High-toughness flame-retardant foamed PVC wood-plastic board and preparation method thereof

A foaming and high-toughness technology, which is applied in the field of high-toughness flame-retardant foamed PVC wood-plastic board and its preparation, can solve the problems of poor oxidation resistance, wear resistance and aging resistance, surface wear and tear of wood-plastic board furniture, and To achieve the flame retardant effect and other issues, to achieve the effect of easy operation, no influence on curing and molding speed, and ideal pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

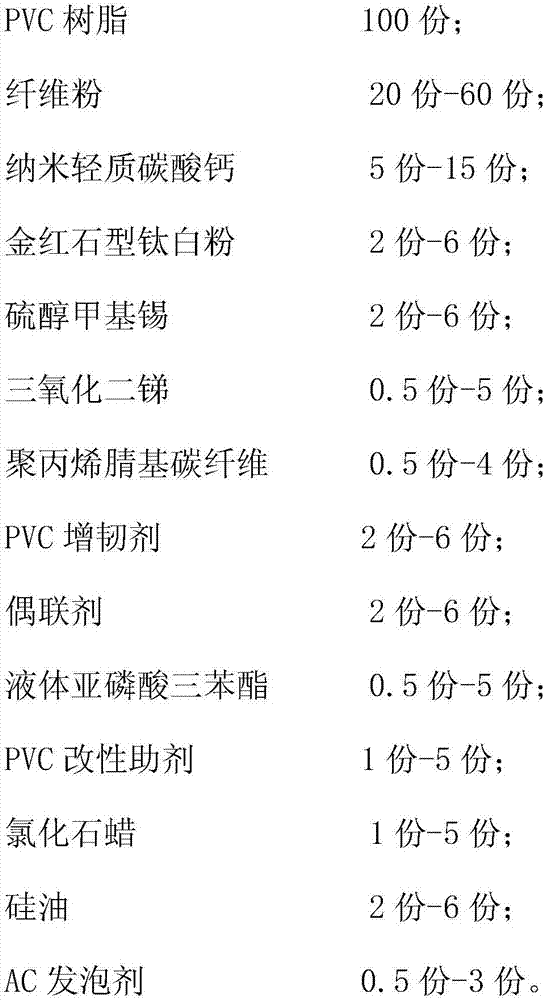

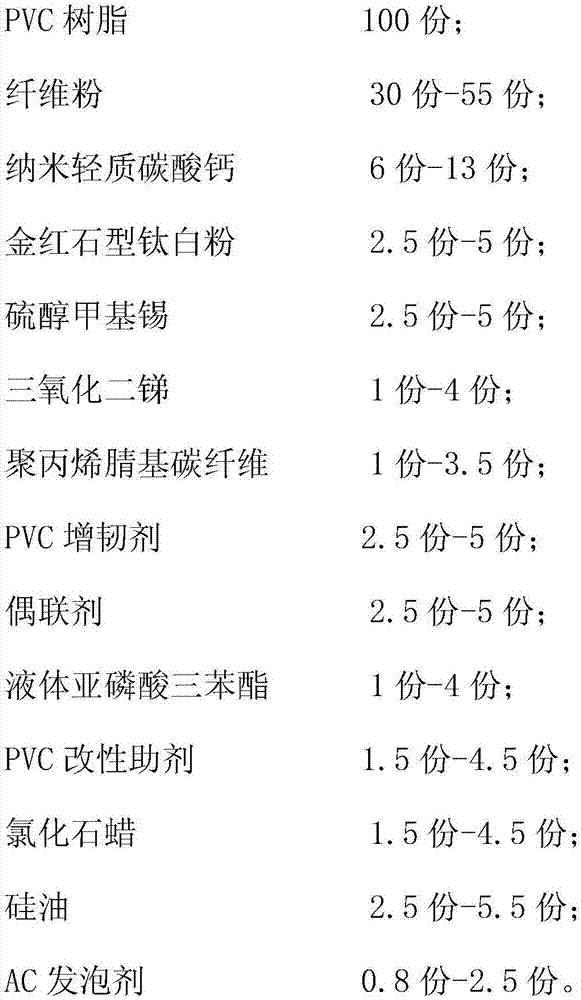

Method used

Image

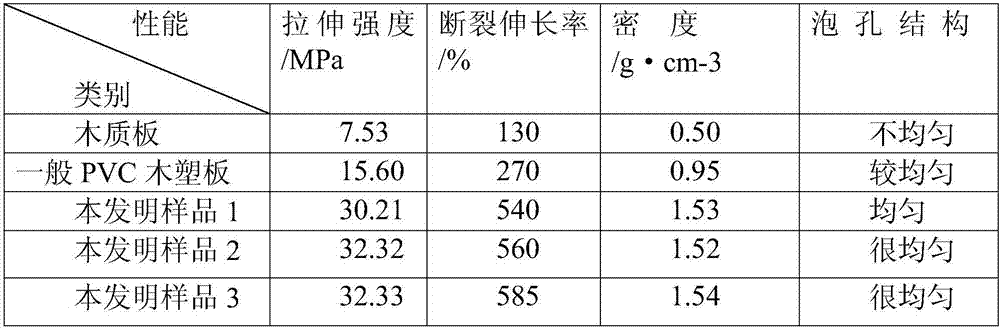

Examples

Embodiment 1

[0036] A high-toughness flame-retardant foamed PVC wood-plastic board, comprising: 100 parts of PVC resin SG4, 20 parts of wood flour, 5 parts of nano-light calcium carbonate, 2 parts of rutile titanium dioxide, and mercaptan 2 parts of base tin, 0.5 parts of antimony trioxide, 0.5 parts of polyacrylonitrile-based carbon fiber, 2 parts of PVC toughening agent, 2 parts of siloxane coupling agent KH-792, 0.5 parts of liquid triphenyl phosphite, PVC modification 1 part of sex aid ACR401, 1 part of chlorinated paraffin, 2 parts of silicone oil, 0.5 part of AC foaming agent.

Embodiment 2

[0038] A high-toughness flame-retardant foamed PVC wood-plastic board, comprising: 100 parts of PVC resin SG4, 40 parts of wood flour, 10 parts of nano light calcium carbonate, 4 parts of rutile titanium dioxide, and mercaptan 4 parts of base tin, 2.5 parts of antimony trioxide, 2 parts of polyacrylonitrile-based carbon fiber, 4 parts of PVC toughening agent, 4 parts of siloxane coupling agent KH-792, 2.5 parts of liquid triphenyl phosphite, PVC modified 3 parts of sex aid ACR401, 3 parts of chlorinated paraffin, 4 parts of silicone oil, 1.5 parts of AC foaming agent.

Embodiment 3

[0040] A high-toughness flame-retardant foamed PVC wood-plastic board, comprising: 100 parts of PVC resin SG4, 60 parts of wood flour, 15 parts of nano-light calcium carbonate, 6 parts of rutile titanium dioxide, and mercaptan 6 parts of base tin, 5 parts of antimony trioxide, 4 parts of polyacrylonitrile-based carbon fiber, 6 parts of PVC toughening agent, 6 parts of siloxane coupling agent KH-792, 5 parts of liquid triphenyl phosphite, PVC modified 5 parts of sex aid ACR401, 5 parts of chlorinated paraffin, 6 parts of silicone oil, 3 parts of AC foaming agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com