Double-sided aluminum metallized polypropylene film and preparation method thereof and capacitor core

A technology of polypropylene film and aluminum metallization, which is applied in the field of capacitors to achieve uniform aluminum metallization layer, long service life and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

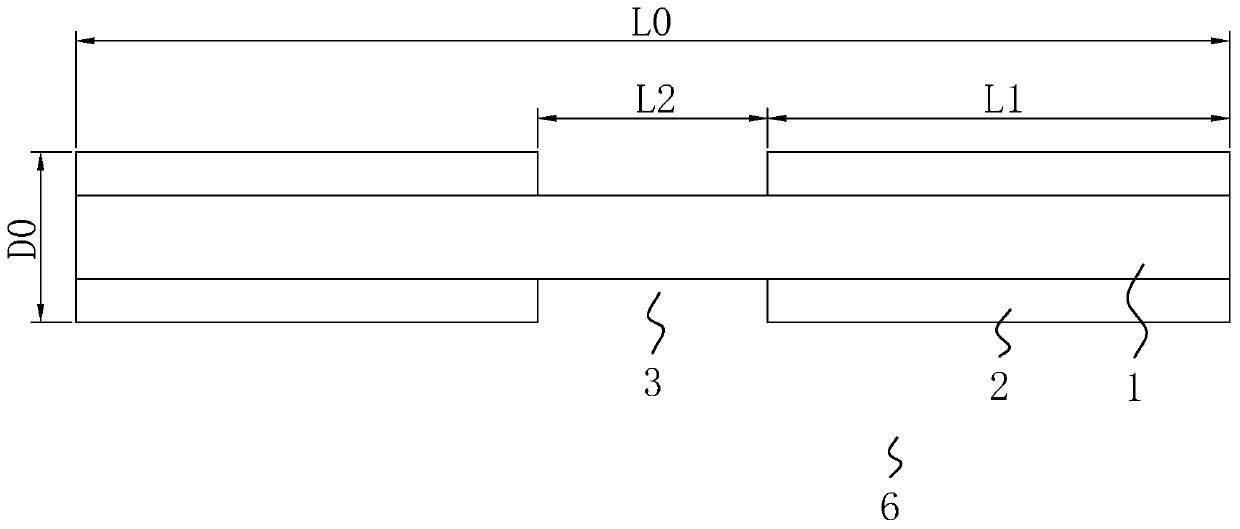

[0043] Embodiment 1: refer to figure 1, is a double-sided aluminum metallized polypropylene film disclosed by the present invention, comprising a polypropylene base film 1 and two pairs of aluminum metallized layers 2 respectively attached to the surface of the polypropylene base film 1, that is, one pair of aluminum metallized layers The layer 2, the polypropylene base film 1 and another pair of aluminum metallization layers 2 are arranged side by side closely in sequence. In addition, the outer edge of the aluminum metallization layer 2 is flush with the side edge of the polypropylene base film 1 , and the strip-shaped space between the aluminum metallization layers 2 on the same surface of the polypropylene base film 1 forms a middle margin 3 .

[0044] The double-sided aluminum metallized polypropylene film 6 has a total thickness of 4.6 μm-5.0 μm and a total width of 21.8 mm-22.2 mm. The width of the middle margin 3 is 2.8mm-3.2mm. The aluminum metallization layer 2 has...

Embodiment 2

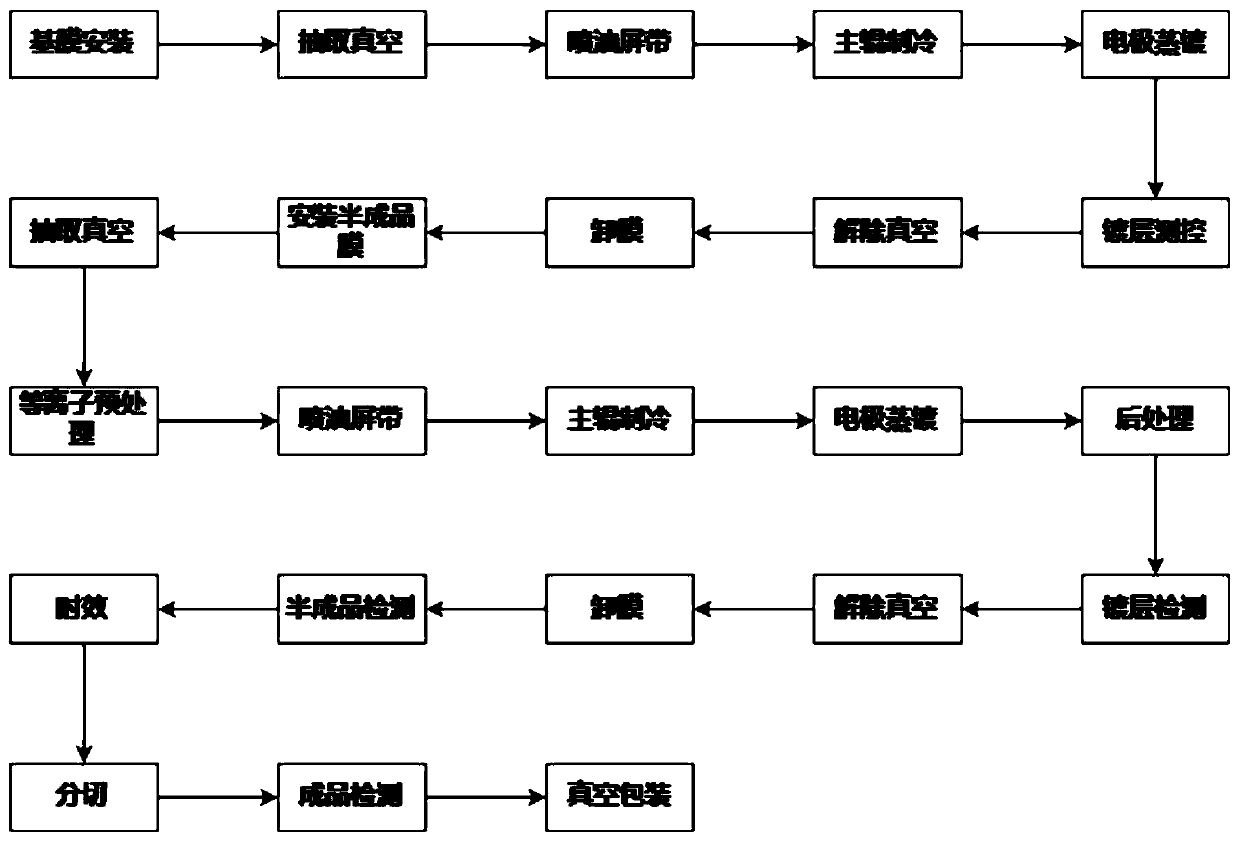

[0045] Embodiment 2: refer to figure 2 , is the preparation method of a kind of double-sided aluminum metallized polypropylene film disclosed by the present invention, is used for preparing the double-sided aluminum metallized polypropylene film 6 of embodiment 1, comprises the following steps: the first pre-installation, the first time Vacuum evaporation, second pre-installation, corona on non-corona surface, second vacuum evaporation, semi-finished product inspection, aging and slitting, post-processing.

[0046] (1) Pre-installation for the first time

[0047] The polypropylene base film 1 is sent into the vacuum winding chamber by a crane, and installed on the machine unwinding roller, so that the first corona surface of the polypropylene base film 1 is exposed. Then the pressing roller presses the four edges of the polypropylene base film 1, and closes the vacuum winding chamber. Finally, the vacuum pump works to evacuate the inside of the vacuum winding chamber, and t...

Embodiment 3

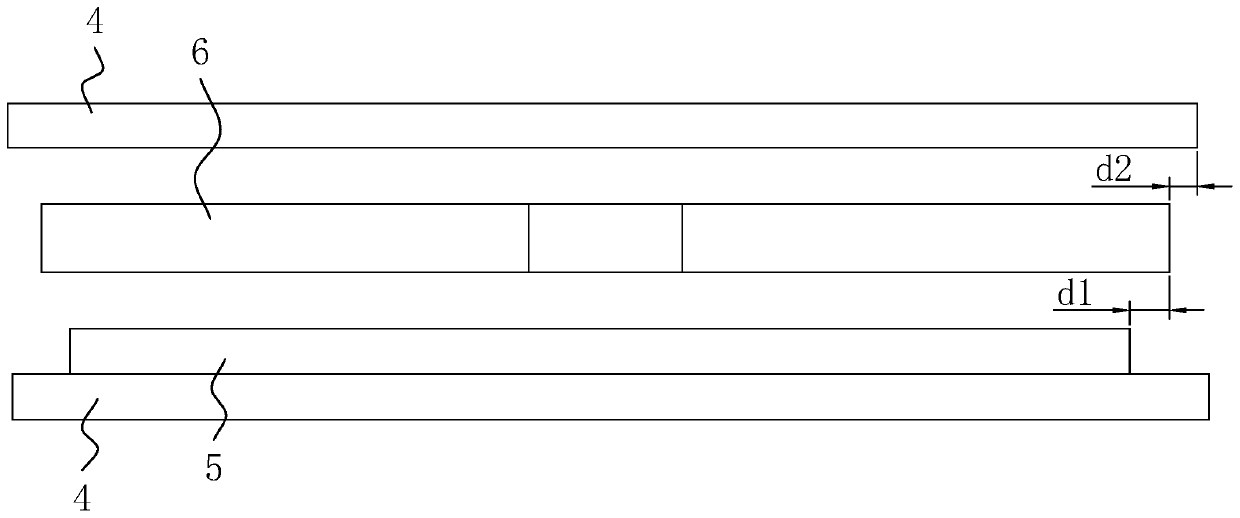

[0072] Embodiment 3: refer to image 3 , is a capacitor core disclosed by the present invention, comprising a pair of single-sided metallized polypropylene films 4 arranged side by side, a polypropylene optical film 5 arranged between the single-sided metallized polypropylene films 4 and double-sided aluminum metal Thin polypropylene film6. Among them, the single-side metallized polypropylene film 4 , the polypropylene light film 5 , the double-side aluminum metallized polypropylene film 6 and the single-side metallized polypropylene film 4 are arranged side by side in sequence. The single-sided metallized polypropylene film 4 is the single-sided metallized polypropylene film 4 with the middle edge 3, and the double-sided aluminum metallized polypropylene film 6 is the double-sided aluminum metal with the middle edge 3 described in embodiment 1. Thin polypropylene film6.

[0073] In addition, the width of the double-sided aluminum metallized polypropylene film 6 is greater t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com