Graphene-loaded multi-metal oxide-coated positive electrode material as well as preparation method and application thereof

A technology of multi-metal oxides and positive electrode materials, which is applied in the field of materials, can solve the problems of weak interaction between graphene and positive electrode materials, powdering and falling off, weakening the electrochemical stability of positive electrode materials, etc., to improve capacity stability and improve Conductivity and effect of improving Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

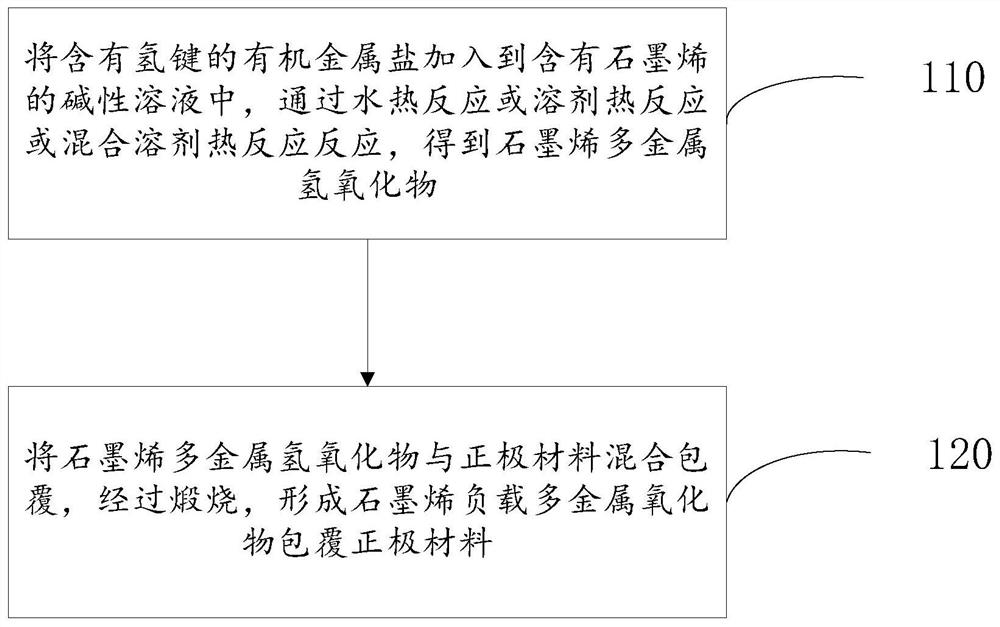

[0042] Main preparation method flow process step of the present invention comprises:

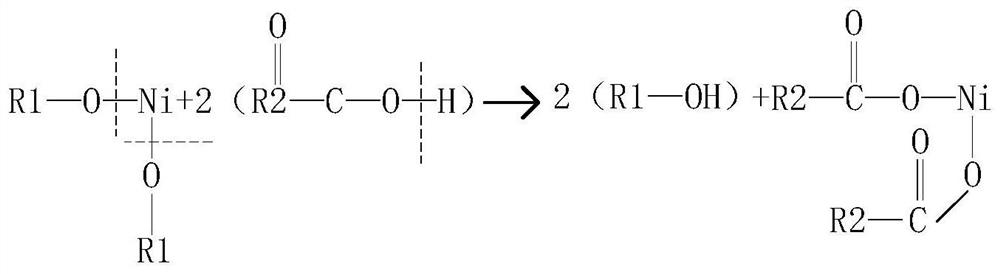

[0043] Step 110, adding an organic metal salt containing hydrogen bonds to an alkaline solution containing graphene, and performing a hydrothermal reaction or a solvothermal reaction or a mixed solvothermal reaction to obtain a graphene polymetallic hydroxide;

[0044] Specifically, the reaction temperature of hydrothermal reaction, solvothermal reaction or mixed solvothermal reaction is 100°C-250°C, the reaction time is 5 hours-15 hours, and the drying temperature is 60°C-120°C. The solvent for hydrothermal reaction is water; the solvent for solvothermal reaction includes methanol, dimethylformamide, ethanol, acetonitrile, acetone, ethyl acetate, isopropanol, tetrahydrofuran, propanol, n-butanol, n-propanol, isopropanol, One or more of propanol; the mixed solvent in the mixed solvent thermal reaction includes water and the above solvents, wherein the volume ratio of water to solvent is betw...

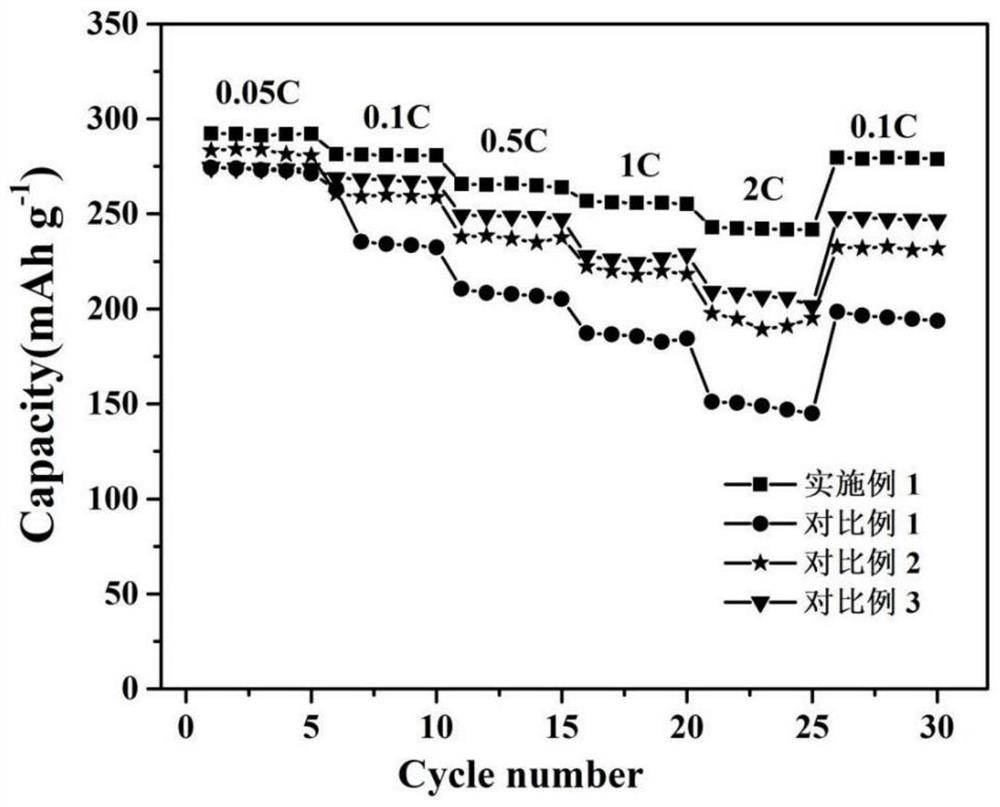

Embodiment 1

[0075] Step 1), take corresponding amount of nickel acetate and cobalt acetate tetrahydrate by 1:1 metal molar ratio and be mixed with total concentration and be 2mol L -1 aqueous solution, magnetically stirred for 30mins. Add urea to the above mixed solution to adjust the pH value to 10. Afterwards, a certain mass of graphene powder was added to the mixed solution so that the content of graphene in the solution was 2g / L, and magnetically stirred for 30mins again to obtain a uniformly stirred mixed solution.

[0076] In step 2), the mixed solution was transferred to a 100ml reaction kettle, placed in an oven at 120°C, and reacted for 12 hours. After the product was cooled to room temperature, it was washed several times with deionized water and absolute ethanol, and then dried at 80 °C for 6 hours to obtain graphene-nickel-cobalt hydroxide.

[0077] Step 3), the graphene nickel-cobalt hydroxide and lithium-rich manganese-based positive electrode material Li (Li 0.2 Ni 0.13...

Embodiment 2

[0079] Change the amount of graphene in embodiment 1 step 1) so that the content of graphene in the solution becomes 1g / L, other steps are the same as in embodiment 1, and the final product obtained is graphene-supported nickel-cobalt-oxygen-coated lithium-rich manganese base Cathode material II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com