Graphene-based positive electrode material and preparation method thereof and lithium-sulfur battery

A cathode material, graphene-based technology, applied in the field of nanomaterials, can solve problems such as unsuitability for large-scale production, unsatisfactory firmness, and complicated steps, and achieve the effects of improving electrochemical performance, improving capacity stability, and improving conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a preparation method of a graphene-based positive electrode material, which can solve the technical problems of low sulfur load, poor conductivity, low specific capacity, and poor cycle stability of lithium-sulfur batteries.

[0040] The technical solution is:

[0041] A preparation method of graphene-based positive electrode material, comprising the following steps:

[0042]Disperse the MXene / graphene composite material, copper salt and sulfur source in the solvent to obtain the first mixed solution;

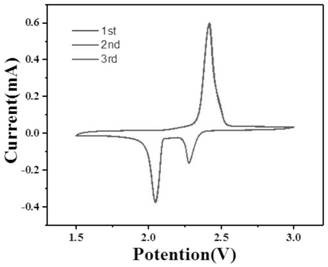

[0043] placing the first mixed solution under a closed pressure system, and performing a solvothermal reaction at 100°C to 180°C for 18h to 24h to prepare a copper sulfide / MXene / graphene nanocomposite material;

[0044] Mixing the copper sulfide / MXene / graphene nanocomposite material with elemental sulfur, and after grinding, place it at 155°C-180°C for 10h-18h to prepare a graphene-based positive electrode material;

[0045] The MXene is Ti 3 C ...

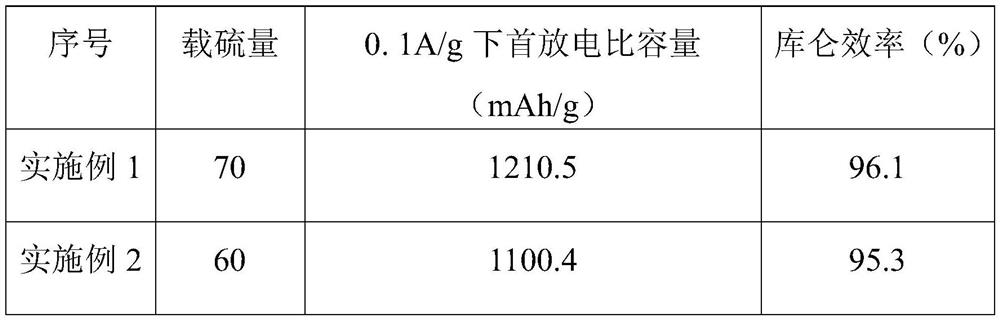

Embodiment 1

[0080] This embodiment provides a graphene-based positive electrode material and a preparation method thereof, and the specific steps are as follows:

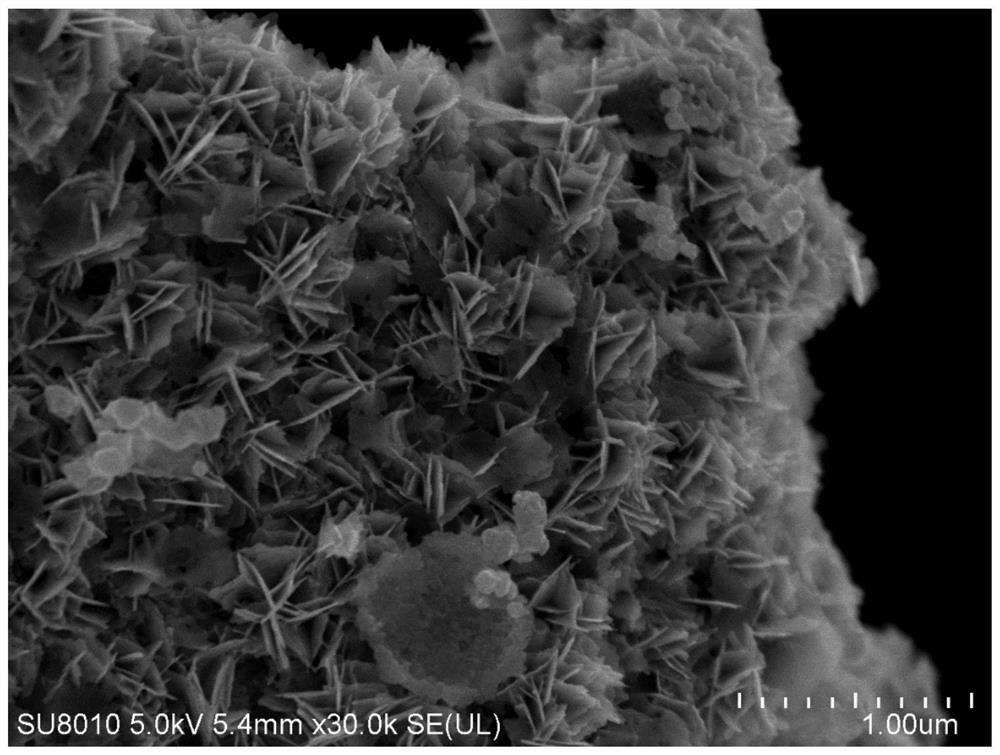

[0081] Step 1, prepare MXene(Ti 3 C 2 ) / graphene composite

[0082] a) Preparation of few-layer MXene(Ti 3 C 2 ): Weigh 2g of lithium fluoride with an electronic balance, measure 40ml of HCl aqueous solution with a concentration of 9mol / L in a graduated cylinder, place them in plastic beakers at a constant temperature of 35°C, stir and dissolve for 30min, and then use an electronic balance to weigh the titanium-based MAX ( Ti 3 AlC 2 ) phase precursor 2g, slowly put into a plastic beaker at a constant temperature of 35°C and continue to stir for 24 hours; then add distilled water to the product, centrifuge at 4000 rpm for 5 minutes, repeat 5 times, and then sonicate in an ice bath for 1 hour, When the pH value is close to 7, the supernatant is collected to be the final product few-layer MXene (Ti 3 C 2 ), and finally fr...

Embodiment 2

[0093] This embodiment provides a graphene-based positive electrode material and a preparation method thereof, and the specific steps are as follows:

[0094] Step 1, prepare MXene(Ti 3 C 2 ) / graphene composite

[0095] a) Preparation of few-layer MXene(Ti 3 C 2 ): use a graduated cylinder to measure 40ml of HF aqueous solution with a mass fraction of 40%, pour it into a plastic beaker, and then use an electronic balance to weigh the titanium series MAX (Ti 3 AlC 2 ) phase precursor 2g, slowly put it into a plastic beaker with a constant temperature of 35°C under magnetic stirring and continue to react for 24h; then add distilled water to the product, centrifuge at 4000 rpm for 5 minutes, repeat 5 times, and then sonicate in an ice bath 1h, when the pH value was close to 7, the supernatant was collected to be the final product few-layer MXene (Ti 3 C 2 ), and finally freeze-dry the suspension to obtain graphene-like few-layer MXene (Ti 3 C 2 ) solid powder.

[0096] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com