Metal oxide modified positive electrode material and preparation method thereof, lithium battery and electric equipment

A positive electrode material and oxide technology, which is applied in the direction of battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of capacity fading, poor cycle performance, and inability to carry out industrial and commercial applications, so as to reduce the preparation cost and be easy to operate , Promote the effect of industrialization and commercial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] According to a second aspect of the present invention, the present invention provides a method for preparing a metal oxide modified positive electrode material, comprising the following steps:

[0079] Disperse the metal oxide in the solvent evenly, then add the positive electrode material and mix evenly, then remove the solvent and sinter to obtain the metal oxide modified positive electrode material, wherein the positive electrode material includes one of lithium nickel manganese oxide and lithium nickel chromium manganate or two.

[0080] In the present invention, the metal oxide modified positive electrode material is prepared by the improved solid phase method of mixing the metal oxide with the positive electrode material evenly and then sintering, which is not only simple in process, easy to operate, suitable for large-scale production, but also can effectively save energy consumption. Reduce Mn 3+ The production cost is reduced at the same time.

[0081] Prefer...

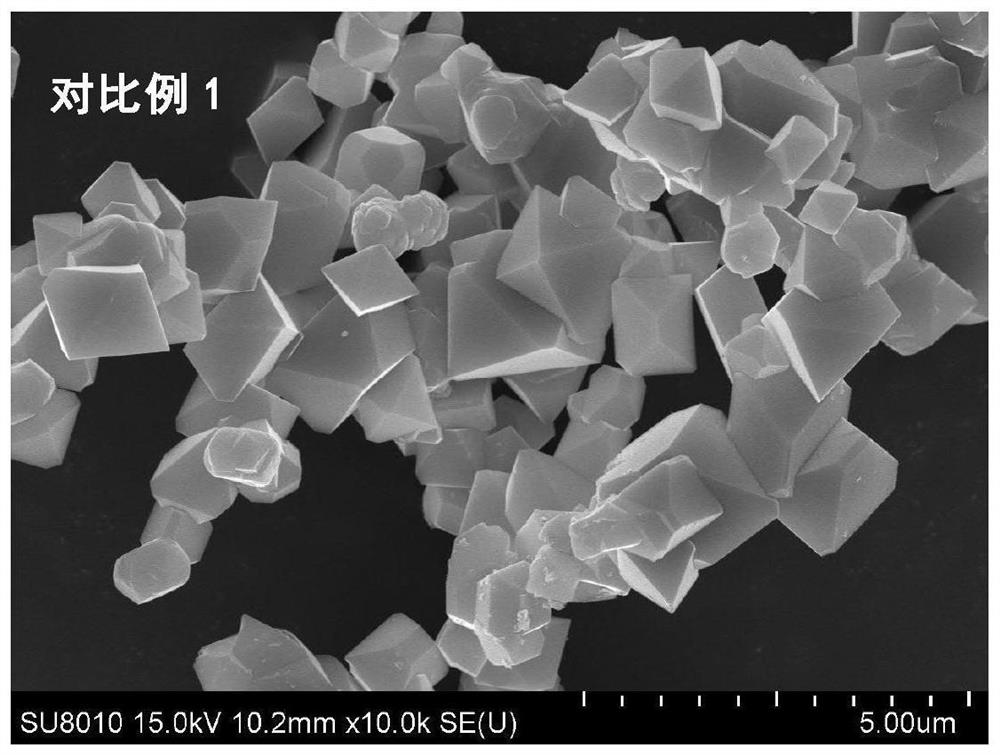

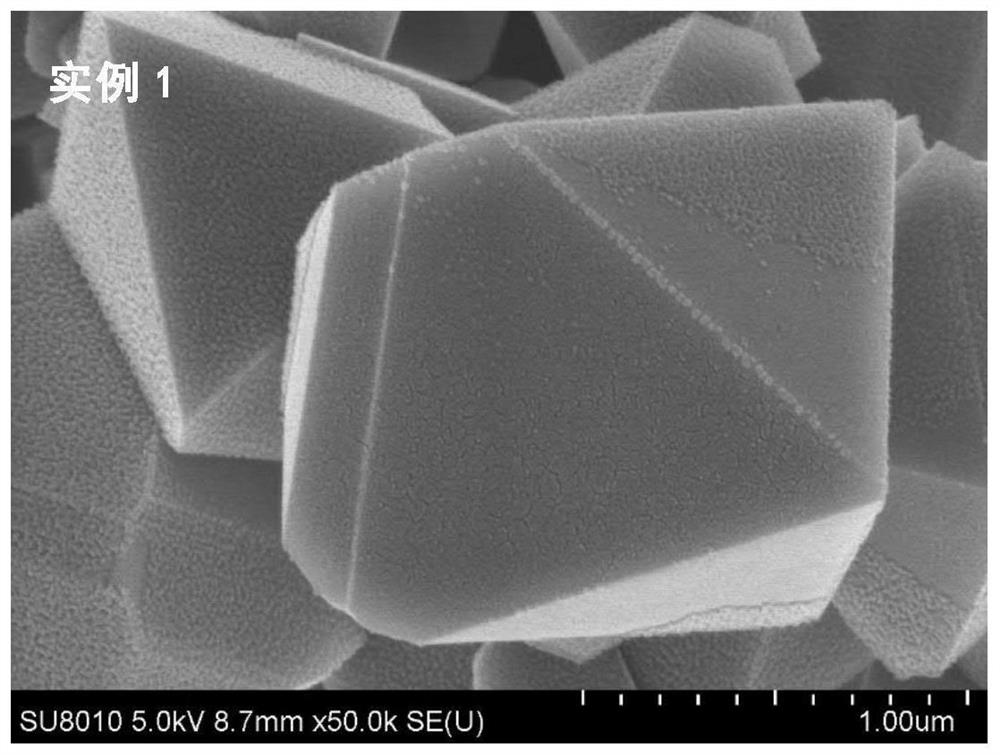

Embodiment 1

[0106] This embodiment provides an Al 2 o 3 Modified lithium nickel chromium manganate (LiNi 0.45 Cr 0.1 mn 1.45 o 4 Hereinafter referred to as the preparation method of LNCMO), prepare according to the following steps:

[0107] (1) Preparation of LNCMO cathode material

[0108] (1.1) Add polyvinylpyrrolidone to absolute ethanol to prepare an absolute ethanol solution in which polyvinylpyrrolidone is dissolved, wherein the mass volume ratio of polyvinylpyrrolidone to absolute ethanol is 2g:1000mL;

[0109] (1.2) will Li 2 CO 3 0.5315g, LiOH0.3442g, NiO0.9209g, Cr 2 o 3 0.2082g and MnO 2 3. Put 4541 g in a ball mill jar, add dropwise into the absolute ethanol solution dissolved with polyvinylpyrrolidone until the solution is submerged in the material, ball mill for 5 hours, and then dry to remove the absolute ethanol to obtain the dried material;

[0110] (1.3) Put the dried material in a muffle furnace, raise the temperature to 800°C at a rate of 5°C / min and keep it...

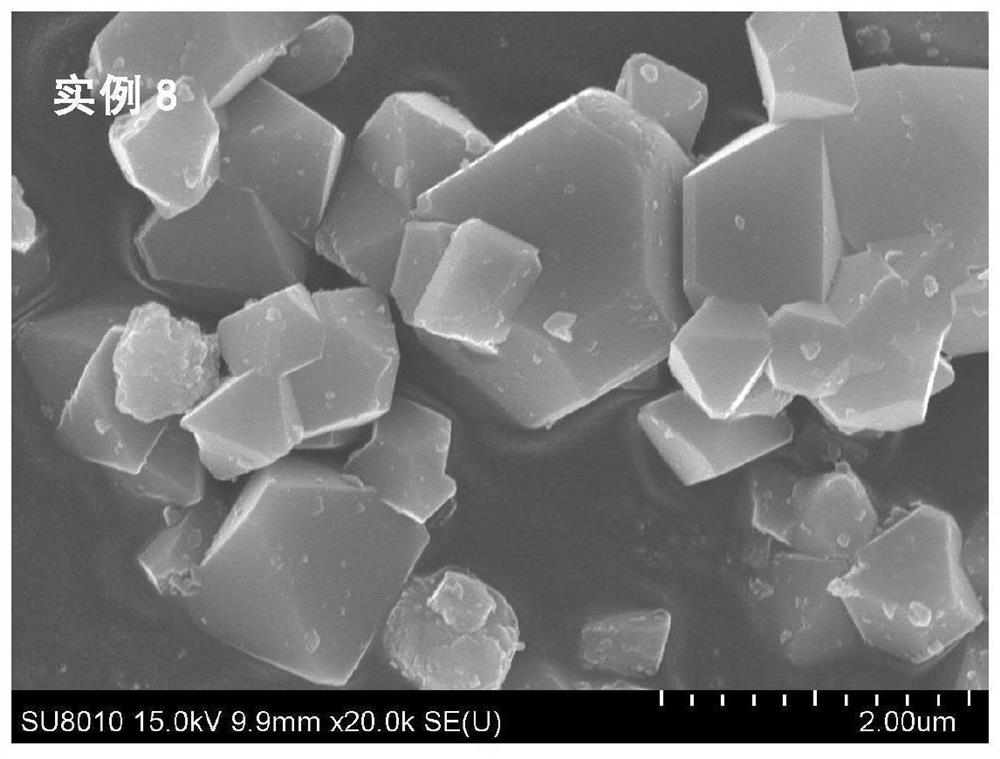

Embodiment 2

[0116] This embodiment provides an Al 2 o 3 Modified lithium nickel chromium manganate (LiNi 0.45 Cr 0.1 mn 1.45 o 4 Hereafter abbreviated as the preparation method of LNCMO), it differs from Example 1 in that in step (2), Al 2 o 3 The consumption is 1g, and all the other steps are identical with embodiment 1, do not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com