Preparation method for temperature compensation type multi-layer ceramic chip capacitor

A multi-layer ceramic and capacitor technology, applied in capacitors, fixed capacitors, fixed capacitor electrodes, etc., can solve the problems of increasing product manufacturing costs, rising market prices, scarcity, etc., to reduce product costs, save precious metal resources, and have a wide range of capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

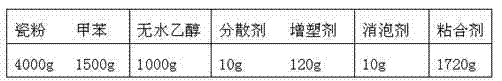

[0009] A method for preparing a Ni electrode SL (the temperature coefficient of the capacitor is SL) chip multilayer ceramic capacitor, mainly by preparing porcelain slurry, casting a dielectric diaphragm, alternately overprinting internal electrodes and dielectric layers, laminating, cutting, and debinding , Sintering, chamfering, capping, and firing process.

[0010] The porcelain material used in the preparation process of porcelain paste, its main component is CaZrO 3 and SrTiO 3 . The two are mixed according to the weight ratio of 1: (1.5~3) to adjust the dielectric constant and temperature coefficient of the dielectric material. Porcelain also includes ZnO, MnO 2 , SiO 2 One or several of them are used as sintering aids, and the total amount does not exceed 5wt%. The adhesive (PVB), plasticizer (DOP, DBP), dispersant (GTO, AKM0531), defoamer (methyl silicone oil) used are all materials commonly used by those skilled in the art, and the solvent used is toluene and A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com