Photocuring method of large-area dark fiber cloth epoxy composite material

A technology of composite materials and cloth epoxy, which is applied in the light curing of fiber cloth epoxy composite materials and the field of light curing of large-area dark fiber cloth epoxy composite materials, and can solve curing termination, resin cracking, and resin system preparation steps cumbersome and other problems, to achieve the effects of reduced viscosity, smooth surface, high reactivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: curing large area carbon fiber epoxy composite material

[0033] Resin formula: bisphenol A epoxy resin, accounts for 60% of total mass, 15g; Photoinitiator diphenyliodonium antimonate, accounts for 2% of total mass, 0.5g; Thermal initiator benzopinacol, accounts for 2% of the total mass, 0.5g; active solvent 3,3'-(oxybis(methylene))bis(3-ethoxyethane), 20% of the total mass, 5g; toughening agent 201 poly Esters, accounting for 15.5% of the total mass, 3.875g; heat-conducting particles of aluminum nitride, accounting for 0.5% of the total mass, 0.125g.

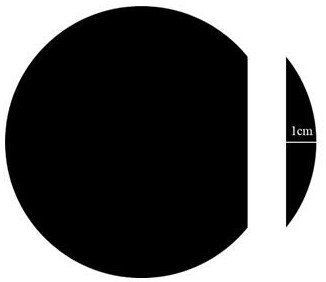

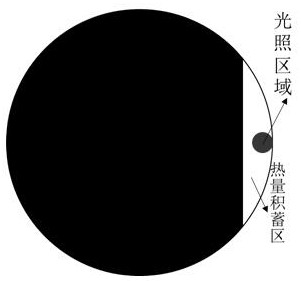

[0034] The carbon fiber cloth is first cut into a circle with a diameter of 14 cm, and then a piece is cut parallel to the diameter at a distance of 1 cm from the circumference to reserve a heat accumulation area. Cutting diagrams such as figure 1 shown.

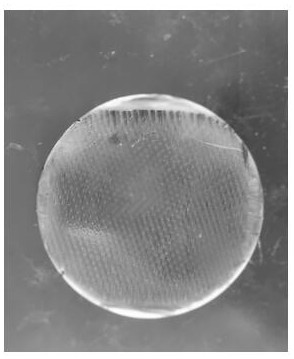

[0035] Put the three layers of cut carbon fiber cloth into a round silicone mold with a diameter of 14 cm.

[0036] Dissolve the photoinitiator and ...

Embodiment 2

[0039] Embodiment 2: curing large-area silicon rubber cloth epoxy composite material

[0040]Storage resin formula: bisphenol A epoxy resin, accounting for 65% of the total mass, 195g; thermal initiator benzopinacol, accounting for 2% of the total mass, 6g; active solvent 3,3'-(oxybis(methylene base)) bis(3-ethoxyethane), accounting for 20.6% of the total mass, 61.8g; toughening agent 201 polyester, accounting for 12% of the total mass, 36g; 0.4%, 1.2g.

[0041] Dissolve the thermal initiator in an active solvent and dissolve it completely by ultrasonication for 5 minutes. Add epoxy resin, toughening agent and heat-conducting particles, and mechanically stir for 10 min to obtain 300 g of a resin system that can be stored stably.

[0042] One month later, 30 g of the stored resin was weighed, 0.6 g of photoinitiator diphenyliodonium antimonate was added thereto, and mechanically stirred for 3 min. Put the system into a 90°C oven and heat for 15 minutes. The silicone cloth i...

Embodiment 3

[0044] Embodiment 3: curing large area carbon fiber epoxy composite material

[0045] Resin formula: bisphenol A epoxy resin, accounting for 30% of the total mass, 7.5g; bisphenol S epoxy resin, accounting for 30% of the total mass, 7.5g; photoinitiator diphenyliodonium antimonate, accounting for 2 % of the total mass, 0.5 g; thermal initiator benzopinacol, 2 % of the total mass, 0.5 g; active solvent 3,3'-(oxybis(methylene))bis(3-ethoxy Ethane), accounting for 20% of the total mass, 5g; toughening agent 201 polyester, accounting for 15.5% of the total mass, 3.875g; heat-conducting particles aluminum nitride, accounting for 0.5% of the total mass, 0.125g.

[0046] The carbon fiber cloth is first cut into a square with a side length of 8cm, and then a square with a side length of 4mm is cut at one corner to reserve a heat accumulation area. Put the five layers of cut carbon fiber cloth into the silicone mold.

[0047] Dissolve the photoinitiator and thermal initiator in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com