Composite film for lithium-sulfur battery

A technology of lithium-sulfur batteries and composite membranes, which is applied to battery components, circuits, electrical components, etc., and can solve the problems of lithium nitrate consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

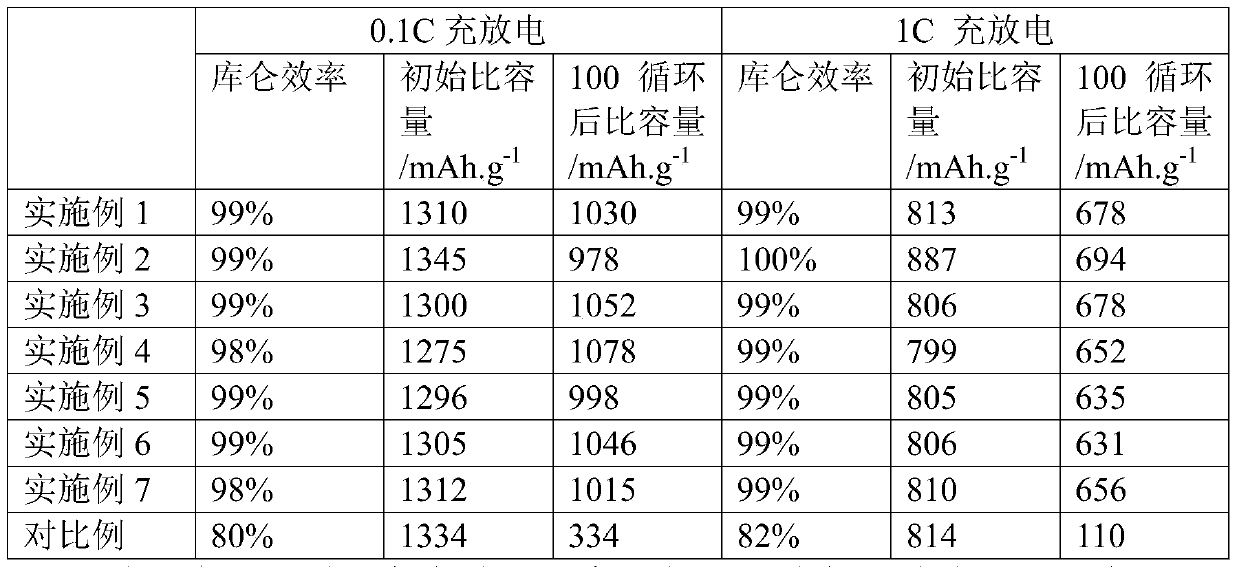

Examples

Embodiment 1

[0020] Preparation of composite membrane rich in nitrate ions: polyvinylidene fluoride (PVDF) and lithium nitrate are mixed and dissolved in N-methylpyrrolidone (NMP) according to the mass ratio of 1:1 to form a film-forming solution with a concentration of 10%. . The film-forming solution is cast to form a film. Naturally dry at 70°C, vacuum dry at 70°C to remove water and set aside.

[0021] The negative electrode of the lithium-sulfur battery is a lithium foil with a thickness of 20 microns, and the positive electrode is prepared by the following method: 20 parts by mass of SuperP carbon, 70 parts by mass of elemental sulfur, and polyvinylidene fluoride (PVDF) of 10 parts by mass in N - Blend in methylpyrrolidone (NMP), coated onto aluminum foil. The sulfur content in the positive electrode active layer after drying was 1.0 mg / cm2. The electrolyte of the lithium-sulfur battery is dioxolane / ethylene glycol dimethyl ether (volume ratio 1:1) of 1 mol / L lithium trifluorometh...

Embodiment 2

[0024] Preparation of composite membrane rich in nitrate ions: polyvinylidene fluoride (PVDF) and cesium nitrate are mixed and dissolved in N-methylpyrrolidone (NMP) according to the mass ratio of 1:2, and a film-forming solution with a concentration of 15% is prepared . The film-forming solution is cast to form a film. Naturally dry at 70°C, vacuum dry at 70°C to remove water and set aside.

[0025] The negative electrode of the lithium-sulfur battery is a lithium foil with a thickness of 20 microns, and the positive electrode is prepared by the following method: 20 parts by mass of SuperP carbon, 70 parts by mass of elemental sulfur, and polyvinylidene fluoride (PVDF) of 10 parts by mass in N - Blend in methylpyrrolidone (NMP), coated onto aluminum foil. The sulfur content in the positive electrode active layer after drying was 1.0 mg / cm2. The electrolyte of the lithium-sulfur battery is dioxolane / ethylene glycol dimethyl ether (volume ratio 1:1) of 1 mol / L lithium triflu...

Embodiment 3

[0028] Preparation of composite membrane rich in nitrate ions: polysulfone (PSF) and lithium nitrate are mixed and dissolved in N,N-dimethylformamide (DMF) according to the mass ratio of 1:1, and the concentration is 20% membrane solution. The film-forming solution is cast to form a film. Naturally dry at 70°C, vacuum dry at 70°C to remove water and set aside.

[0029] The negative electrode of the lithium-sulfur battery is a lithium foil with a thickness of 20 microns, and the positive electrode is prepared by the following method: 20 parts by mass of SuperP carbon, 70 parts by mass of elemental sulfur, and polyvinylidene fluoride (PVDF) of 10 parts by mass in N - Blend in methylpyrrolidone (NMP), coated onto aluminum foil. The sulfur content in the positive electrode active layer after drying was 1.0 mg / cm2. The electrolyte of the lithium-sulfur battery is dioxolane / ethylene glycol dimethyl ether (volume ratio 1:1) of 1 mol / L lithium trifluoromethanesulfonamide.

[0030]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com