Lithium battery cell composite coated positive electrode material, preparation method thereof, and lithium ion battery

A technology of lithium ion battery and positive electrode material, applied in the field of new energy battery, can solve the problems of undisclosed, increased preparation cost of lithium battery, difficult operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

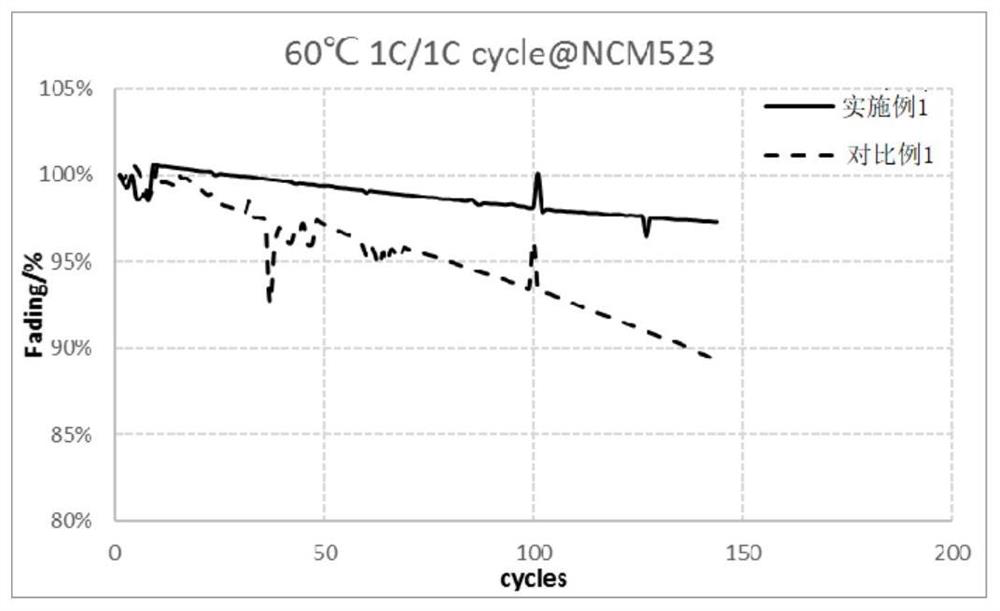

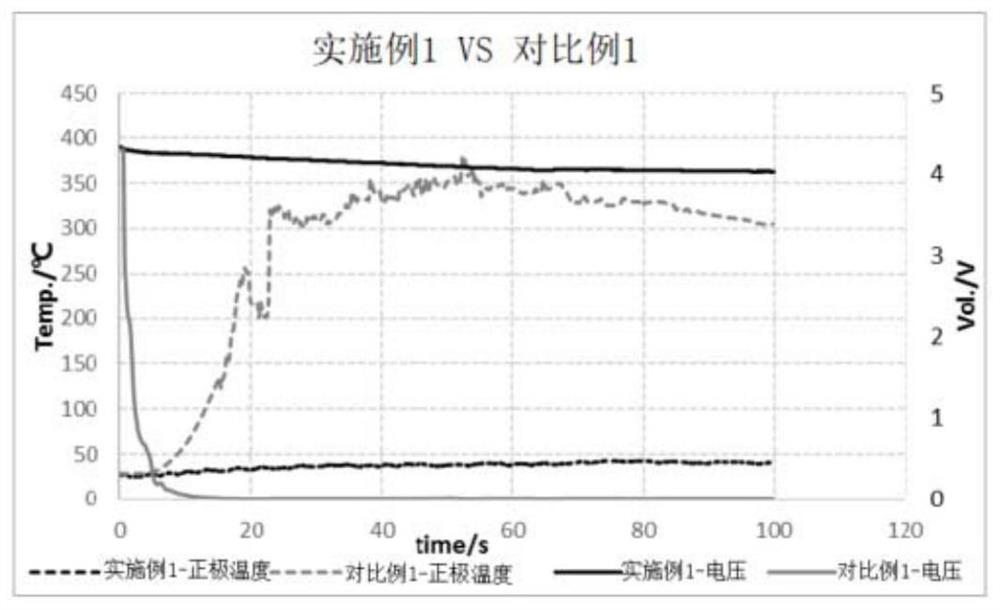

[0035] Example 1

[0036] The preparation method of lithium battery core composite coated positive electrode material (coated positive electrode NCM523) includes the following steps:

[0037] 1) Add the commercially available lithium nickel cobalt manganate 523 material matrix to the ethanol solvent, add ethyl silicate, lithium dihydrogen phosphate and magnesium dihydrogen phosphate in sequence, solid mass ratio: nickel cobalt manganese lithium 523 material matrix : Ethyl silicate: Lithium dihydrogen phosphate: Magnesium dihydrogen phosphate = 85%: 2%: 5%: 8%; Solid content: 60%; Stir in a constant temperature water bath, where the temperature of the water bath is controlled within the range of 80±5°C, The rotation speed is 1000 rpm, and the stirring time is controlled at 150 min to obtain a mixed solution A.

[0038] 2) Put the above solution A in a centrifuge for centrifugation, with a centrifugal speed of 10,000 rpm, and a centrifugal time of 60 minutes, to obtain a solid-liquid ...

Example Embodiment

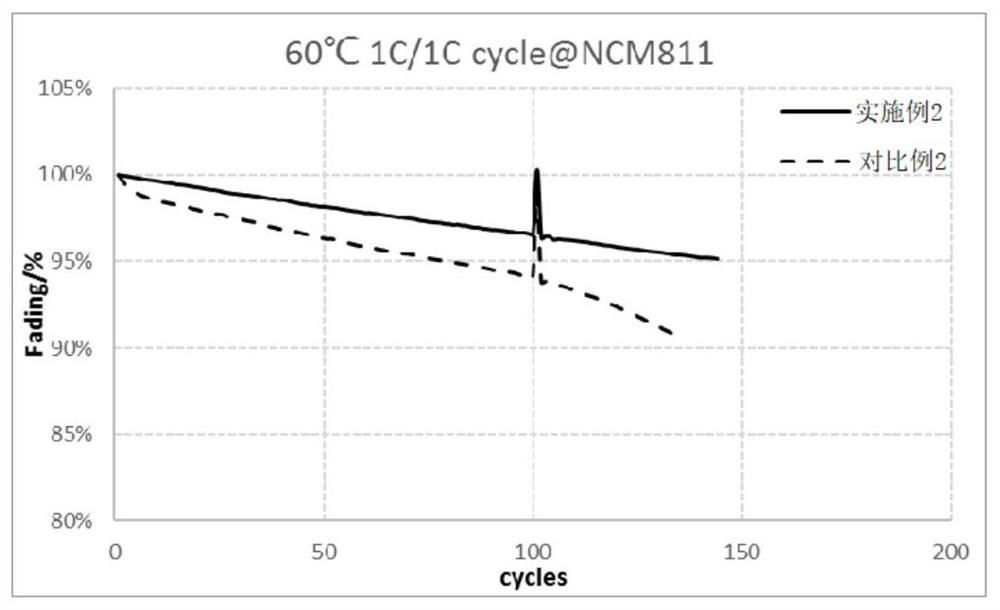

[0049] Example 2

[0050] The preparation method of lithium battery core composite coated positive electrode material (coated positive electrode NCM811) includes the following steps:

[0051] 1) Put the purchased commercial lithium nickel cobalt manganese oxide 811 material into the acetone solvent, and add ethyl silicate, lithium hydroxide, and aluminum dihydrogen phosphate in sequence. Among them, the mass ratio, the lithium nickel cobalt manganese oxide 811 material: Ethyl silicate: Lithium hydroxide: Aluminum dihydrogen phosphate = 90%: 1%: 4%: 5%, solid content: 72%, and then stir at 120°C in a water bath at constant temperature for 180 minutes at a speed of 1200 rpm to obtain a mixture Solution D;

[0052] 2) Put the above solution D in a centrifuge, centrifuge at a speed of 20,000 rpm, and centrifuge for 60 minutes to obtain a solid-liquid mixture E with a solid content of 85%;

[0053] 3) Use a mullite crucible to hold solution E and put it into the muffle furnace. The load c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com