Three-dimensional micro-nano composite porous iron tin-iron tin nitrogen compound integrated lithium ion battery negative electrode and one-step preparation method thereof

A lithium-ion battery and tin compound technology, applied in battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of restricting the popularization and application of tin, tin powdering and peeling, large internal stress, etc., and achieve improved cycle performance and rate performance , to avoid falling off, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

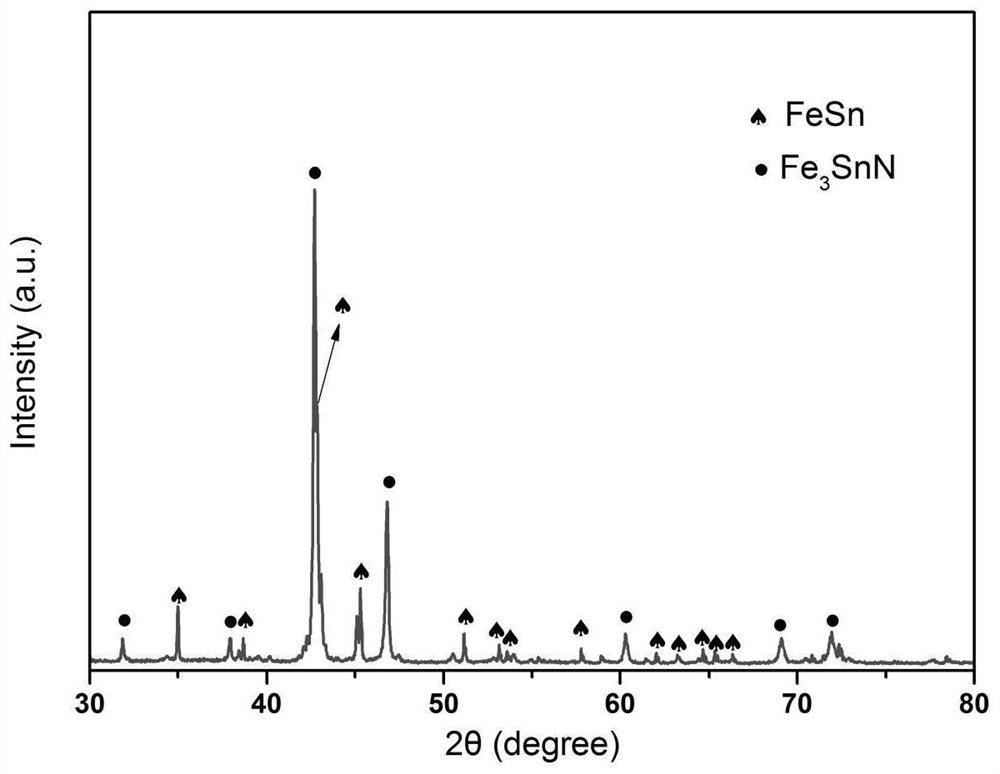

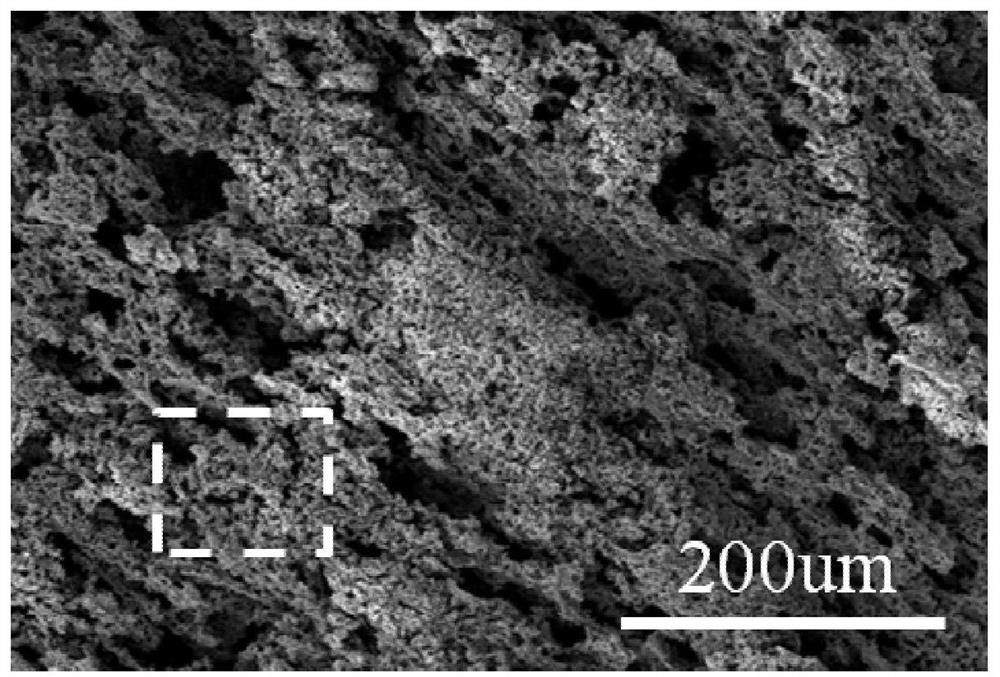

[0037] In this example, a three-dimensional micro-nano composite porous FeSn-Fe 3 SnN integrated lithium ion battery negative electrode and one-step preparation method thereof, specifically as follows:

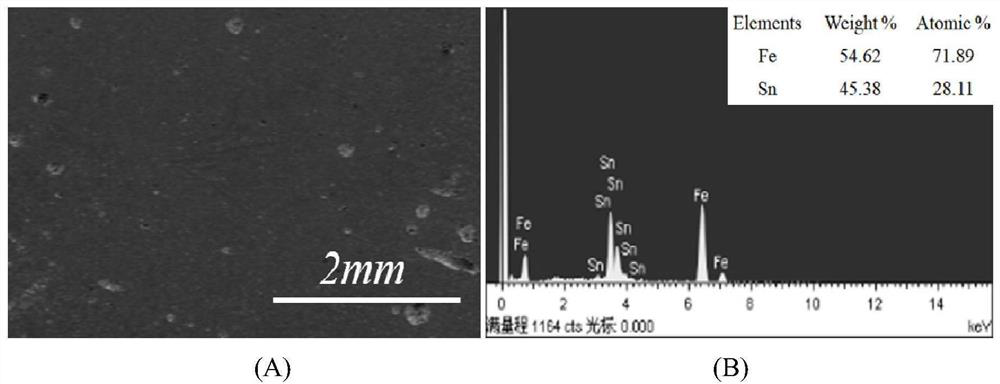

[0038] (1) Weigh the iron block and the tin block according to the ratio of the atomic percentage of iron and tin being 70:30, and melt them in a muffle furnace to obtain an iron-tin alloy ingot. The scanning electron microscope photos of the surface of the iron-tin alloy ingot are as follows: figure 1 As shown in the (A) figure, the EDS spectrum of the iron-tin alloy ingot is as follows figure 1 As shown in (B) figure.

[0039] (2) The iron-tin alloy ingot is cut into iron-tin alloy sheets with a thickness of 500 μm with a wire cutting machine, and the surface of the iron-tin alloy sheet is polished with 380 mesh, 800 mesh, 1200 mesh, and 2000 mesh water sandpaper successively, and then The diamond polishing paste with a particle size of 0.5 μm is used for polishing, and t...

Embodiment 2

[0046] In this example, a three-dimensional micro-nano composite porous FeSn-Fe 3 SnN integrated lithium ion battery negative electrode and one-step preparation method thereof, specifically as follows:

[0047] (1) Weigh the iron block and the tin block according to the ratio of the iron to tin atomic percentage of 60:40, and melt them in a muffle furnace to obtain an iron-tin alloy ingot.

[0048] (2) The iron-tin alloy ingot is cut into iron-tin alloy sheets with a thickness of 500 μm with a wire cutting machine, and the surface of the iron-tin alloy sheet is polished with 380 mesh, 800 mesh, 1200 mesh, and 2000 mesh water sandpaper successively, and then The diamond polishing paste with a particle size of 0.5 μm is used for polishing, and the polished iron-tin alloy sheet is cleaned with deionized water and dried.

[0049] (3) The iron-tin alloy sheet is placed in a corrosion solution composed of hydrofluoric acid and nitric acid for corrosion, in the corrosion solution, t...

Embodiment 3

[0052]In this example, a three-dimensional micro-nano composite porous FeSn-Fe 3 SnN integrated lithium ion battery negative electrode and one-step preparation method thereof, specifically as follows:

[0053] (1) Weigh the iron block and the tin block according to the ratio of the atomic percentage of iron to tin being 45:55, and melt them in a muffle furnace to obtain an iron-tin alloy ingot.

[0054] (2) The iron-tin alloy ingot is cut into iron-tin alloy sheets with a thickness of 500 μm with a wire cutting machine, and the surface of the iron-tin alloy sheet is polished with 380 mesh, 800 mesh, 1200 mesh, and 2000 mesh water sandpaper successively, and then The diamond polishing paste with a particle size of 0.5 μm is used for polishing, and the polished iron-tin alloy sheet is cleaned with deionized water and dried.

[0055] (3) The iron-tin alloy sheet is placed in a corrosion solution composed of hydrofluoric acid and nitric acid for corrosion, in the corrosion soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com