Patents

Literature

32results about How to "Improve capacity stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for temperature compensation type multi-layer ceramic chip capacitor

ActiveCN102354599AIncrease capacityReduce lossFixed capacitor electrodesFixed capacitor dielectricCapacitanceElectronics

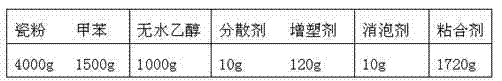

The invention discloses a preparation method for a temperature compensation type multi-layer ceramic chip capacitor, which mainly includes the processes of ceramic slurry preparation, medium film curtain-casting, alternate inner electrode and medium layer overprinting, lamination, cutting, binder removal, sintering, chamfering, end capping and firing. In the ceramic slurry preparation, the used ceramic materials are CaZrO3 ceramic material and SrTiO3 ceramic material, and the weight ratio of the CaZrO3 to the SrTiO3 is 1:(1.5 to 3); the maximum temperature for binder removal is 270 DEG C to 290 DEG C; the maximum temperature for sintering is 1270 DEG C to 1300 DEG C, and the sintering temperature-keeping time is 2 to 3 hours. With the adoption of the preparation method, the production cost is greatly reduced, and also temperature compensation type multi-layer ceramic capacitors with nickel-sputtered metal electrodes can be prepared. The capacitor is quite suitable for the fields of automotive electronics, illuminating electronics and other new industries in China.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Compound cathode slurry of graphene high-power lithium batteries and preparation method of compound cathode slurry

ActiveCN107528054AHigh discharge specific capacityImprove fade resistanceCell electrodesSecondary cellsUltrasound attenuationSlurry

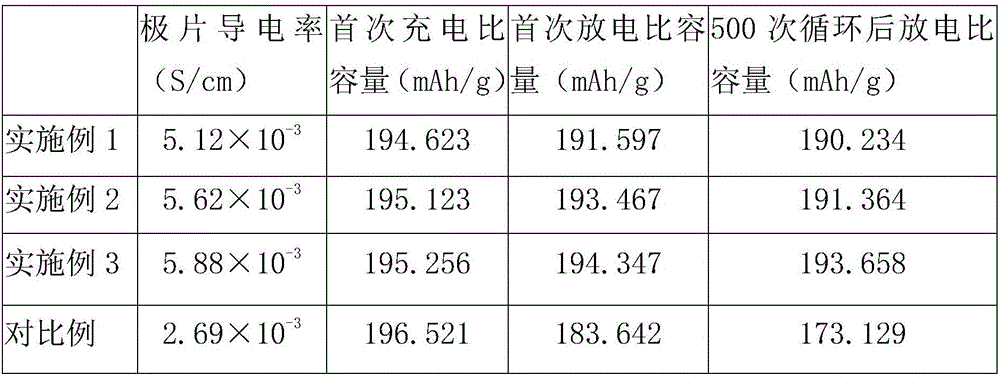

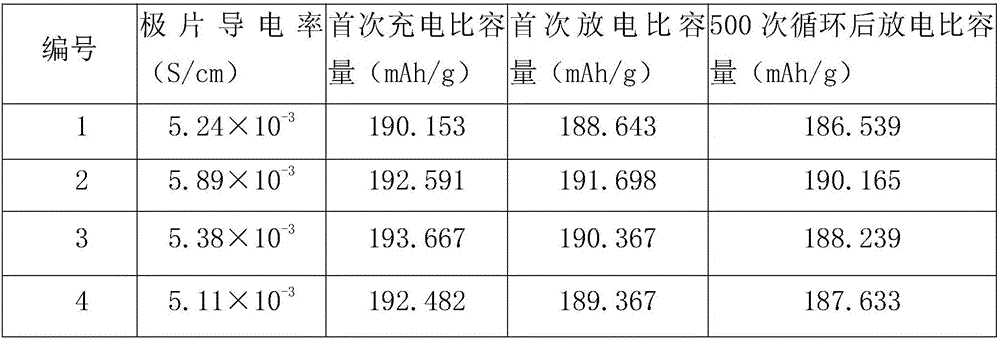

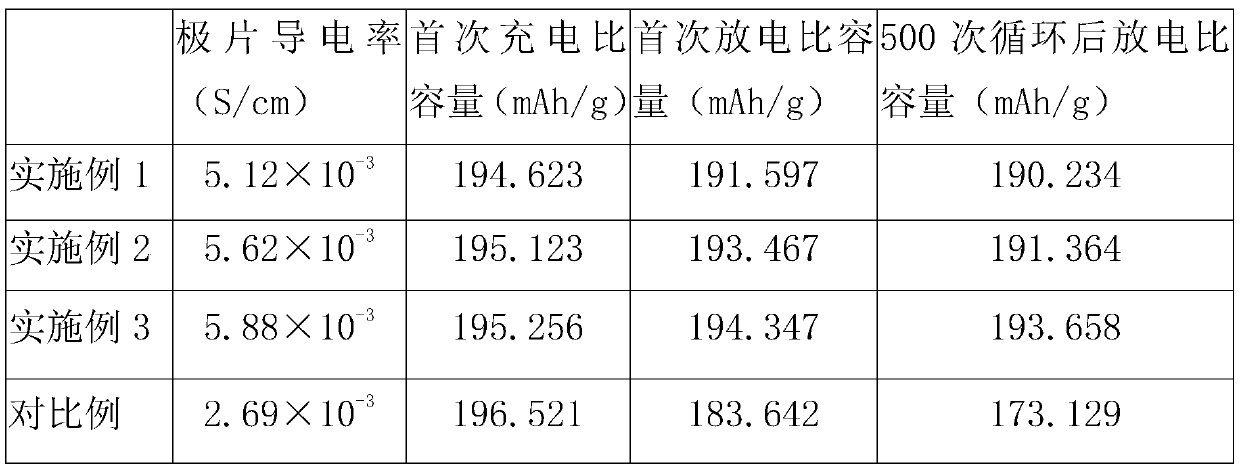

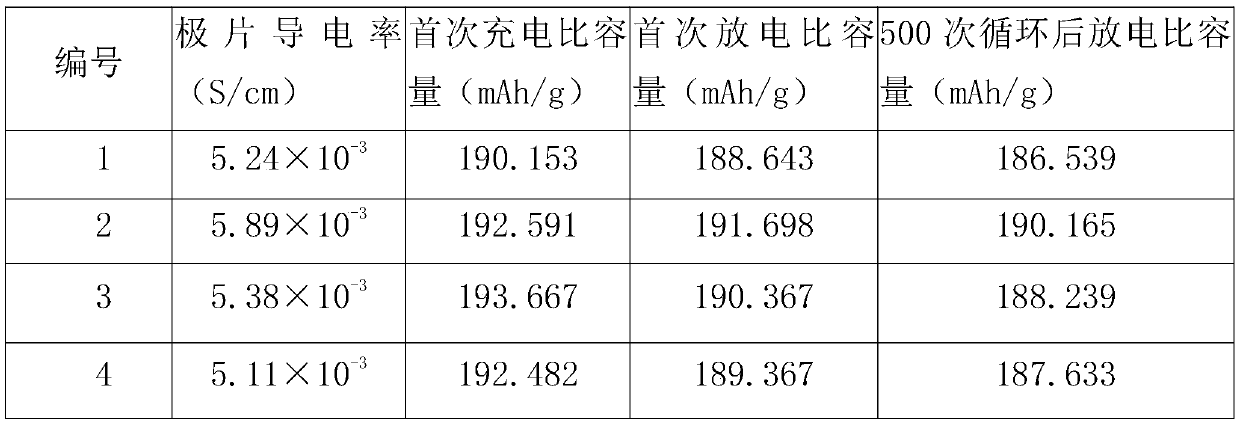

The invention provides compound cathode slurry of graphene high-power lithium batteries, relates to the technical field of cathode slurry of lithium batteries and aims to solve the technical problems that cathode slurry used in the prior art causes reduced energy storage capacity and poor cycle performance and stability of the lithium batteries, as a result, the lithium batteries easily heat and are short in service life and low in utilization rate during usage. Thus, the invention provides the compound cathode slurry of graphene high-power lithium batteries. Compared with traditional cathode slurry for the lithium batteries, the prepared compound cathode slurry has the battery capacity reduced from 195.256 mAh / g to 193.658 mAh / g and the capacity retention rate up to 99.18% under the conditions that the temperature is 35 DGE C and 1C charge and 6C discharge are circulated 500 times, the discharge specific capacity and attenuation resistance are improved, and the high cycle life and high capacity stability are realized.

Owner:上海玖银电子科技有限公司

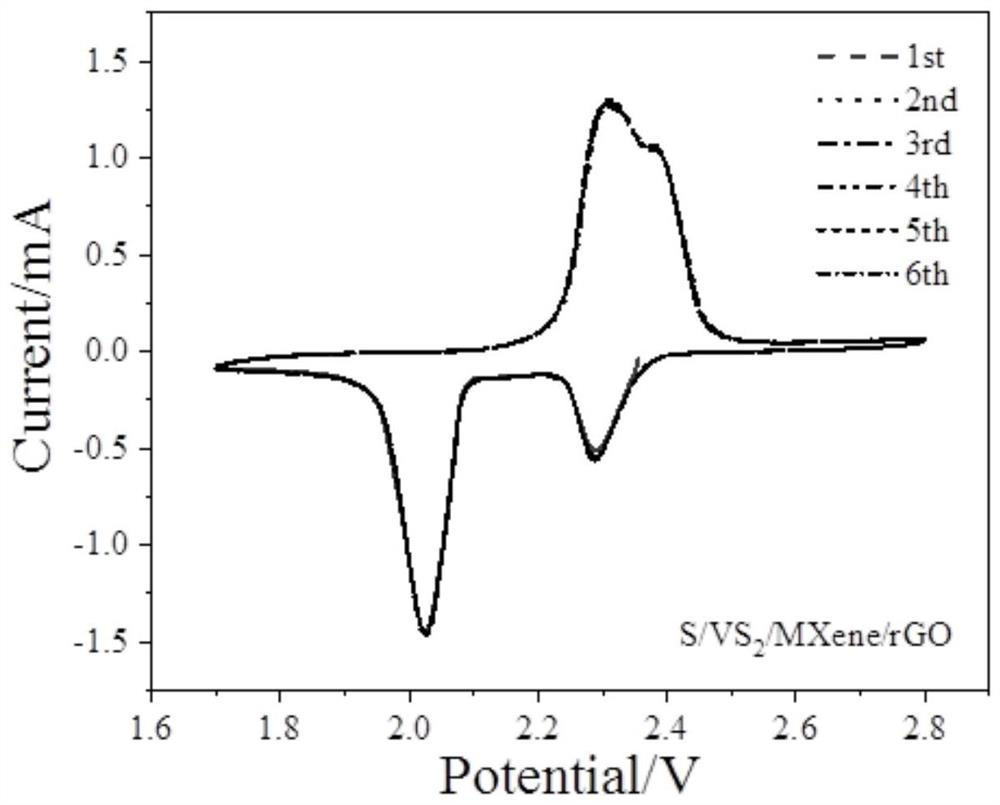

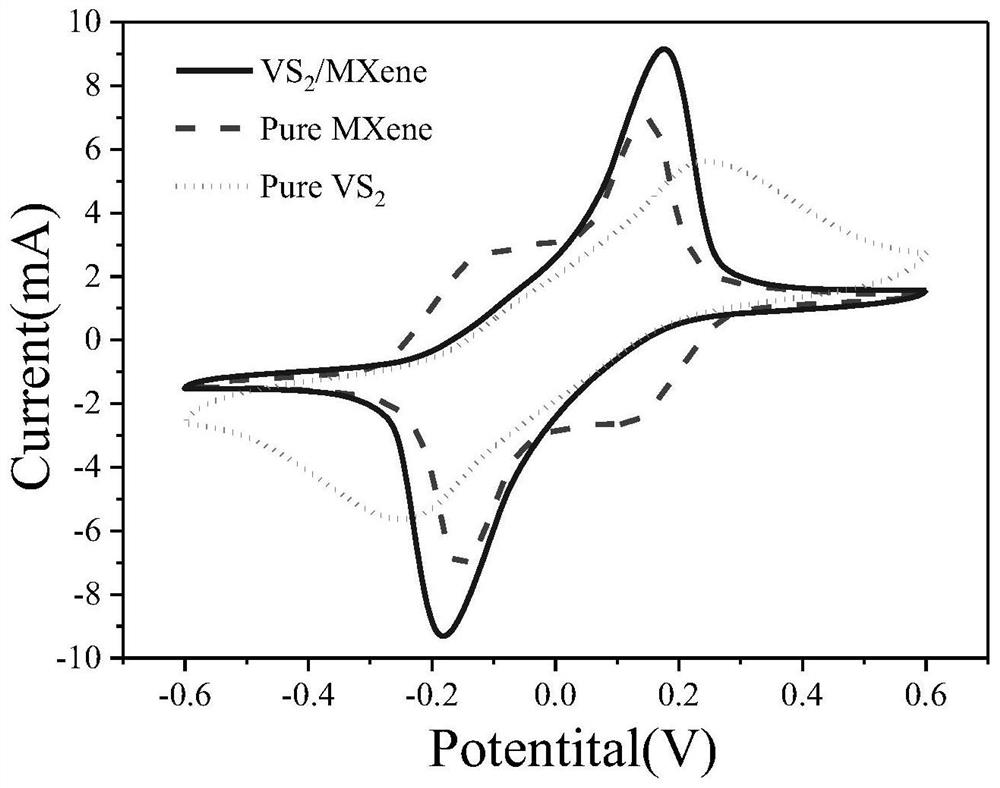

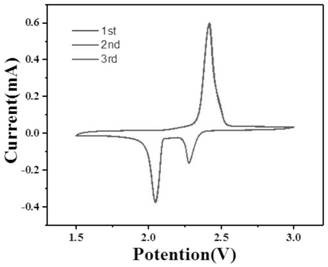

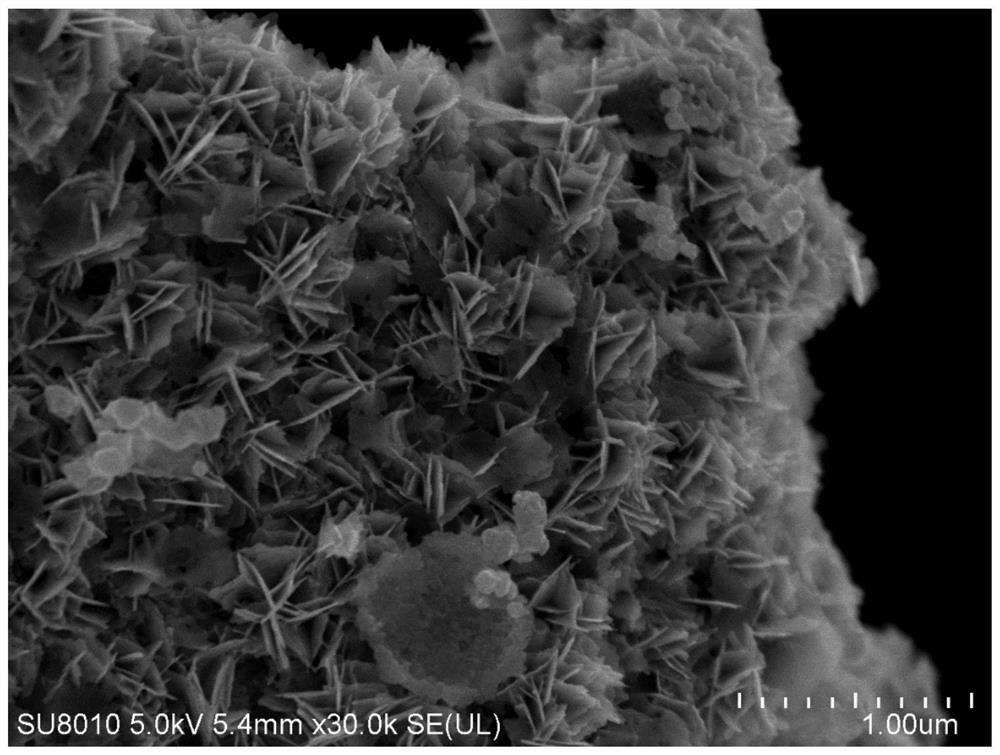

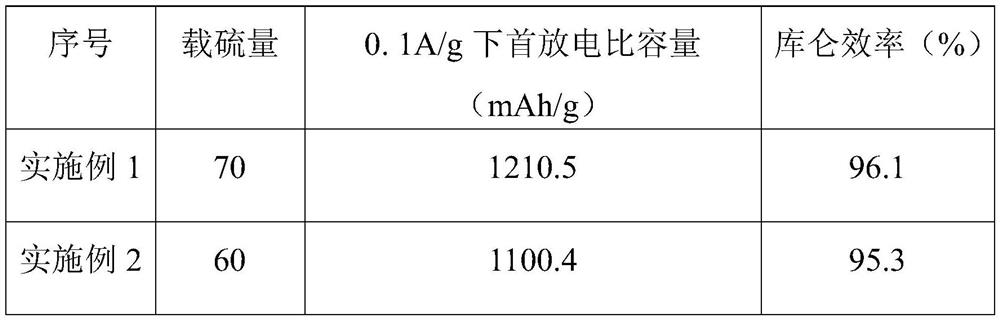

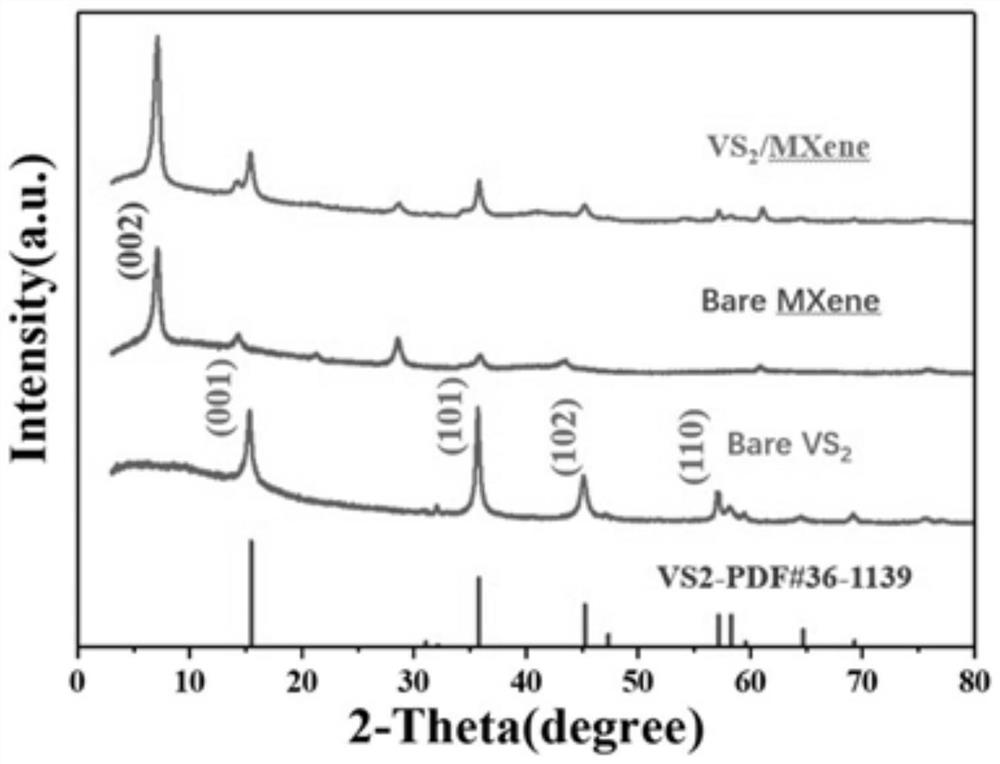

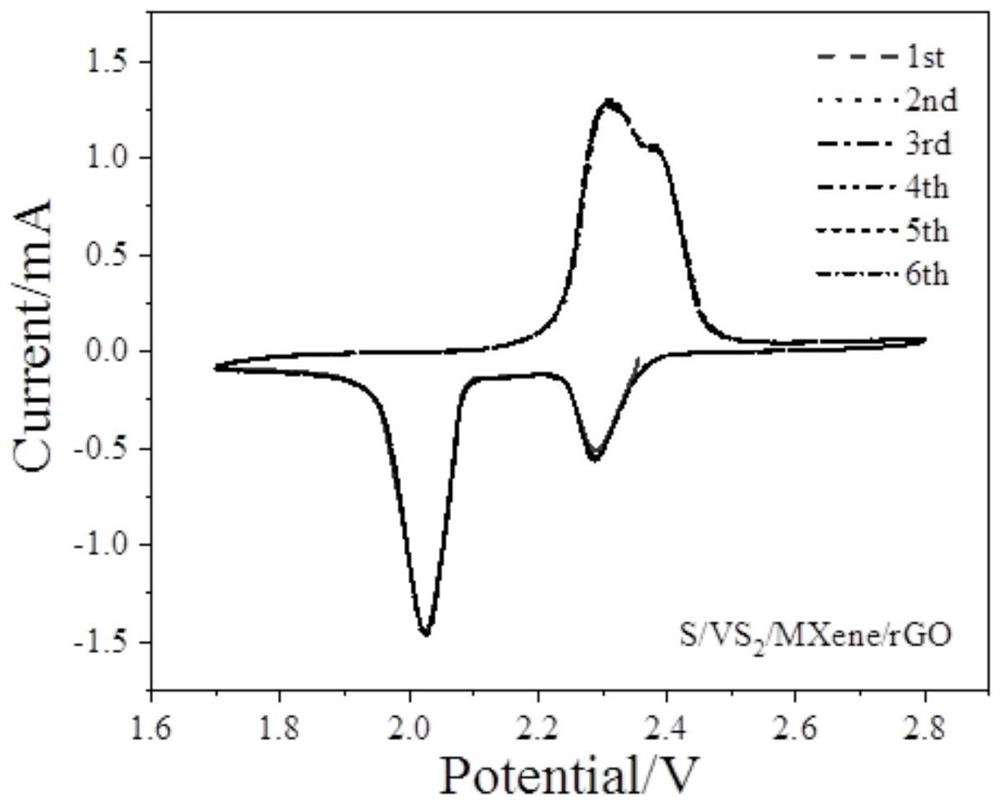

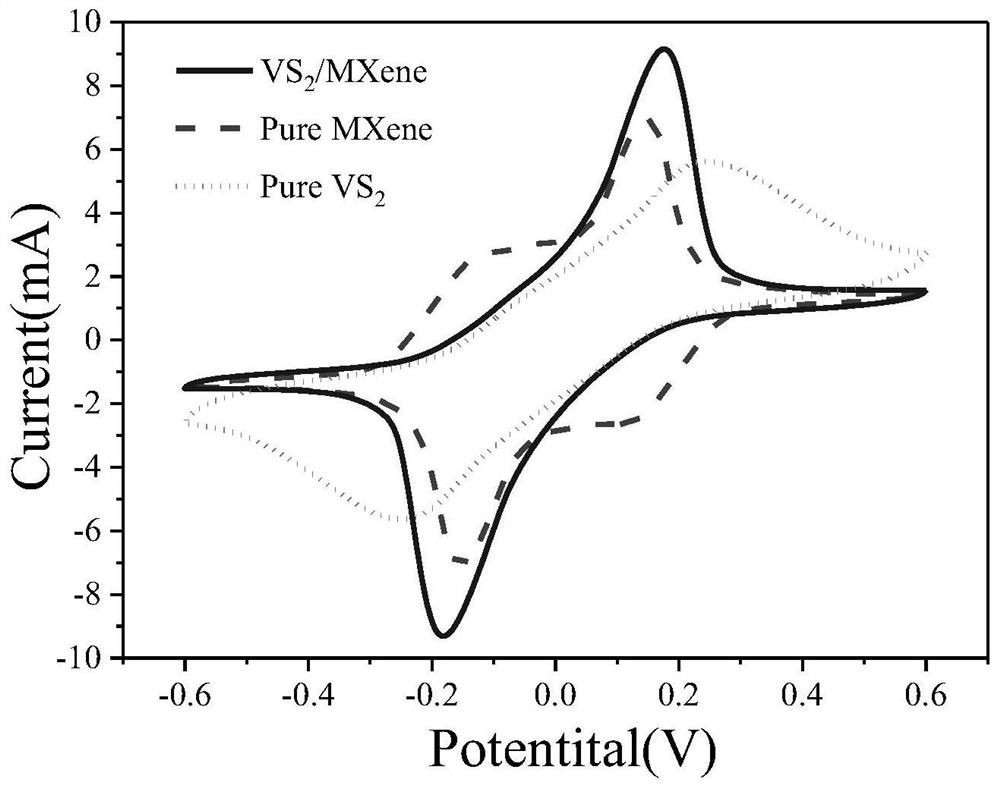

Sulfur/vanadium disulfide/MXene composite material as well as preparation method and application thereof

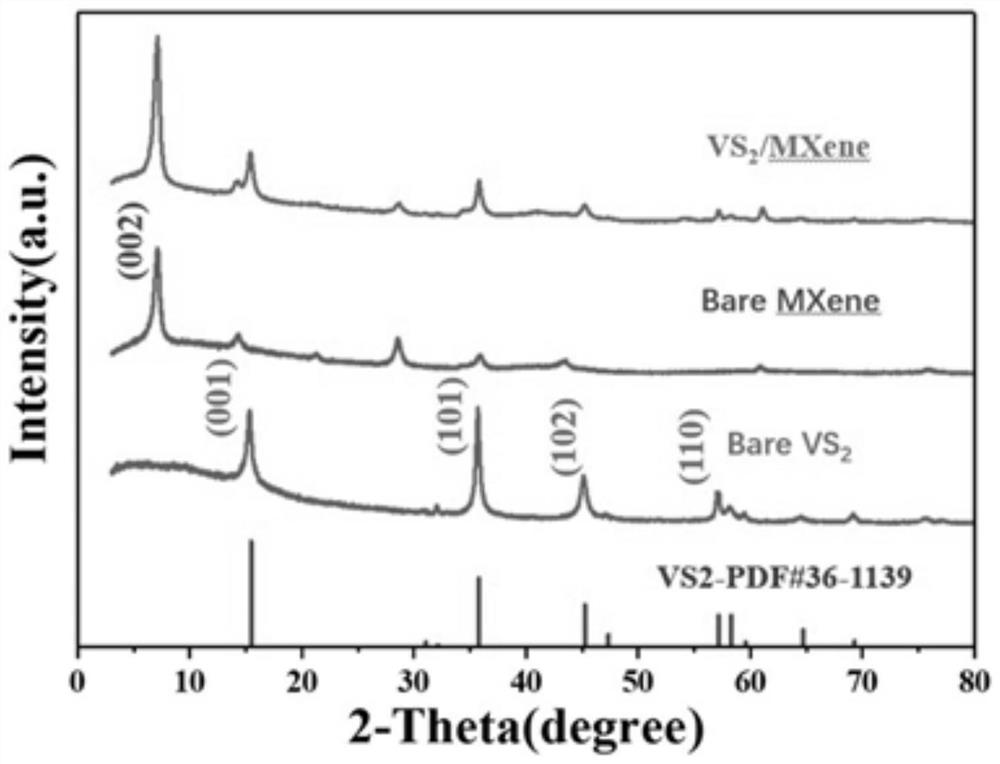

ActiveCN111816858AUniform particlesUniform particle sizeMaterial nanotechnologyCell electrodesElectrolytic agentVanadium disulfide

The invention relates to the technical field of battery materials, in particular to a sulfur / vanadium disulfide / MXene composite material as well as a preparation method and application thereof. According to the preparation method disclosed by the invention, the sulfur loading capacity can be improved due to the high specific surface area and a large number of active sites of the sulfur loading material MXene; MXene has unique flexibility and conductivity, so that the volume change of the positive electrode material can be buffered, and the conductivity of the composite material can be improved; the surface of the MXene is provided with a large number of functional groups and static electricity, so that vanadate ions can be attracted to generate a coordination effect; the vanadate ions areuniformly adsorbed on the surface of the MXene, so that the vanadate ions and a sulfur source generate uniform vanadium disulfide nanosheets on the surface of the MXene in situ at a proper temperature; by introducing the vanadium disulfide nanosheet with catalytic activity and high conductivity into MXene, lithium polysulfide can be chemically adsorbed, and the vanadium disulfide nanosheet can bequickly catalyzed and converted into insoluble Li2S2 / Li2S in an electrolyte, so that a serious shuttle effect is inhibited, the stability of the lithium-sulfur battery is improved, and the cycle lifeof the lithium-sulfur battery is prolonged.

Owner:GUANGDONG UNIV OF TECH

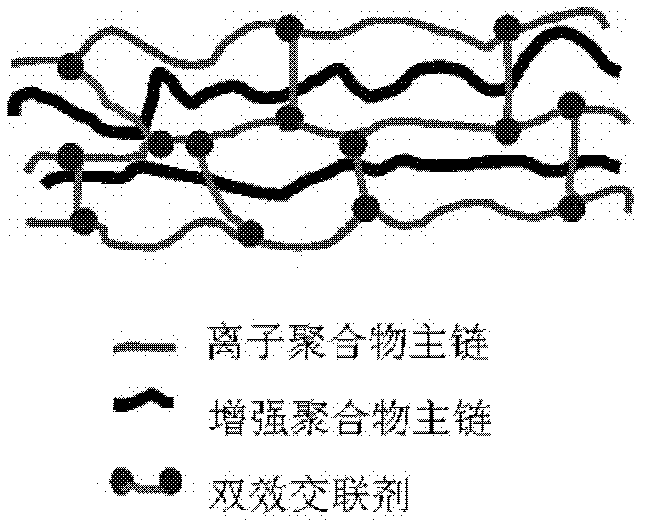

Composite anion-exchange membrane, its preparation and application

InactiveCN102867929AStrength doesn't hurtGuaranteed conductivityCell component detailsFuel cell detailsCross-linkPolymer science

The invention relates to a composite anion-exchange membrane, its preparation and application. The membrane comprises a halomethylation polymer, an ion exchange-based precursor, a double-effect cross-linking agent and a reinforcing material. In the preparation process, the reinforcing material molecular chain is linked with the conductive ionic polymer molecular chain by the double-effect cross-linking agent to form a mandatory interpenetrating polymer network to avoid macroscopic phase separation. The preparation method disclosed herein is easy to operate and has the advantages of low cost and no damage to the membrane strength in the implementation process, the obtained anionic membrane has stable interface and mechanical stability, and the conductivity and swelling resistance of the membrane can be simultaneously guaranteed.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Manufacture method of super capacitor

InactiveCN102543481BImprove capacity stabilityImprove cycle lifeHybrid/EDL manufactureNew energyAdhesive

A manufacture method of a super capacitor belongs to the technical field of new energy accumulation and includes conducting roughness processing on the surface of a metal collector, evenly mixing active materials, conductive materials and composite adhesive, pressing the mixture into a pole piece with the thickness between 30 micrometer to 100 micrometer, bonding the pole piece to the surface of the collector to form a belt pole, cutting the belt pole into two poles identical in size, enabling the two poles to be riveted with a wire, adding a pole separation film with the thickness between 10 micrometer to 15 micrometer, winding the film to form a core, drying the core for 8 to 72 hours under the temperature of 100 DEG C to 150 DEG C in vacuum mode, immersing the core in organic electrolyte, electrifying the electrolyte for 10 hours through 2.7V direct current voltage under 50 DEG C temperature, and packaging the core in a round aluminum casing to obtain a product of the super capacitor. The composite adhesive is a mixture of a substance with [NH-R-CO-R-CO]x formula and teflon. Poles manufactured by the composite adhesive are flexible, high in mechanical strength, easy to produce continuously in large scale and substantially longer in service life.

Owner:锦州凯美能源有限公司

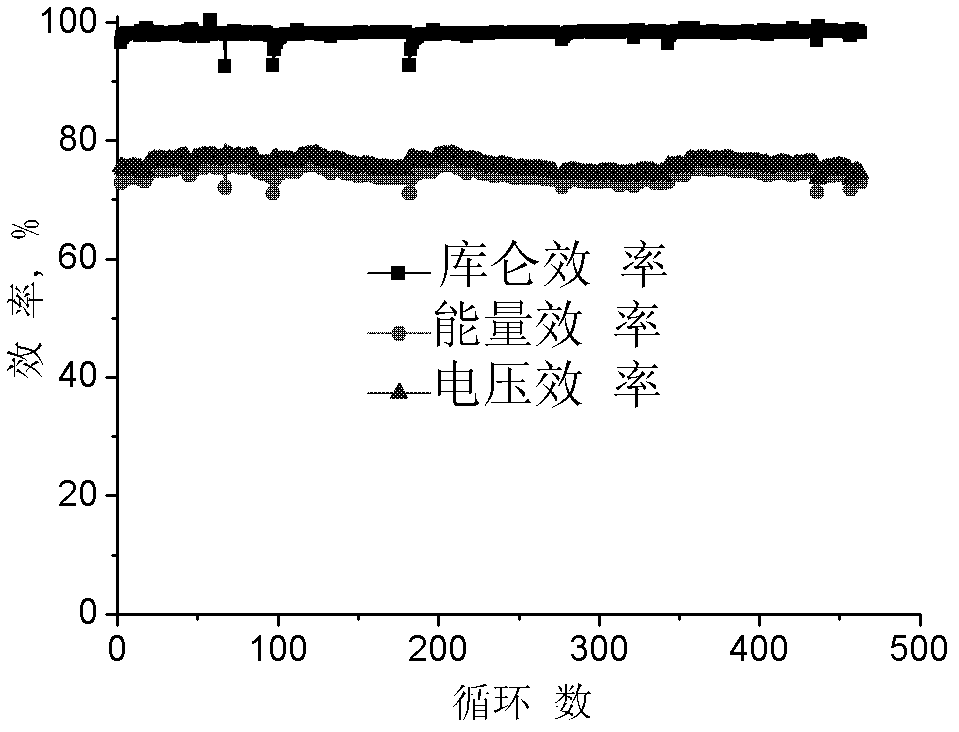

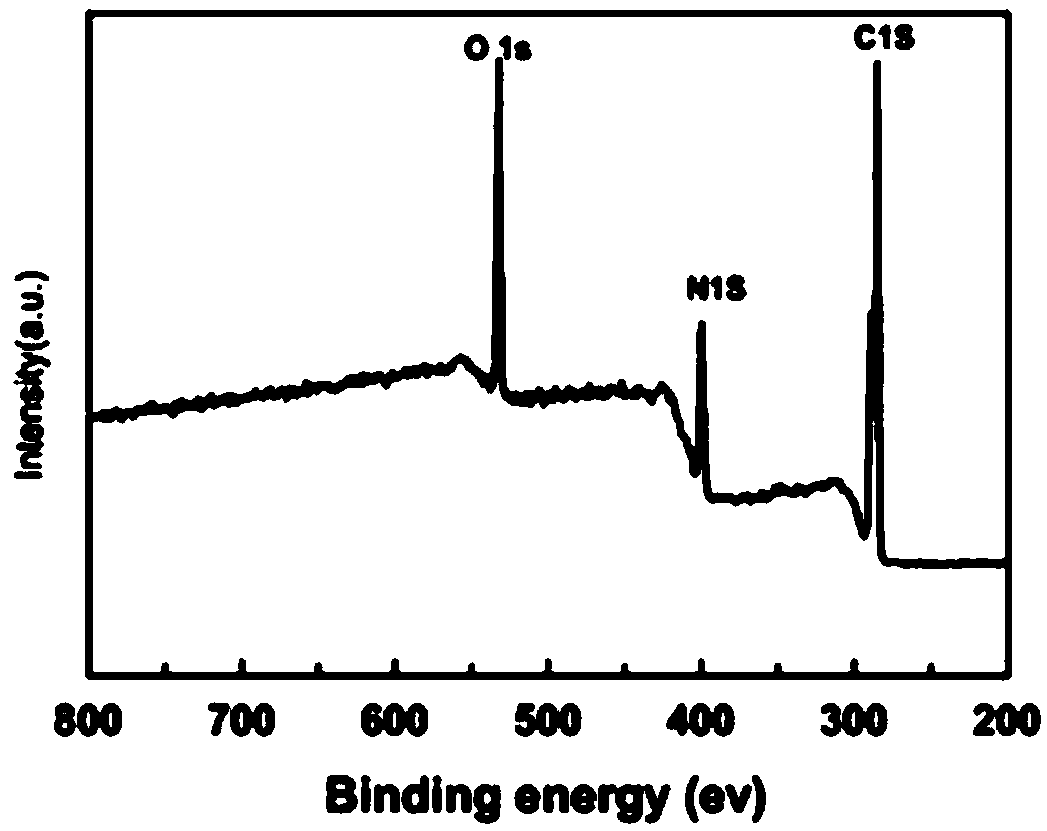

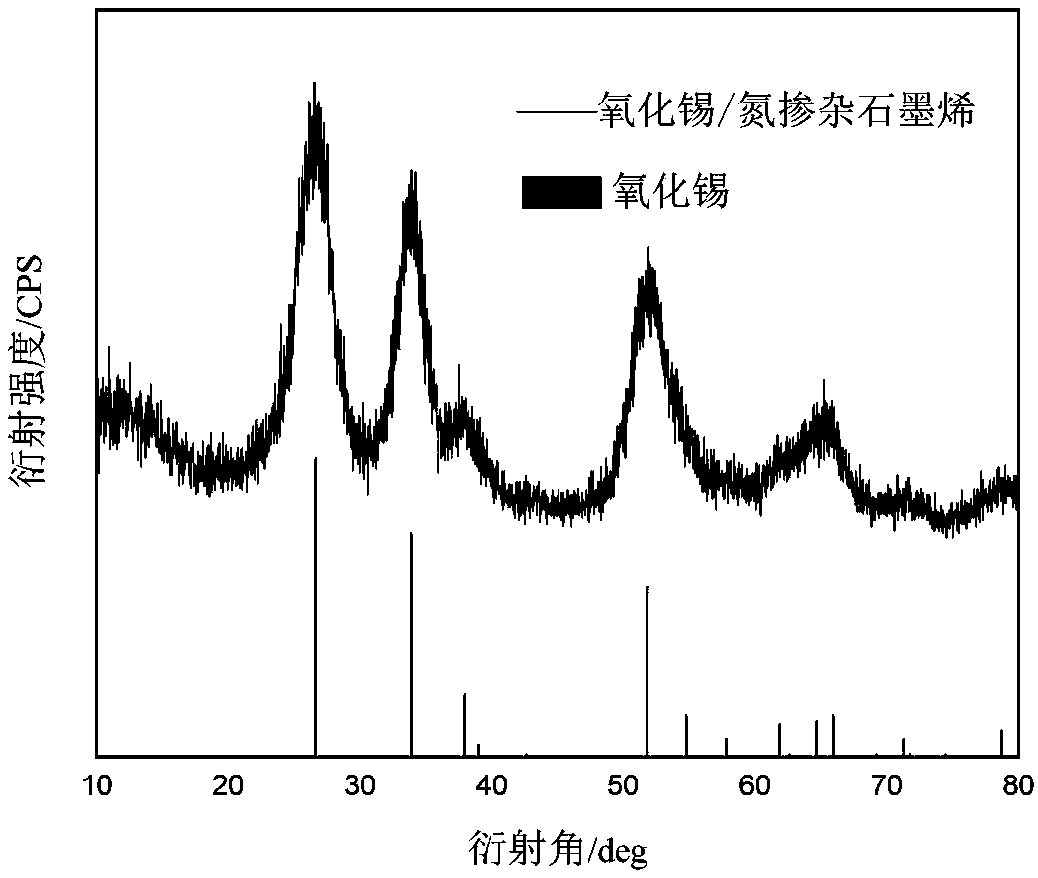

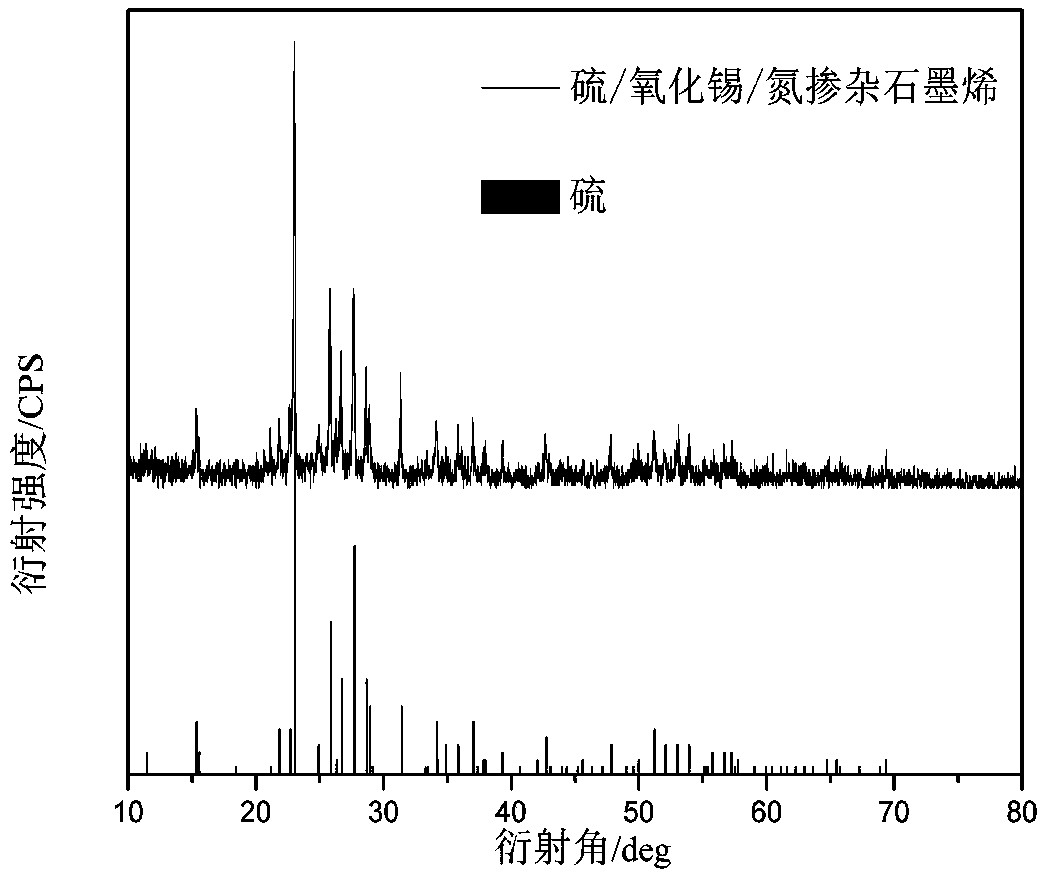

Sulfur/tin oxide/graphene battery cathode material, preparation method and lithium sulfur battery

InactiveCN109119616ALarge specific surface areaIncrease loadMaterial nanotechnologyCell electrodesNitrogen doped grapheneTin

The invention relates to the technical field of nanometer materials, in particular to a sulfur / tin oxide / graphene battery cathode material, a preparation method and a lithium sulfur battery. The invention discloses a preparation method of a sulfur / tin oxide / graphene battery cathode material, comprising the following steps: Step 1, nitrogen doped graphene and a tin salt solution are hydrothermallyreacted to obtain a graphene-tin oxide nano-composite material; and Step 2: the graphene-tin oxide nano-composite material and elemental sulfur are mixed to obtain a mixture, and a vacuum melting diffusion reaction is carried out on the mixture to obtain a sulfur / tin oxide / graphene battery cathode material. The invention also discloses a sulfur / tin oxide / graphene battery cathode material preparedby the method and a lithium sulfur battery thereof. The invention solves the technical problems that the elemental sulfur in the prior art cannot be effectively utilized in the cathode material of thelithium sulfur battery, thereby leading to short service life, and poor conductivity, cycle stability and safety performance of the lithium sulfur battery.

Owner:GUANGDONG UNIV OF TECH

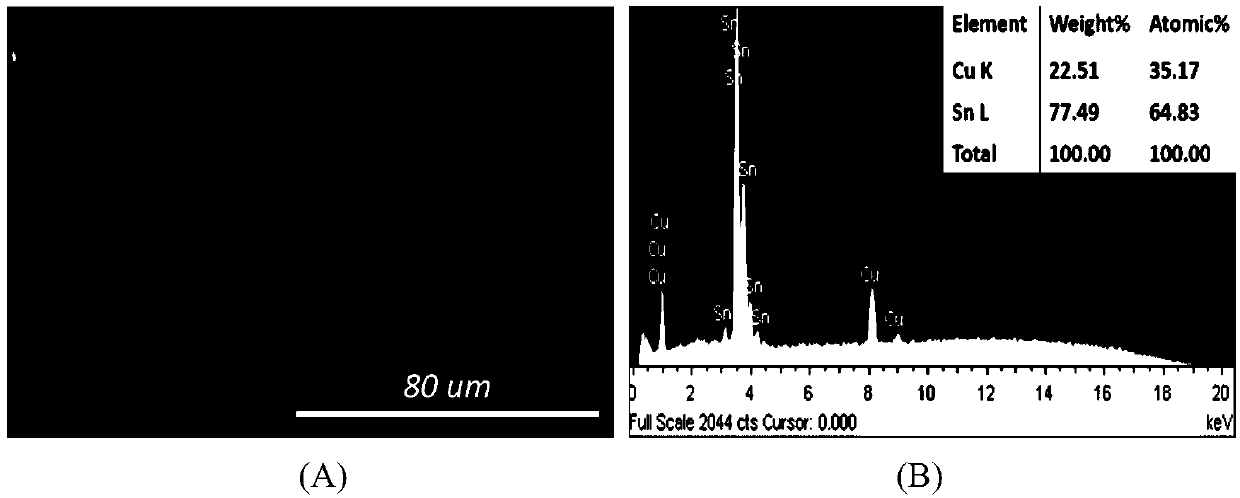

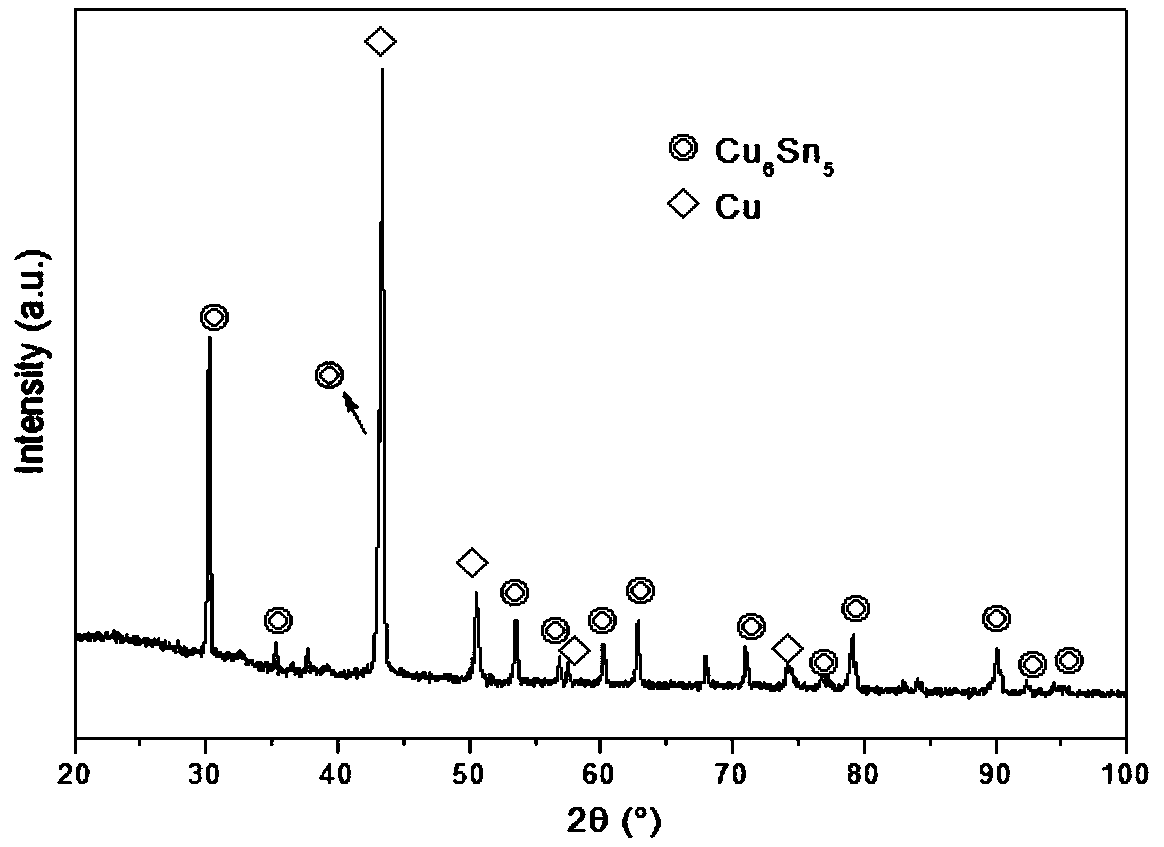

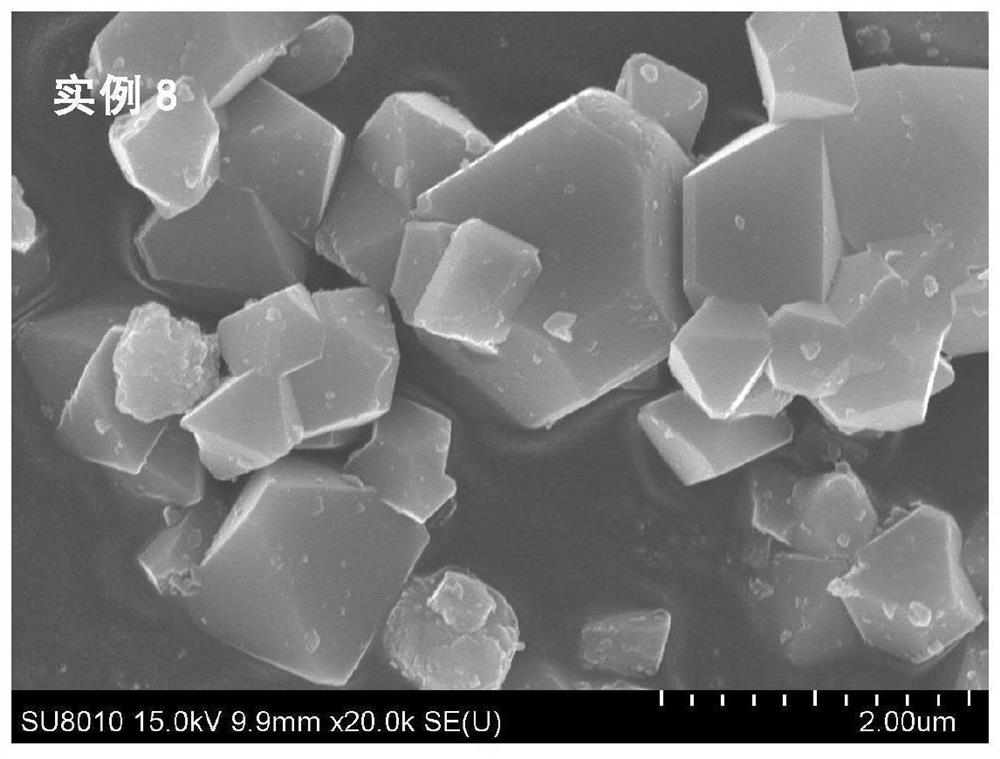

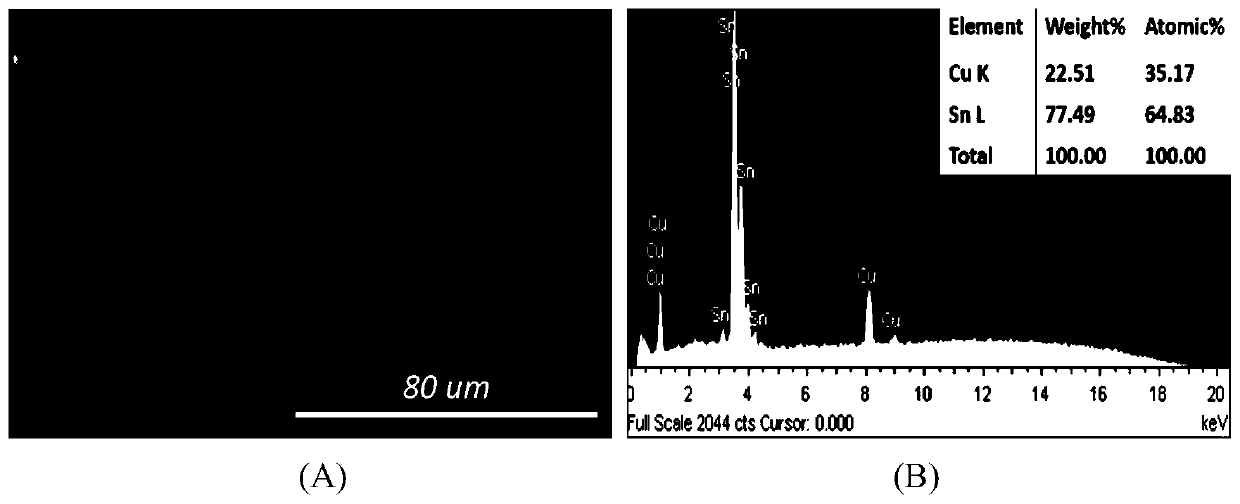

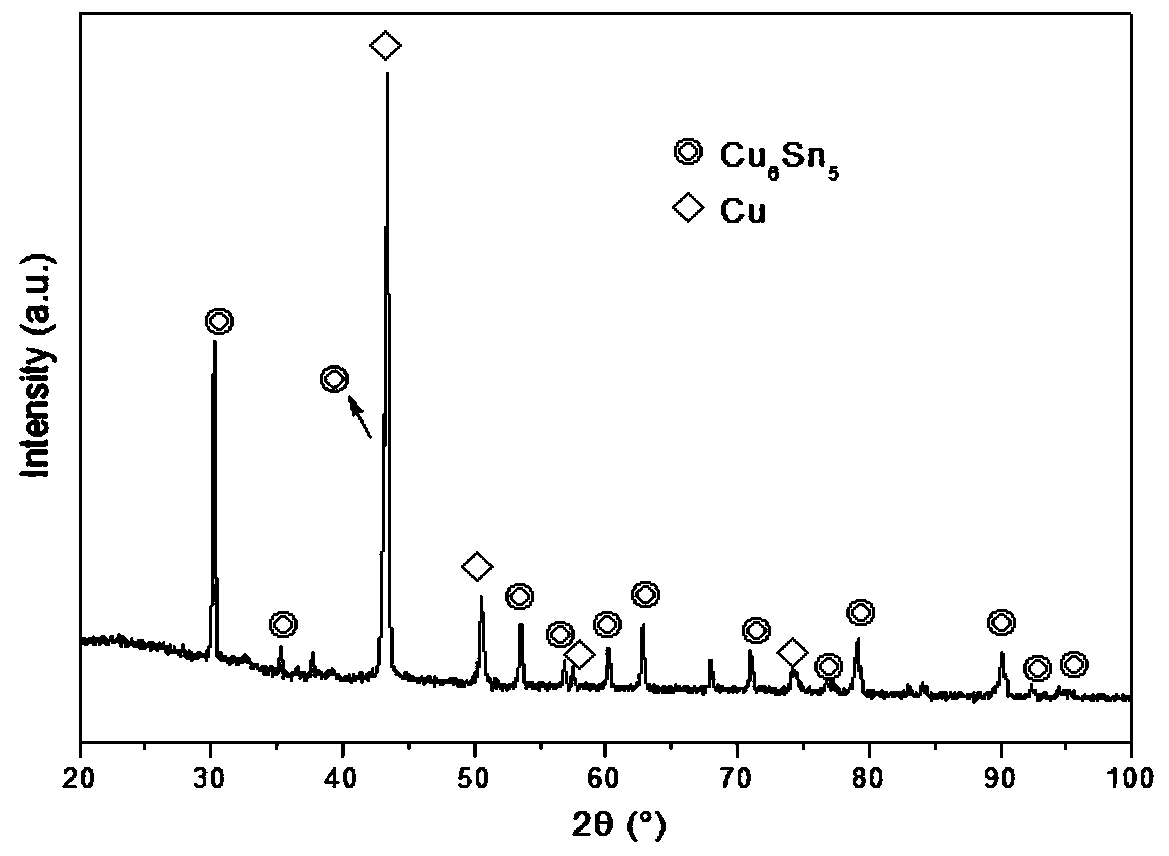

Copper tin alloy-based three-dimensional copper tin compound nanoparticle-microporous copper lithium ion battery cathode and one-step preparation method

ActiveCN109524620ARich nanoporous structureImprove cycle performanceMaterial nanotechnologyNegative electrodesMicro nanoNanoparticle

The invention provides a copper tin alloy-based three-dimensional copper tin compound nanoparticle-microporous copper lithium ion battery cathode and a one-step preparation method. The lithium ion battery cathode is composed of a three-dimensional microporous copper framework with porous walls / pore orientation and copper tin compound nanoparticles. The copper tin compound nanoparticles are Cu6Sn5nanoparticles or mixed particles of Cu6Sn5 nanoparticles and Cu3Sn nanoparticles. The copper tin compound nanoparticles are dispersed and embedded in pore structures of the three-dimensional microporous copper framework with porous walls / pore orientation to form a nanoporous structure so as to finally form a double continuous opened micro-nano graded porous structure. The lithium ion battery cathode provided by the invention can alleviate huge volume change generated in circular lithium embedding and removing processes of the tin cathode material, so that the cyclic performance of the tin cathode is improved.

Owner:SICHUAN UNIV

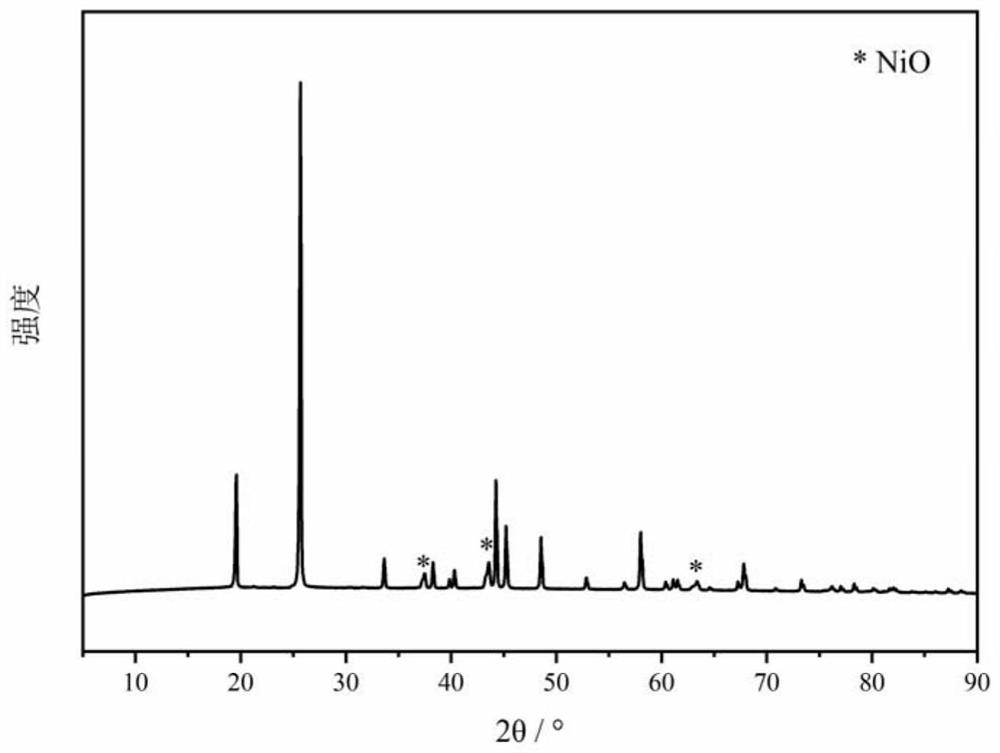

Positive additive and preparation method and application thereof

PendingCN111653770AImprove the first Coulombic efficiencyImprove charging capacitySecondary cellsPositive electrodesLithium-ion batteryBattery cell

The invention discloses a positive additive as well as a preparation method and application thereof. The chemical formula of the positive additive is Li2Ni1-xMxO2, wherein x is equal to 0-0.5, and when x is larger than 0, M is at least one of Co, Mn, Cu, Fe and Cr. The Li2Ni1-xMxO2 prepared by the preparation method disclosed by the invention has the characteristics of high charging capacity and low first effect; when the additive is added into the positive plate of the lithium ion battery, lithium can be removed before the positive electrode material in the battery formation process to replace the positive electrode material to provide lithium required to be consumed for forming an SEI film by a negative electrode, so that the initial coulombic efficiency of the battery is improved, and the cycle performance is improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Lithium battery composite positive electrode material and preparation method thereof, and lithium battery positive electrode

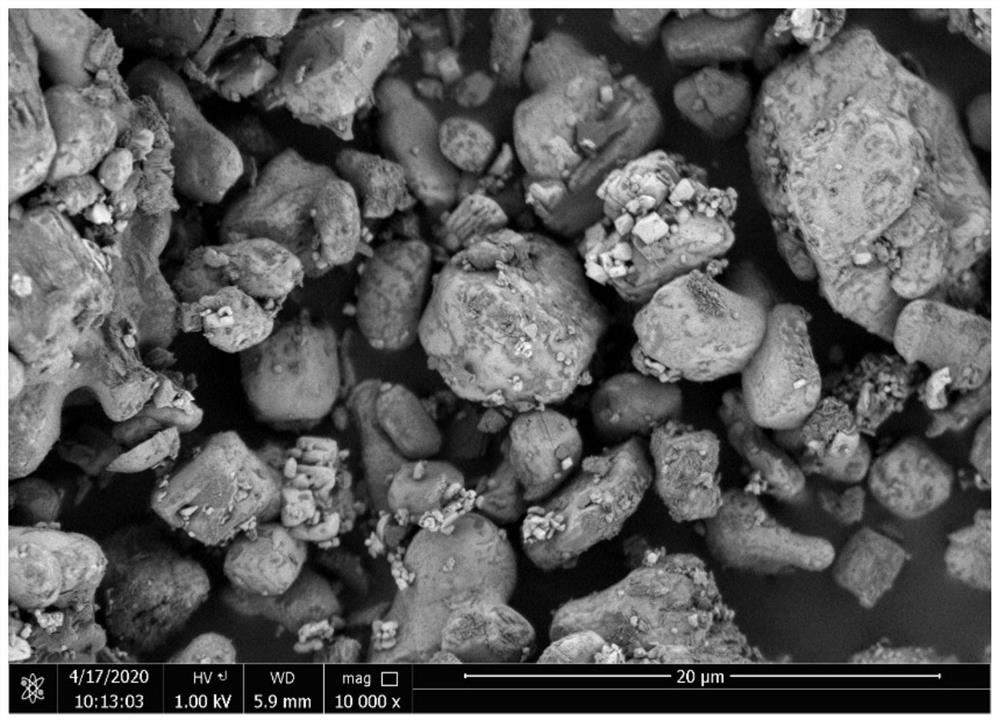

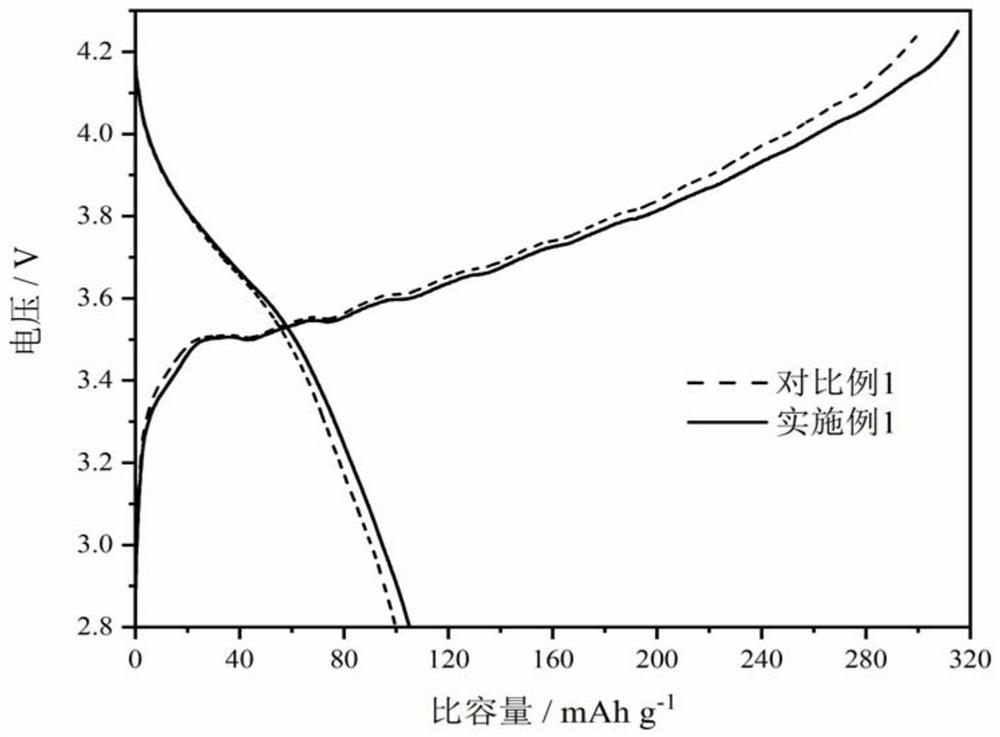

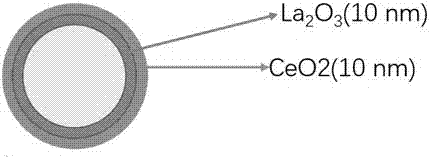

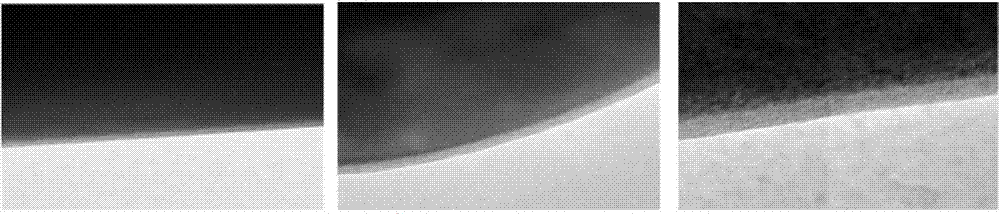

InactiveCN107887589APerformance impactImproved rate cycle performanceMaterial nanotechnologyCell electrodesOxide compositeLanthanum

The invention provides a lithium battery composite positive electrode material comprising positive electrode material particles using as central cores, wherein the central cores are covered with lanthanum trioxide coating layers, the lanthanum trioxide coating layers are coated with cerium oxide coating layers, and diameters of the central cores are 10nm-10microns. An atomic layer deposition method is used for depositing metallic oxide on carbon powder with high specific surface area, and the mass ratio of the thin metallic oxide to the carbon with high specific surface area is 70%-90%. The invention simultaneously provides a method of preparing the high specific surface area carbon / metallic oxide composite electrode material by using the atomic layer deposition method. The high specific surface area carbon / metallic oxide composite electrode material provided by the invention has the characteristic of high mass ratio, and the lithium ion battery prepared by the electrode material has high cycle life and high capacity stability.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN

A modified silicate aluminate additive for lithium sulfur battery electrolyte and a preparation method thereof

InactiveCN109167095AImprove capacity stabilityImprove long cycle performanceLi-accumulatorsSecondary cells servicing/maintenanceLithium sulfideSodium silicate

The invention provides a modified aluminosilicate additive for lithium sulfur battery electrolyte and a preparation method thereof, Y-type molecular sieve precursor was prepared by sodium meta-aluminate, sodium hydroxide and sodium silicate, then mesoporous silicate aluminate was obtained by surfactant and acid-base crystallization, finally mesoporous silicate aluminate was modified by organic lithium salt to make organic lithium source enter mesoporous silicate aluminate pores, and mesoporous silicate aluminate particles loaded with lithium were obtained. The additive prepared by the invention has stable structure, Through the adsorption of modified mesoporous aluminosilicate on polysulfide in electrolyte, The polysulfide is immobilized in the solid particles, which effectively solves theproblem that the electrolyte of the existing lithium sulfide battery is difficult to control the dissolution of lithium polysulfide for a long time, inhibits the polysulfide from passing through theelectrolyte through the separator, thereby keeping the negative electrode material from being corroded, improving the capacity stability of the battery, and improving the long-cycle performance of thebattery.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

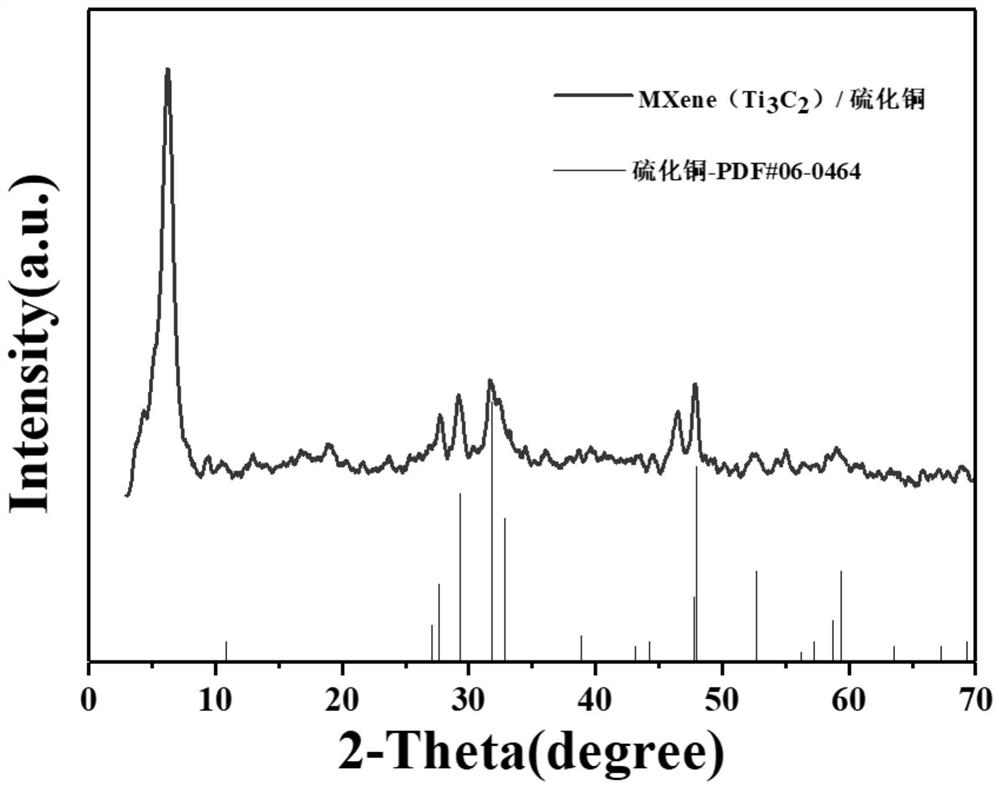

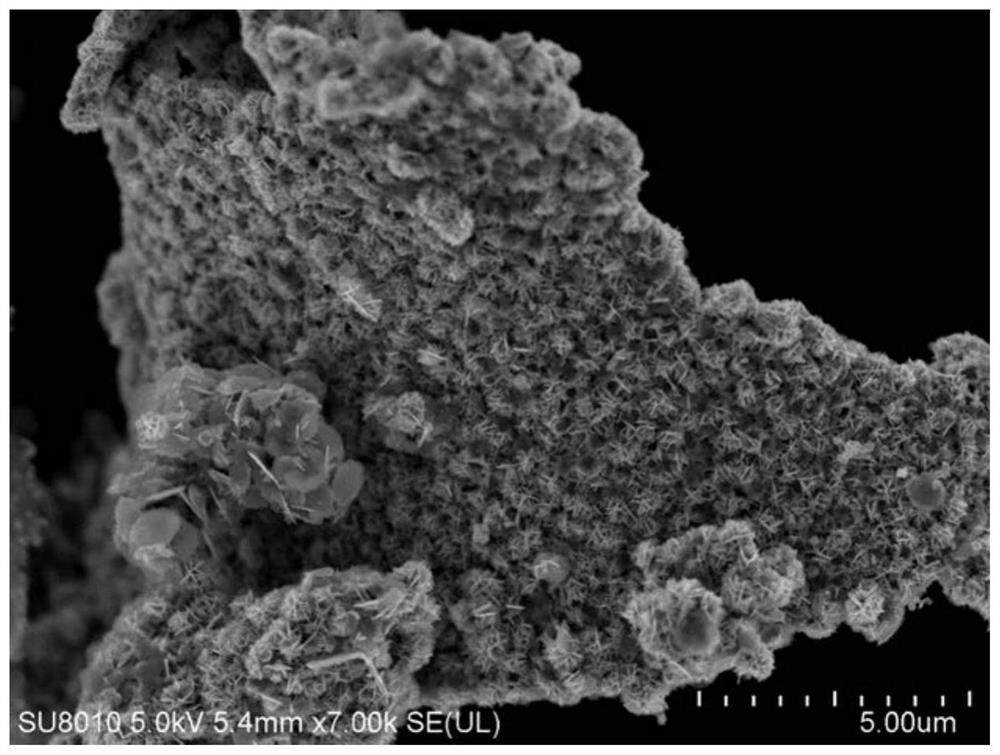

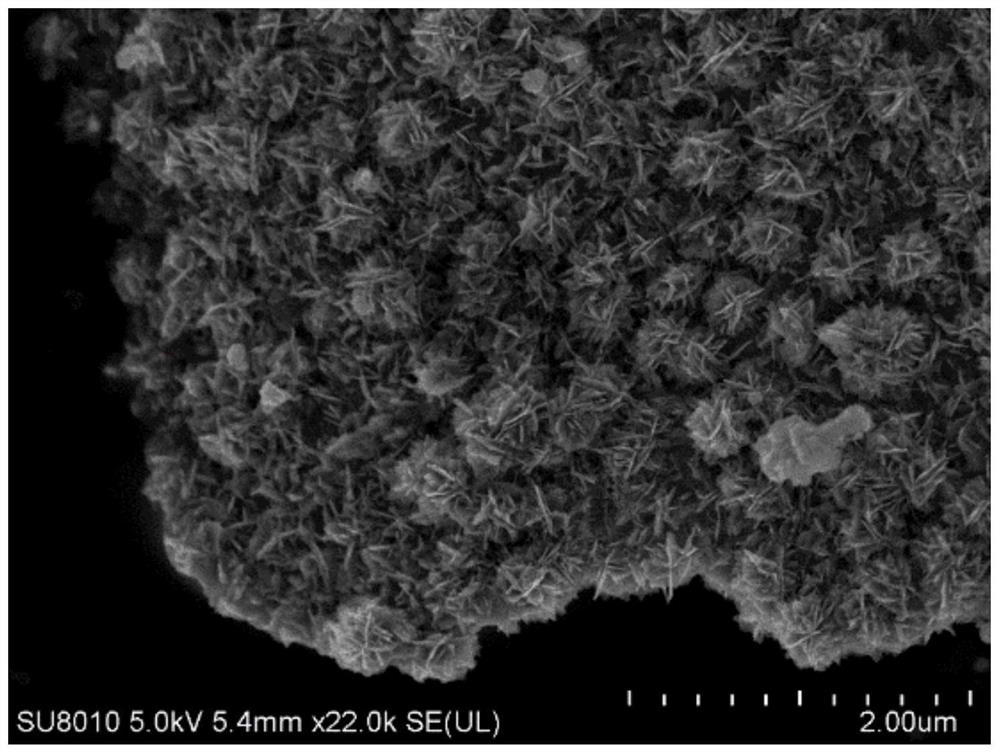

Sulfur/copper sulfide/MXene positive electrode material and preparation method and application thereof

InactiveCN111900404ASmall cluster sizeEffectively fixedMaterial nanotechnologyPositive electrodesElectrical batteryLithium–sulfur battery

The invention relates to a sulfur / copper sulfide / MXene positive electrode material and a preparation method and application thereof. The preparation method comprises the following steps: dispersing MXene, copper salt and a sulfur source in a solvent to obtain a mixed solution; placing the mixed solution in a closed pressure system, and carrying out solvothermal reaction at 100-180 DEG C for 18-24hours to prepare a copper sulfide / MXene nano composite material; mixing the copper sulphide / MXene nano composite material with elemental sulfur, grinding, and standing at 155-180 DEG C for 10-18 hoursto prepare a sulfur / copper sulphide / MXene positive electrode material; and the MXene is Ti3C2. The positive electrode material prepared by the method can improve the electrochemical performance of the lithium-sulfur battery.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

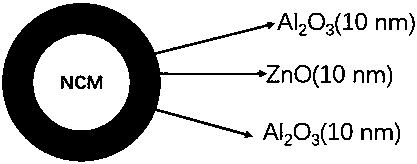

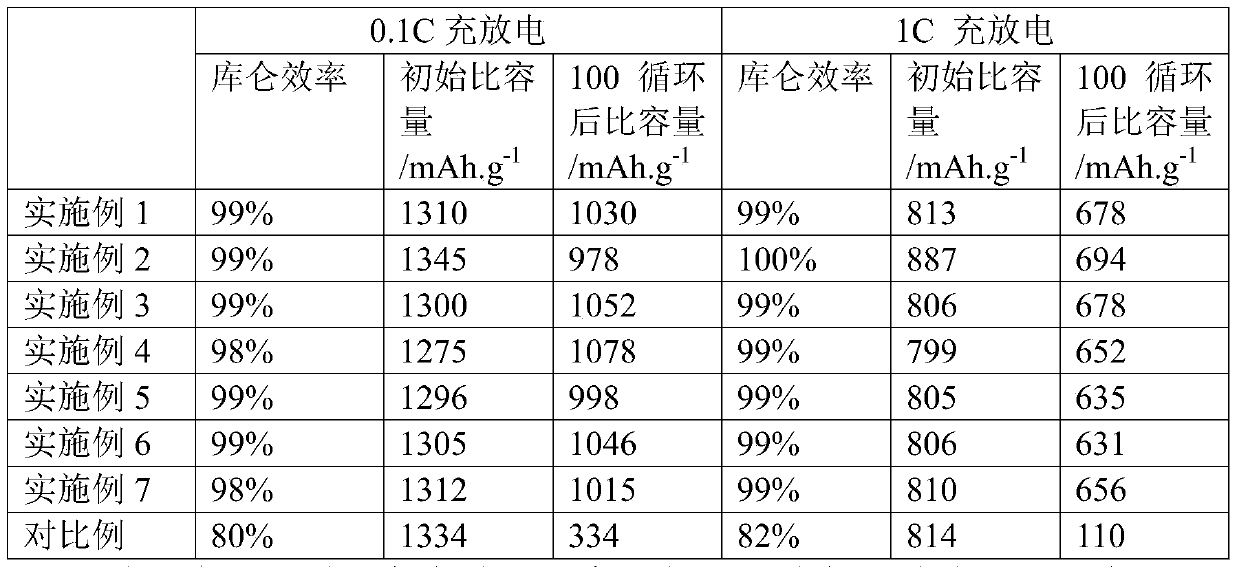

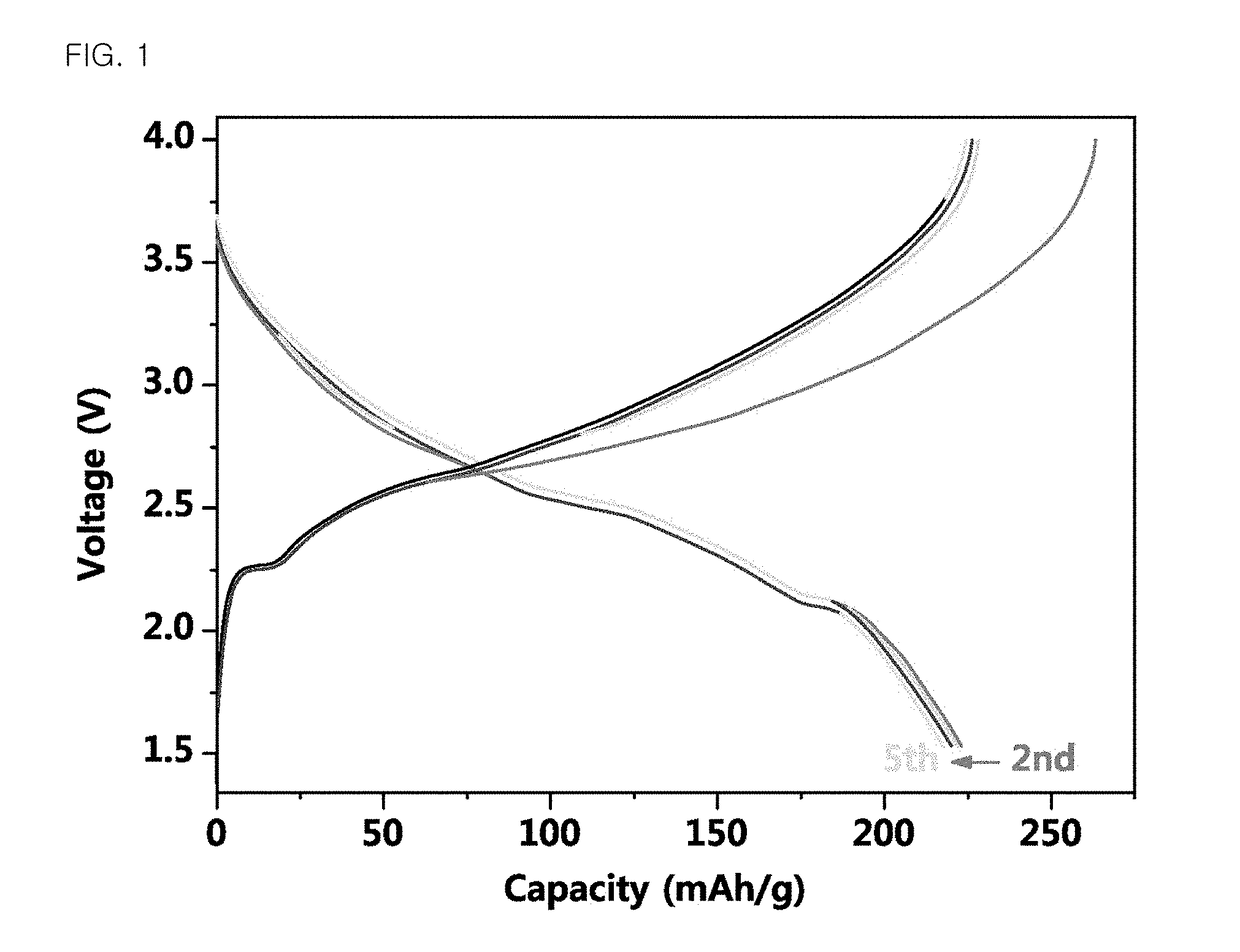

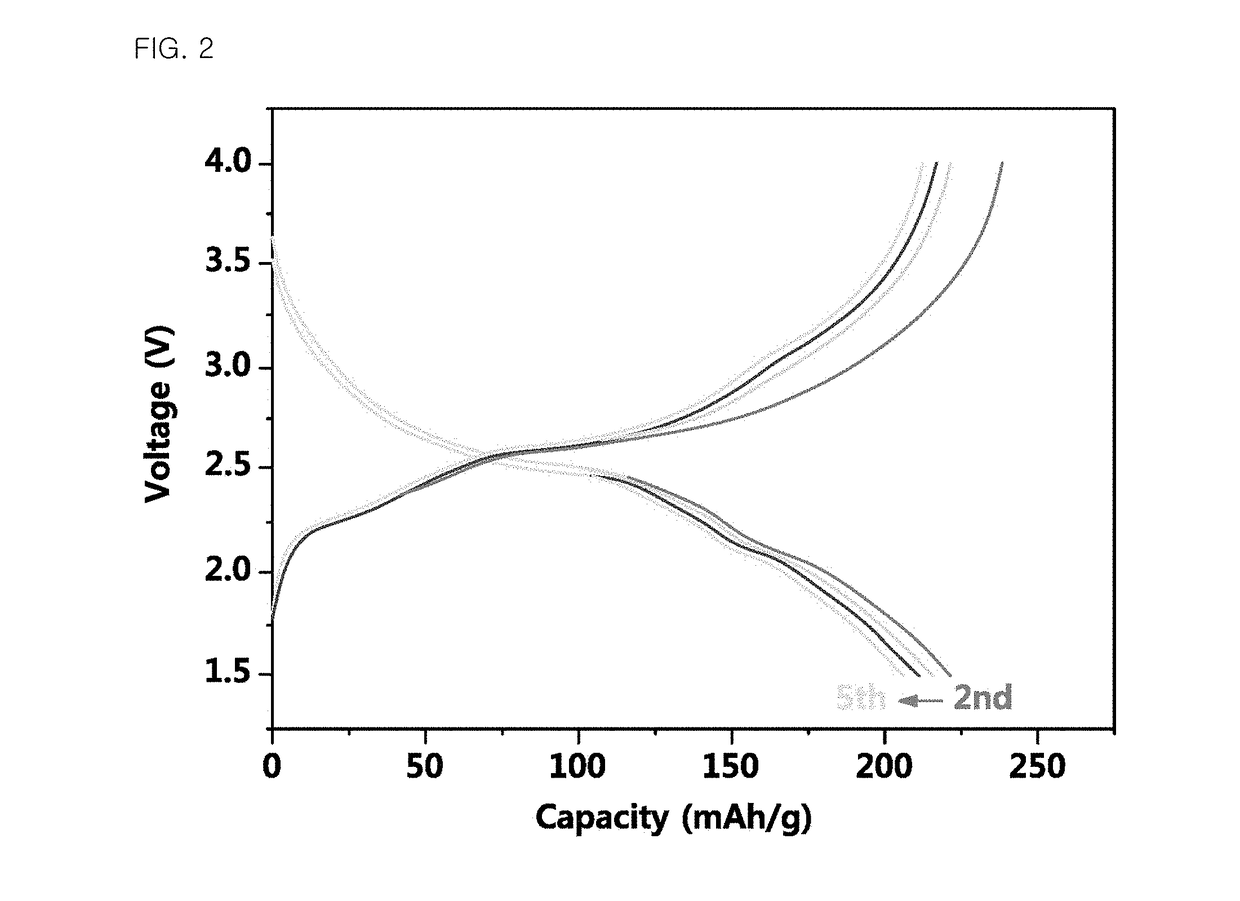

Sandwich type composite positive electrode material of lithium battery, preparation method thereof, and lithium battery positive electrode

InactiveCN107910518AImprove cycle lifeImprove capacity stabilityPhosphatesCell electrodesOxide compositeLithium-ion battery

The invention provides a sandwich type composite positive electrode material of a lithium battery. The sandwich type composite positive electrode material comprises positive electrode material particles, the positive electrode material particles form a central core, three coating layers are located at the outside of the central core, which are sequentially an inner aluminum oxide layer, a zinc oxide layer and an outer aluminum oxide layer from inside to outside, and the diameter of the central core is 10nm to 10microns. A metal oxide is deposited on carbon powder with a high specific surface area by using an atomic layer deposition method, and the mass ratio of the thin metal oxide to carbon with high specific surface area is 70-90%. The invention further provides a method for preparing the carbon with high specific surface area / metal oxide composite positive electrode material by using the atomic layer deposition method, and a method for preparing an electrode by using the carbon withhigh specific surface area / metal oxide composite positive electrode material. The carbon with high specific surface area / metal oxide composite positive electrode material provided by the invention has the characteristics of high mass ratio, and the lithium ion battery prepared by the electrode material has a high cycle life and high capacity stability.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN

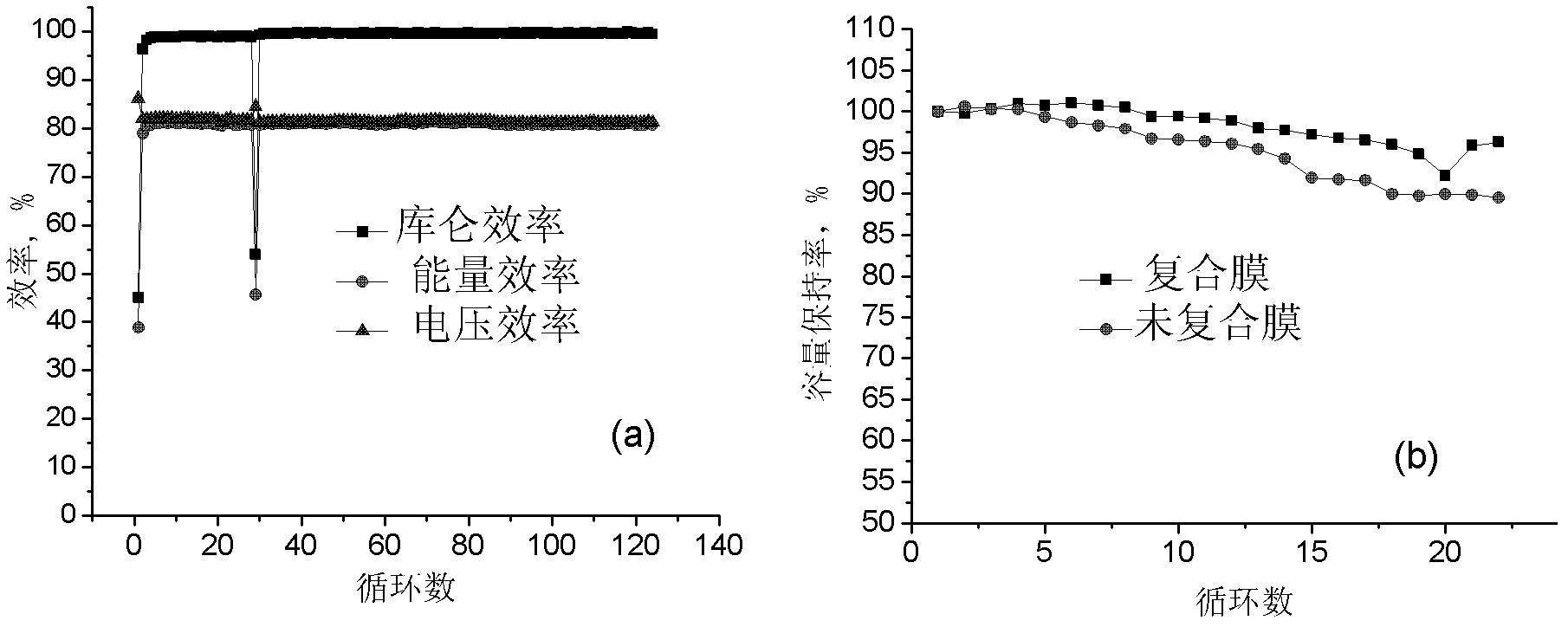

Composite film for lithium-sulfur battery

A composite film for a lithium-sulfur battery is composed of: one or more than two polymers having film-forming property, and one or more than two salts containing nitrate. The mass percentage of the salts containing nitrate in the composite film is 0.1-90%. Because the film is rich in nitrate, better utilization on the nitrate in the composite film can be achieved and further quick uncontrollable consumption of the nitrate is avoided, thereby delaying consumption of the nitrate and further increasing capacity retention ratio of the battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Graphene-Vanadium Oxide Nanowire, Method for Preparation Thereof, Positive Active Material Comprising the Same and Lithium Battery Comprising the Positive Active Material

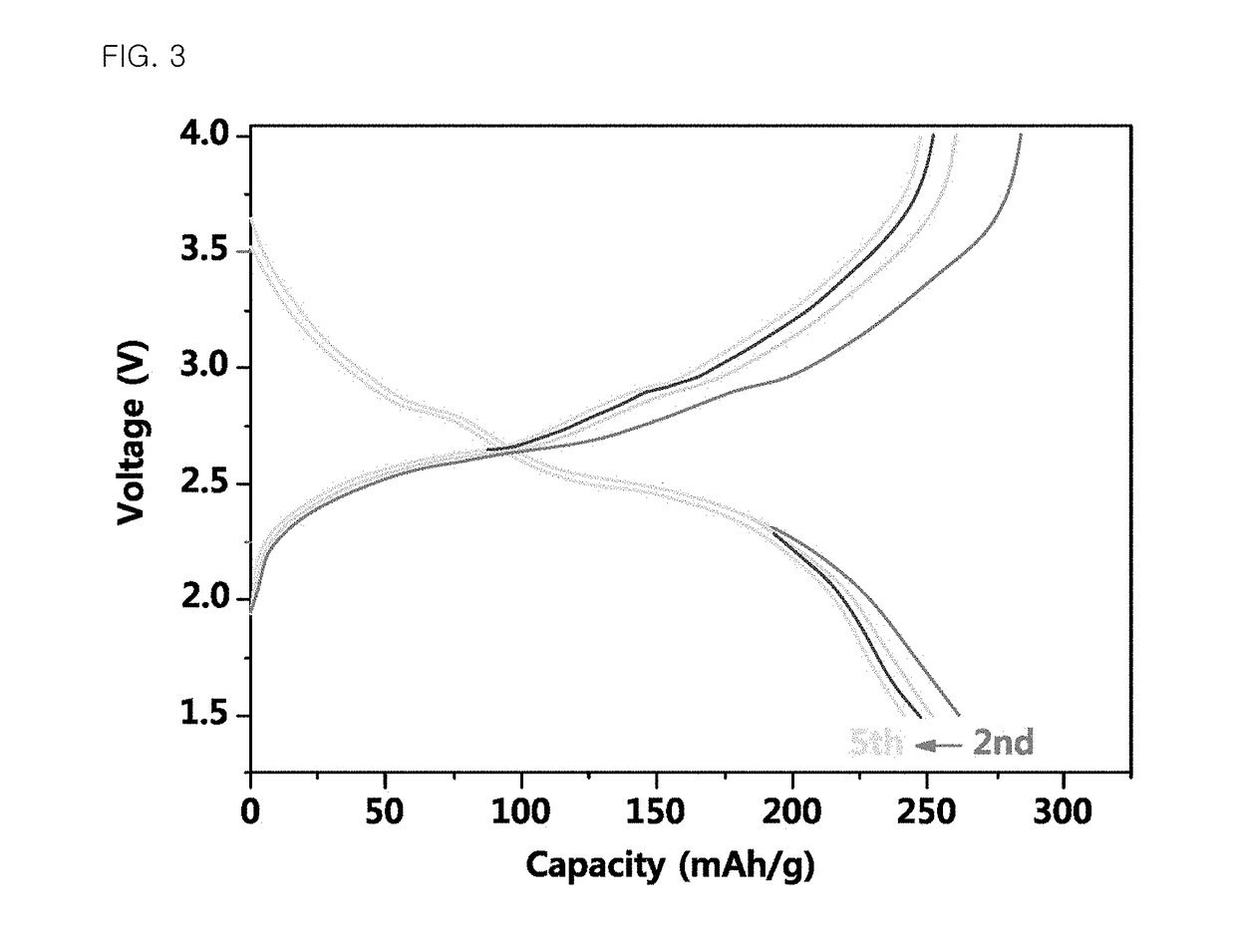

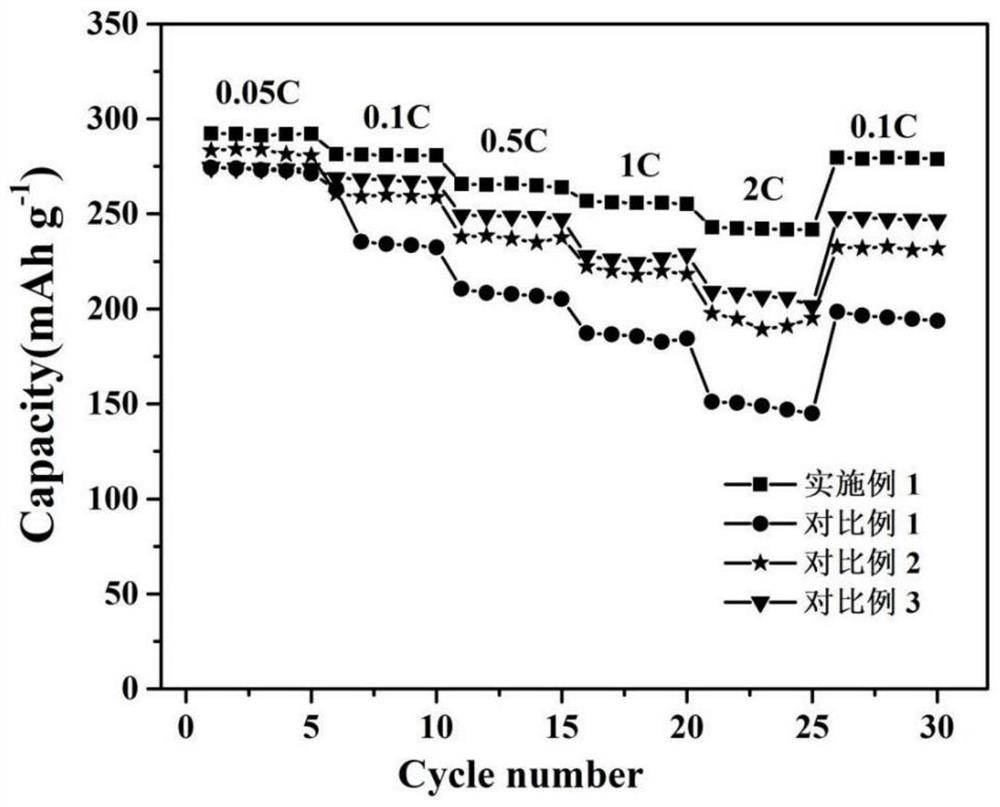

InactiveUS20180175385A1Improve capacity stabilityExcellent cycle characteristicsFinal product manufactureCell electrodesNanowireGraphene

The present disclosure is directed to a graphene-vanadium oxide nanowire including a nanowire core including vanadium oxide and a shell formed on the surface of the nanowire core and including graphene oxide. The graphene-vanadium oxide nanowire having improved capacity stability can be provided by using the graphene-vanadium oxide nanowire according to the present disclosure, the method for preparing the same, and a positive active material and a secondary battery including the same. In addition, by using the graphene-vanadium oxide nanowire according to the present disclosure as a positive active material, it is possible to provide a secondary battery having improved cycle characteristics and capacity retention rates.

Owner:KOREA BASIC SCI INST

Lithium battery cell composite coated positive electrode material, preparation method thereof, and lithium ion battery

PendingCN111606361AImprove securityImprove capacity stabilityCell electrodesSecondary cells servicing/maintenanceComposite materialLithium electrode

Owner:WUHU ETC BATTERY LTD

Preparation method for lithium ion battery negative electrode material

InactiveCN107611366AIncrease capacityImprove structural stabilityCell electrodesSecondary cellsPowder mixtureCarbonization

The invention relates to a preparation method for a lithium ion battery negative electrode material, and belongs to the technical field of a lithium ion battery. The preparation method comprises the steps of taking and placing silicate glass in a ball-milling tank, adding a sodium chloride solution for ball-milling, and sieving to obtain silicate glass powder; taking and placing Arabic gum and tragacanth gum in the ball-milling tank for ball-milling, and sieving to obtain tragacanth gum and Arabic gun mixture power; mixing the silicate glass ball-milling powder, the Arabic gum and the tragacanth gum, adding zinc powder, and performing stirring to obtain a colloid powder mixture; filling the colloid powder mixture in a die, performing pressing and pressure preservation, placing the die in abaking box, and performing standing and cooling to a room temperature after thermal curing to obtain a cured material; and placing the cured material in a tubular atmosphere furnace, introducing nitrogen to remove air, controlling a temperature, performing heat preservation and carbonization, and performing standing and cooling to the room temperature, thereby obtaining a silicon carbon compositenegative electrode material. The obtained negative electrode material has good rate performance, high capacity and good conductivity, and the application of the silicon negative electrode material isexpanded by electrical contact.

Owner:宁夏西墨新材料科技有限公司

A kind of preparation method of graphene-lithium battery cathode composite material

InactiveCN103500826BIncrease volume capacityImprove fade resistanceCell electrodesLi-accumulatorsMass ratioHydrogen-Ion Concentrations

The invention discloses a preparation method of a positive composite material of a graphene-lithium battery. The preparation method comprises the following steps of (1) performing coprecipitation-loading on graphene, a graphene precursor, graphene powder or graphene dispersion and a positive material of a lithium battery, namely adding the graphene, the graphene precursor, the graphene powder or the graphene dispersion and the positive material of the lithium battery in the mass ratio of 1:8 to 1:100 into a solvent to keep the concentration at 1-120 g / L, then adding auxiliaries which is 1-10 mass percent of the grapheme, adjusting the hydrogen ion concentration to be 1.0*10<-5> to 1.0*10<2> mol / L through a pH value adjustment agent, and mixing at the temperature of 10-80 DEG C for 1-96 hours to obtain a loaded product; (2) performing centrifugal separation on the loaded product, wherein one product is a solid sample; (3) roasting the separated solid sample at the temperature of 400-700 DEG C for 0.5-4 hours, and performing activation to obtain the positive composite material of the graphene-lithium battery. The preparation method disclosed by the invention has the beneficial effects that the volume specific capacity and the attenuation resistance are improved, the cycle life is long, and the capacity stability is high.

Owner:LUXI GRP

Graphene-based positive electrode material and preparation method thereof and lithium-sulfur battery

ActiveCN111900405AReduce contentMaintain electrode structureMaterial nanotechnologyPositive electrodesElectrical batteryLithium sulfur

The invention relates to a graphene-based positive electrode material and a preparation method thereof and a lithium-sulfur battery. The preparation method of the graphene-based positive electrode material comprises the following steps: dispersing an MXene / graphene composite material, a copper salt and a sulfur source in a solvent to obtain a first mixed solution; putting the first mixed solutioninto a closed pressure system, and carrying out solvothermal reaction at 100-180 DEG C for 18-24 hours to prepare a copper sulfide / MXene / graphene nano composite material; mixing the copper sulfide / MXene / graphene nano composite material with elemental sulfur, performing grinding, and performing standing at 155-180 DEG C for 10-18 hours to prepare a graphene-based positive electrode material; and the MXene is Ti<3>C<2>. The positive electrode material prepared by adopting the method can improve the electrochemical performance of the lithium-sulfur battery.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

High-capacity low-voltage chip-type laminated aluminum capacitor and preparation method thereof

PendingCN114709081AImprove withstand voltage performanceImprove reliabilityLiquid electrolytic capacitorsCapacitor terminalsCapacitanceAluminum foil

The invention discloses a high-capacity low-voltage chip-type laminated aluminum capacitor and a preparation method thereof, and belongs to the technical field of capacitors, the high-capacity low-voltage chip-type laminated aluminum capacitor comprises a shell, a plurality of cathode waterproof shells are arranged in the shell, silver-containing cathode layers are arranged on the inner sides of the cathode waterproof shells, carbon-containing cathode layers are arranged on the inner sides of the silver-containing cathode layers, and the carbon-containing cathode layers are arranged on the inner sides of the carbon-containing cathode layers. An electrolyte layer is arranged on the inner side of the carbon-containing cathode layer, an aluminum foil body is arranged on the inner side of the electrolyte layer, a positive electrode gasket is fixedly installed in the shell and makes contact with the aluminum foil body, a positive electrode leading-out terminal is arranged on the surface of the positive electrode gasket, one end of the positive electrode leading-out terminal makes contact with the positive electrode gasket, and the other end of the positive electrode leading-out terminal makes contact with the aluminum foil body. And the other end of the positive electrode leading-out terminal extends to the outer side of the positive electrode leading-out terminal, and a negative electrode leading-out terminal is arranged in the shell. On the basis of realizing large capacitance of the capacitor, the capacitor can bear high temperature, and the liquid leakage probability is reduced.

Owner:南通飞泰电子科技有限公司

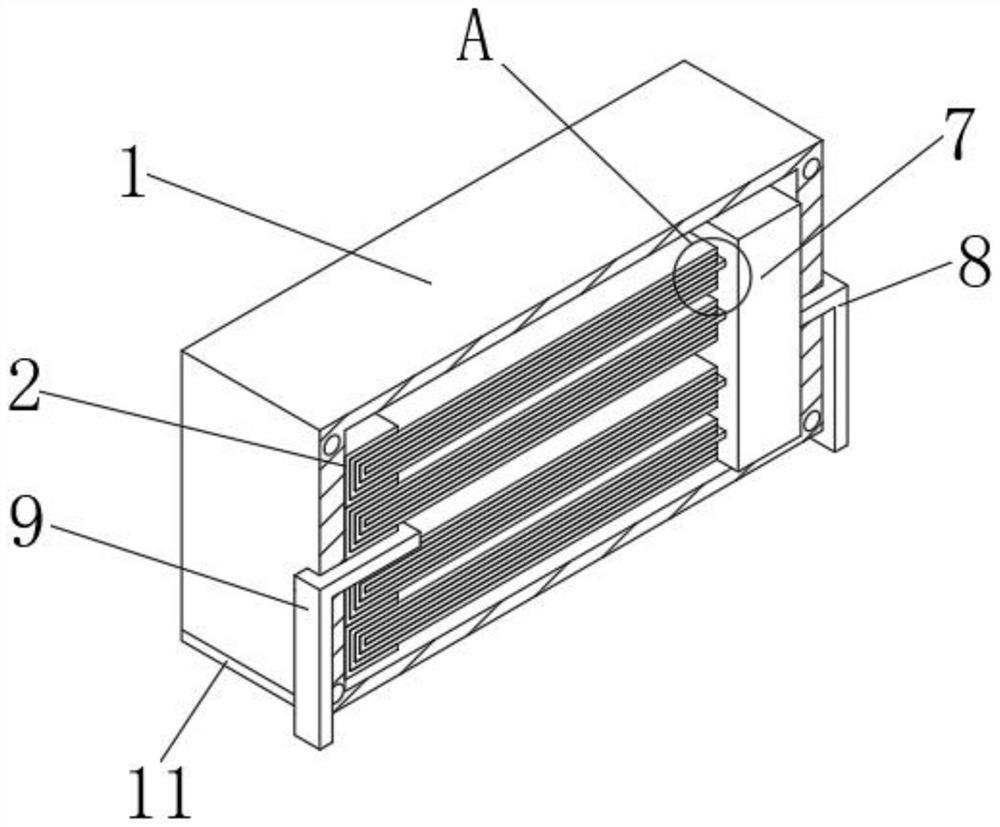

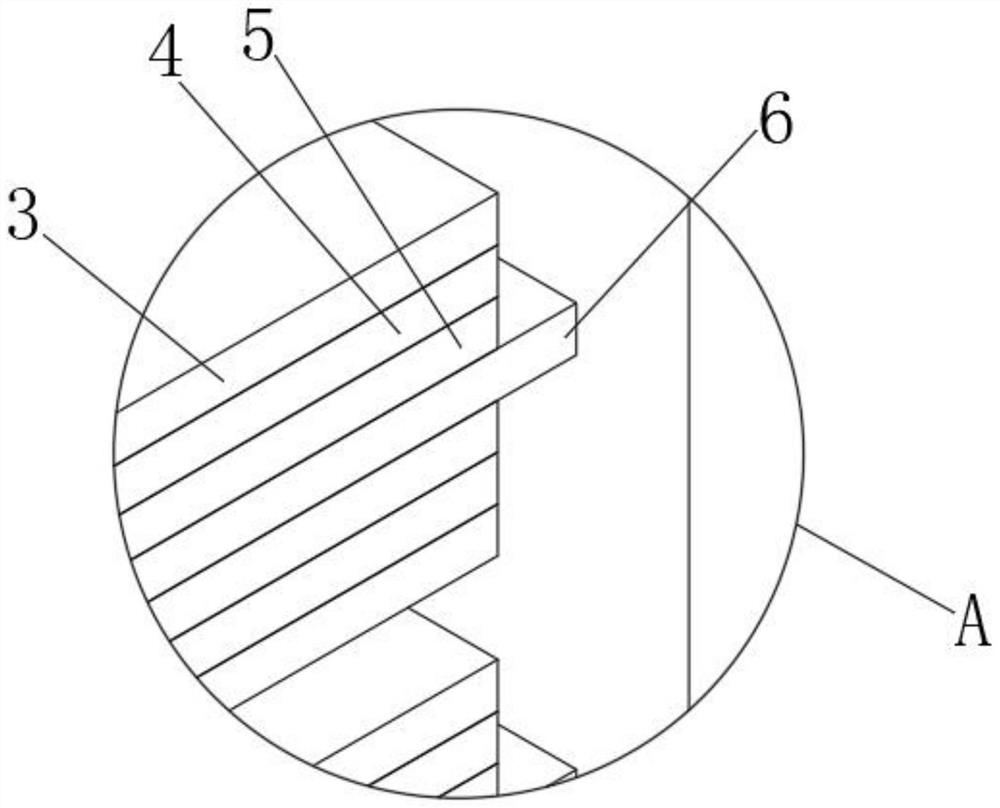

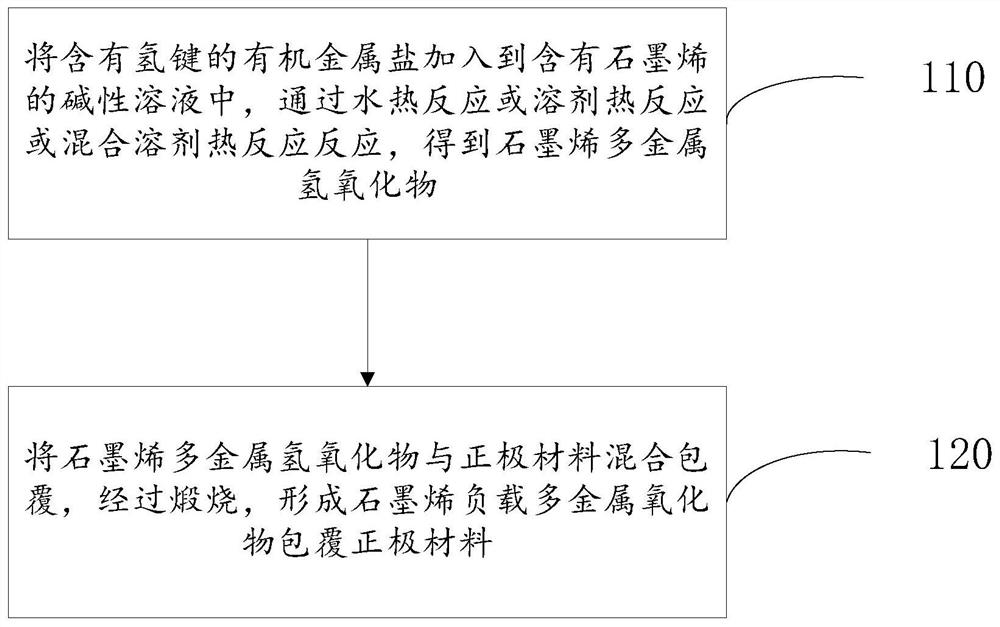

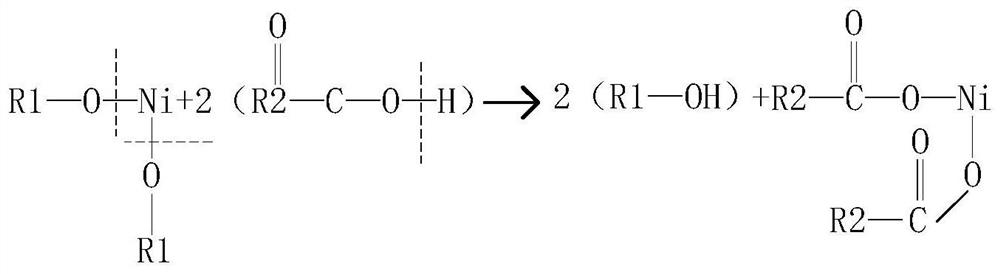

Graphene-loaded multi-metal oxide-coated positive electrode material as well as preparation method and application thereof

ActiveCN112624211AImprove conductivityImproved magnification performanceCarbon compoundsCell electrodesEthyl acetateN-Butyl Alcohol

The invention relates to a graphene-loaded multi-metal oxide-coated positive electrode material as well as a preparation method and application thereof. The preparation method comprises the steps that organic metal salt containing hydrogen bonds is added into an alkaline solution containing graphene, and graphene multi-metal hydroxide is obtained through a hydrothermal reaction or a solvothermal reaction or a mixed solvothermal reaction, wherein the organic metal salt specifically comprises at least two of a nickel source, a cobalt source, a manganese source, an aluminum source, an iron source and a magnesium source, the solvent of the hydrothermal reaction is water, a solvent of the solvothermal reaction comprises one or more of methanol, dimethylformamide, ethanol, acetonitrile, acetone, ethyl acetate, isopropanol, tetrahydrofuran, propanol, n-butyl alcohol, n-propanol and isopropanol, and a mixed solvent in the mixed solvothermal reaction comprises water and the solvent, and the volume ratio of the water to the solvent is 1:0.5 to 1:3; and the graphene multi-metal hydroxide and a positive electrode material are mixed for coating, and calcining is conducted to form the graphene-loaded multi-metal oxide-coated positive electrode material.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

High-capacity metallized polyester film direct current capacitor

InactiveCN103680942AExtended service lifeWear-resistantFixed capacitor electrodesFixed capacitor dielectricDielectricPolyester

The invention discloses a high-capacity metallized polyester film direct current capacitor, which includes a high-temperature-resistant and flame-retardant shell, two wires and a capacitor core. The capacitor core is packaged in the high-temperature-resistant and flame-retardant shell; the capacitor core is formed by winding of a two-sided metallized film which is used as a dielectric and an electrode; the two-sided metallized film includes a polyester film and a metal zinc layer which is respectively evaporated on upper and lower surfaces of the polyester film; each wire uses a tin-coated copper-clad steel wire; and the high-temperature-resistant and flame-retardant shell adopts a high-temperature-resistant ABS plastic. With the above method, the capacitor has the characteristics of large capacity, excellent electrical performance, good reliability, high temperature resistance, small volume and good self-healing performance.

Owner:张家港市星河电子有限公司

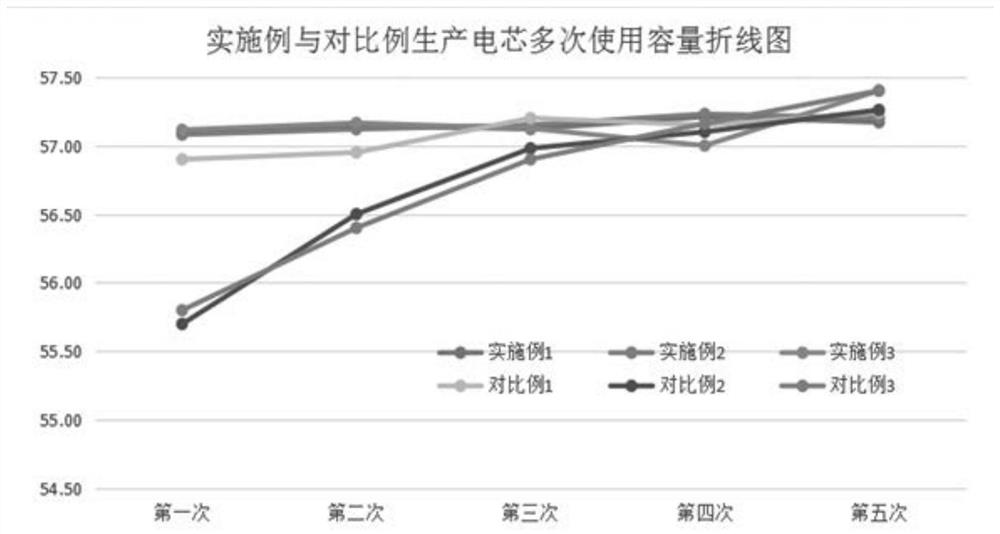

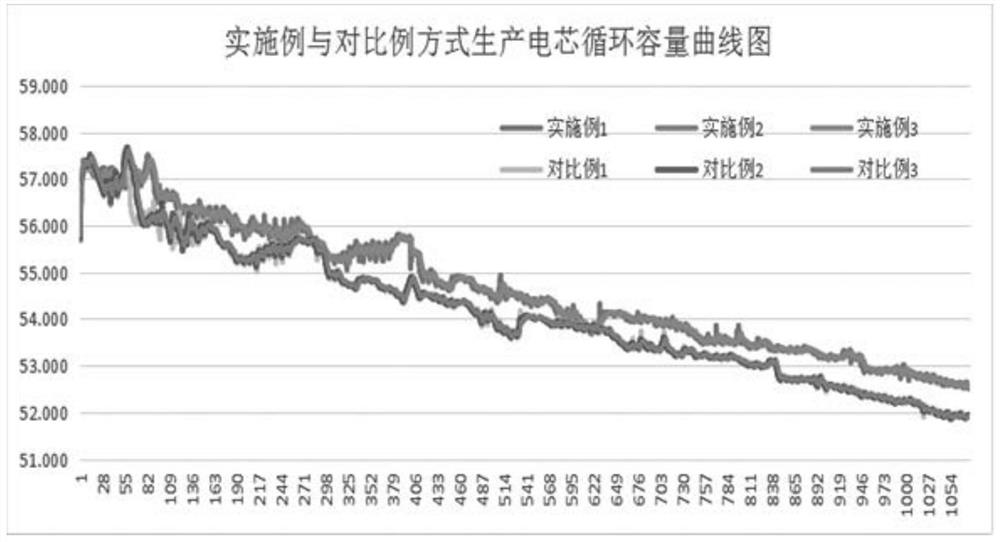

Aging and capacity grading method for lithium ion battery

ActiveCN112820964AImprove capacity stabilityGuaranteed compactnessElectrical testingSecondary cells charging/dischargingPhysical chemistryEngineering

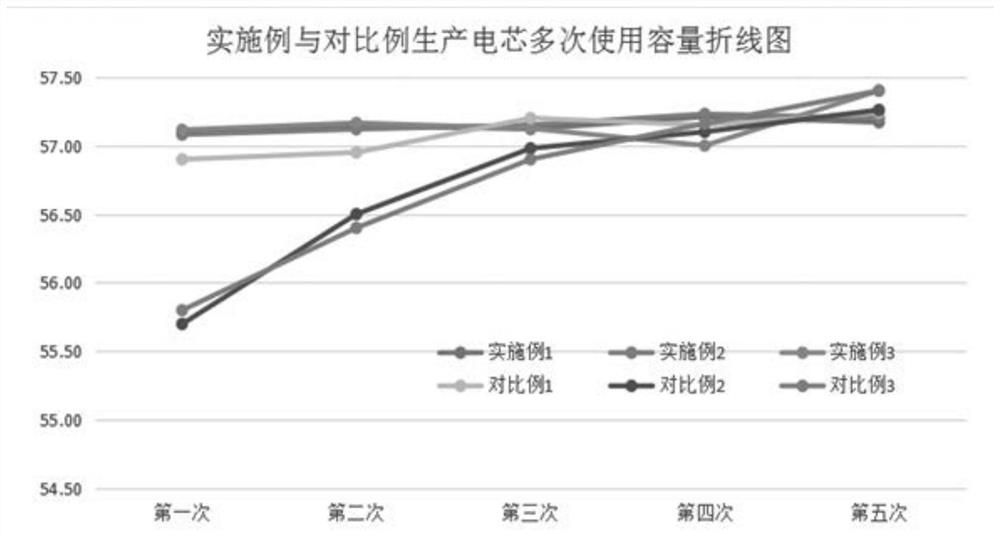

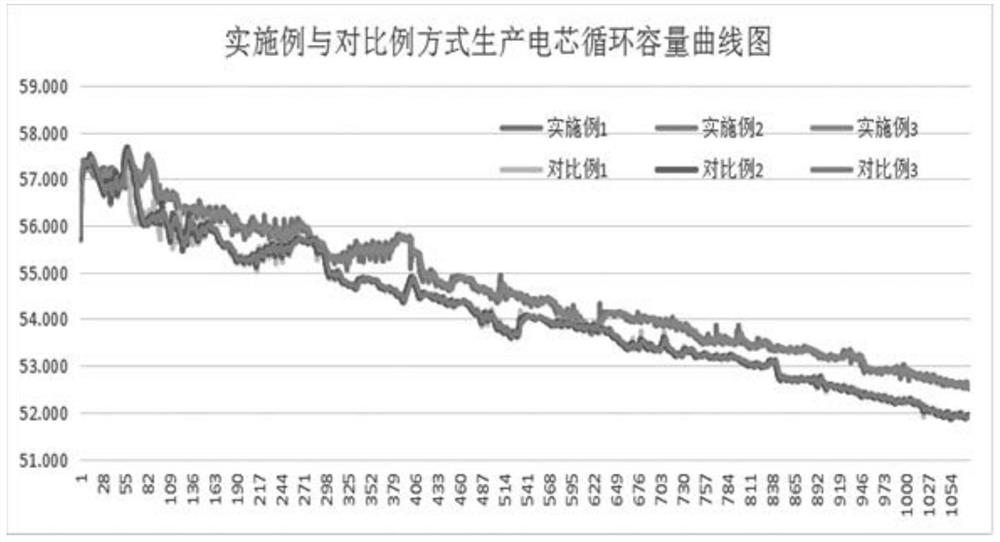

The invention discloses an aging and capacity grading method for a lithium ion battery. The method comprises the following steps: performing high-temperature aging on a to-be-aged battery for 18-24 hours after liquid injection and sealing; performing charging at 1C to 3.65 V, and performing aging at high temperature for 18-24 hours; performing discharging at constant current of 1C for 5-10 minutes; performing charging to 3.65 V at a constant current and a constant voltage of 1C and a cut-off current of 0.2 C; performing discharging to 1.85 V to 2V at a constant current of 1C; performing charging to 3.65 V at a constant current and a constant voltage of 1C and a cut-off current of 0.2 C; performing discharging at a constant current of 1C to 2V-2.5 V; discharging the gradient small current to 2V; and performing charging for 30 minutes at a constant current of 0.2 C. According to the method, the compactness of an SEI film of a battery cell is ensured by adopting a low-voltage aging mode and a high-voltage aging mode, and then the activity of a battery material is activated by adopting a shallow discharging, deep charging and deep discharging mode during capacity grading, so that the difference between the first capacity grading discharging capacity and the subsequent use capacity is small; meanwhile, the battery capacity stability is obviously superior to that of a battery prepared by an original capacity grading process in the aspect of long-term circulation.

Owner:江西安驰新能源科技有限公司

A kind of sulfur/vanadium disulfide/mxene composite material and its preparation method and application

ActiveCN111816858BUniform particlesUniform particle sizeMaterial nanotechnologyCell electrodesElectrolytic agentVanadium disulfide

The invention relates to the technical field of battery materials, in particular to a sulfur / vanadium disulfide / MXene composite material and a preparation method and application thereof. In the preparation method disclosed in the present invention, the high specific surface area and a large number of active sites of the sulfur-loading material MXene can increase the loading capacity of sulfur; MXene has unique flexibility and good conductivity, so it can buffer the volume change of the positive electrode material And improve the conductivity of the composite material; MXene surface has a large number of functional groups and static electricity can attract vanadate ions and then undergo coordination, so that vanadate ions are evenly adsorbed on the surface of MXene, and the vanadate ions and sulfur source are formed at an appropriate temperature Uniform vanadium disulfide nanosheets are generated in situ on the surface of MXene, and the introduction of catalytically active and conductive vanadium disulfide nanosheets into MXene can chemically adsorb lithium polysulfide, and can quickly convert it into electrolyte in the electrolyte. Insoluble Li 2 S 2 / Li 2 S, thereby inhibiting the severe shuttle effect and improving the stability and cycle life of lithium-sulfur batteries.

Owner:GUANGDONG UNIV OF TECH

A kind of graphene high-energy lithium battery composite positive electrode slurry and preparation method thereof

ActiveCN107528054BHigh discharge specific capacityImprove fade resistanceCell electrodesSecondary cellsHigh energySlurry

The invention provides compound cathode slurry of graphene high-power lithium batteries, relates to the technical field of cathode slurry of lithium batteries and aims to solve the technical problems that cathode slurry used in the prior art causes reduced energy storage capacity and poor cycle performance and stability of the lithium batteries, as a result, the lithium batteries easily heat and are short in service life and low in utilization rate during usage. Thus, the invention provides the compound cathode slurry of graphene high-power lithium batteries. Compared with traditional cathode slurry for the lithium batteries, the prepared compound cathode slurry has the battery capacity reduced from 195.256 mAh / g to 193.658 mAh / g and the capacity retention rate up to 99.18% under the conditions that the temperature is 35 DGE C and 1C charge and 6C discharge are circulated 500 times, the discharge specific capacity and attenuation resistance are improved, and the high cycle life and high capacity stability are realized.

Owner:上海玖银电子科技有限公司

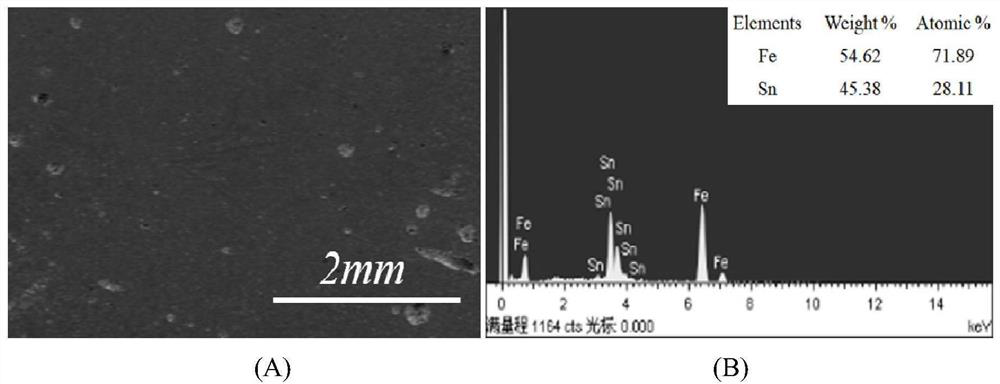

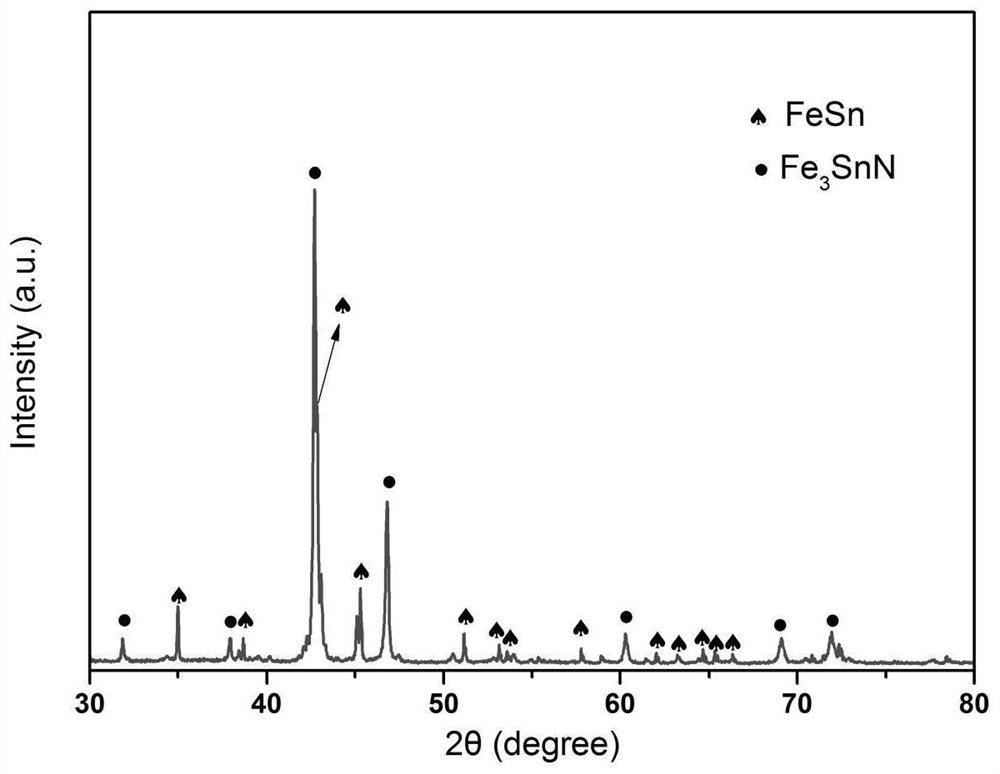

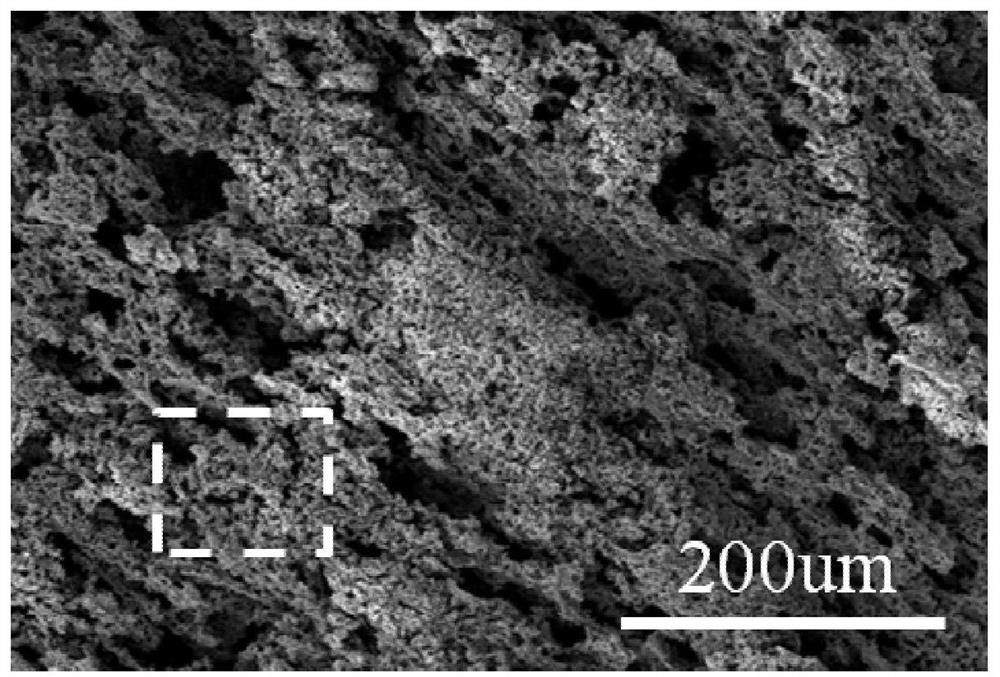

Three-dimensional micro-nano composite porous iron tin-iron tin nitrogen compound integrated lithium ion battery negative electrode and one-step preparation method thereof

ActiveCN112331815ABuffer volume expansionInhibit sheddingSecondary cellsNegative electrodesMicro nanoLithium intercalation

The invention provides a three-dimensional micro-nano composite porous iron-tin-iron-tin-nitrogen compound integrated lithium ion battery negative electrode and a one-step preparation method thereof.The lithium ion battery negative electrode is composed of an iron-tin compound and an iron-tin-nitrogen compound, wherein the iron-tin compound is single FeSn or FeSn / FeSn2, and the iron-tin-nitrogencompound is Fe3SnN; the lithium ion battery negative electrode has a bicontinuous open-pore three-dimensional micron-nano composite hierarchical pore structure, and the nano pore structure is distributed on a three-dimensional micron-porous skeleton formed by an iron-tin compound and an iron-tin-nitrogen compound. According to the invention, the huge volume change of the tin negative electrode material in the cyclic lithium intercalation and deintercalation process can be relieved, and the cycle performance and specific capacity of the tin negative electrode of the lithium ion battery are improved.

Owner:SICHUAN UNIV

A kind of lithium-ion battery aging capacity classification method

ActiveCN112820964BImprove capacity stabilityGuaranteed compactnessElectrical testingSecondary cells charging/dischargingLow voltageEngineering

The invention discloses a lithium-ion battery aging capacity classification method, which comprises the following steps: high-temperature aging of the aging battery for 18h-24h after liquid injection and sealing; 18h-24h high-temperature aging after 1C power supply to 3.65V; constant current 1C discharge for 5min-24h 10min; constant current and constant voltage 1C charge to 3.65V cut-off current 0.2C; constant current 1C discharge to 1.85V ~ 2V; constant current constant voltage 1C charge to 3.65V cut-off current 0.2C; constant current 1C discharge to 2V ~ 2.5V; Gradient small current discharge to 2V; constant current 0.2C charge for 30min. In the present invention, the low-voltage and high-voltage aging methods are used to ensure the compactness of the SEI film of the battery cell, and then the battery material activity is activated by shallow discharge, deep charge and deep discharge during the capacity division, and the difference between the discharge capacity of the first capacity division and the subsequent use capacity The difference is not big, and at the same time, the stability of the battery capacity in the long-term cycle is obviously better than that of the battery made by the original capacity separation process.

Owner:江西安驰新能源科技有限公司

Manufacturing method of super capacitor

InactiveCN102543482BImprove capacity stabilityImprove cycle lifeHybrid/EDL manufactureNew energyAdhesive

The invention relates to a manufacturing method of a super capacitor, which belongs to the technical field of new energy storage. The surface of a metal collector electrode is roughed, active material, conductive material and a compound adhesive are mixed uniformly and pressed into a pole piece with the thickness of 100-150 mum, the pole piece is stuck onto the surface of the collector electrode to form a band-shaped electrode, the electrode is cut into two electrodes with the same size, and after the two electrodes are riveted with a leading wire, an electrode diaphragm with the thickness of 10-50 mum is added to be wound into a core, the core is dried in vacuum for 8-72 hours at the temperature of 100-150 DEG C, then is soaked in an organic electrolyte and electrified for 10 hours at the temperature of 50 DEG C and the direct current voltage of 2.7V, and finally is packaged in a circular aluminum shell to obtain a super capacitor product, wherein the compound adhesive is the mixture of the substance with the general formula of (CH3) n (SiOSiOSi) mC3H6O (CpH2pOH) and polytetrafluoroethylene. The electrode manufactured by the compound adhesive disclosed by the invention is soft, has large mechanical strength and is easy for large-scale continuous production, and the service life is greatly prolonged.

Owner:锦州凯美能源有限公司

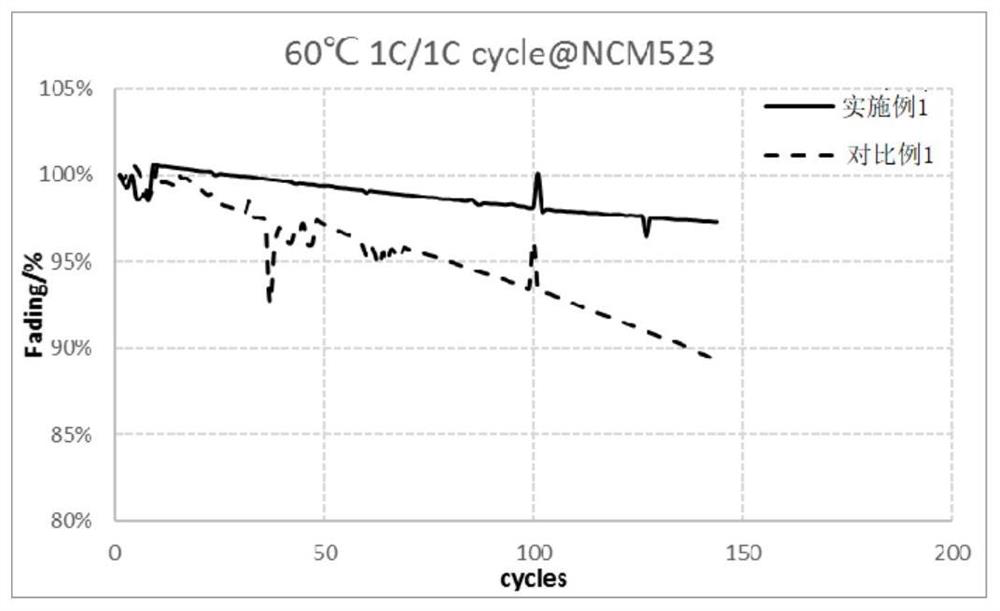

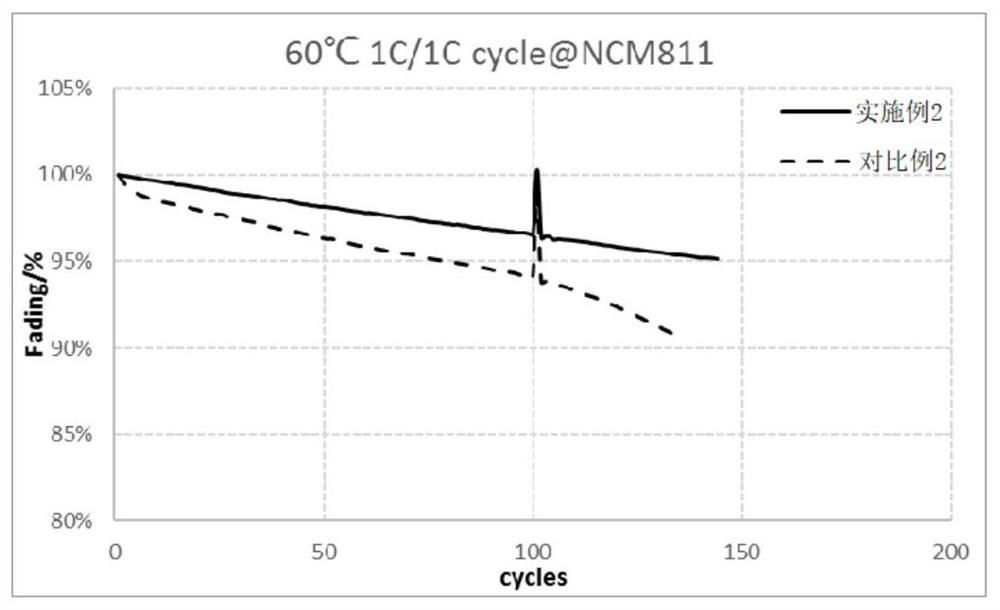

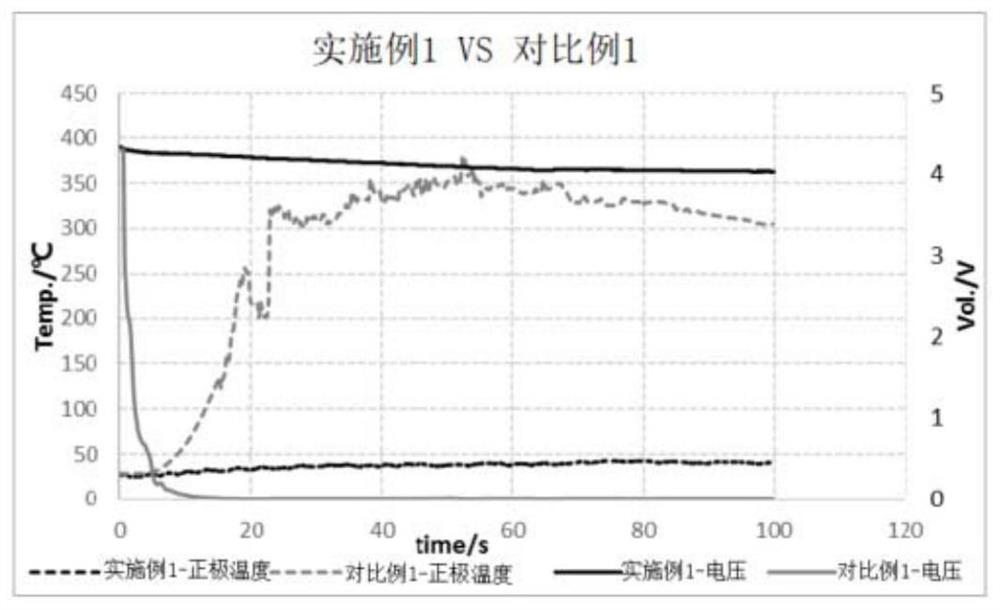

Metal oxide modified positive electrode material and preparation method thereof, lithium battery and electric equipment

PendingCN113725420AImprove cycle stabilityEasy to industrializeSecondary cellsPositive electrodesPhysical chemistryManganate

The invention provides a metal oxide modified positive electrode material and a preparation method thereof, a lithium battery and electric equipment, which relate to the technical field of positive electrode materials. The metal oxide modified positive electrode material comprises a positive electrode material, the outer surface of the positive electrode material is modified with a metal oxide, the positive electrode material comprises at least one of nickel lithium manganate and nickel chromium lithium manganate. The surface of the positive electrode material is modified by adopting the metal oxide, so that the positive electrode material can be effectively prevented from being in direct contact with an electrolyte, side reaction is inhibited, the positive electrode material is protected from being soaked and etched by the electrolyte, and the cycling stability and the capacity stability under high-temperature and high-rate conditions are improved; and industrial and commercial application of spinel and other positive electrode materials is promoted.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD +1

Three-dimensional copper-tin compound nanoparticles based on copper-tin alloy-microporous copper lithium-ion battery anode and its one-step preparation method

ActiveCN109524620BRich nanoporous structureImprove cycle performanceMaterial nanotechnologySecondary cellsNanoholeNanoparticle

Owner:SICHUAN UNIV

A kind of preparation method of negative electrode material of lithium ion battery

InactiveCN107611366BIncrease capacityImprove structural stabilityCell electrodesSecondary cellsPowder mixtureCarbonization

The invention relates to a preparation method for a lithium ion battery negative electrode material, and belongs to the technical field of a lithium ion battery. The preparation method comprises the steps of taking and placing silicate glass in a ball-milling tank, adding a sodium chloride solution for ball-milling, and sieving to obtain silicate glass powder; taking and placing Arabic gum and tragacanth gum in the ball-milling tank for ball-milling, and sieving to obtain tragacanth gum and Arabic gun mixture power; mixing the silicate glass ball-milling powder, the Arabic gum and the tragacanth gum, adding zinc powder, and performing stirring to obtain a colloid powder mixture; filling the colloid powder mixture in a die, performing pressing and pressure preservation, placing the die in abaking box, and performing standing and cooling to a room temperature after thermal curing to obtain a cured material; and placing the cured material in a tubular atmosphere furnace, introducing nitrogen to remove air, controlling a temperature, performing heat preservation and carbonization, and performing standing and cooling to the room temperature, thereby obtaining a silicon carbon compositenegative electrode material. The obtained negative electrode material has good rate performance, high capacity and good conductivity, and the application of the silicon negative electrode material isexpanded by electrical contact.

Owner:宁夏西墨新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com