High-capacity low-voltage chip-type laminated aluminum capacitor and preparation method thereof

A large-capacity, capacitor technology, applied in the field of capacitors, can solve the problems of large changes in resistivity due to temperature changes, leakage safety, hidden dangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

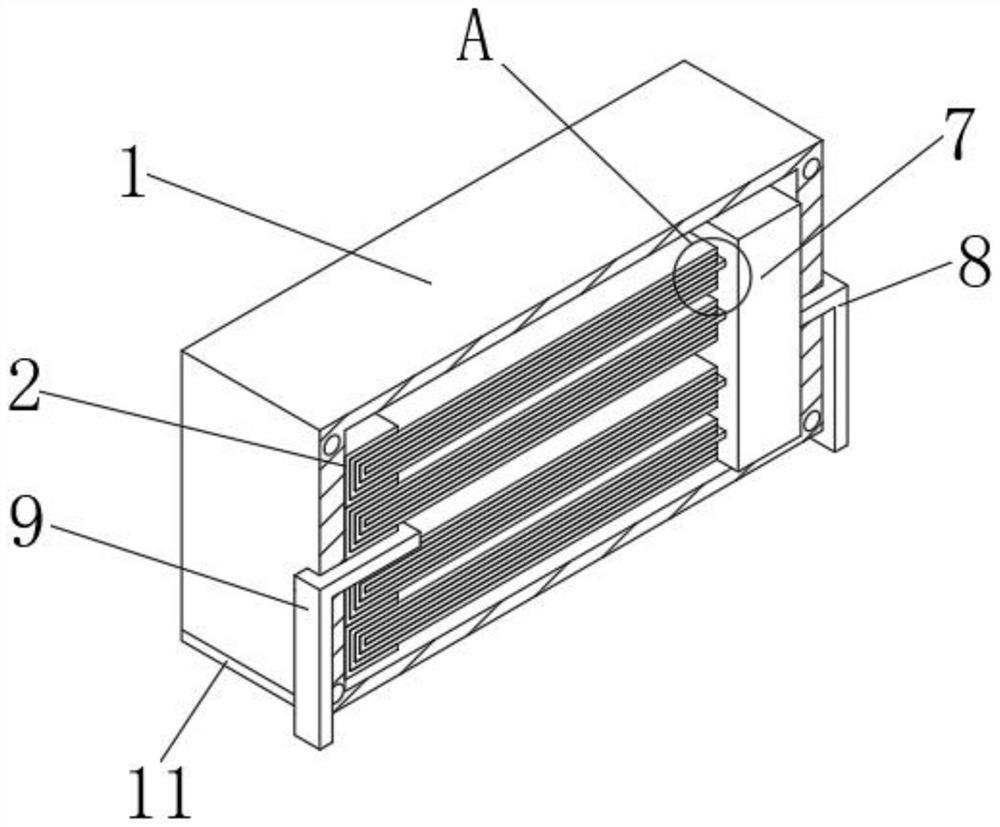

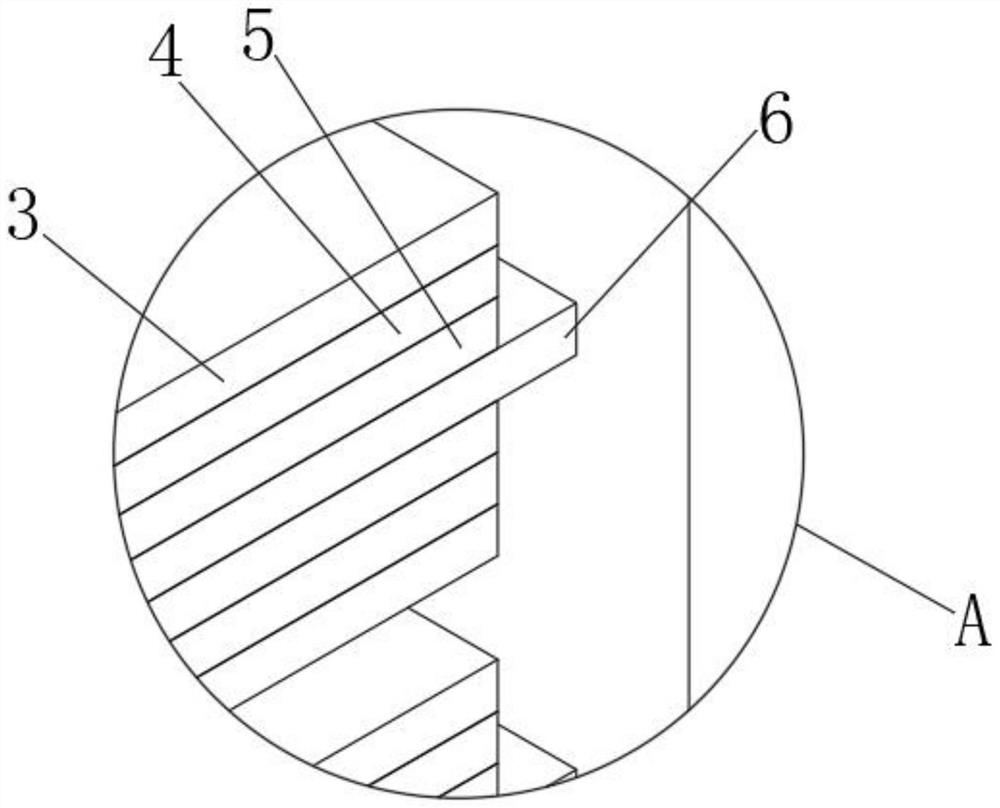

[0039] see Figure 1-5 , A large-capacity low-voltage chip laminated aluminum capacitor and a preparation method thereof, comprising: an outer casing 1, a plurality of cathode waterproof casings 2 are arranged inside the outer casing 1, and a silver-containing cathode layer 3 is arranged on the inner side of the cathode waterproof casing 2; A carbon-containing cathode layer 4 is arranged on the inner side of the silver cathode layer 3, an electrolyte layer 5 is arranged on the inner side of the carbon-containing cathode layer 4, an aluminum foil body 6 is arranged on the inner side of the electrolyte layer 5, and a positive electrode gasket 7 is fixedly installed inside the casing 1, And the positive electrode gasket 7 is in contact with the aluminum foil body 6, the surface of the positive electrode gasket 7 is provided with a positive electrode lead-out terminal 8, one end of the positive electrode lead-out terminal 8 is in contact with the positive electrode gasket 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com