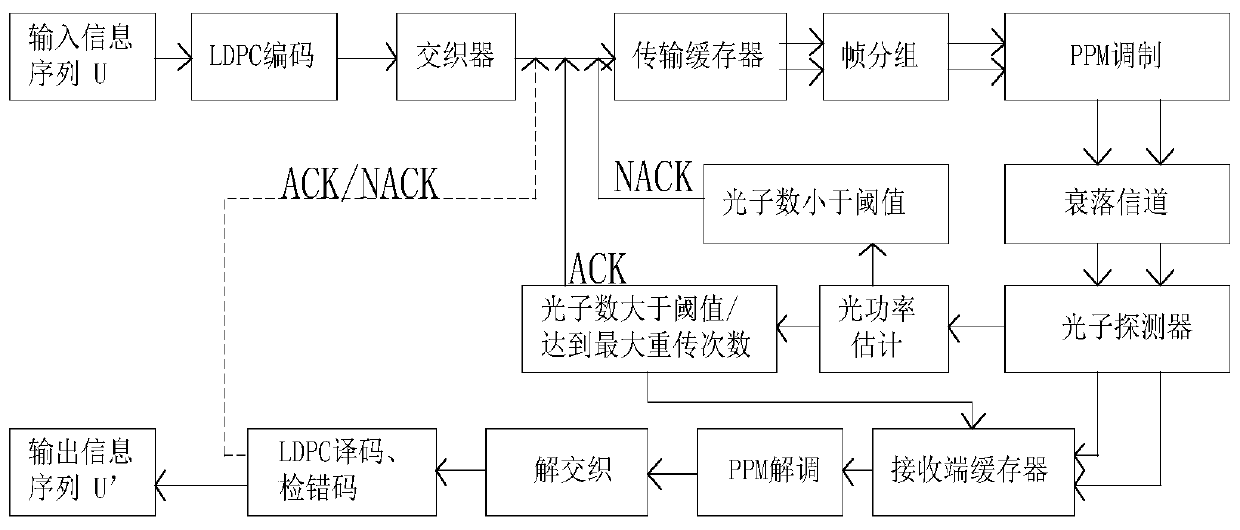

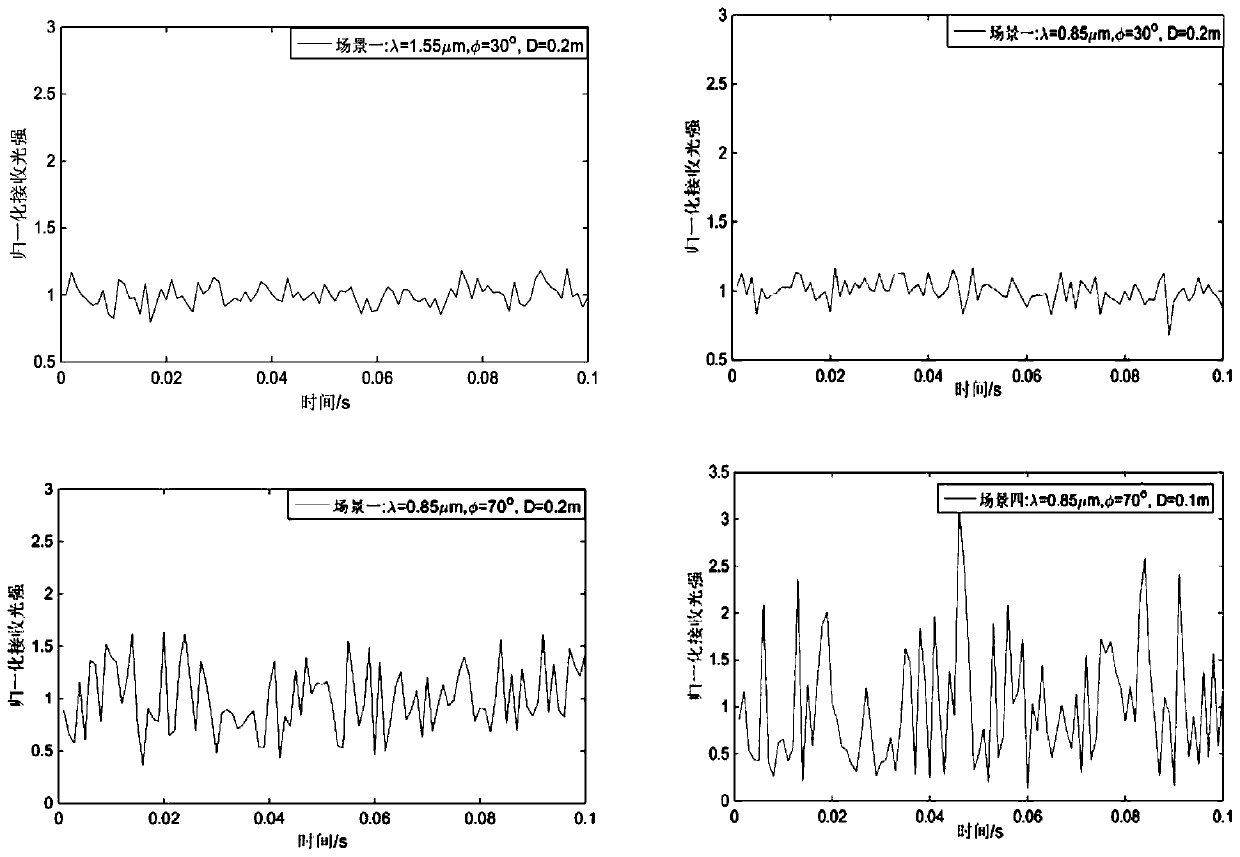

Transmission method and system based on HARQ anti-fading in space optical communication

ActiveCN111162881AReduce bit error rateImprove throughputError prevention/detection by using return channelTransmitted data organisation to avoid errorsTelecommunicationsOptical power

The invention belongs to the technical field of space optical communication anti-fading, and particularly relates to a transmission method and system based on HARQ anti-fading in space optical communication. The method comprises the steps of carrying out the frame grouping of data transmitted by a transmitting end buffer, carrying out the PPM modulation after the grouping is completed, and carrying out the transmission through a fading channel; enabling a photon detector to estimate and judge the optical power of each frame of signal; if the actual photon number is greater than the threshold value of the photon detector, carrying out error correction in combination with an error correction code and an interleaving mode, and sending ACK confirmation data to a sending end buffer; and otherwise, sending a NACK non-acknowledgement signal to the sending end buffer, and retransmitting the retransmission frame of which the photon number is lower than the threshold value and is prone to error. Compared with a traditional HARQ scheme and a long interleaving combined LDPC error correction code scheme, the method has the advantages that the bit error rate of the system is reduced; the throughput is larger; and the anti-fading performance of the system is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

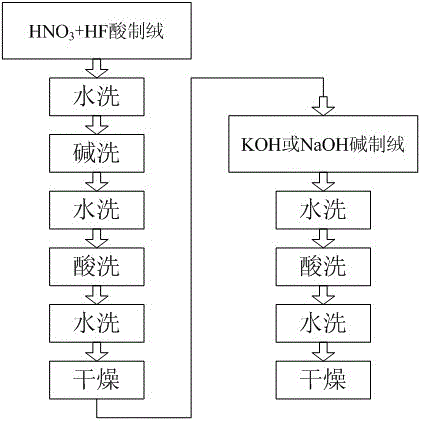

Monocrystalline solar cell texturing process

InactiveCN102703989BWith anti-reflection propertiesReduce appearanceAfter-treatment detailsRenewable energy productsMicrometerAcid corrosion

The invention discloses a monocrystal-like solar battery texturing process which comprises the following steps: placing a silicon wafer into a HNO3 and HF mixed acid solution for corrosion; taking out the treated silicon wafer from the mixed acid solution when the corrosion depth of the silicon wafer is up to 2-5 micrometers; carrying out water washing and drying treatment on the silicon wafer after acid corrosion; placing the dried silicon wafer into KOH or NaOH aqueous alkali with a single crystal for corrosion; taking out the silicon wafer from the aqueous alkali when the corrosion depth of the silicon wafer is up to 2-5 micrometers; and carrying out water washing and drying treatment on the silicon wafer after alkali corrosion. According to the process, the texturing treatment is carried out on the silicon wafer, a battery piece which is manufactured by the silicon wafer treated by using the process is small in reflectivity difference rate among crystalline grains with different sizes, and has better anti-damping performances.

Owner:TIANWEI NEW ENERGY HLDG +1

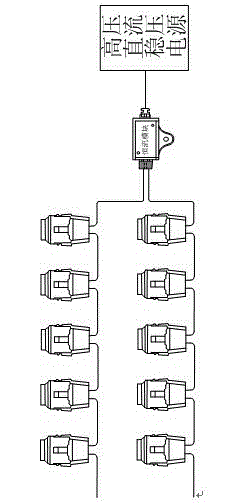

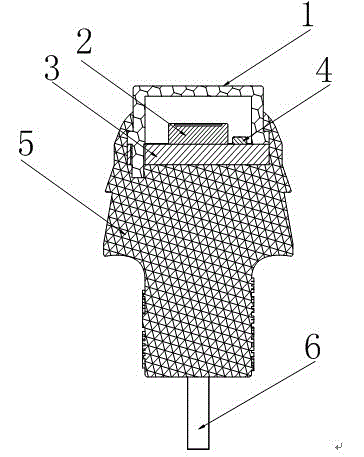

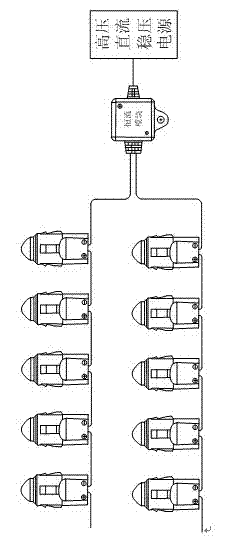

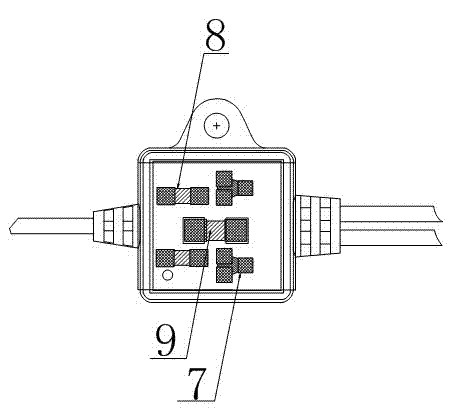

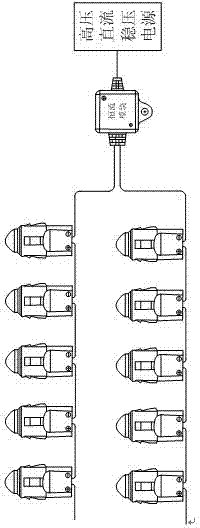

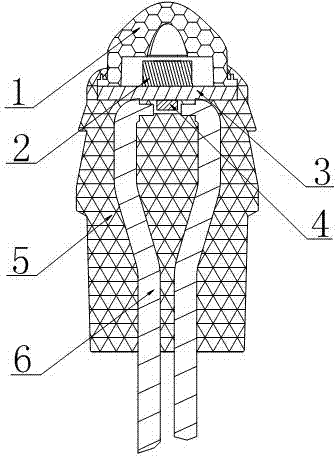

LED 5050 module based on high voltage constant current technology

ActiveCN103148393AEnsure consistencyAvoid uneven brightnessPoint-like light sourceElectric circuit arrangementsHigh-voltage direct currentEngineering

The invention discloses an LED (light-emitting diode) 5050 module based on a high voltage constant current technology, which is characterized in that the LED 5050 module comprises two groups of LED single lamps in parallel connection, a constant current module, and a high voltage direct current stabilized voltage supply connected with an input end of the constant current module, wherein each LED single lamp comprises an LED secondary light distribution lens, an injection molding housing located below the LED secondary light distribution lens and forming an integral structure with the LED secondary light distribution lens through injection molding, a PCB (printed circuit board) located in the injection molding housing, an LED 5050 located on the upper surface of the PCB, and a voltage stabilizing diode in reverse parallel connection with the LED 5050; the voltage stabilizing diodes are communicated with an output end of the constant current module by wires. According to the LED 5050 module, with the improvement of the inner LED single lamps and the design of the constant current technology, all the LED single lamps emit light uniformly, the convenience of mounting and maintenance is improved, the overall performance of the LED module is improved, and the LED 5050 module has higher practical and popularization values.

Owner:BLUEVIEW ELEC OPTIC TECH CO LTD

Textile printing and dyeing auxiliary

The invention relates to the technical field of textile printing and dyeing, in particular to a textile printing and dyeing auxiliary, which comprises, by mass, 20-30 parts of cocamide diethanolamine,10-20 parts of polyalkylacrylate, 8-12 parts of stearyldimethylbenzylammonium chloride, 15-23 parts of sodium carboxymethyl cellulose, 5-14 parts of sorbitan fatty acid ester, 5-9 parts of barium chloride, and 12-16 parts of polyethylene glycol laurate. The textile printing and dyeing auxiliary has advantages that color fastness, color protection and fading prevention can be well improved, the process is simple and the textile printing and dyeing auxiliary has a good industrial prospect and good market value.

Owner:XUZHOU YUTU TEXTILE

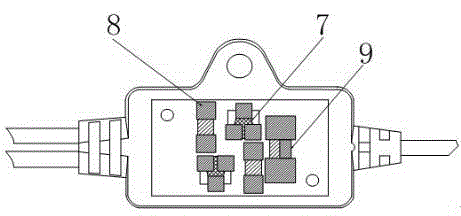

Light-emitting diode (LED) module based on high-voltage constant current technology

ActiveCN103162143AImprove waterproof effectImprove anti-attenuation abilityPoint-like light sourceElectric circuit arrangementsPrinted circuit boardRegulated power supply

The invention discloses a light-emitting diode (LED) module based on a high-voltage constant current technology. The LED module comprises a constant current module, a high-voltage direct current stabilized power source which is connected with an input end of the constant current module and an LED lamp set which is connected with an output end of the constant current module, wherein the constant current module comprises an injection outer shell and a constant current circuit board which is totally coated by the injection outer shell. The constant current circuit board comprises a second printed circuit board (PCB) and a constant current circuit which is installed on the second PCB. The constant current circuit comprises two LC1912 triodes and a fast-recovery voltage stabilizing diode SS14, wherein the two LC1912 triodes are connected in parallel, and the fast-recovery voltage stabilizing diode SS14 is connected with a parallel branch of the two LC1912 triodes in series. A collector electrode of each LC1912 triode is connected with a resistor. An input end of the constant current circuit is connected with the high-voltage direct current stabilized power source, and the output end of the constant current circuit is connected with the LED lamp set. The LED module based on the high-voltage constant current technology is capable of achieving uniform luminescence of all LED lamps and improving whole performance of the LED module, and has high practical value and promotional value.

Owner:BLUEVIEW ELEC OPTIC TECH CO LTD

Method for preparing B4C/17-4PH high-strength steel composite material through SLM

ActiveCN114559053AReduce manufacturing costShort cycleAdditive manufacturing apparatusTransportation and packagingMechanical equipmentCorrosion fatigue

The invention discloses a method for preparing a B4C / 17-4PH high-strength steel composite material through SLM. The method comprises the following steps that (1) 17-4PH high-strength steel powder is pretreated; (2) pretreatment of B4C powder; (3) the 17-4PH high-strength steel powder obtained through pretreatment and B4C powder are mixed and subjected to ball milling, and finally mixed powder with the B4C powder evenly distributed in the 17-4PH powder is prepared; (4) filling powder according to a preset powder filling mode; (5) after powder filling is finished, SLM forming is carried out, and a complete B4C / 17-4PH composite material with the B4C reinforced phase evenly distributed in a matrix is printed; and (6) the SLM-formed B4C / 17-4PH composite material is subjected to solid solution aging treatment, and the B4C / 17-4PH composite material with the B4C reinforced phase evenly distributed in a matrix after SLM-formed solid solution aging treatment is obtained. And compared with 17-4PH high-strength steel, the composite material has the advantages that the comprehensive properties such as attenuation resistance and corrosion fatigue resistance are greatly improved, so that the development requirements of China in the fields of aerospace, military industry, mechanical equipment and the like are met.

Owner:ZHONGBEI UNIV

A kind of graphene high-energy lithium battery composite positive electrode slurry and preparation method thereof

ActiveCN107528054BHigh discharge specific capacityImprove fade resistanceCell electrodesSecondary cellsHigh energySlurry

The invention provides compound cathode slurry of graphene high-power lithium batteries, relates to the technical field of cathode slurry of lithium batteries and aims to solve the technical problems that cathode slurry used in the prior art causes reduced energy storage capacity and poor cycle performance and stability of the lithium batteries, as a result, the lithium batteries easily heat and are short in service life and low in utilization rate during usage. Thus, the invention provides the compound cathode slurry of graphene high-power lithium batteries. Compared with traditional cathode slurry for the lithium batteries, the prepared compound cathode slurry has the battery capacity reduced from 195.256 mAh / g to 193.658 mAh / g and the capacity retention rate up to 99.18% under the conditions that the temperature is 35 DGE C and 1C charge and 6C discharge are circulated 500 times, the discharge specific capacity and attenuation resistance are improved, and the high cycle life and high capacity stability are realized.

Owner:上海玖银电子科技有限公司

Strong acid corrosion resistant color master batch and preparation method thereof

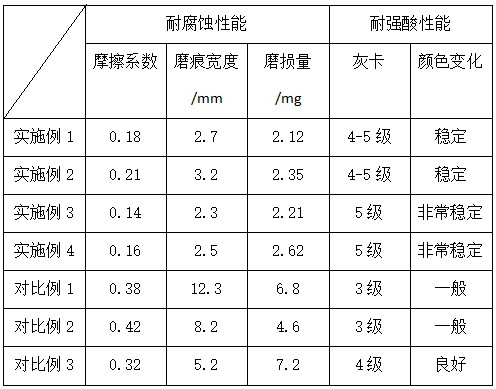

InactiveCN113429771AHigh mechanical strengthImprove fade resistanceCarbide siliconCorrosion resistant

The invention discloses a strong acid corrosion resistant color master batch, the color master batch is prepared from the following raw materials in parts by weight: 50-80 parts of carrier resin, 6-12 parts of a toner, 0.5-1 part of an additive and 0.3-0.5 part of a filler, the carrier resin is a mixture of PC resin and HIPS resin, the toner is titanium dioxide, and the filler is silicon carbide, the invention also discloses a preparation method of the color master batch. The filler adopts silicon carbide to enhance and modify the color master batch and improve the mechanical strength, the toner adopts titanium dioxide to improve the fading resistance of the color master batch, and the resin adopts the combination of PC resin and HIPS resin to improve the impact toughness and surface smoothness of the color master batch. The additive is silicon dioxide, the filler is silicon carbide, and the toner is titanium dioxide, so that the strong acid and strong alkali resistance and corrosion resistance of the color master batch can be improved, and a foaming agent and a plasticizer are combined to weaken secondary valence bonds among resin molecules and increase the mobility of resin molecular bonds, so that the flexibility is enhanced, the color master batch is easy to process, and the stability of the color master batch is improved.

Owner:安徽缤飞塑胶科技有限公司

A kind of mine microseismic detector installed in deep hole

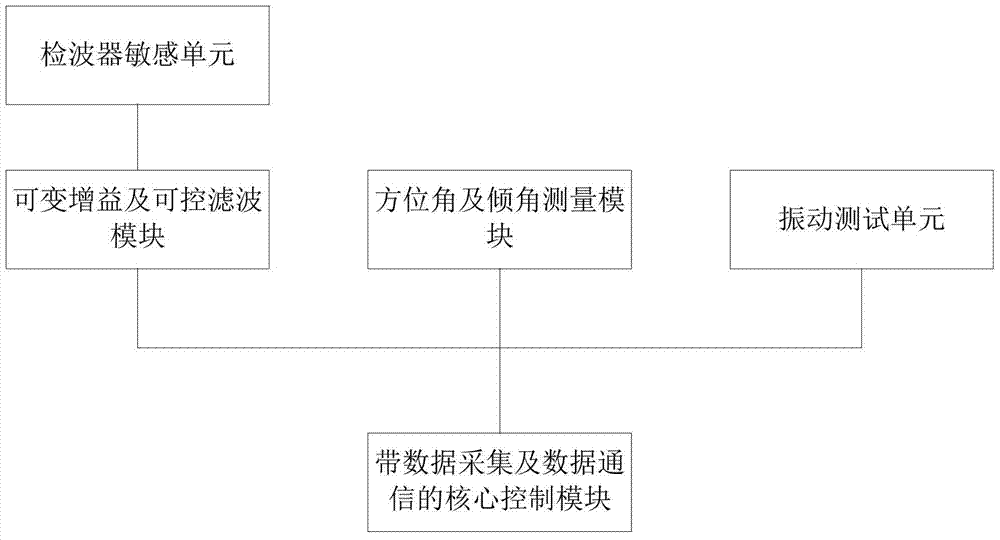

ActiveCN103941283BReduce automatic loggingRealize automatic recordingSeismic signal receiversObservational errorData acquisition

The invention discloses a mine microseism wave detector installed in a deep hole. The mine microseism wave detector installed in the deep hole comprises a wave detector sensing unit, a vibration testing unit, a variable gain and controllable filtering module, an azimuthal angle and dip angle measurement module and a core control module with data collection and communication functions. The wave detector can achieve automatic recording of related information, lowers the complexity of artificial operation, avoids introducing more artificial measurement errors, achieves self-measurement of the azimuthal angle and the dip angle, reduces the amount of the related information recorded manually, lightens the workload of manual recording and the probability of wrong recording, and guarantees normal work. A work state self-detection function of the wave detector is added, maintenance difficulty and complexity are lowered, the utilization rate is improved, variable gains and controllable filtering are increased, the grain range and the filtering frequency band are adjustable, the signal-to-noise ratio and the anti-attenuation capacity of a single source are improved, and the wave detector sensing unit is favorable for improving the signal-to-noise ratio of the wave detector array.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Cable anti-theft device

ActiveCN106157509BImprove noise marginImprove fade resistanceBurglar alarm electric actuationPower flowEngineering

The invention discloses a cable anti-theft device, and belongs to the technical field of anti-theft of street lamp cables. The anti-theft device comprises a detecting host and a terminal node, wherein the detecting host comprises a control unit, a current pulse sending unit and a current loop signal resolving unit, and the control unit controls the current pulse sending unit to send current pulse signals to the terminal node; the terminal node resolves the current pulse signals and sends response current pulse signals to the current loop signal resolving unit of the detecting host according to the resolution result, and the current loop signal resolving unit of the detecting host resolves the response current pulse signals and transmits the resolution result to the control unit; the control unit calculates the terminal node address information according to the resolution result and judges whether the terminal node is lost or not according to the address information and uploads the lost information to a street lamp manager when the terminal node is lost. The current is used as a carrier to transmit data to ensure the quality of communication and achieve longer-distance signal transmission, so that the cable anti-theft device has the advantages of accurate detection and efficient operation.

Owner:HEFEI DAMING ENERGY SAVING TECH

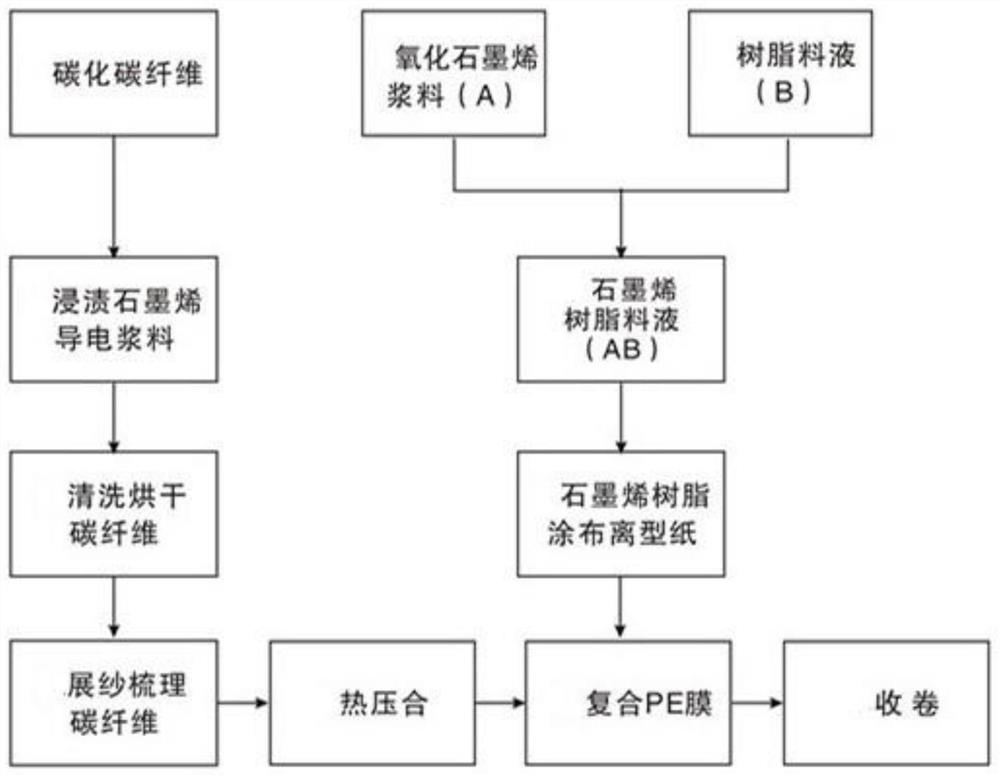

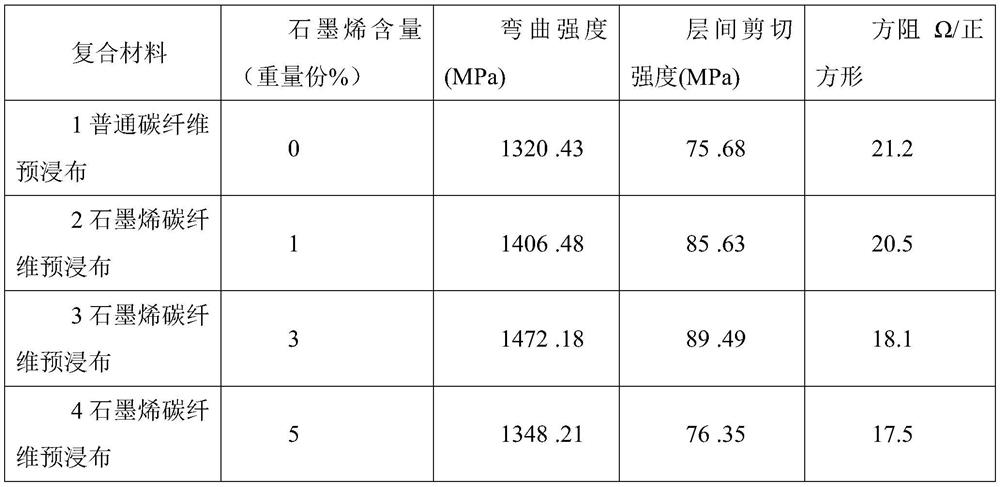

A kind of graphene modified carbon fiber pre-fabric and preparation method thereof

ActiveCN110983759BChange adsorptionHigh strengthCarbon fibresLiquid repellent fibresYarnPolymer science

The invention discloses a graphene-modified carbon fiber prepreg and a preparation method thereof. The preparation raw materials of the graphene-modified carbon fiber prepreg include carbon fiber, resin, graphene, oxidant, diluent, release paper, PE film, carbon fiber is prepared into graphene modified conductive carbon fiber prepreg through carbonization, graphene impregnation, cleaning and drying, hot rolling and yarn spreading composite resin release paper, film coating, winding, etc. The present invention makes the surface of carbon fiber introduce Oxygen-containing groups such as carbonyl and carboxyl groups can change the surface inertness, change the adsorption capacity and composite ability of carbon fibers to active substances, and at the same time improve the strength, toughness, conductivity, etc. of carbon fiber materials, which can be used as conductive heating prepregs. It has unique properties such as ultra-thinness, toughness, water resistance, and attenuation resistance. It can also improve strength, toughness and other properties in special applications of carbon fiber composite materials such as military industry, aerospace, and new energy. It has a very wide range of properties. Modified materials of application value.

Owner:QINGDAO GRAPHENE CARBON NEW MATERIAL TECH CO LTD

Light-emitting diode (LED) module based on high-voltage constant current technology

ActiveCN103162143BEnsure consistencyAvoid uneven brightnessPoint-like light sourceElectric circuit arrangementsHigh-voltage direct currentEngineering

The invention discloses a light-emitting diode (LED) module based on a high-voltage constant current technology. The LED module comprises a constant current module, a high-voltage direct current stabilized power source which is connected with an input end of the constant current module and an LED lamp set which is connected with an output end of the constant current module, wherein the constant current module comprises an injection outer shell and a constant current circuit board which is totally coated by the injection outer shell. The constant current circuit board comprises a printed circuit board (PCB) and a constant current circuit which is installed on the PCB. The constant current circuit comprises two LC1912 triodes and a fast-recovery voltage stabilizing diode SS14, wherein the two LC1912 triodes are connected in parallel, and the fast-recovery voltage stabilizing diode SS14 is connected with a parallel branch of the two LC1912 triodes in series. A collector electrode of each LC1912 triode is connected with a resistor. An input end of the constant current circuit is connected with the high-voltage direct current stabilized power source, and the output end of the constant current circuit is connected with the LED lamp set. The LED module based on the high-voltage constant current technology is capable of achieving uniform luminescence of all LED lamps and improving whole performance of the LED module, and has high practical value and promotional value.

Owner:BLUEVIEW ELEC OPTIC TECH CO LTD

Soft magnetic composite material, preparation method and application thereof

PendingCN113470914AImprove stabilityImprove permeabilityInorganic material magnetismInductances/transformers/magnets manufacturePolymer scienceAdhesive

The invention provides a soft magnetic composite material, a preparation method and application thereof. The soft magnetic composite material is prepared by mixing the following raw materials in parts by weight: 90-110 parts of soft magnetic powder, 2-5 parts of an adhesive and 0.1-3 parts of an auxiliary additive, wherein the adhesive is composed of a resin and a curing agent, the auxiliary additive is selected from at least one of carboxyl-terminated nitrile rubber, polysulfide rubber, polyurethane, 650 low-molecular polyamide resin, 651 low-molecular polyamide resin and bisphenol A type unsaturated polyester resin. According to the invention, by optimizing the composition and proportion of raw materials and adding the auxiliary additive into the soft magnetic powder and the adhesive, the auxiliary additive can be grafted to the resin of the adhesive or the curing agent molecular chain to increase the steric hindrance of the reaction of the resin and the curing agent so as to reduce the reaction activity, so that the stability of the soft magnetic composite material can be effectively improved, and the problem of attenuation of the magnetic conductivity of the soft magnetic composite material stored at room temperature for a long time is obviously solved.

Owner:KUNSHAN CITONG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com