Cascaded structure capacitor core

A series structure and capacitor technology, applied in the field of capacitors, can solve problems such as short life, inability to withstand high pulses, and limited application occasions, and achieve the effects of improving manufacturing quality, high withstand voltage capability, and reducing fluctuations in capacity deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

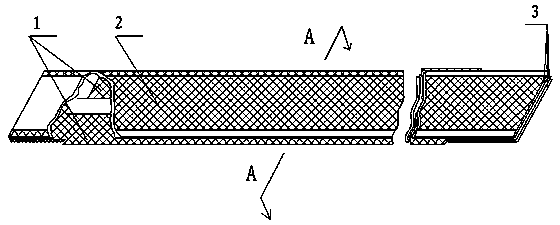

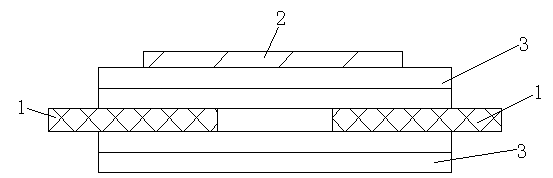

[0015] Referring to the accompanying drawings, a series structure capacitor core is composed of aluminum foil 1, metallized polypropylene film 2 and dielectric layer 3. The core is formed by winding aluminum foil 1 and dielectric layer 3, and metal is wound on the dielectric layer 3 in turn. Polypropylene film 2, the two ends of the aluminum foil 1 extend outwards, the middle part is hollow, and the dielectric layer 3 is made of polypropylene film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com