Patents

Literature

31results about How to "Wide capacity range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

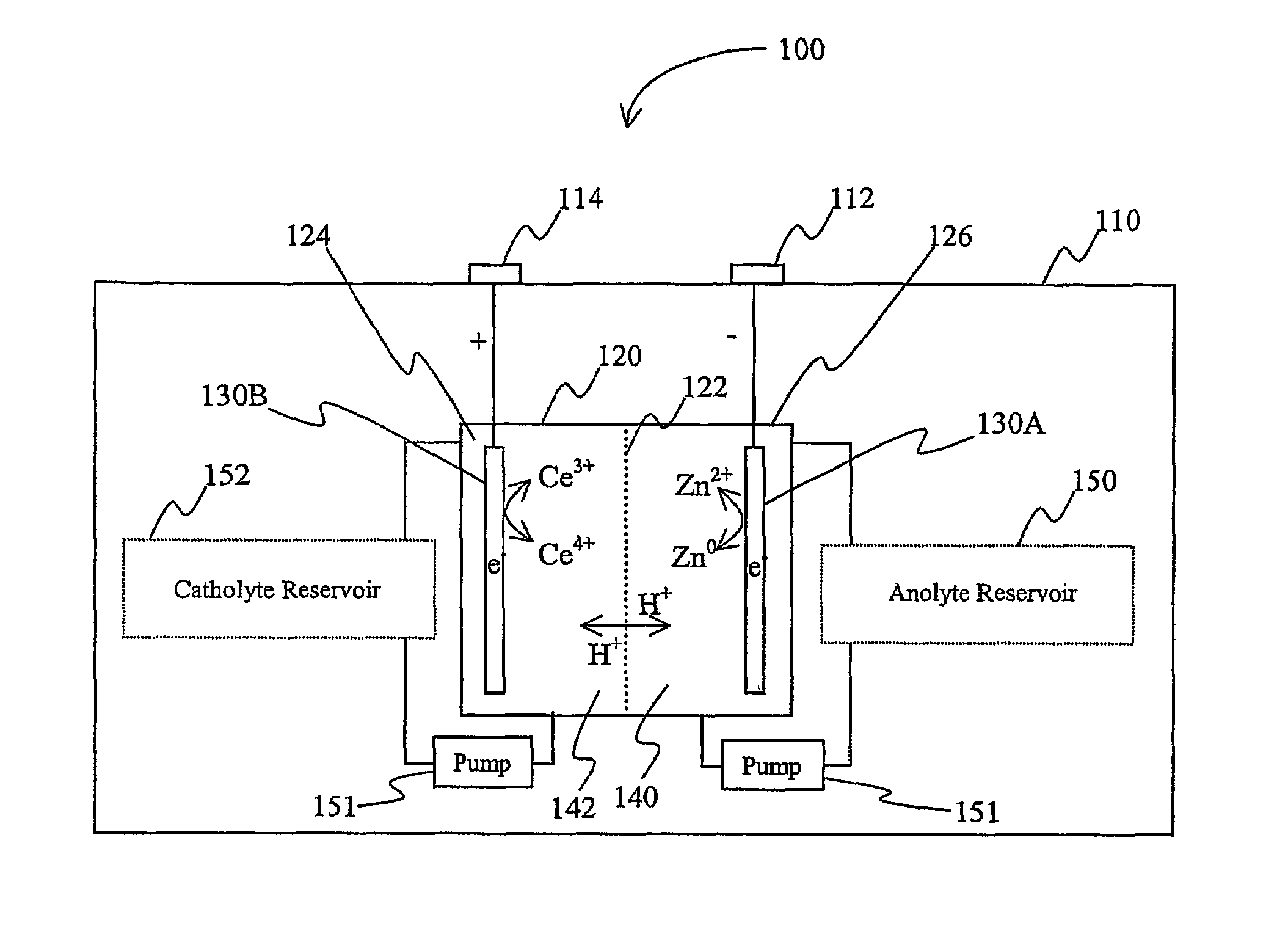

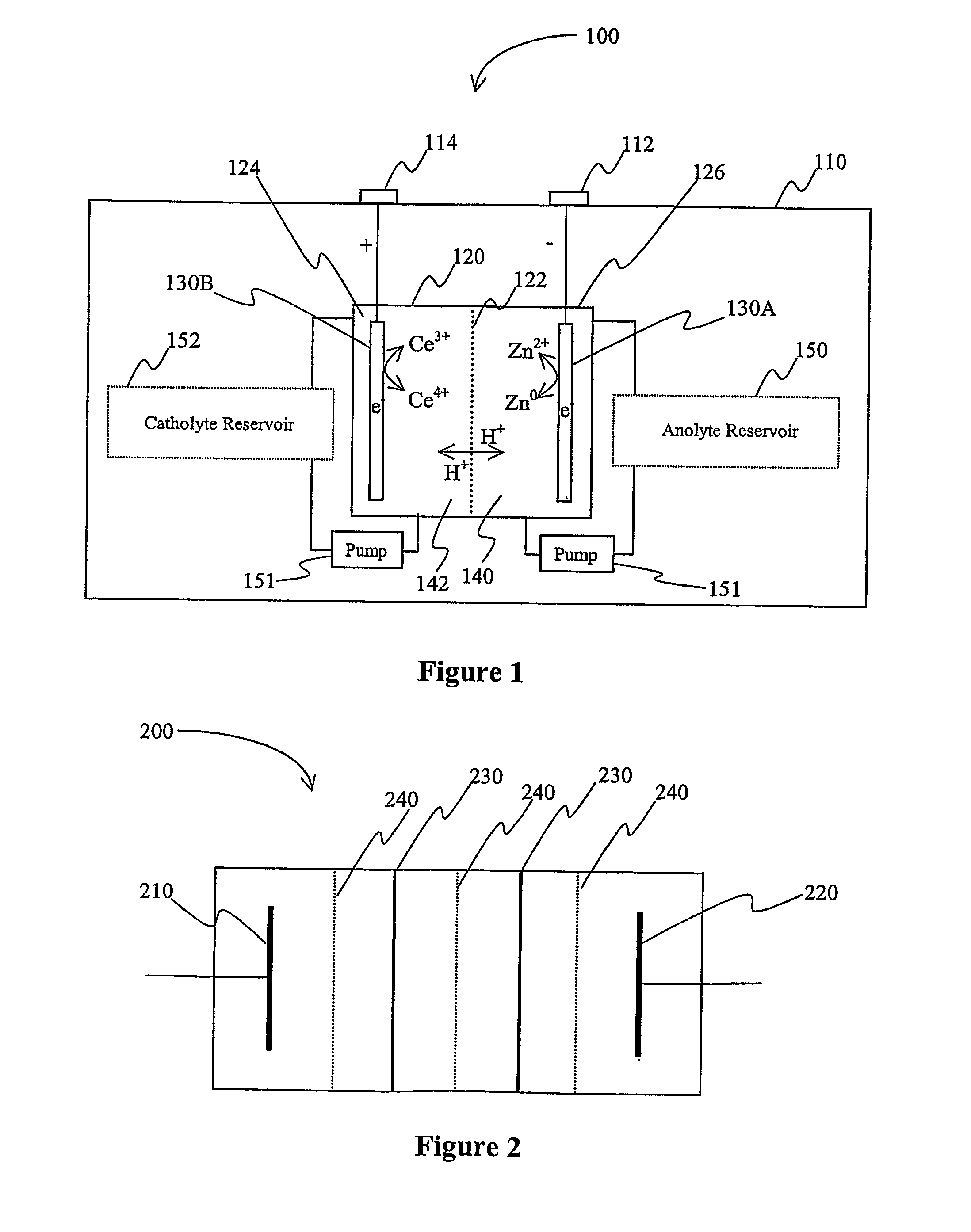

Lanthanide batteries

InactiveUS7252905B2Wide capacity rangeLarge capacityAlkaline accumulatorsSolid electrolyte cellsLanthanideCerium

A battery (100) comprises an electrolyte in which a lanthanide and zinc form a redox pair. Preferred electrolytes are acid electrolytes, and most preferably comprise methane sulfonic acid, and it is further contemplated that suitable electrolytes may include at least two lanthanides. Contemplated lanthanides include cerium, praseodymium, neodymium, terbium, and dysprosium, and further contemplate lanthanides are samarium, europium, thulium and ytterbium.

Owner:PLURION LTD

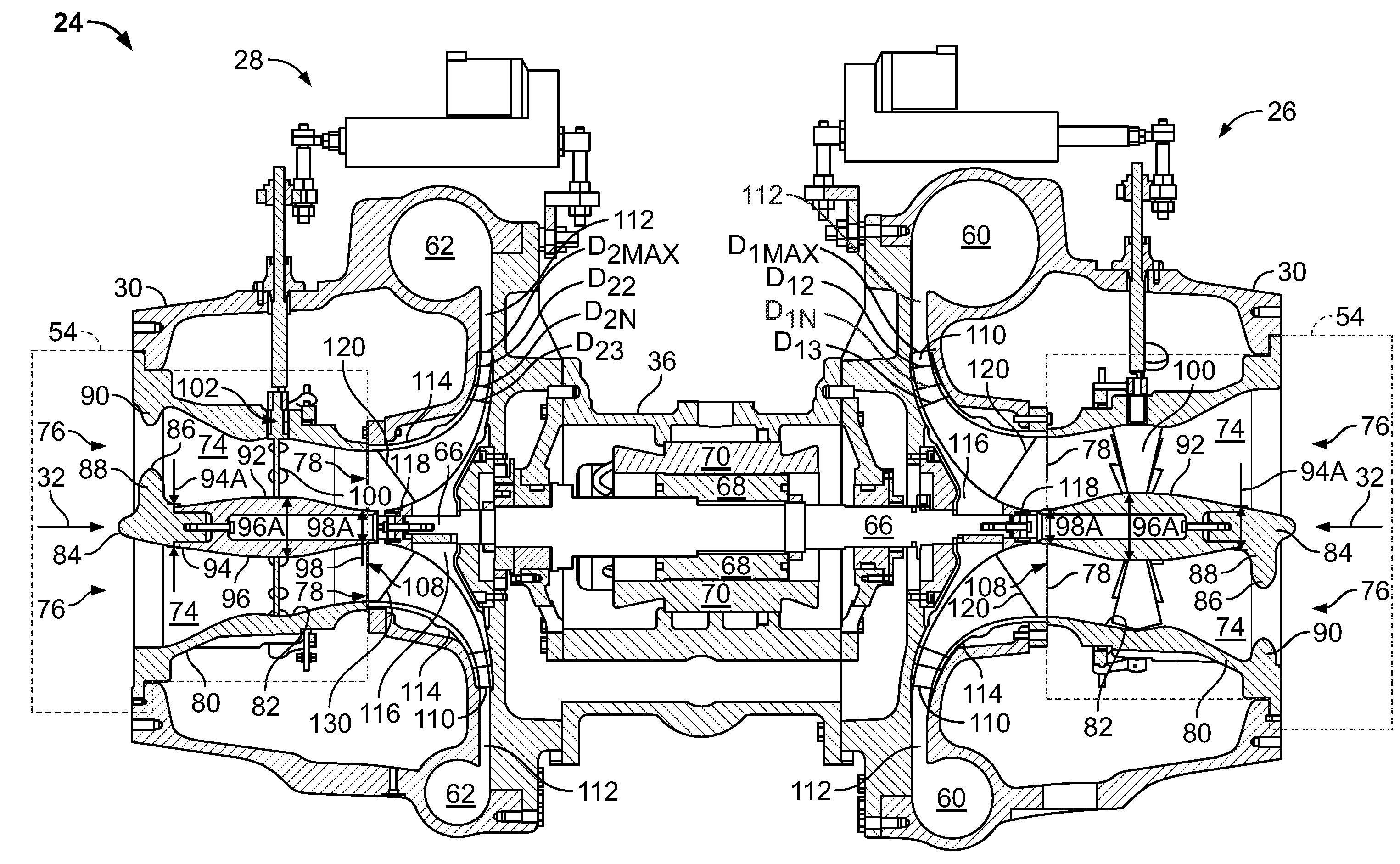

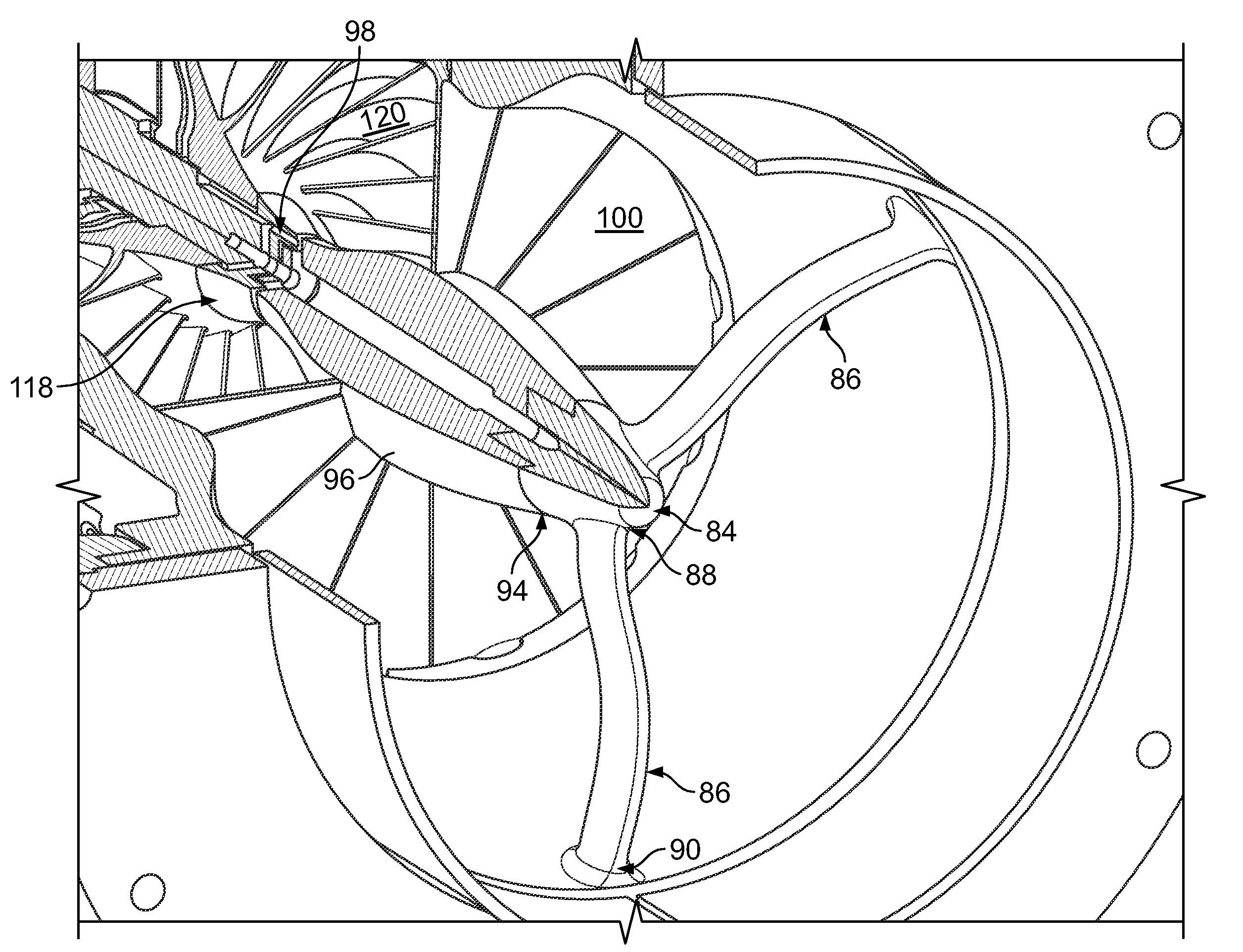

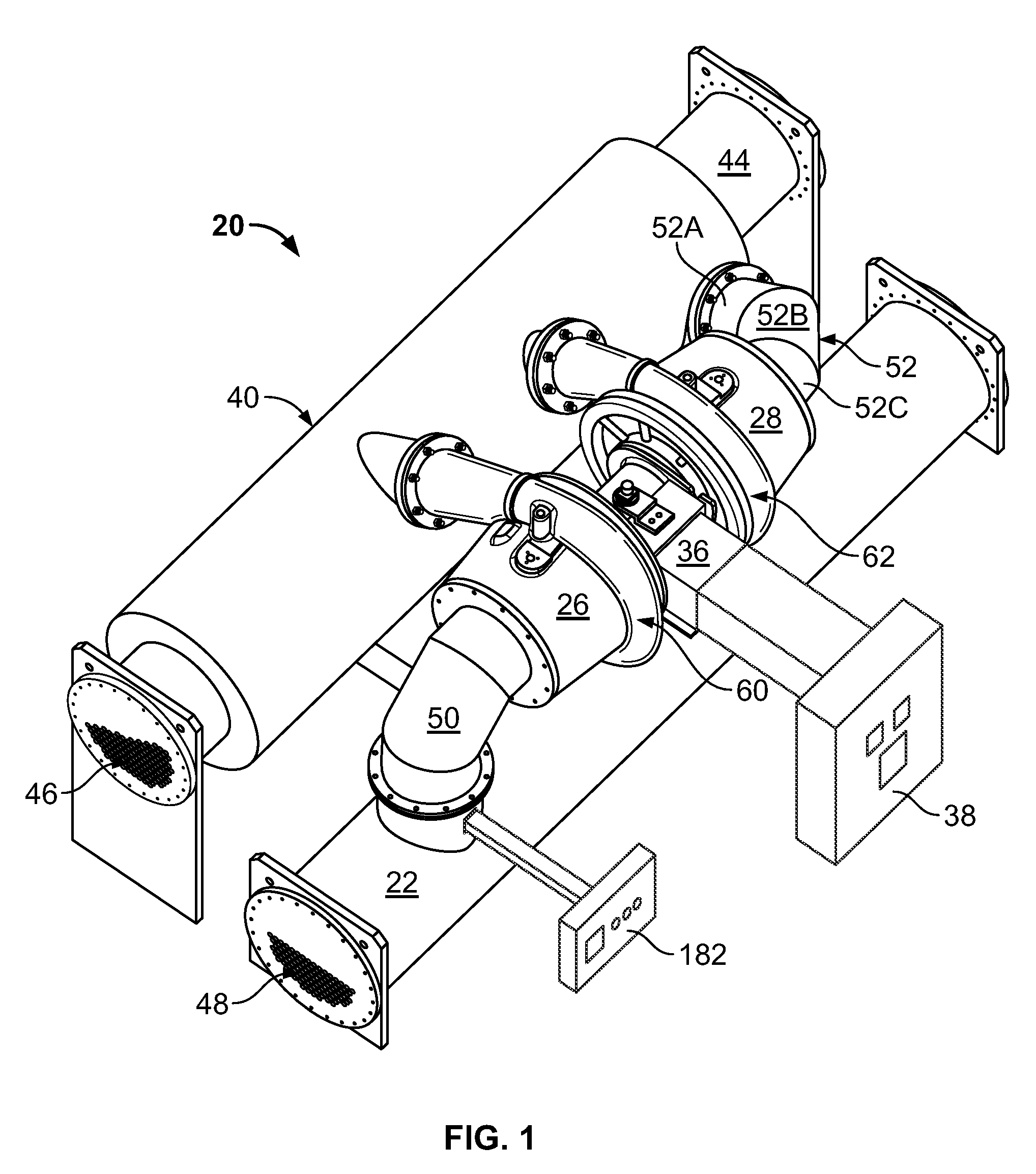

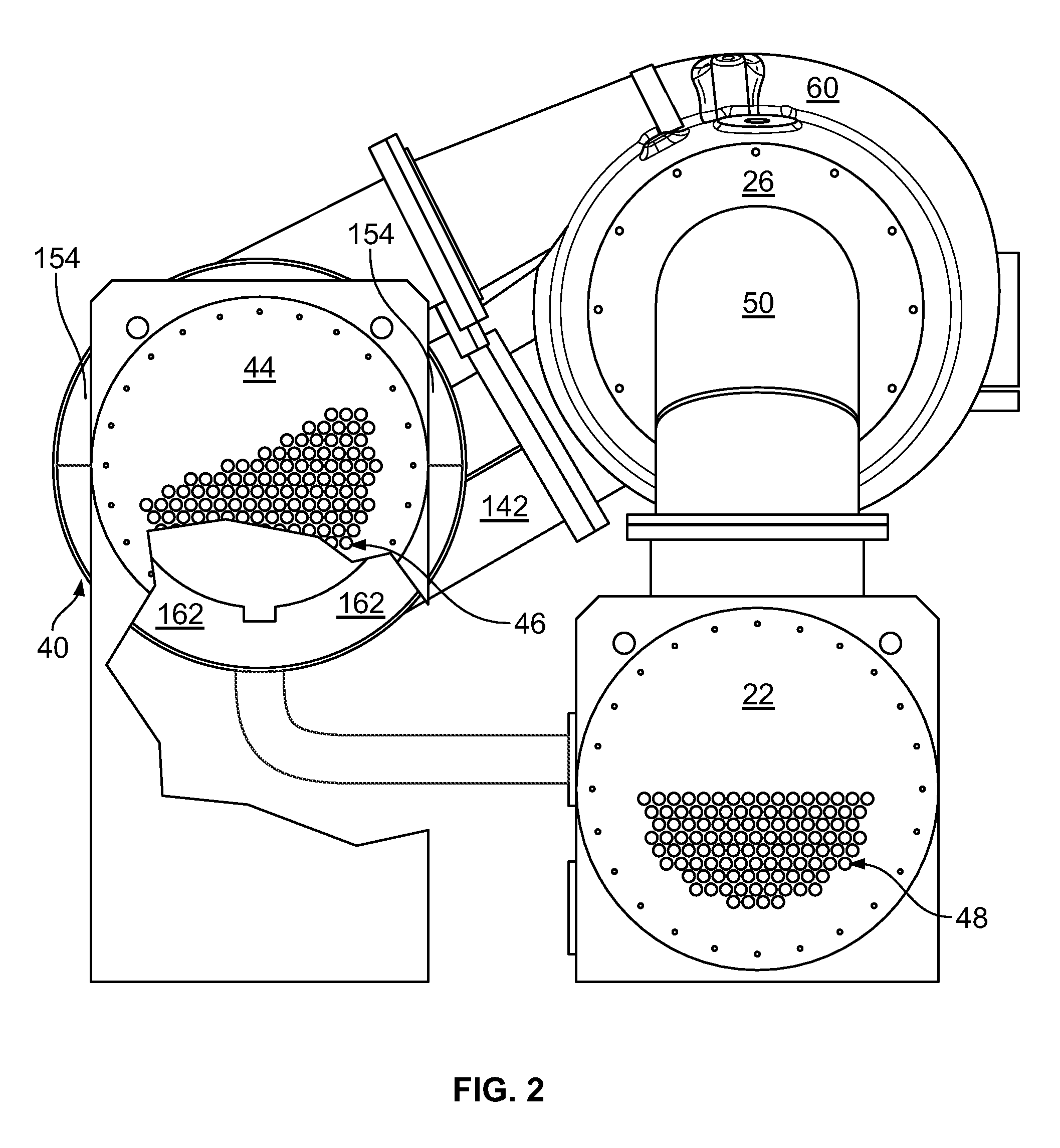

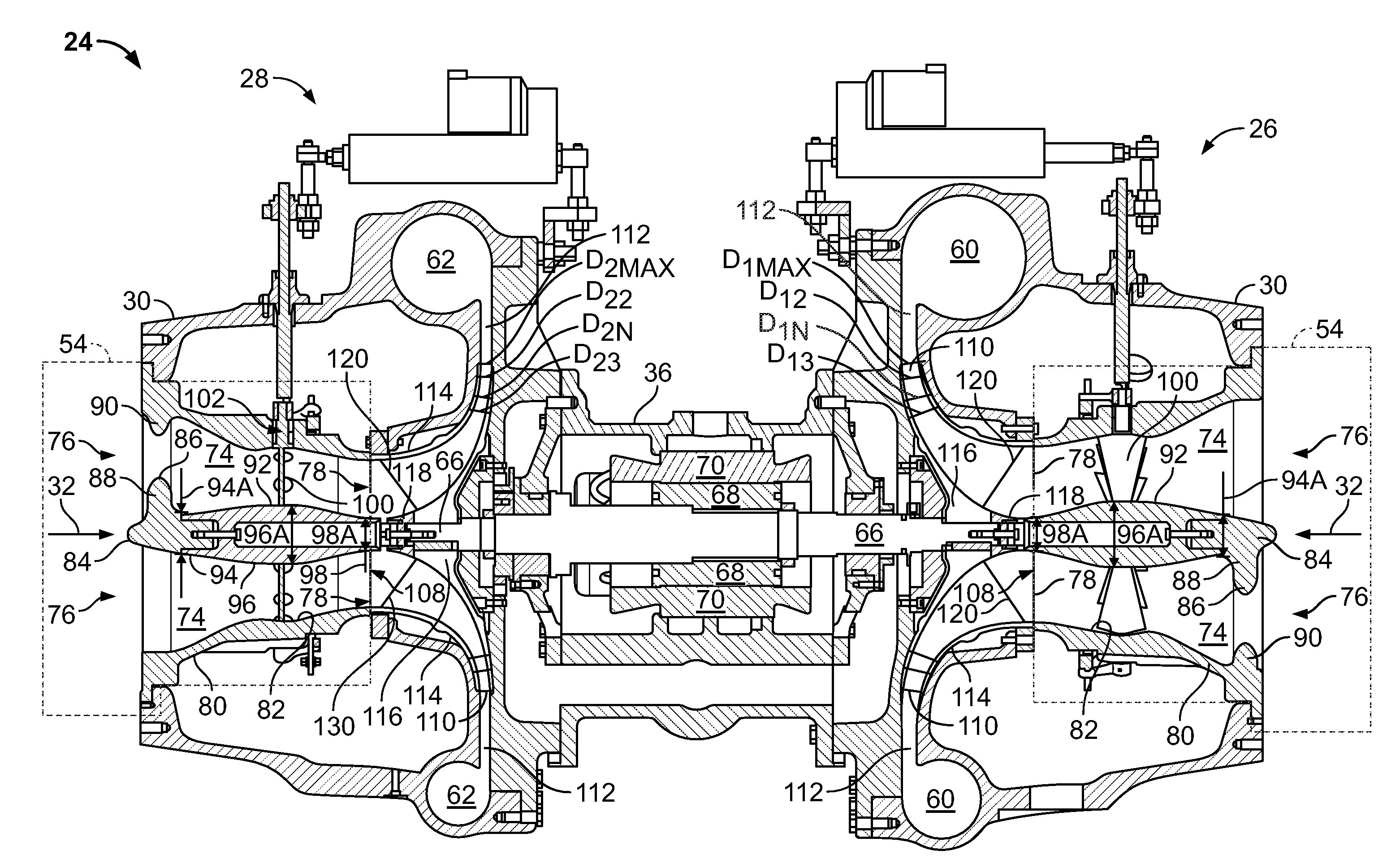

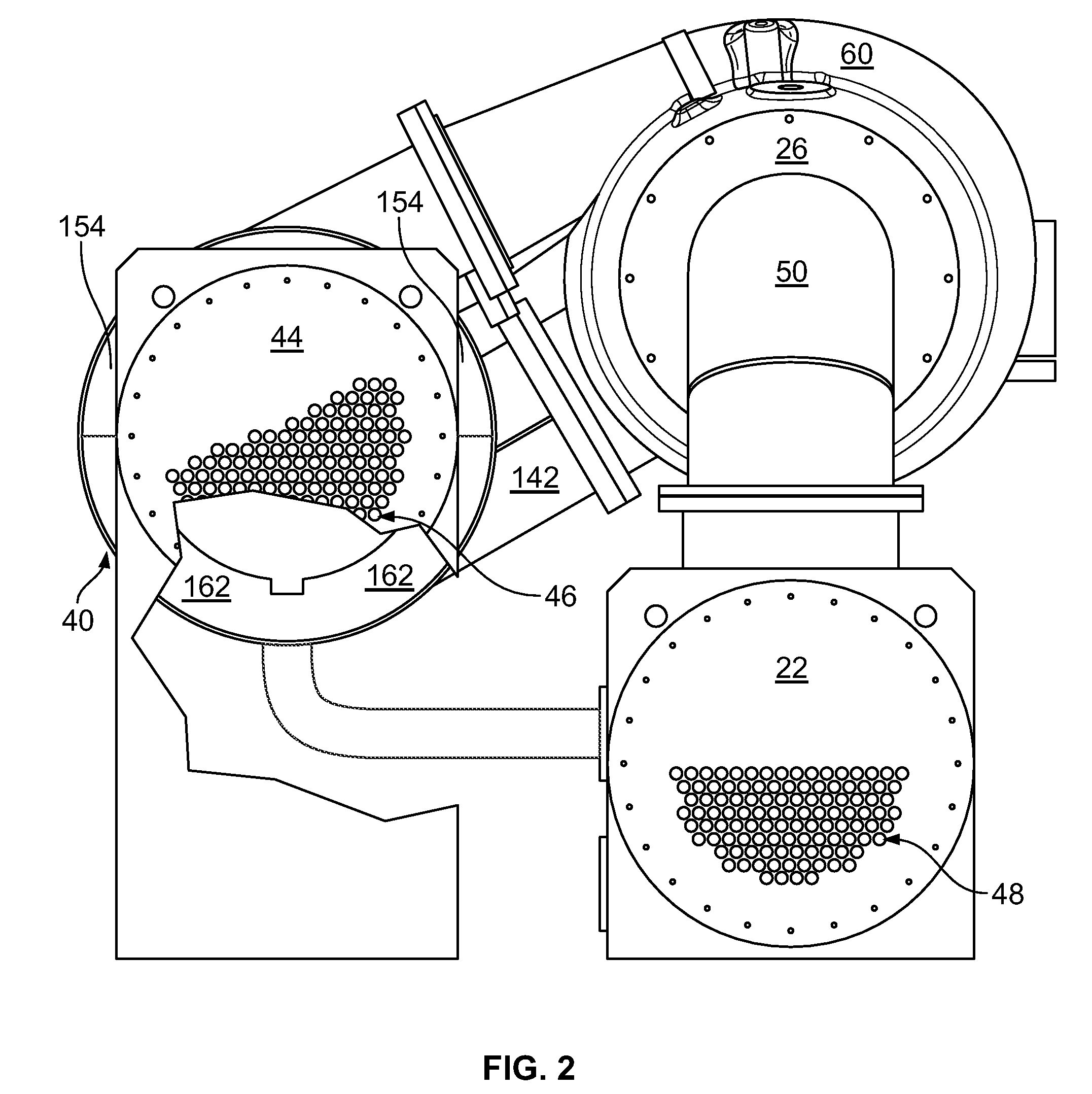

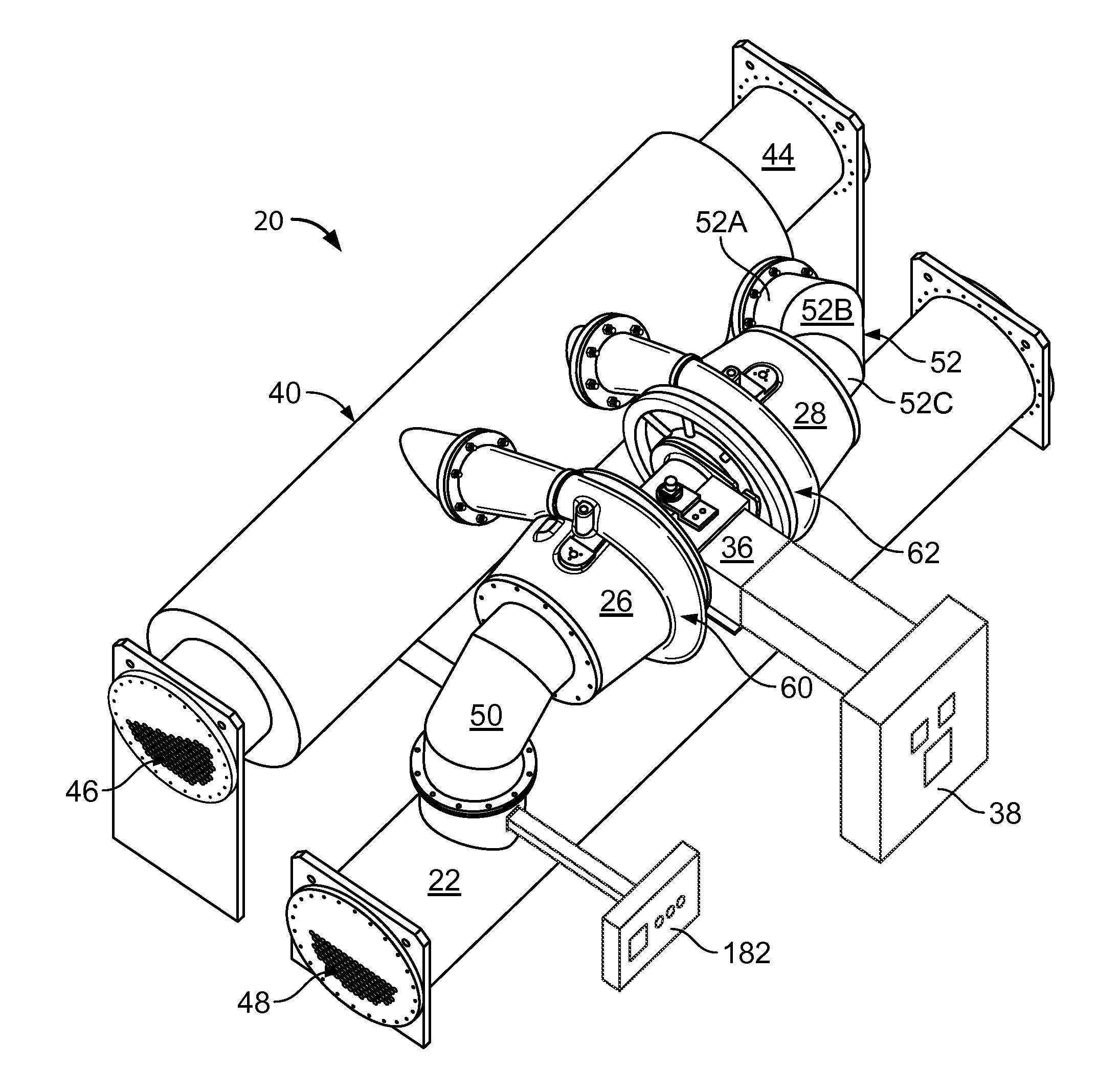

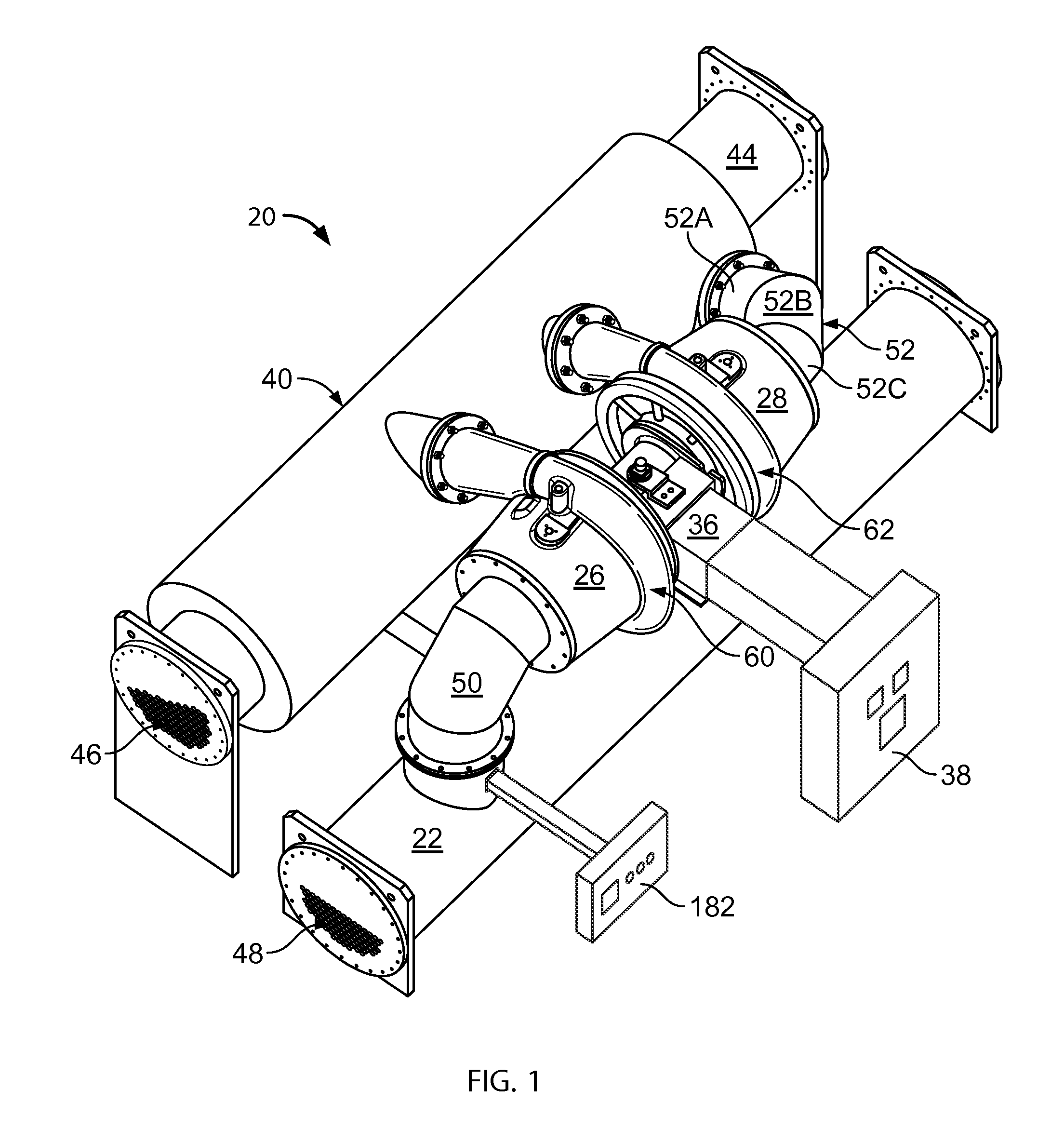

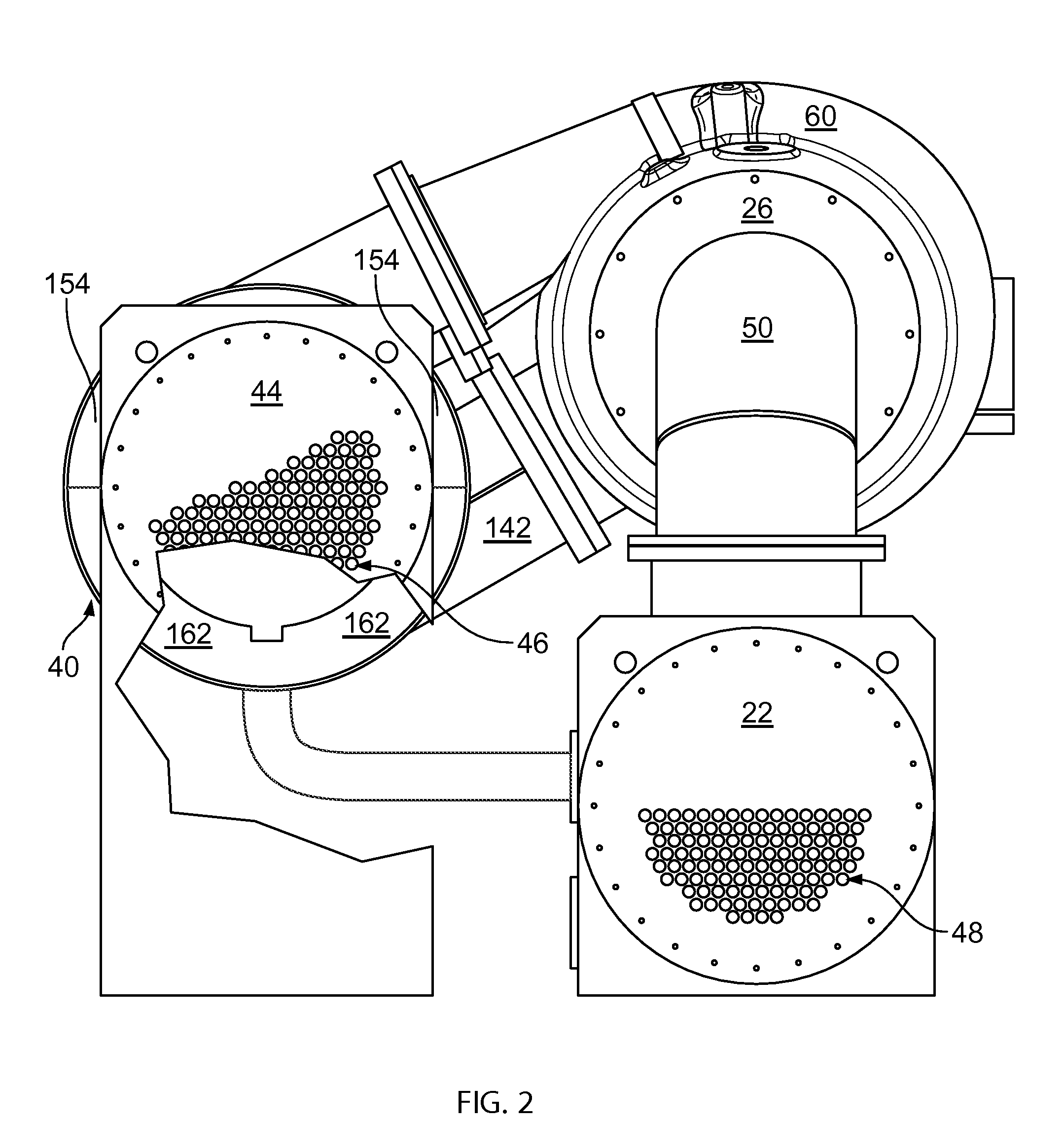

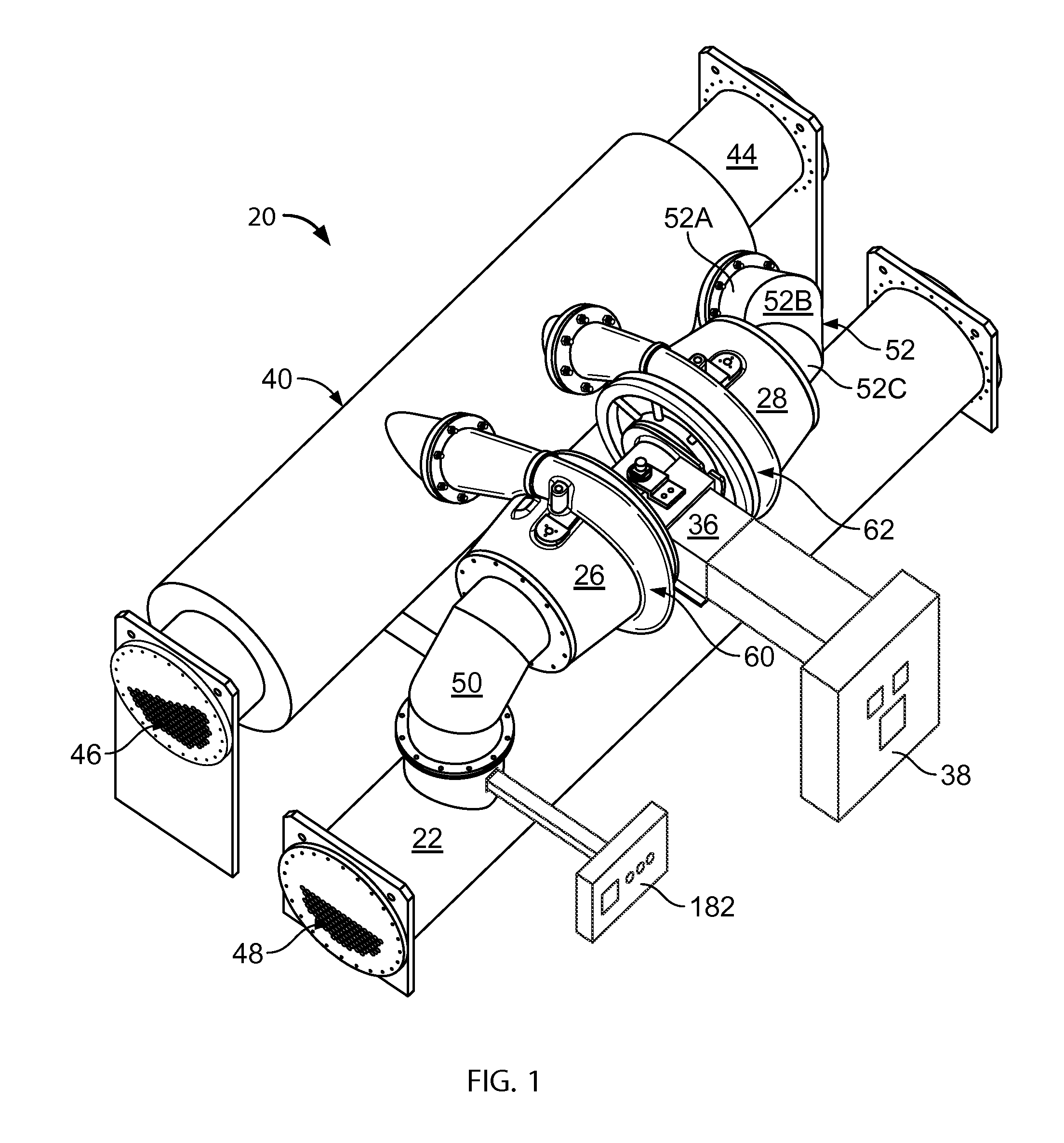

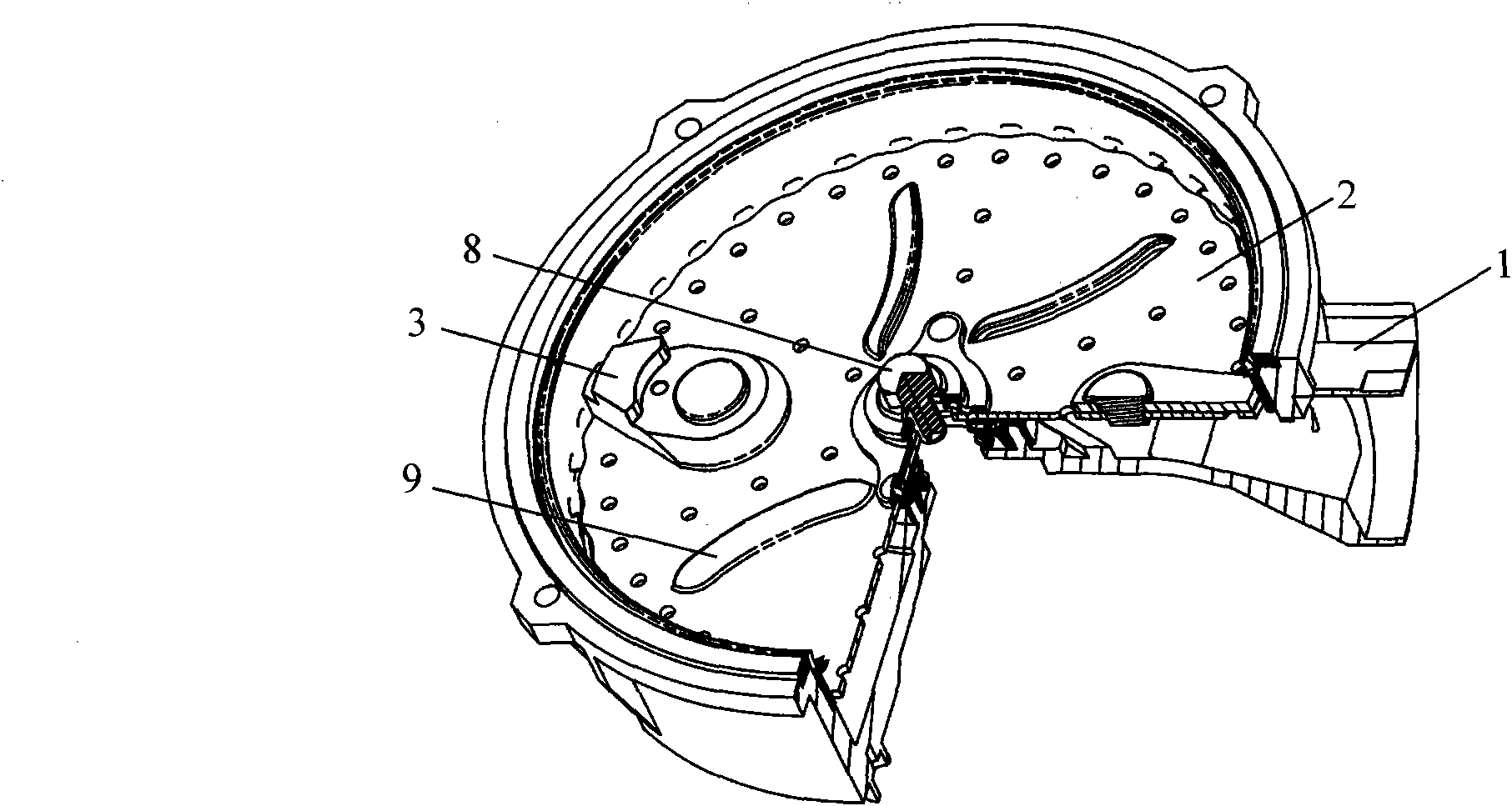

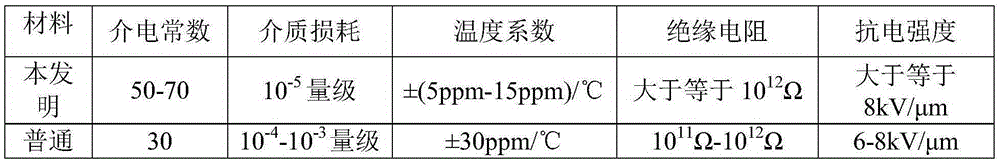

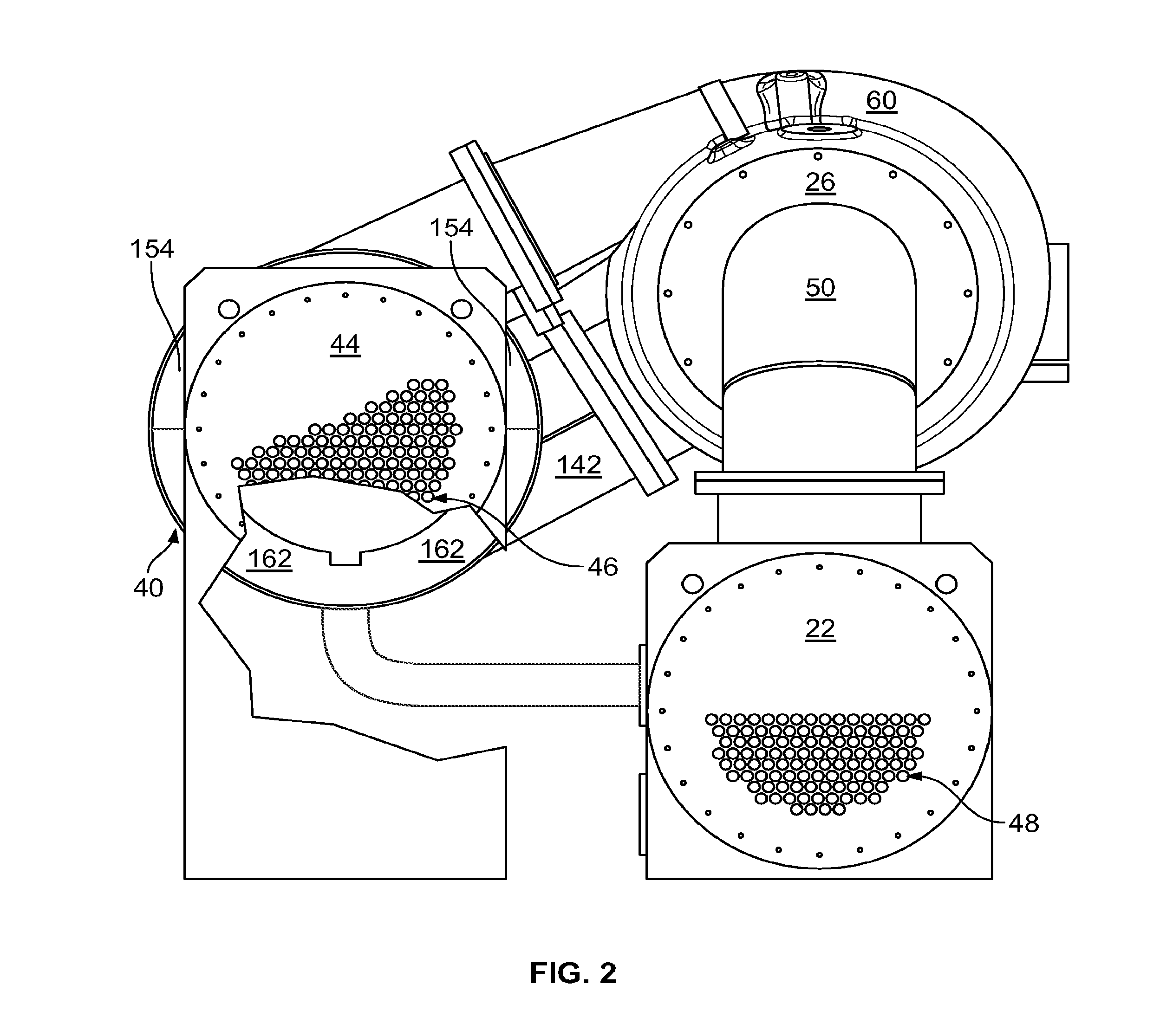

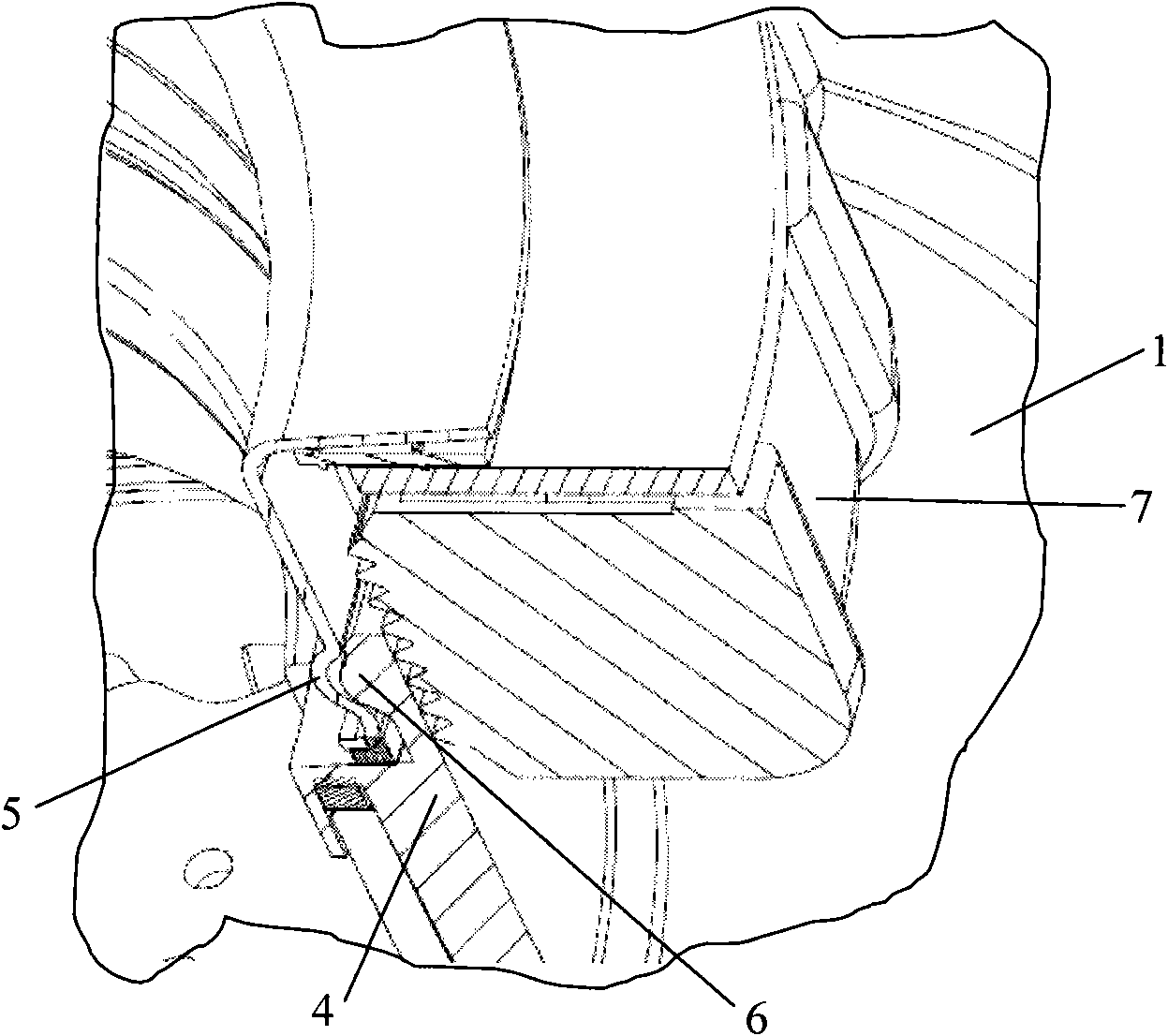

Centrifugal compressor assembly and method

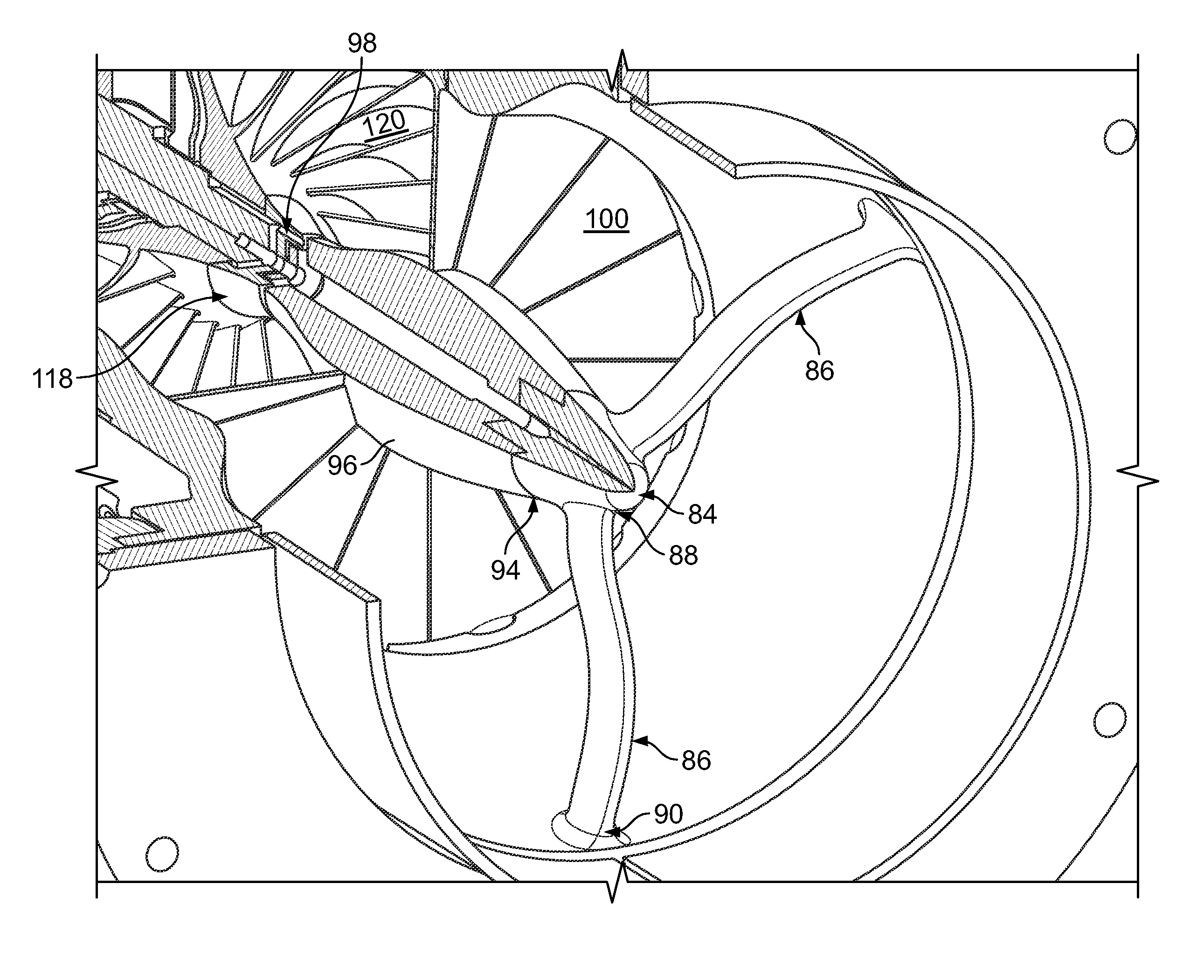

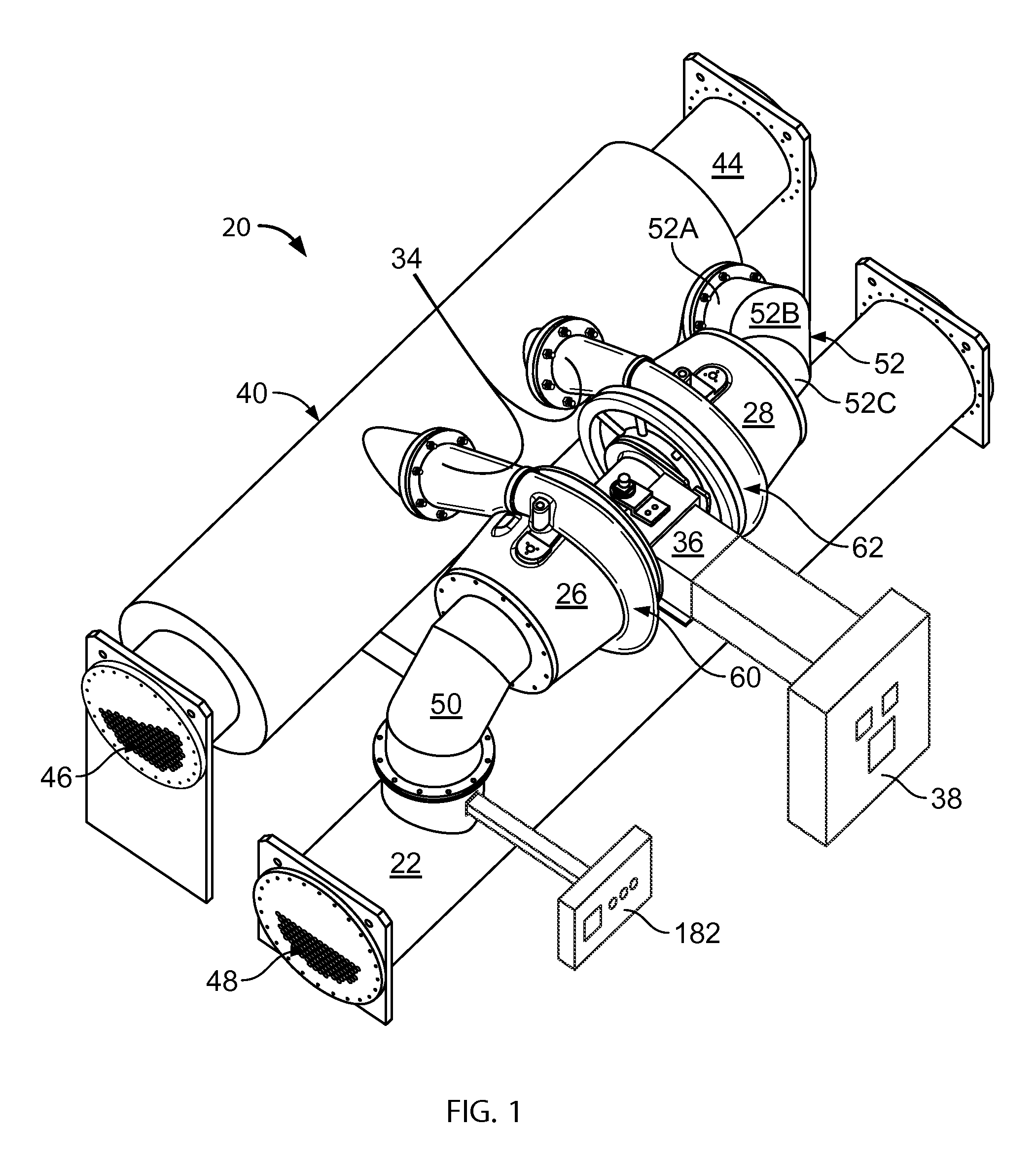

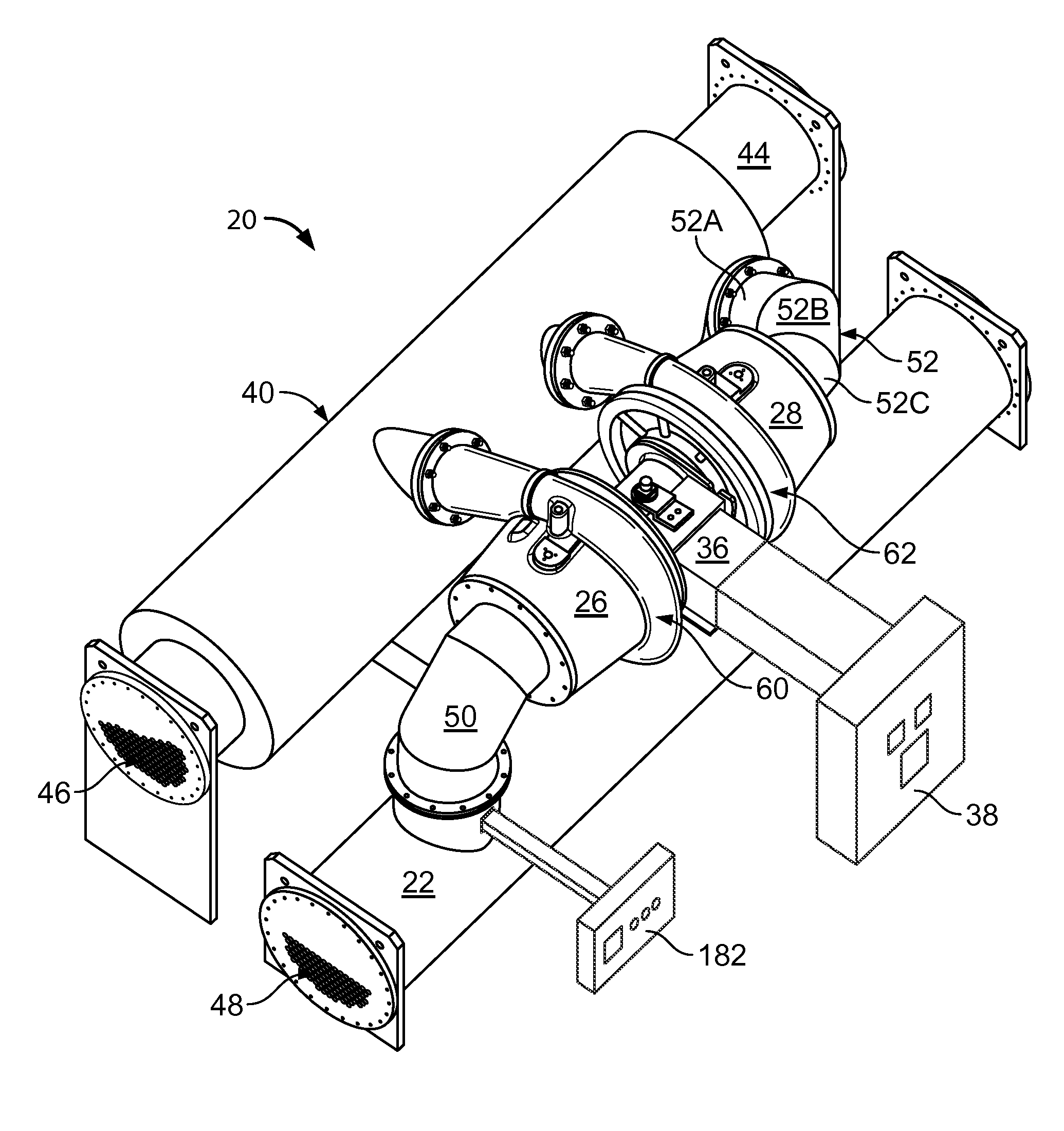

ActiveUS20090205360A1High energy densityImprove performancePump componentsRotary non-positive displacement pumpsConstant angleHigh energy

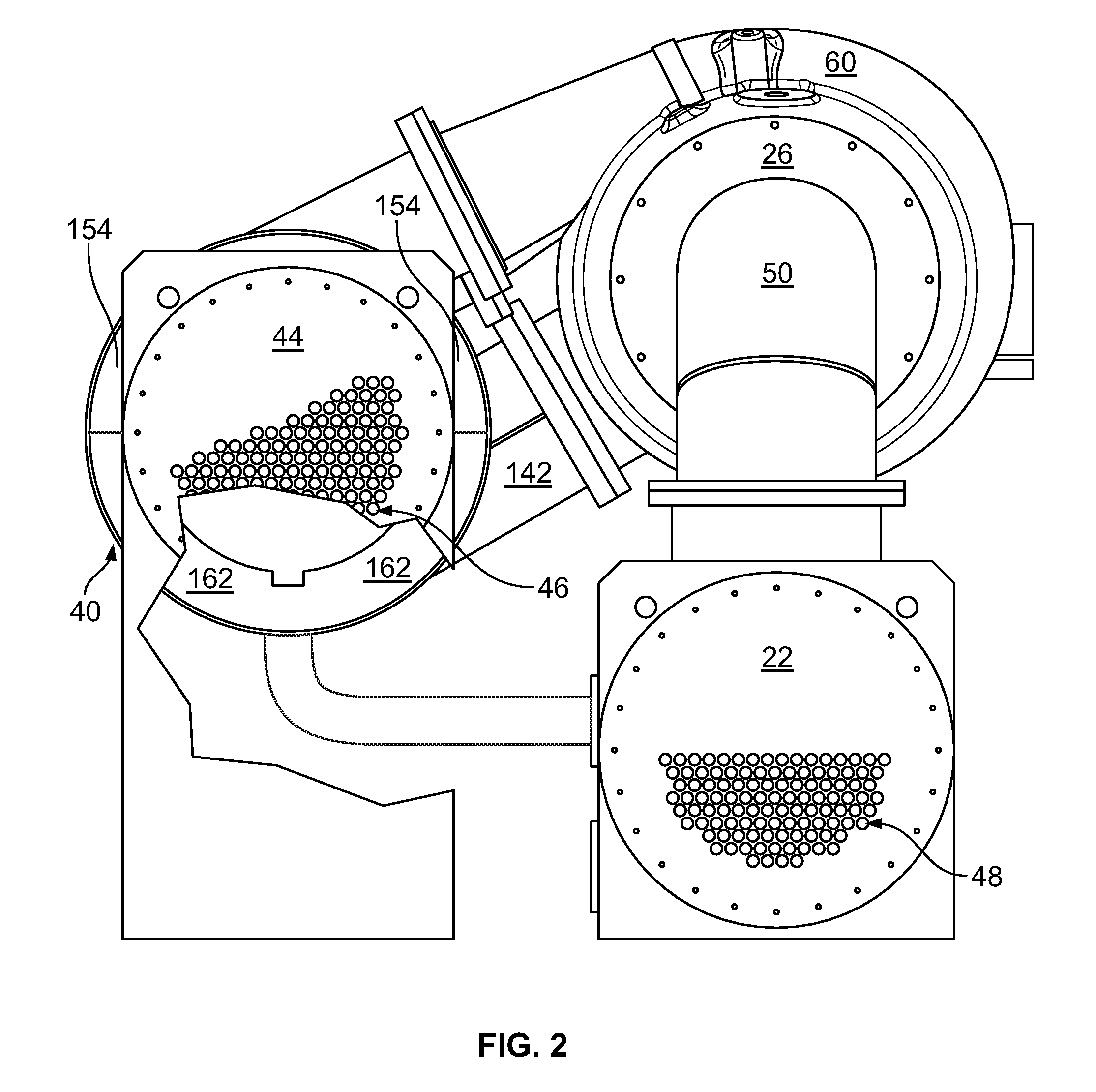

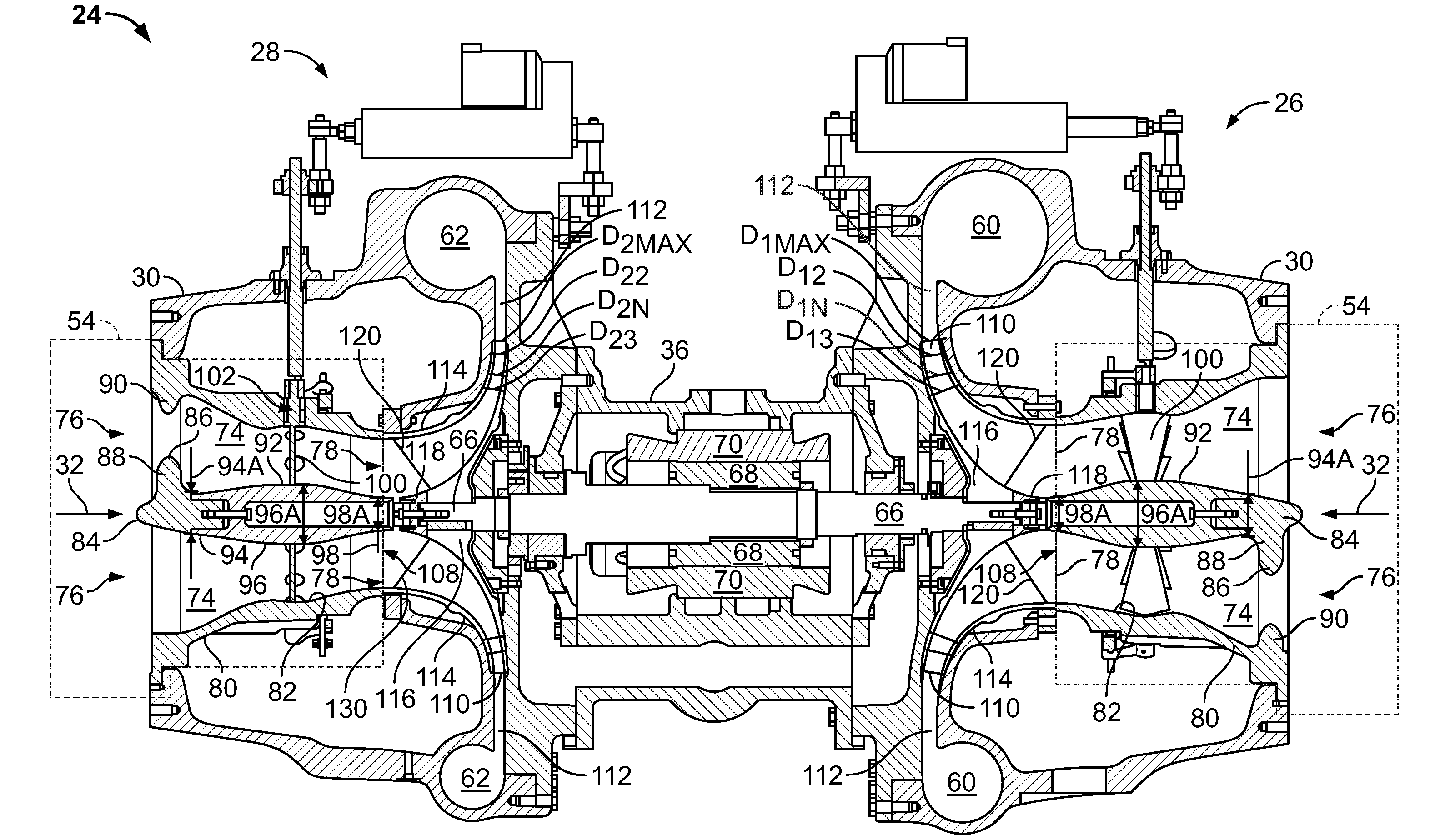

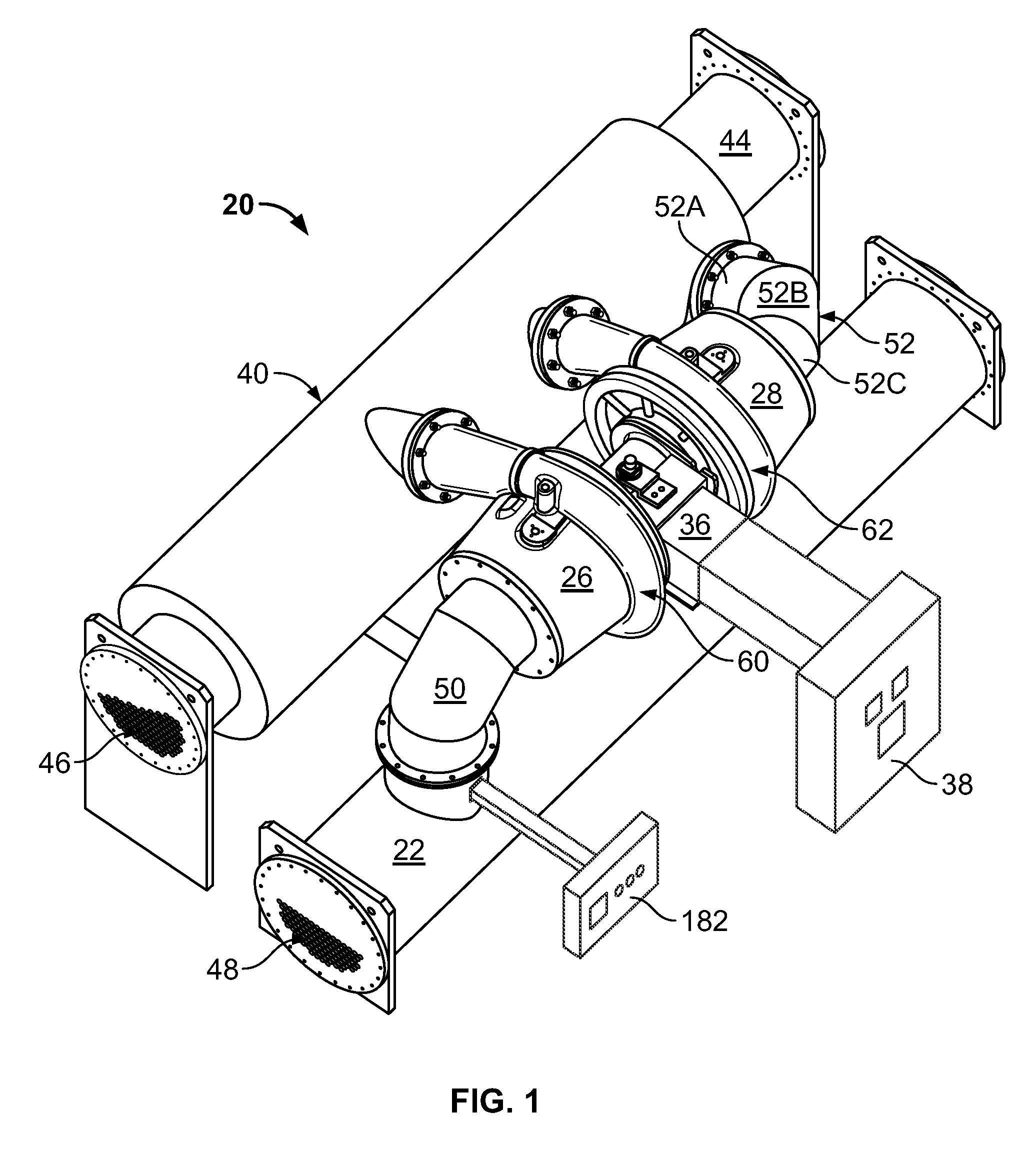

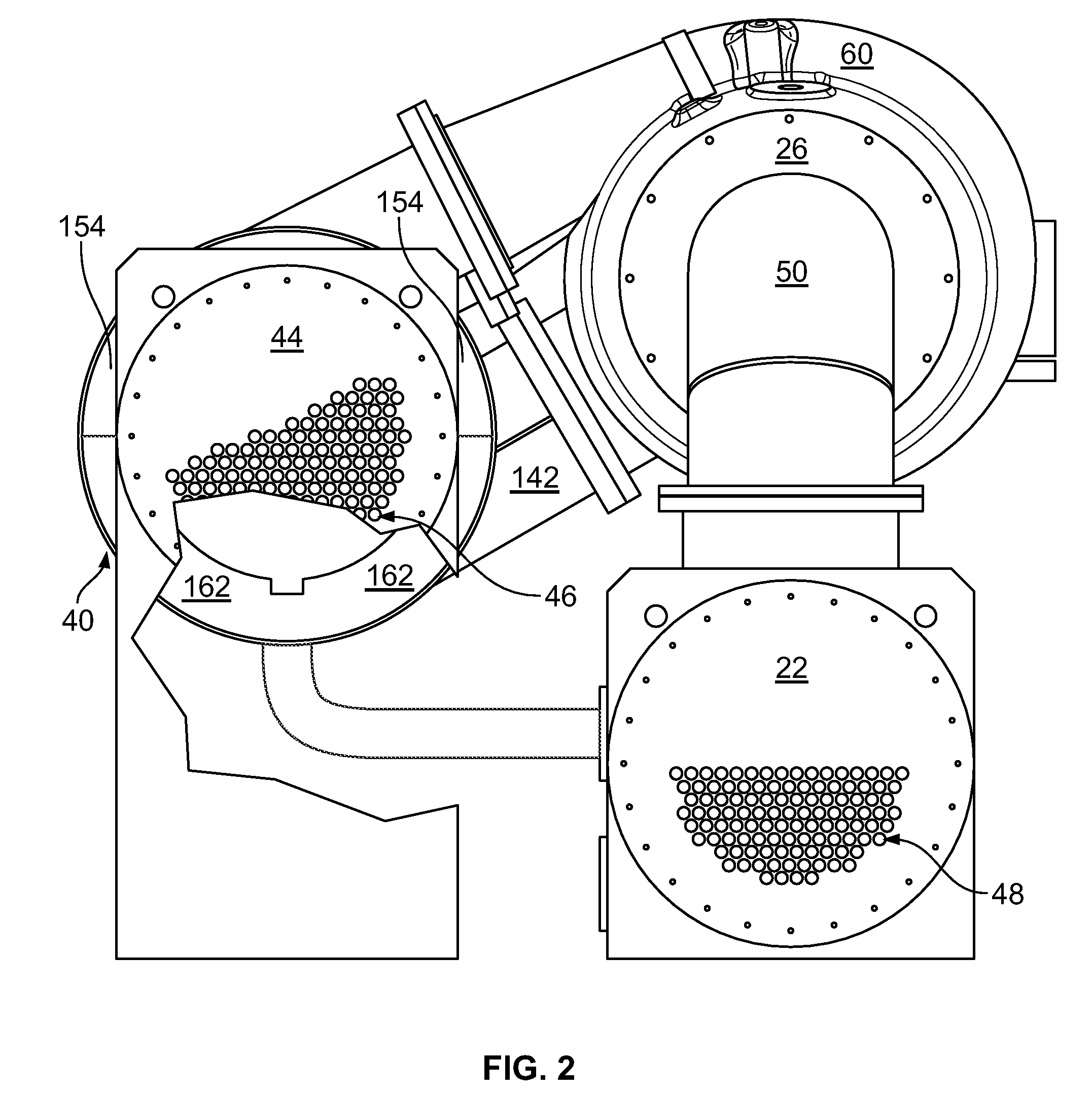

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Centrifugal compressor assembly and method

ActiveUS7856834B2Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Centrifugal compressor assembly and method

ActiveUS8037713B2Improve performanceReduce physical sizePump componentsRotary non-positive displacement pumpsMixed flowHigh energy

Owner:TRANE INT INC

Centrifugal compressor assembly and method

ActiveUS20090208331A1Improve performanceReduce physical sizeEngine manufacturePump componentsMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Centrifugal compressor assembly and method

ActiveUS20090205362A1Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

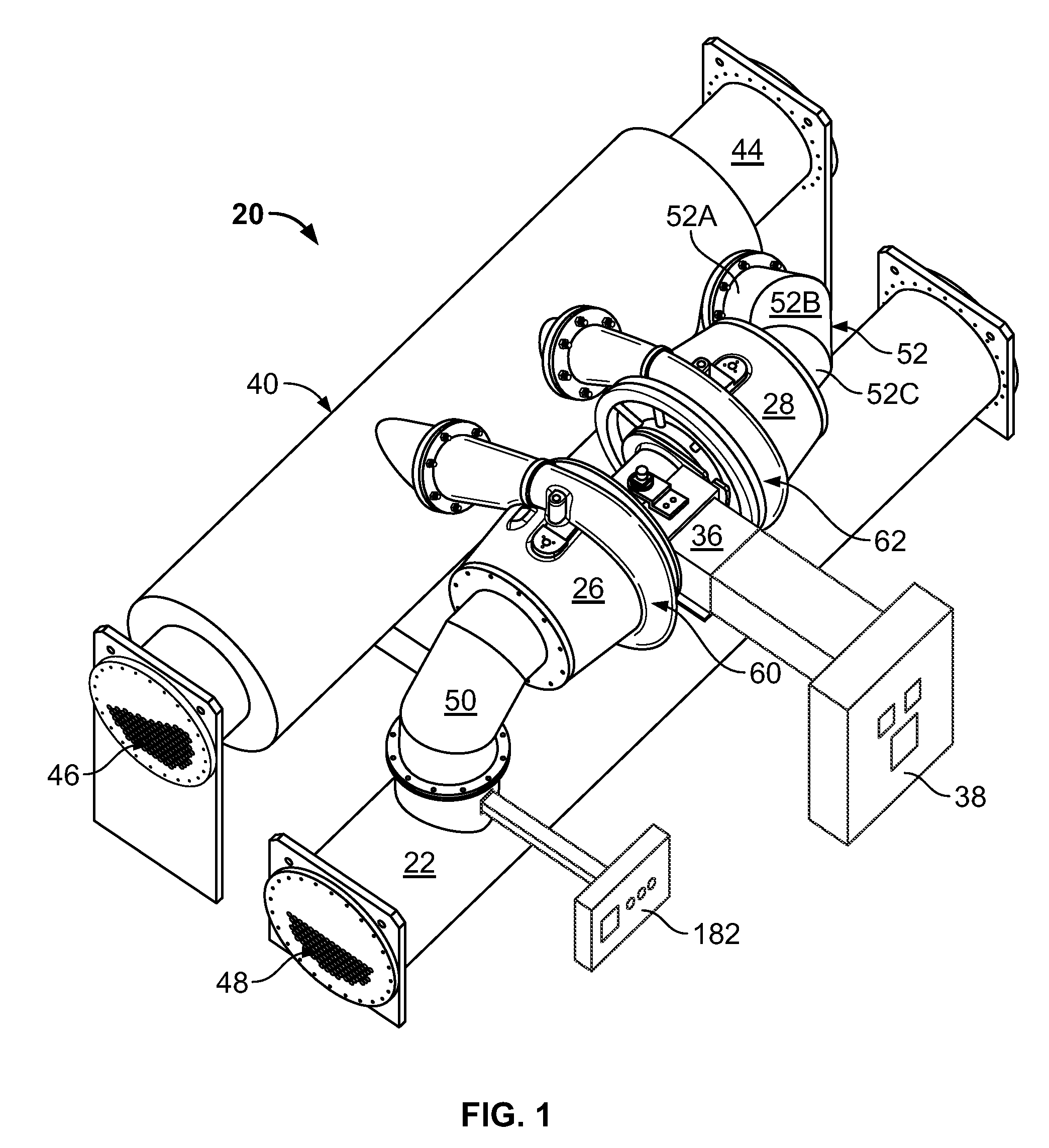

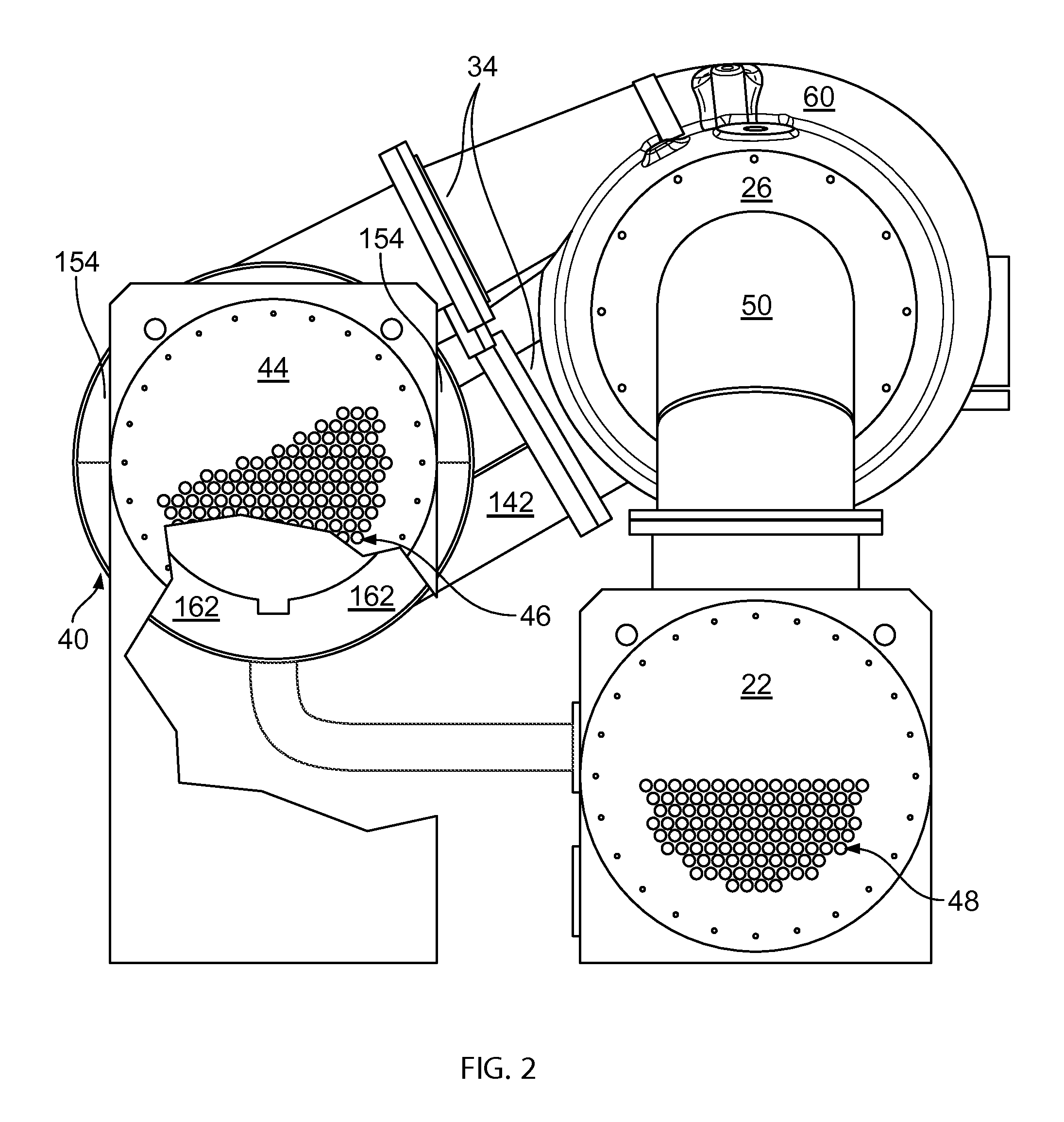

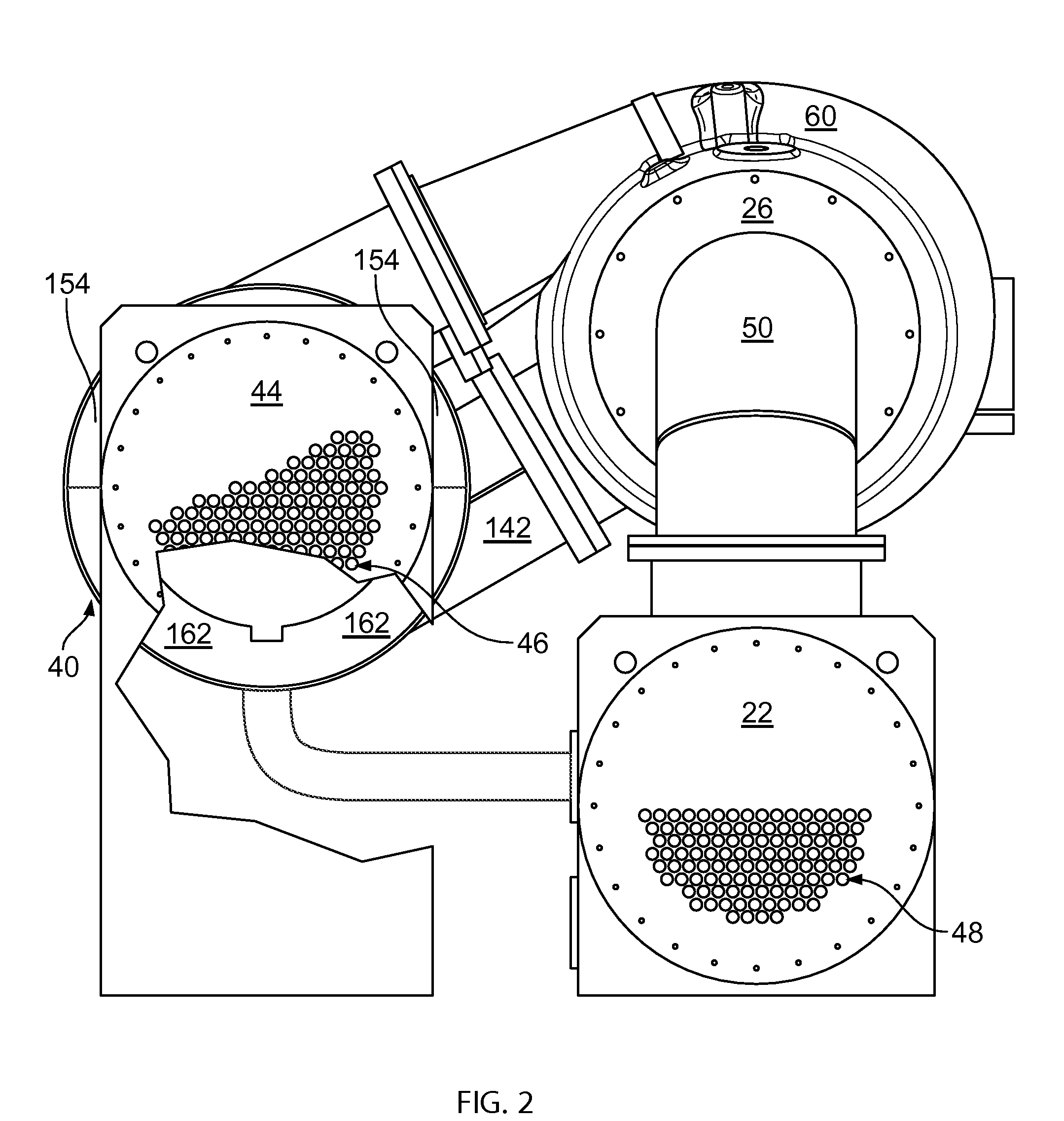

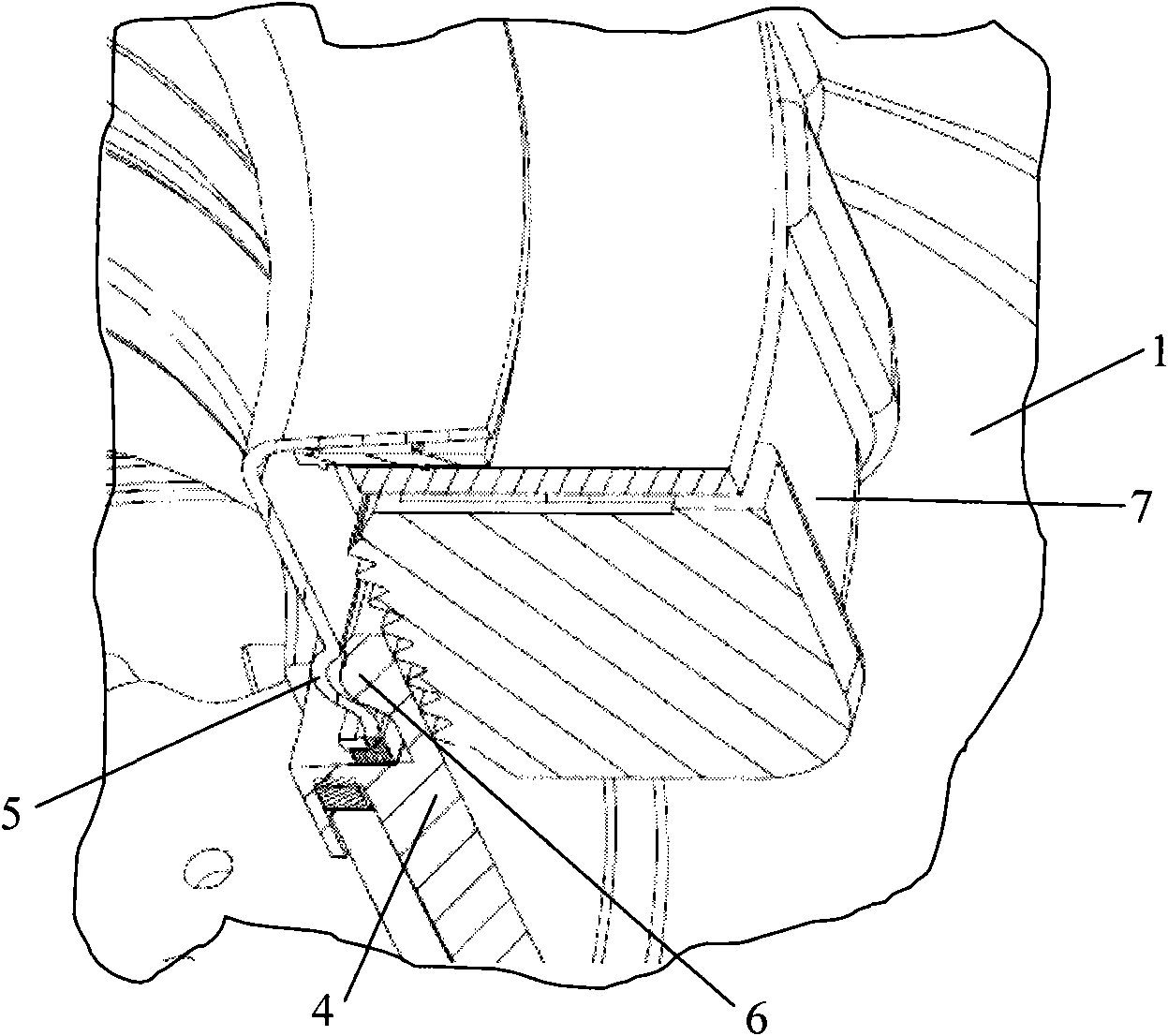

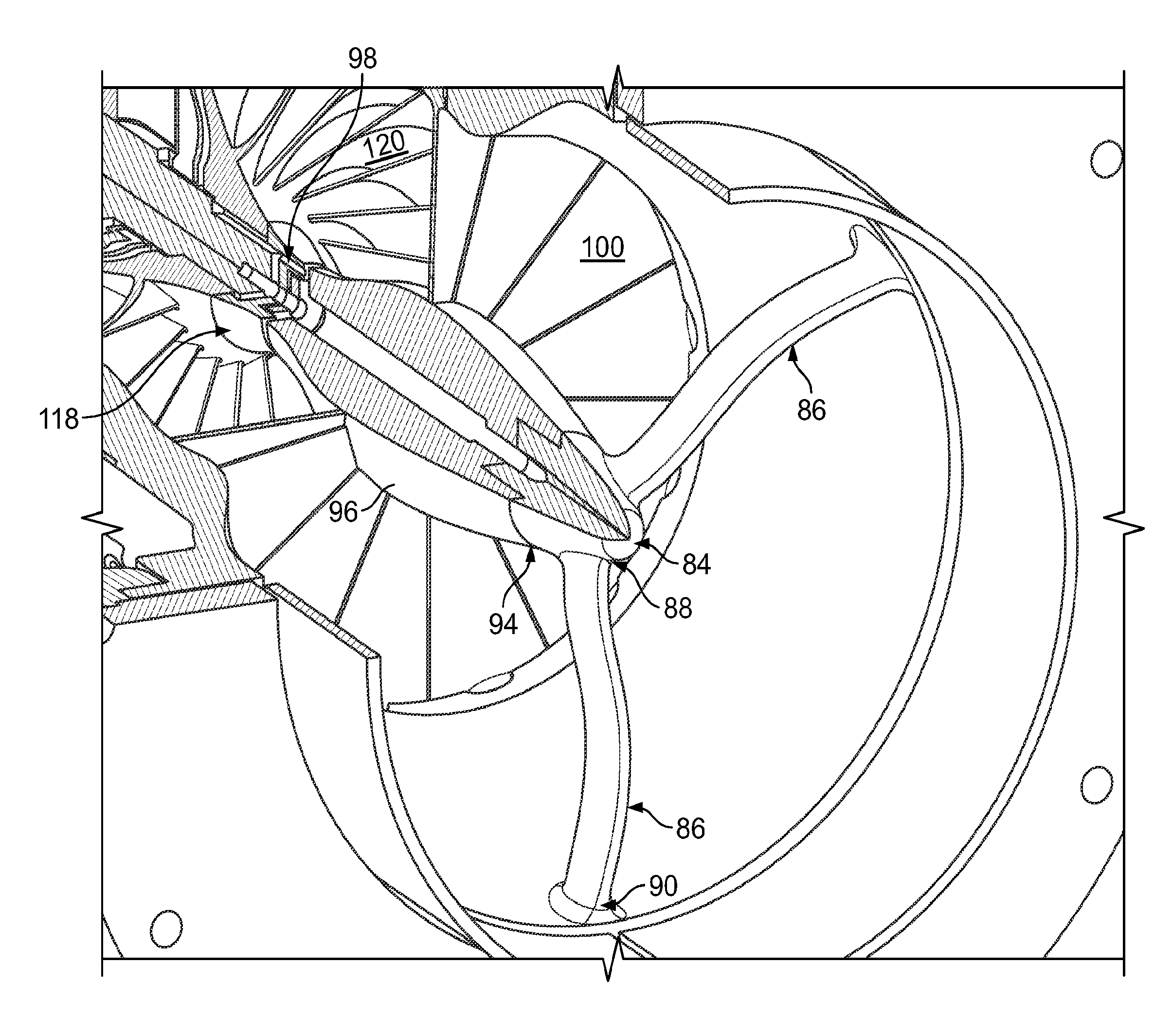

Coaxial economizer assembly and method

ActiveUS20090205361A1Improve fluid flowImprove performanceCompressorMechanical apparatusLiquid stateFlash-gas

A coaxial economizer for use in a chiller system comprising an inner housing and an outer housing having a common longitudinal axis. The outer housing has an inlet for receiving a fluid from a upstream compressor stage of a multistage compressor and an outlet for conveying a fluid to a downstream compressor stage of a multistage compressor. A flow chamber forms a fluid flow path about the inner housing. A flash chamber is coterminous with the flow chamber and flashes fluid in a liquid state to a gas state. A flow passage between said flash chamber and the flow chamber for conveying a flashed gas from the flash chamber to the flow chamber; wherein the flashed gas conveyed from the flash chamber and the fluid received from the inlet of the outer housing mix along the fluid flow path toward the outlet of the outer housing.

Owner:TRANE INT INC

Centrifugal compressor assembly and method

ActiveUS9353765B2Improve performanceReduce physical sizeEngine manufacturePump componentsMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Coaxial economizer assembly and method

ActiveUS7975506B2Improve fluid flowImprove performanceCompressorMechanical apparatusLiquid stateFlash-gas

Owner:TRANE INT INC

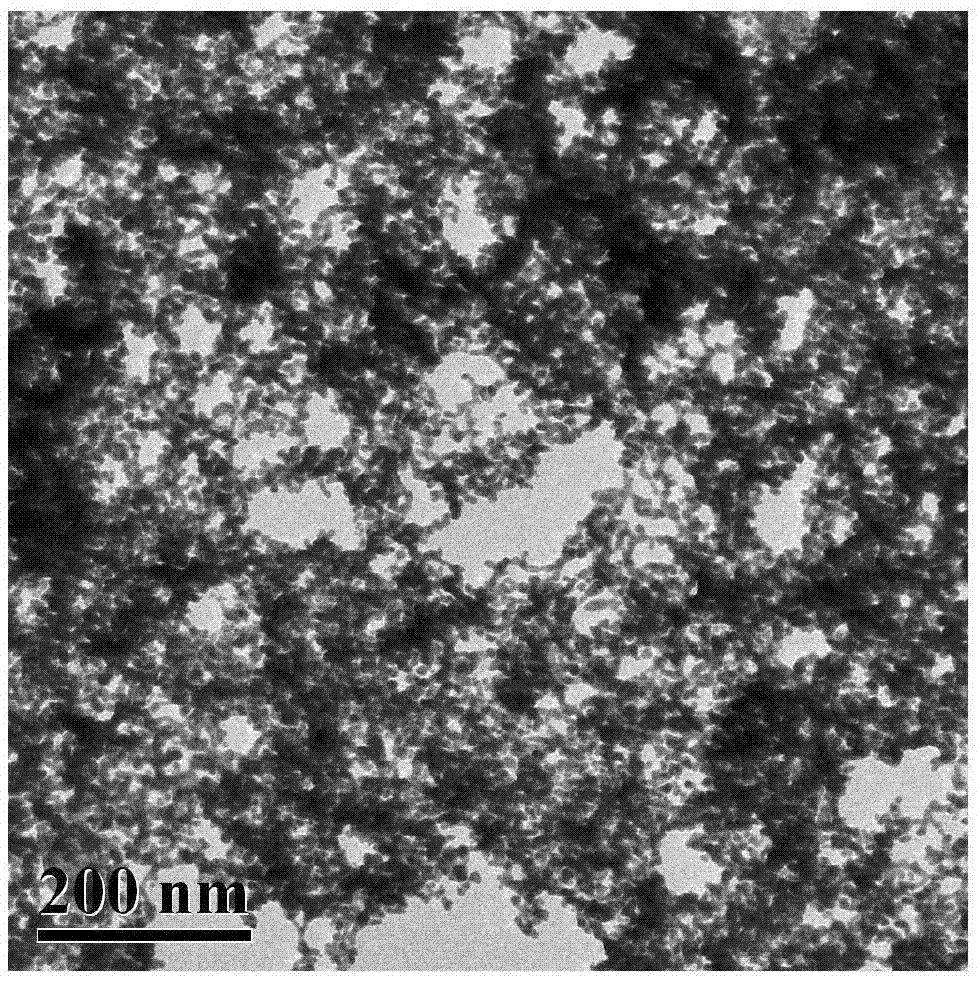

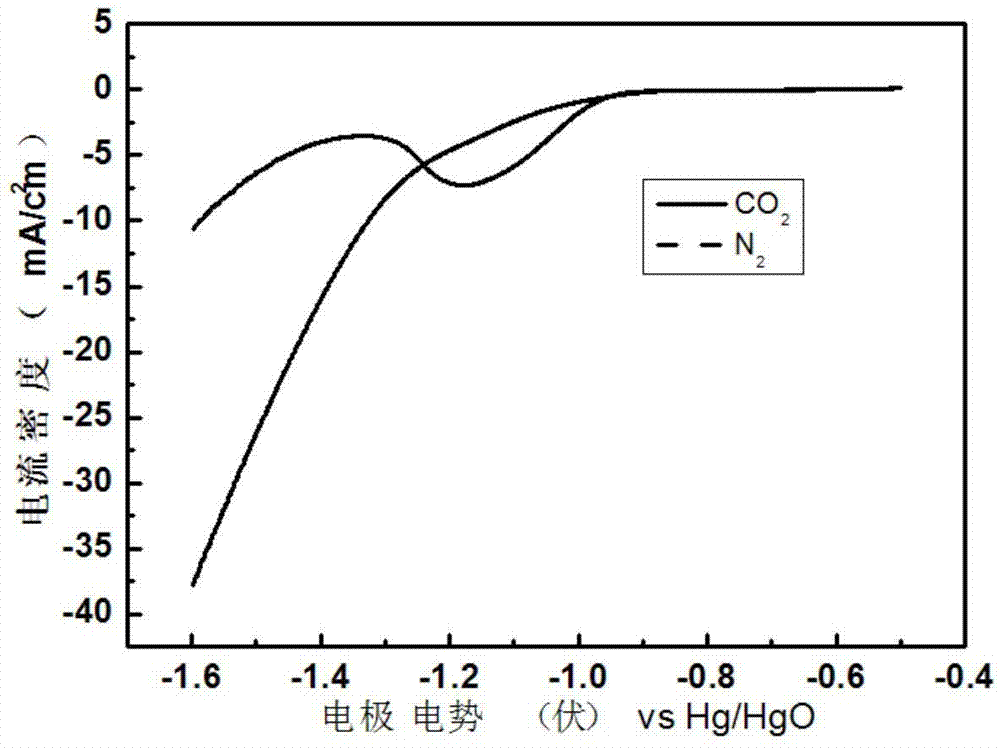

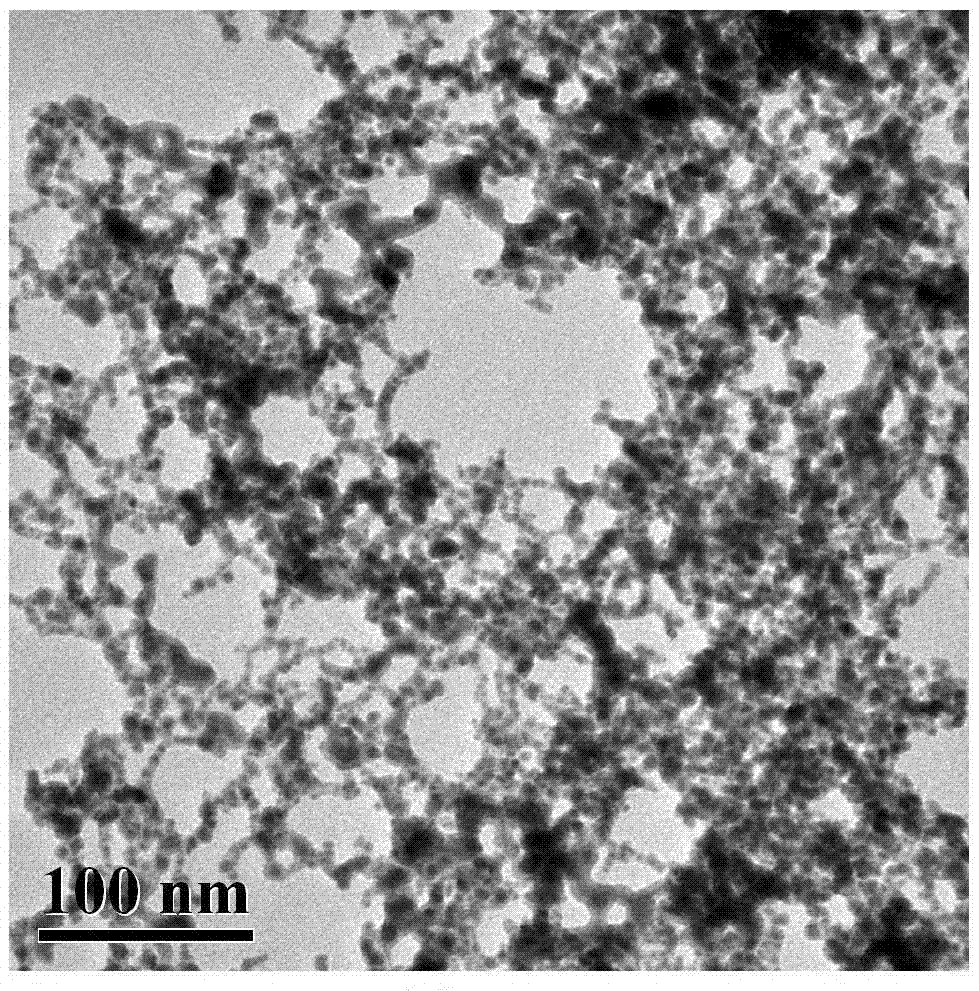

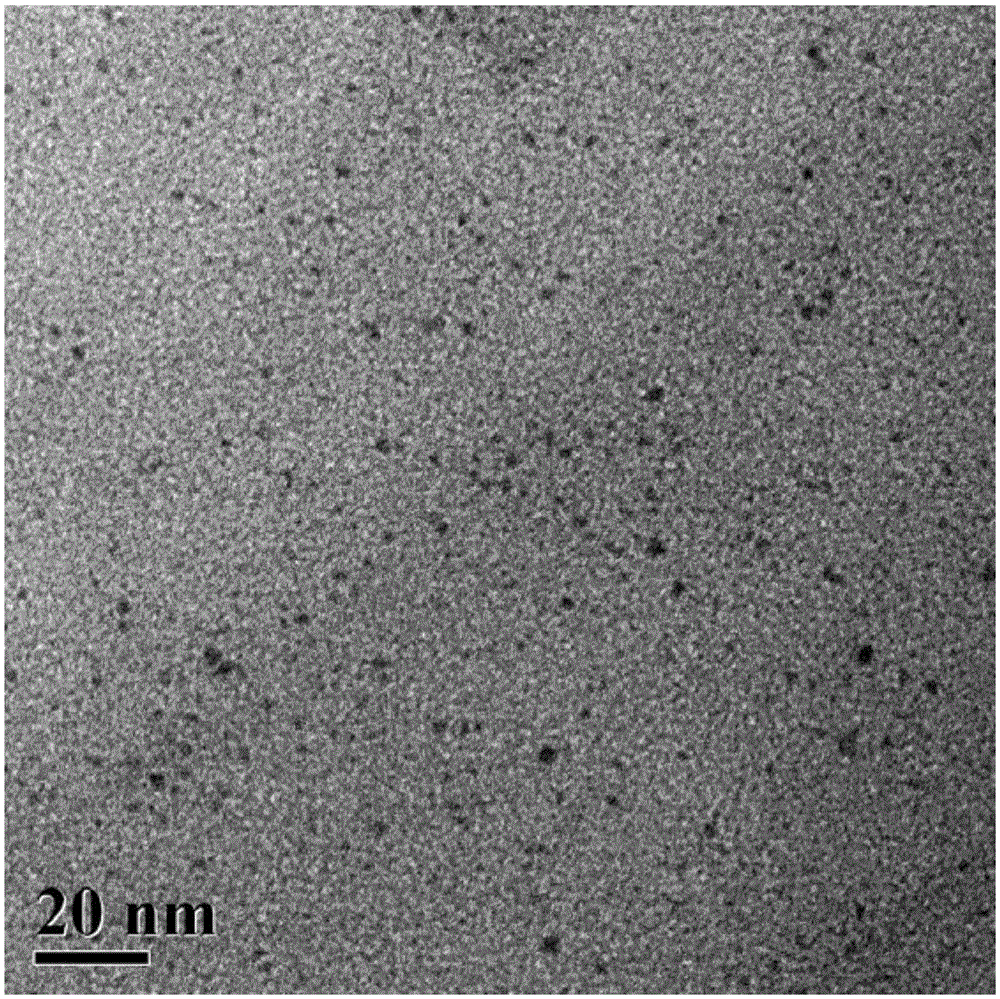

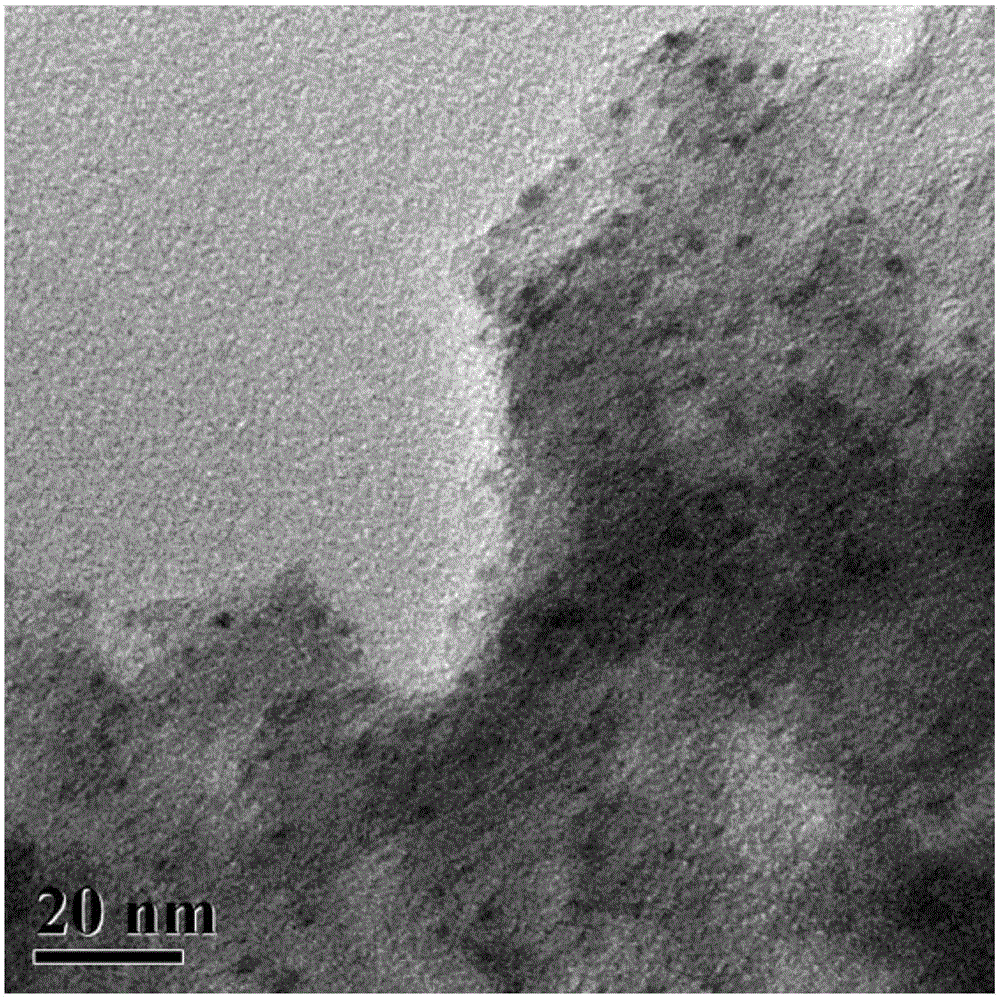

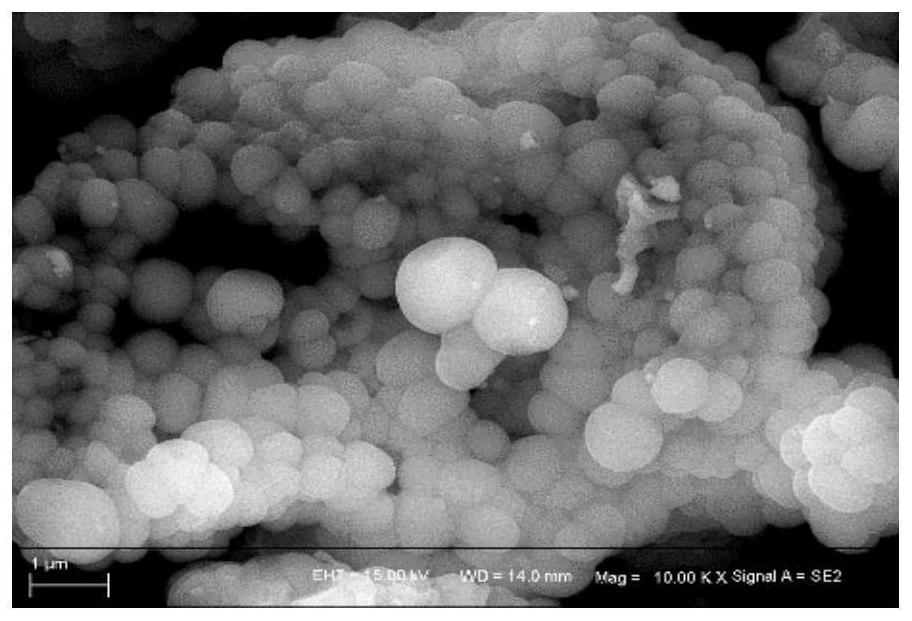

Indium-based two-component or three-component nanocatalyst as well as preparation and application thereof

InactiveCN106890639AEasy to operateMild conditionsGas treatmentDispersed particle separationIridiumNano catalyst

The invention relates to a supported type or non-supported type indium-based two-component or three-component nanocatalyst. The second or third component catalyst is one of platinum, palladium, gold, iridium, copper, silver, tin and lead, and in the catalyst, the molar ratio of indium to the second component or the total molar sum of the second component and the third component is 9 / 1-1 / 9; and when the catalyst is a carbon supported indium-based two-component or three-component nanocatalyst, metals in the catalyst account for 10-90% of the total mass of the catalyst. Preparation steps of the catalyst are as follows: introducing inert gas into prepared precursor solution, reducing, washing, and drying, so that the catalyst is obtained. The catalyst is a CO2 electrochemical reduction catalyst, a NOx removal catalyst and an organic molecule aqueous phase allylation catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

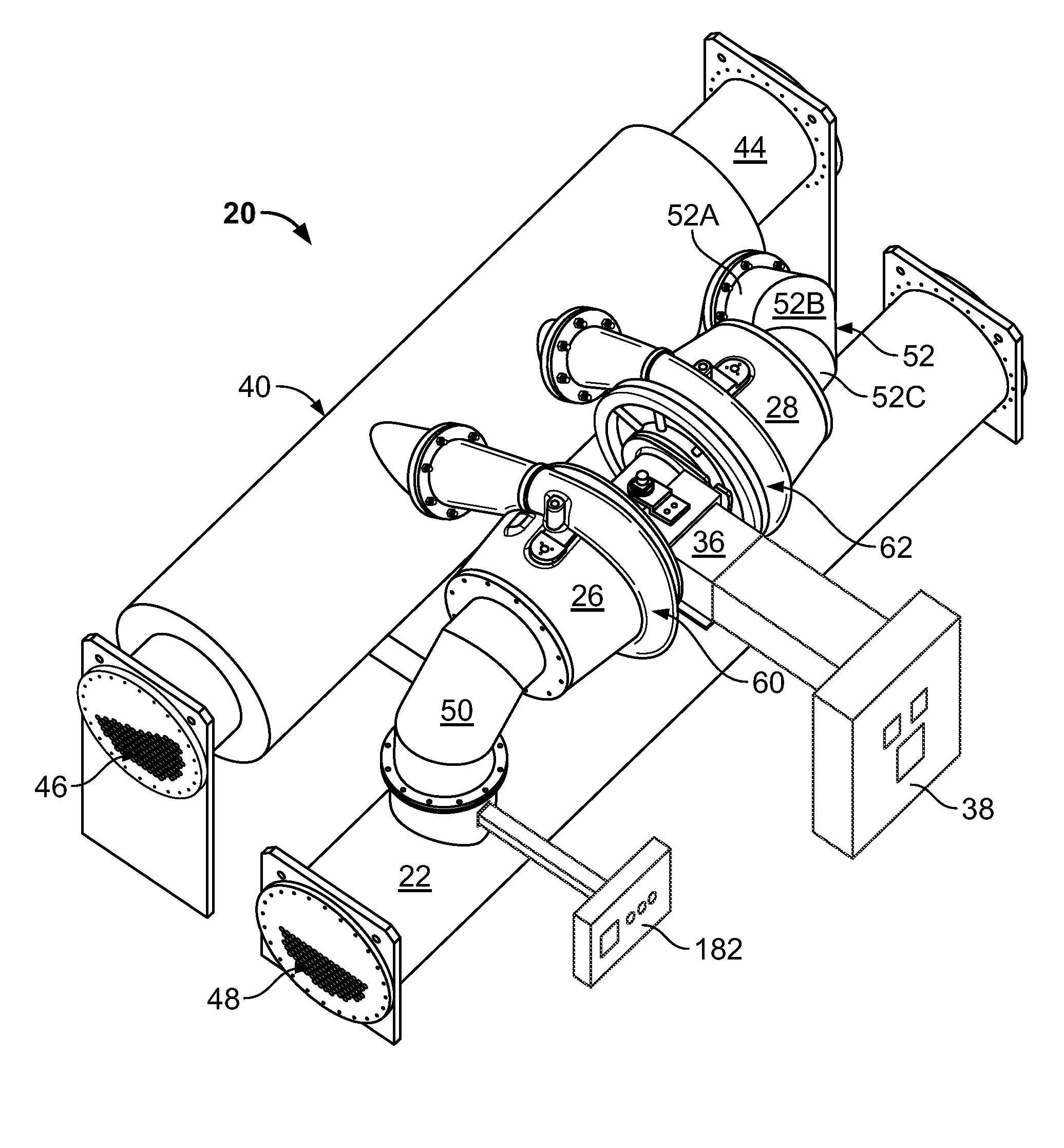

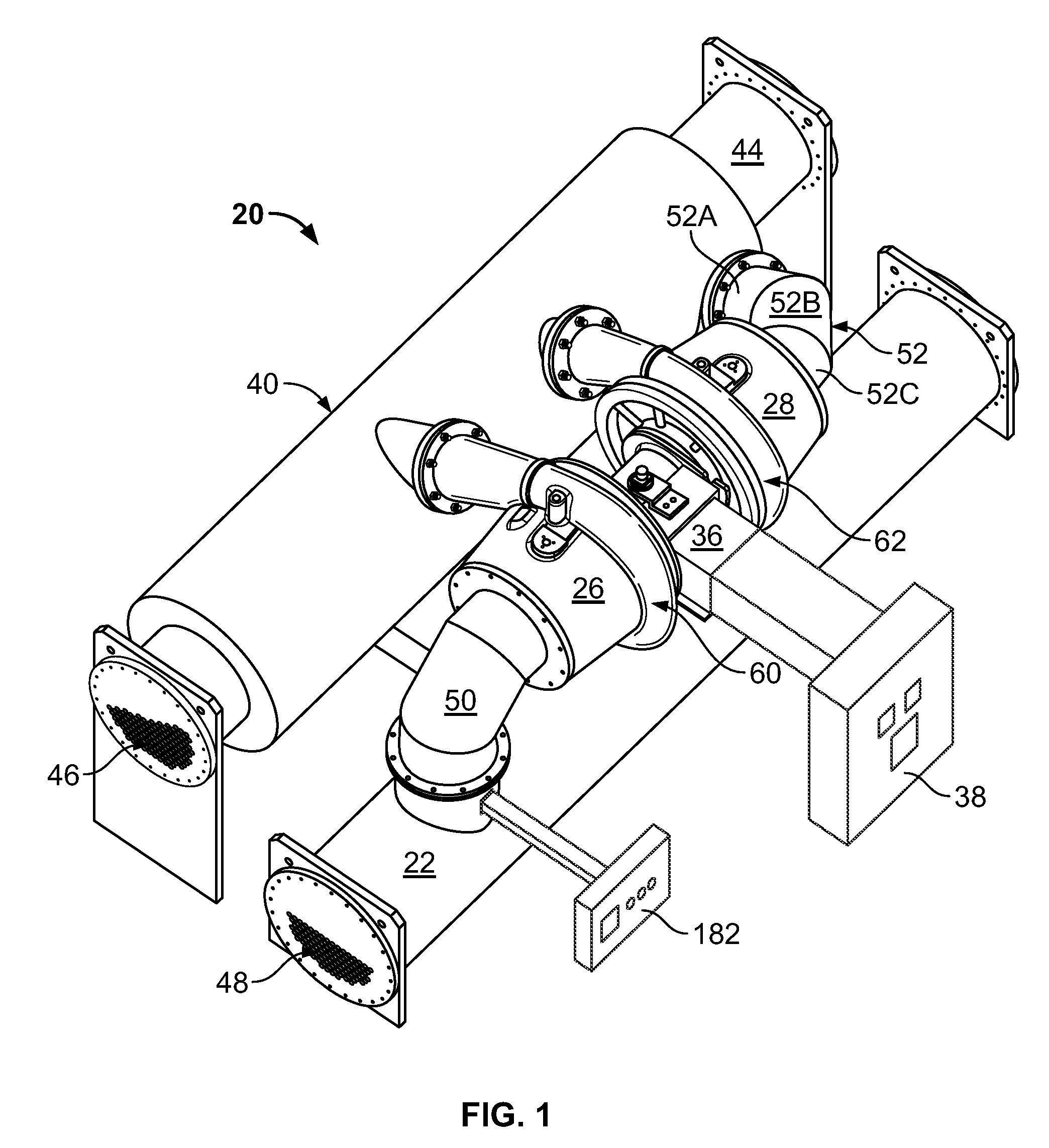

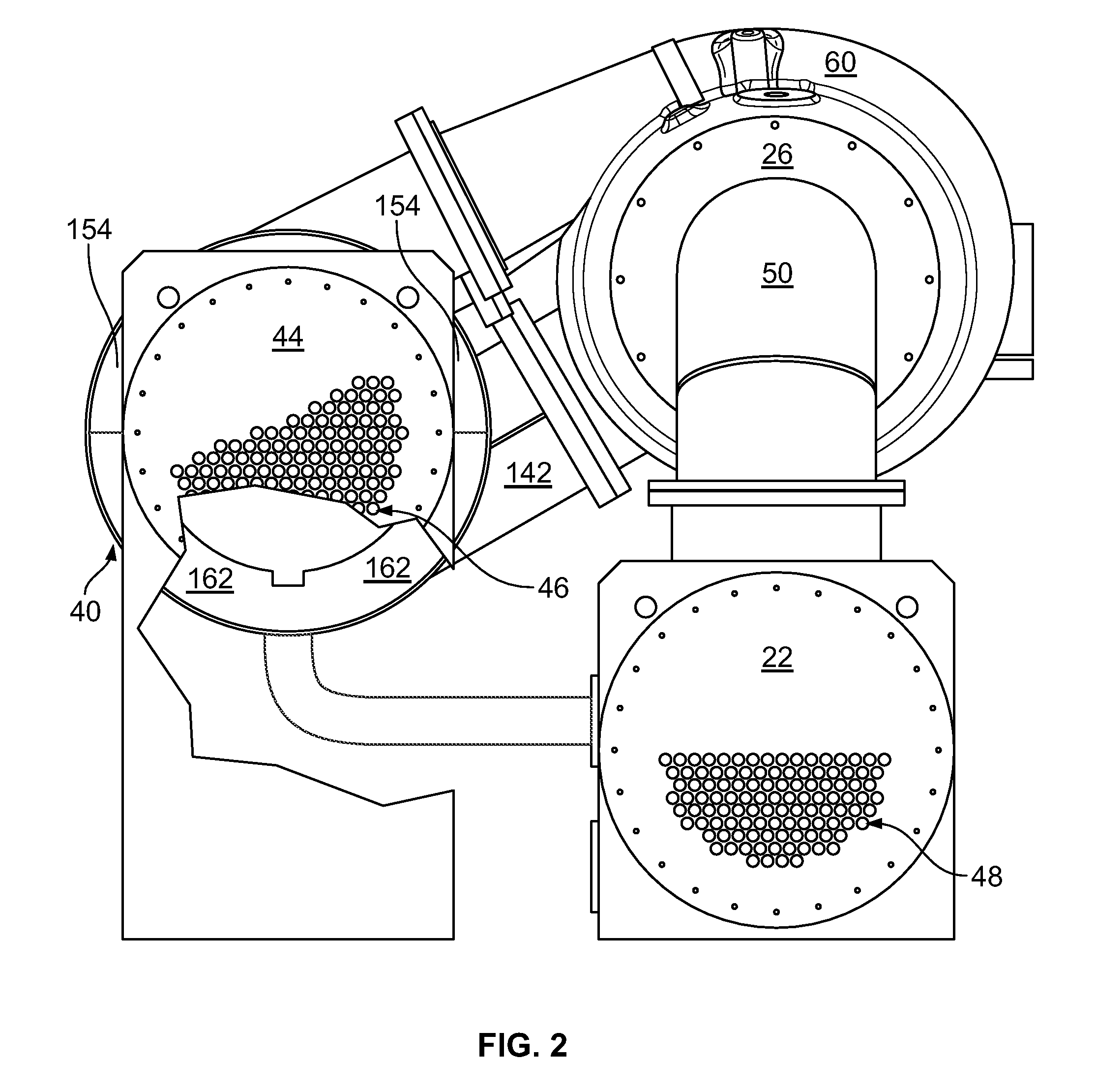

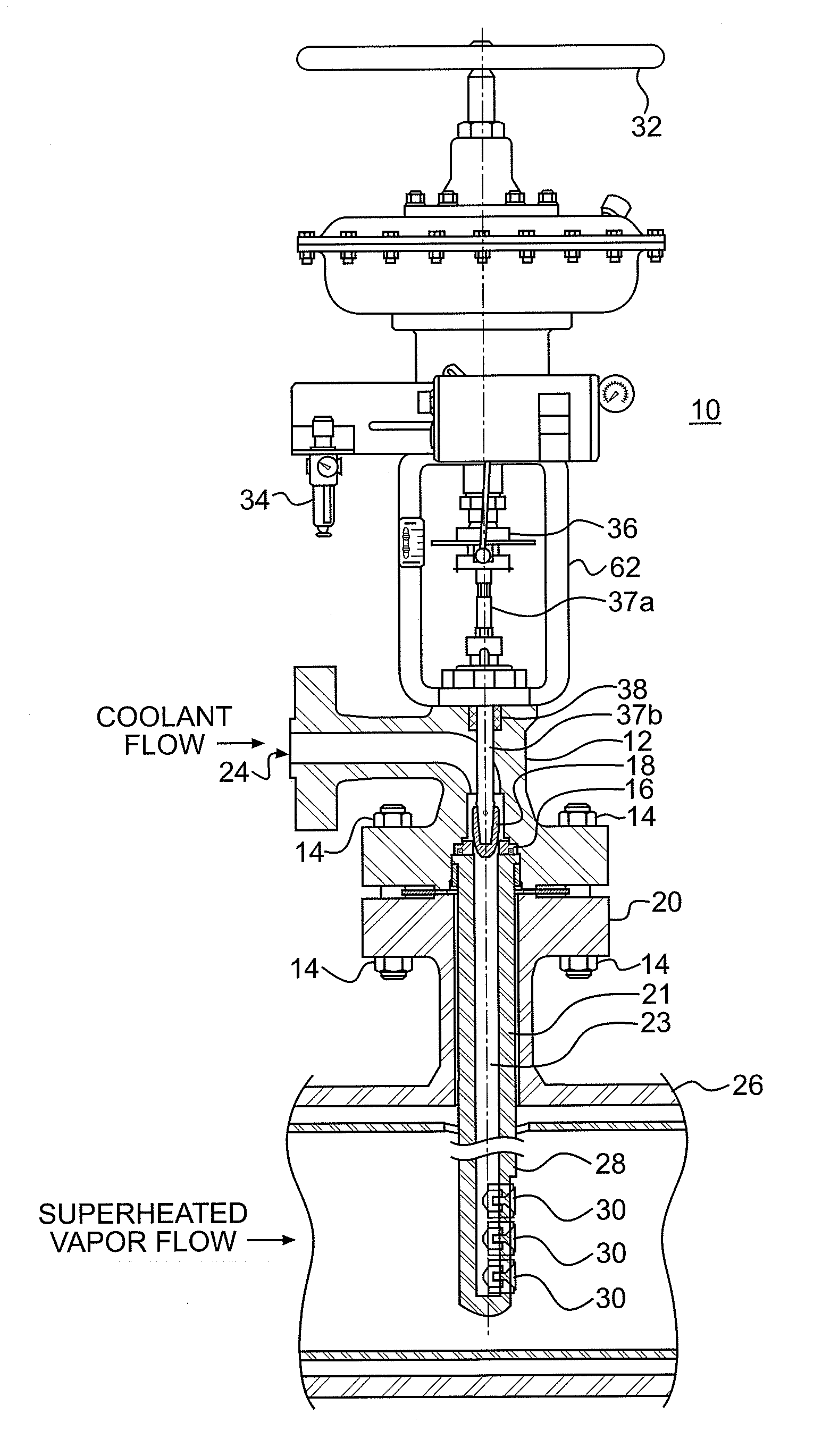

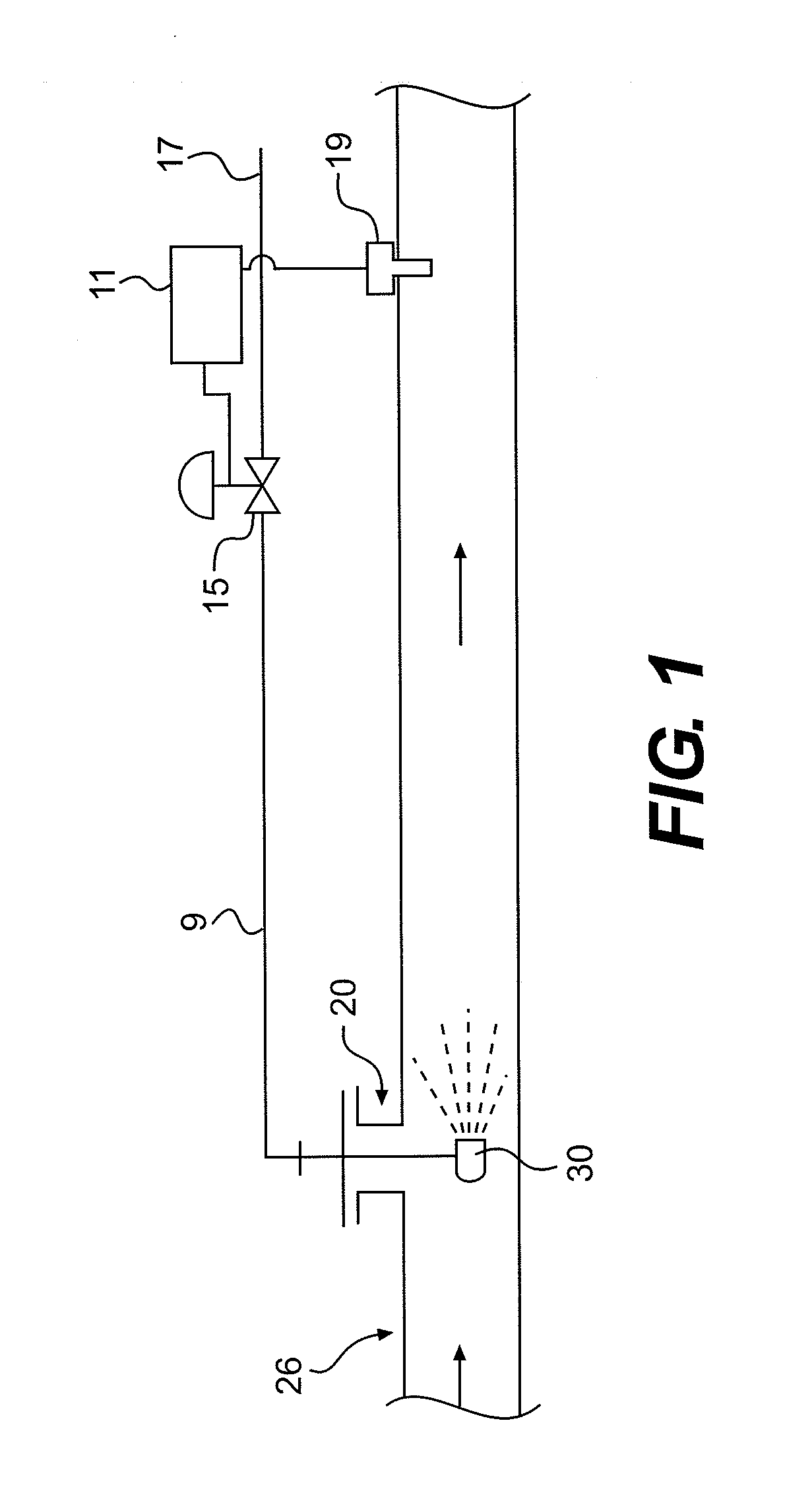

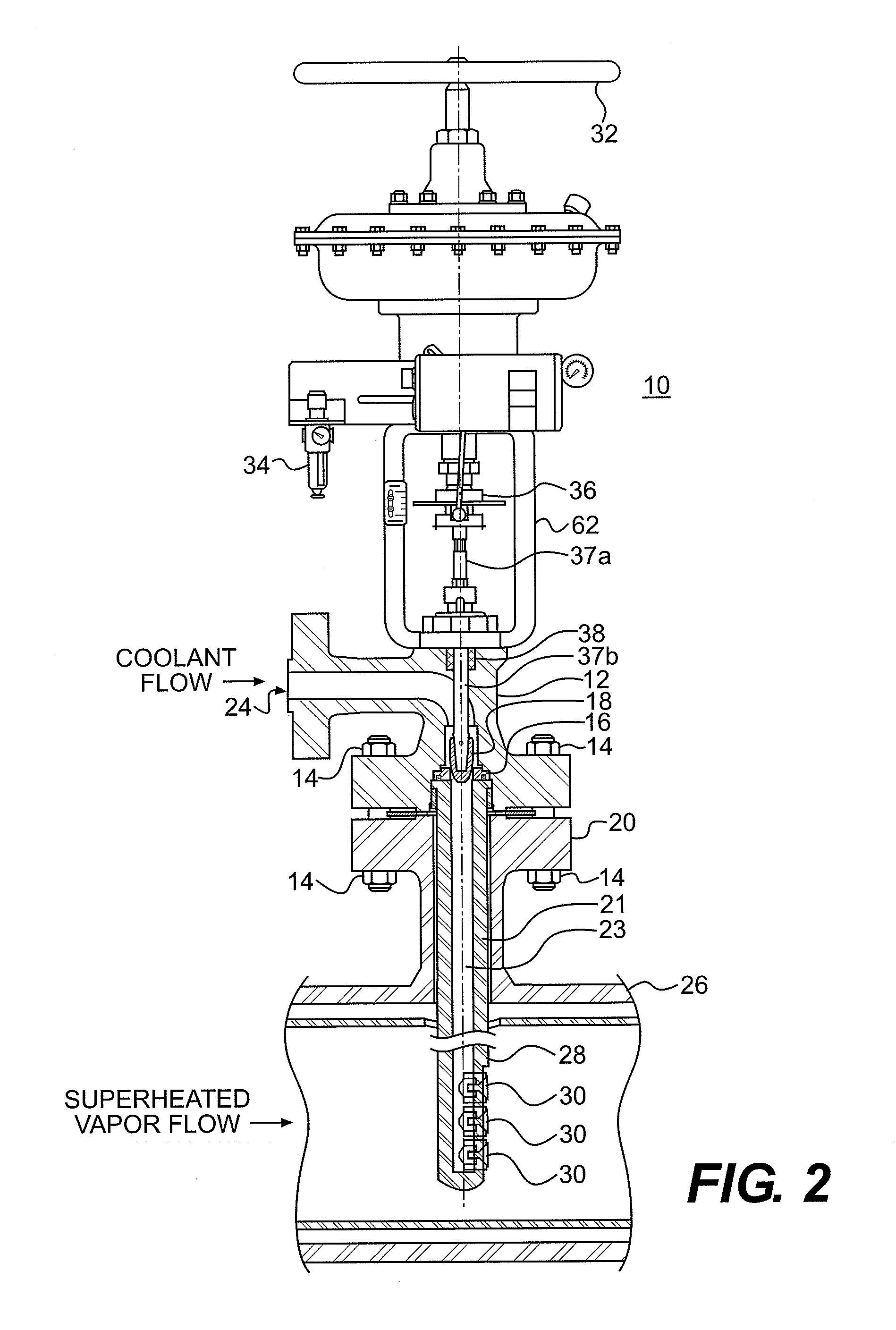

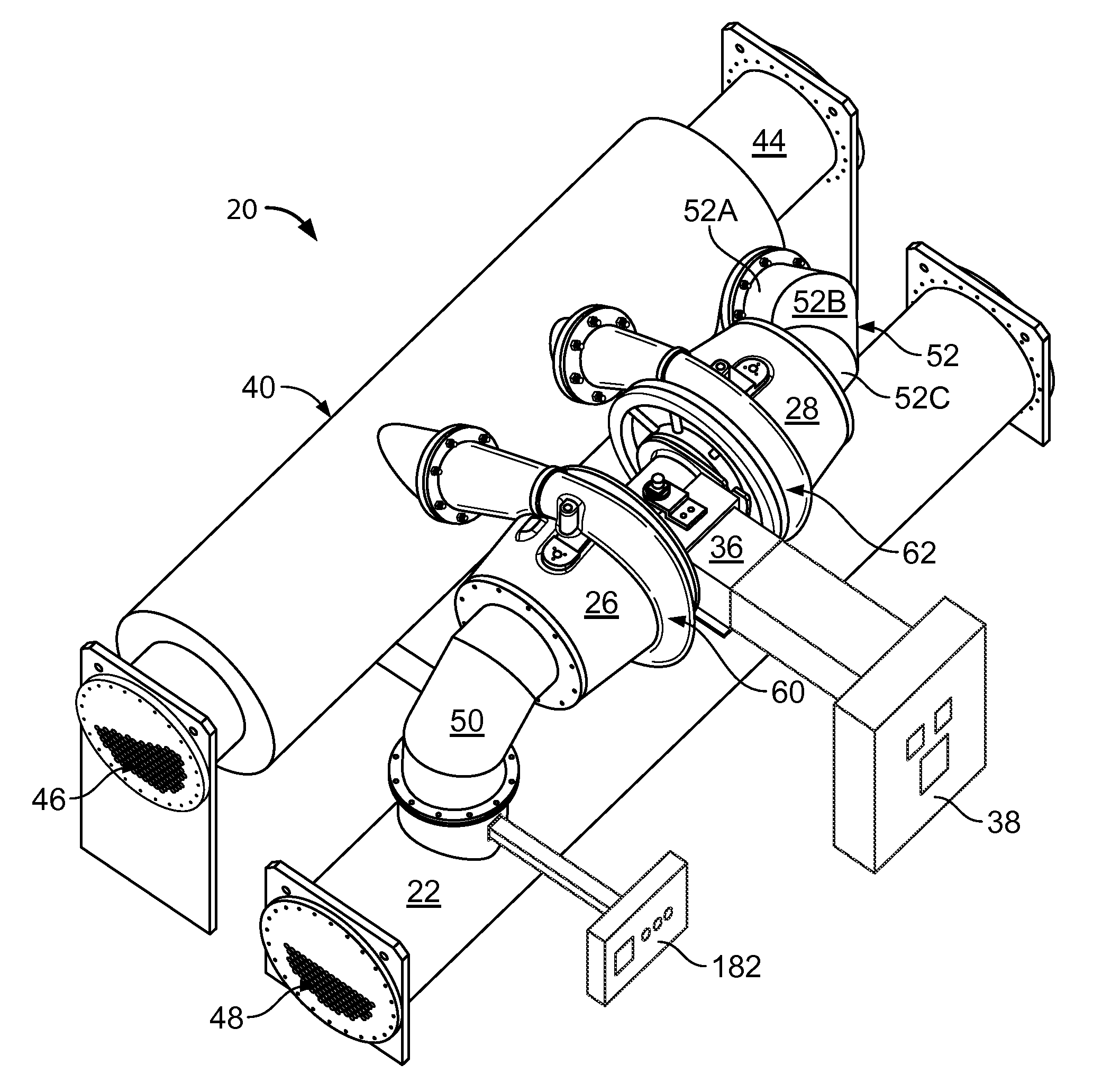

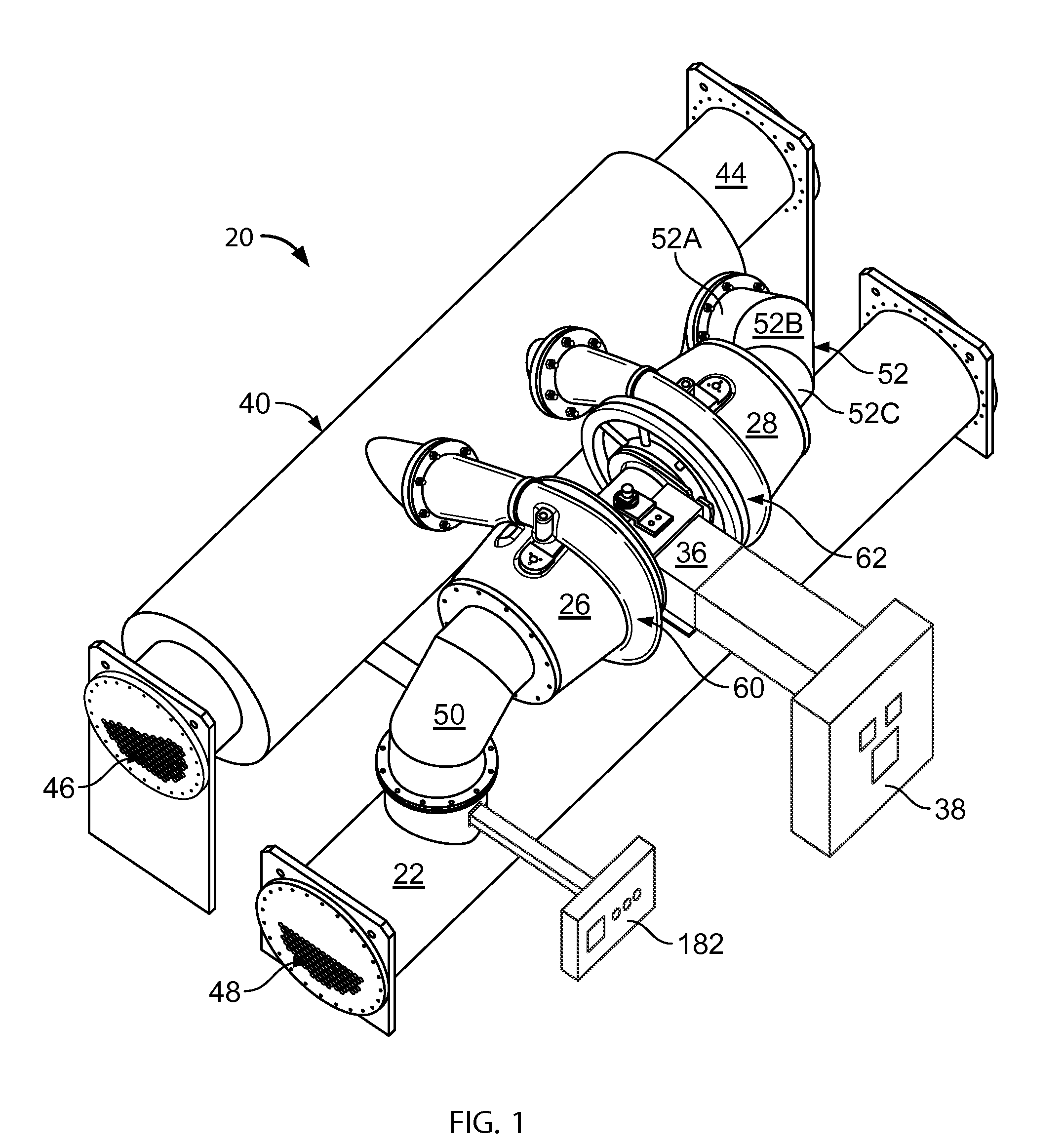

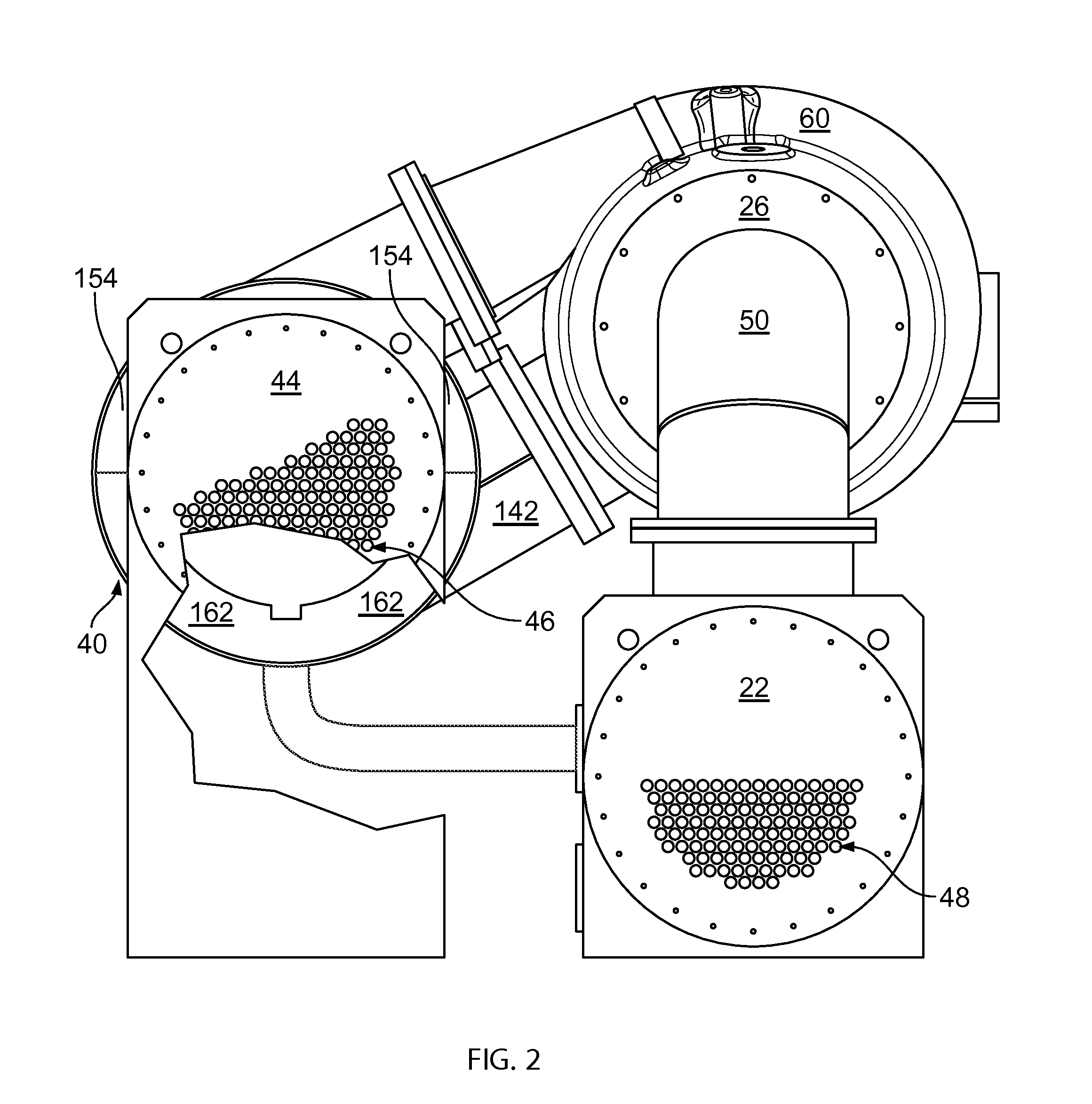

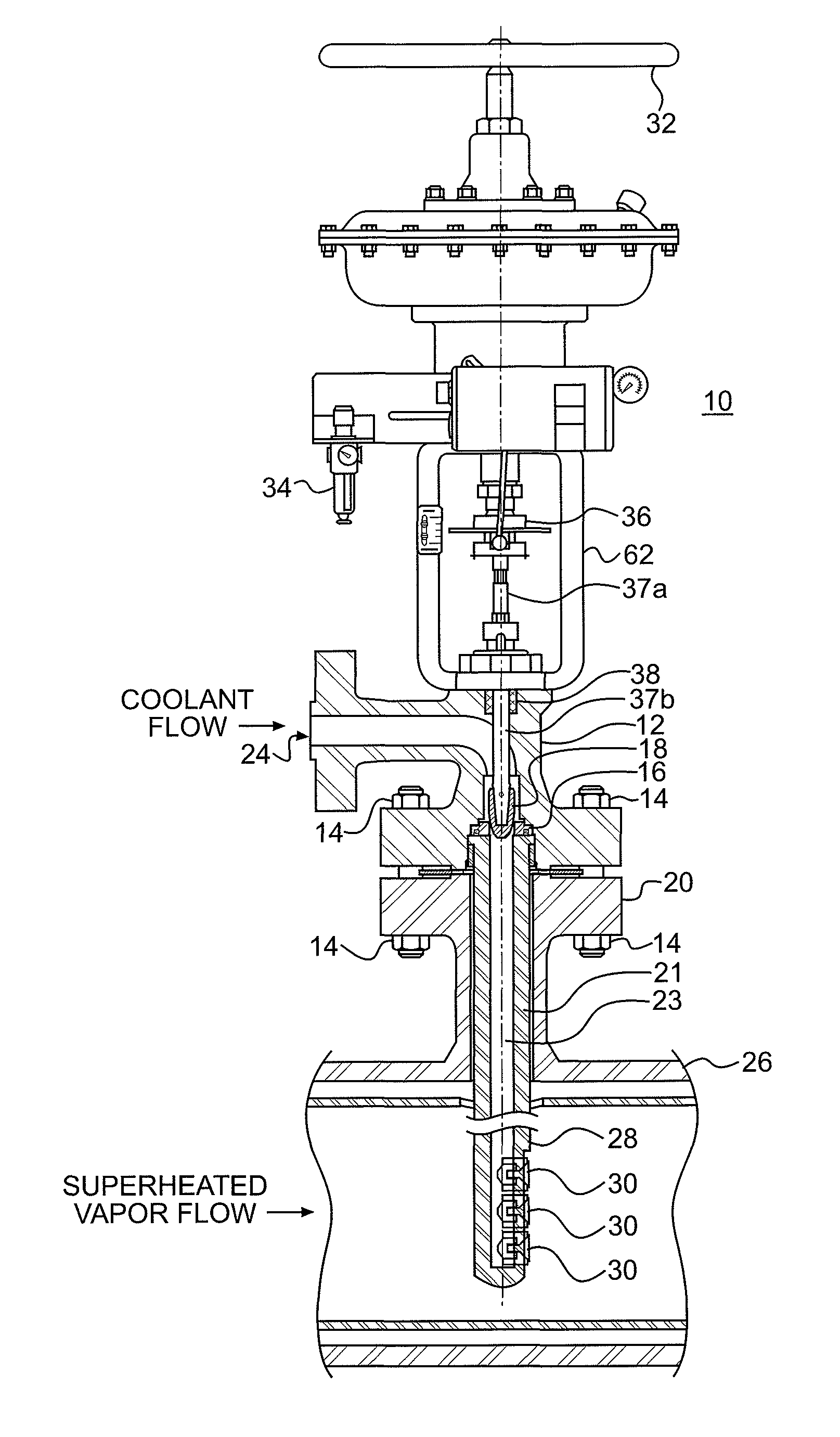

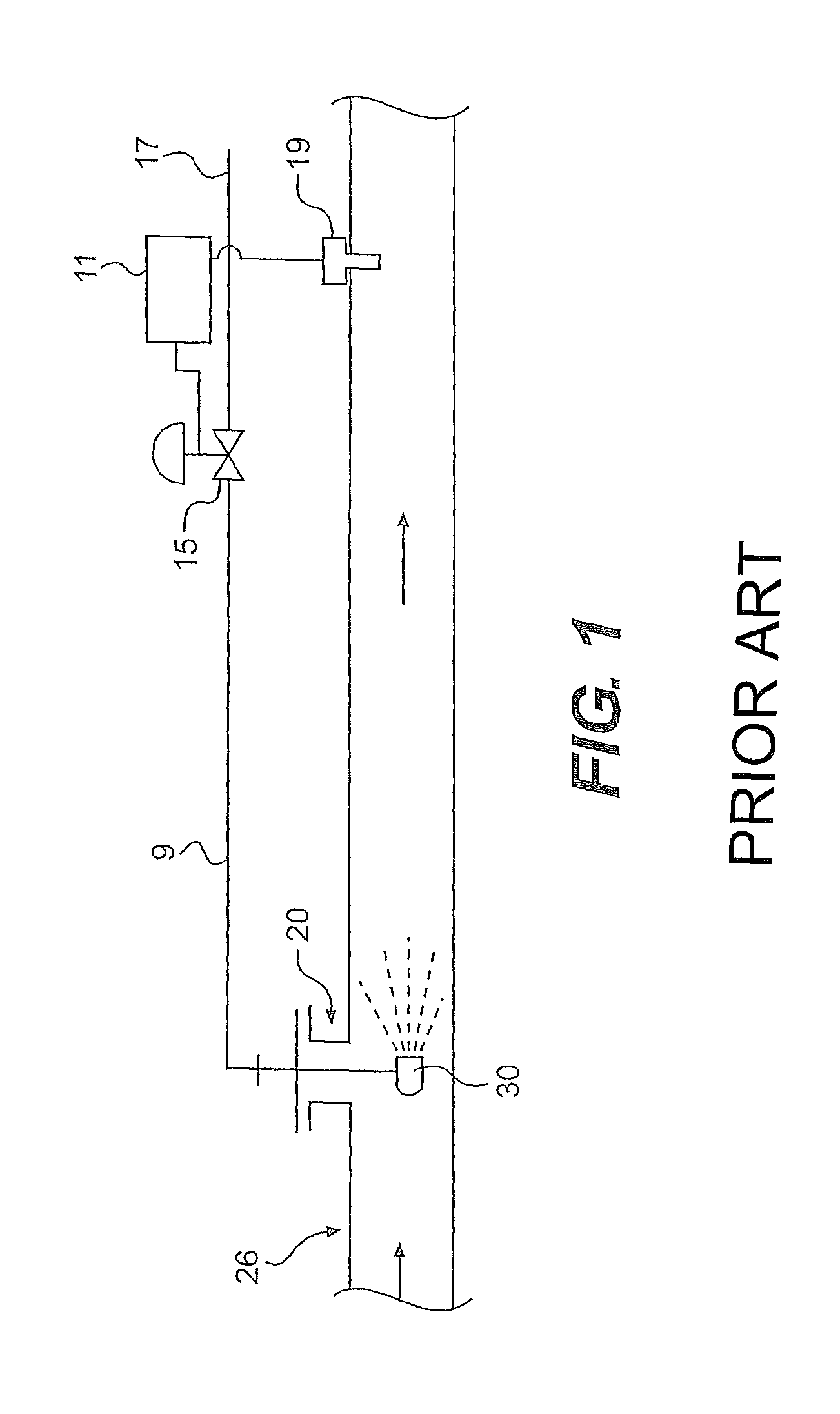

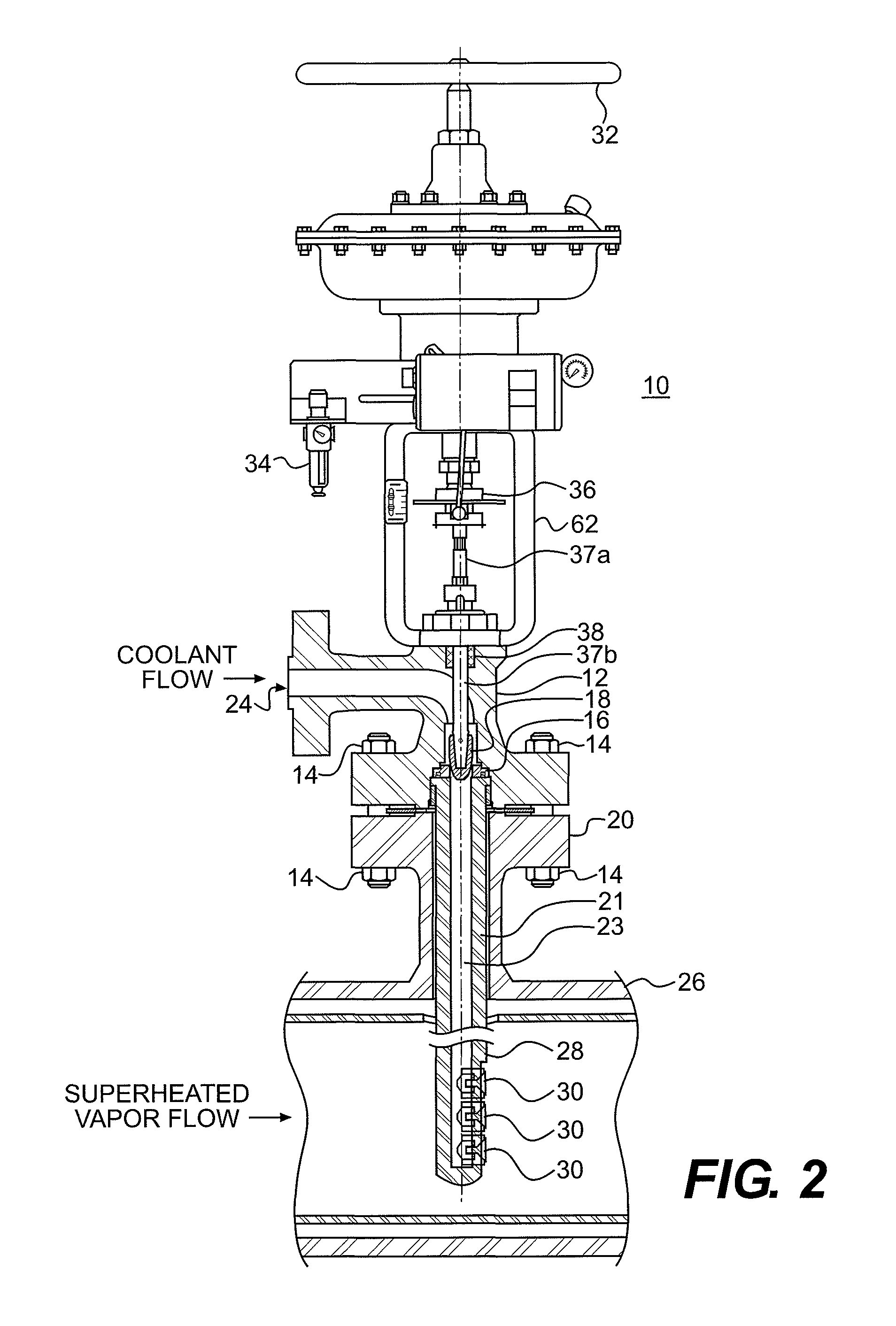

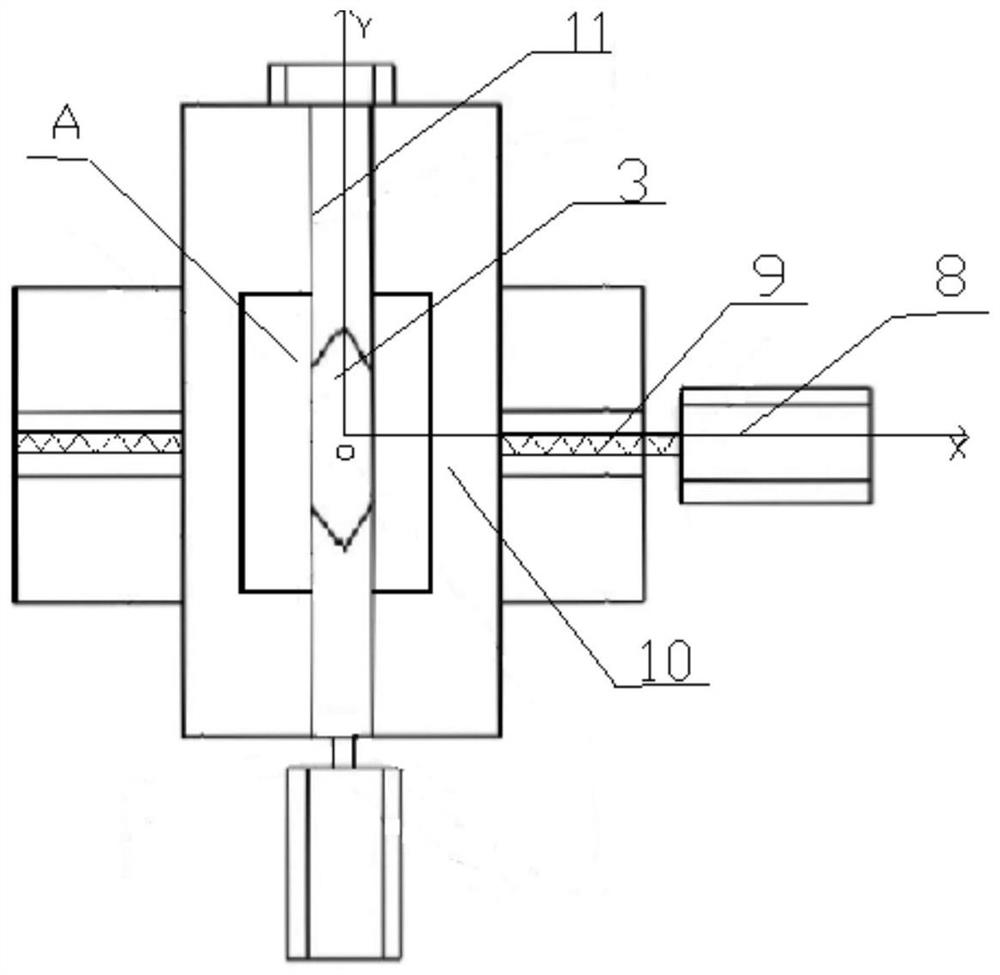

Atomizing desuperheater shutoff apparatus and method

ActiveUS20100319781A1Accelerated operational failure and premature wearLarge capacitySuperheating controlFlow mixersSpray nozzleEngineering

The present invention is directed to a desuperheater spraying valve assembly. More particularly, the invention provides a new and improved valve assembly, whereby cooling liquid may be controllably injected into a gas or a liquid stream, typically steam, to selectively maintain the gas or liquid at a predetermined temperature level. In a possible embodiment of the present invention, a class V valve assembly is disclosed. It comprises an actuator coupled to a plug with a valve seat in the proximity of said plug. The plug is affixed to an actuator rod which transverses the body of the valve assembly. A spray tube may be affixed to said valve seat and at least one spray nozzle is affixed to a to the spray tube. The plug and said valve seat are conical in shape as to when said plug is inserted into said valve, they form a seal.

Owner:CELEROS FLOW TECH LLC

Coaxial economizer assembly and method

ActiveUS20110296859A1Improve fluid flowImprove performanceCompressorMechanical apparatusLiquid stateFlash-gas

A coaxial economizer for use in a chiller system comprising an inner housing and an outer housing having a common longitudinal axis. The outer housing has an inlet for receiving a fluid from a upstream compressor stage of a multistage compressor and an outlet for conveying a fluid to a downstream compressor stage of a multistage compressor. A flow chamber forms a fluid flow path about the inner housing. A flash chamber is coterminous with the flow chamber and flashes fluid in a liquid state to a gas state. A flow passage between said flash chamber and the flow chamber for conveying a flashed gas from the flash chamber to the flow chamber; wherein the flashed gas conveyed from the flash chamber and the fluid received from the inlet of the outer housing mix along the fluid flow path toward the outlet of the outer housing.

Owner:TRANE INT INC

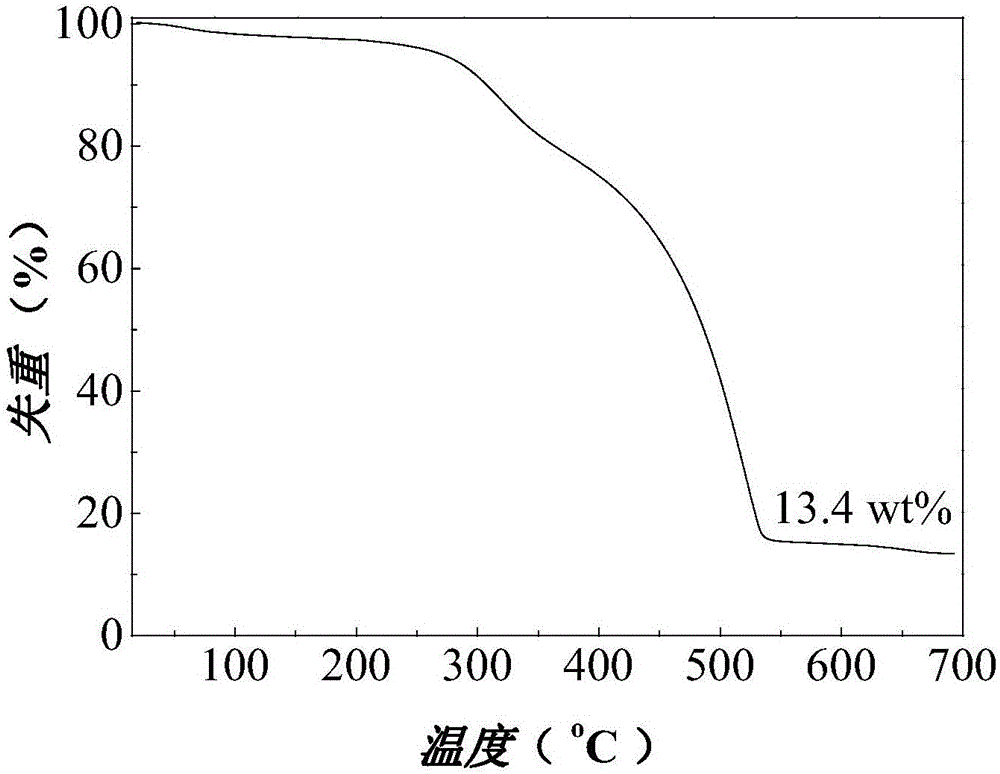

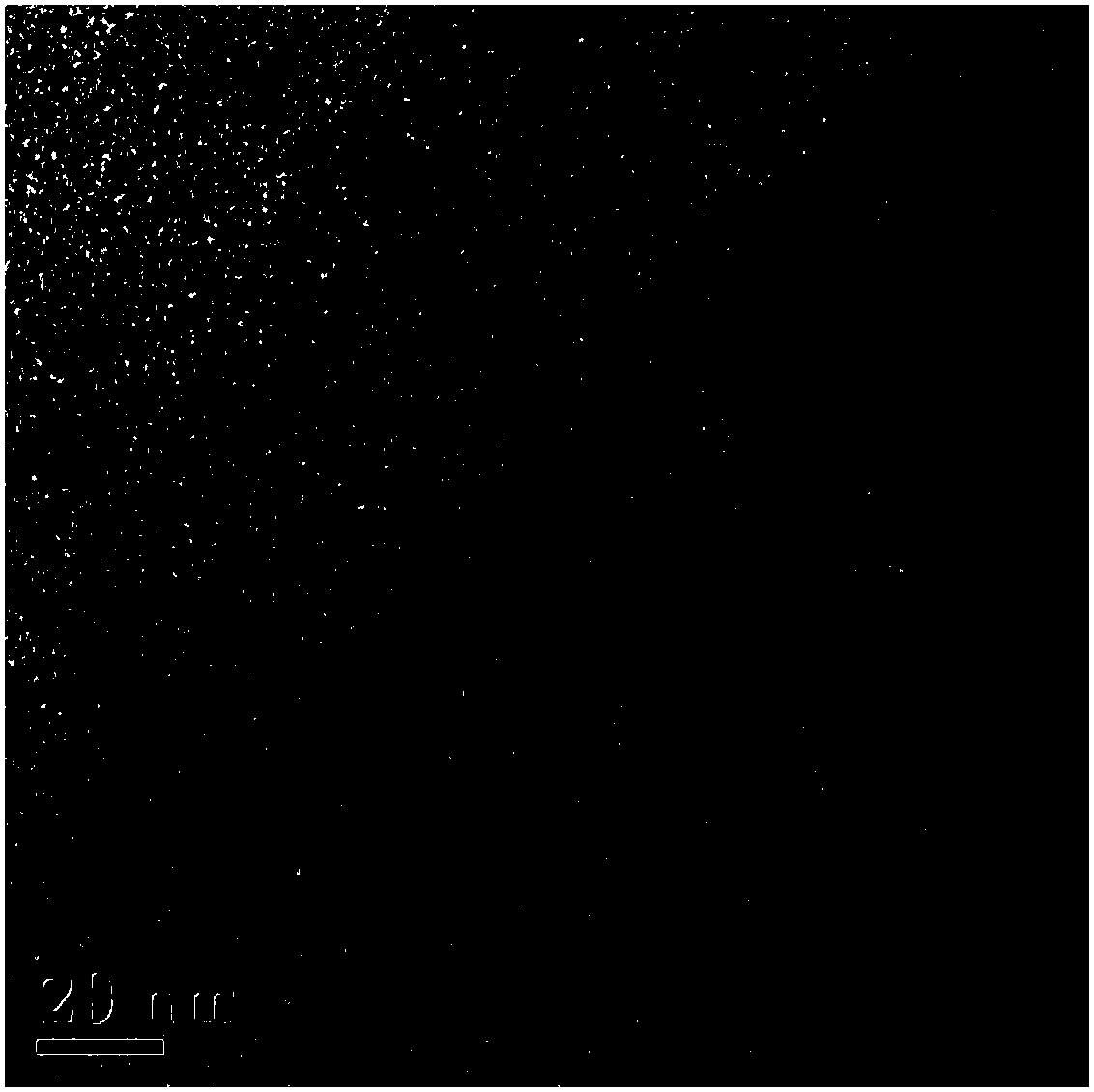

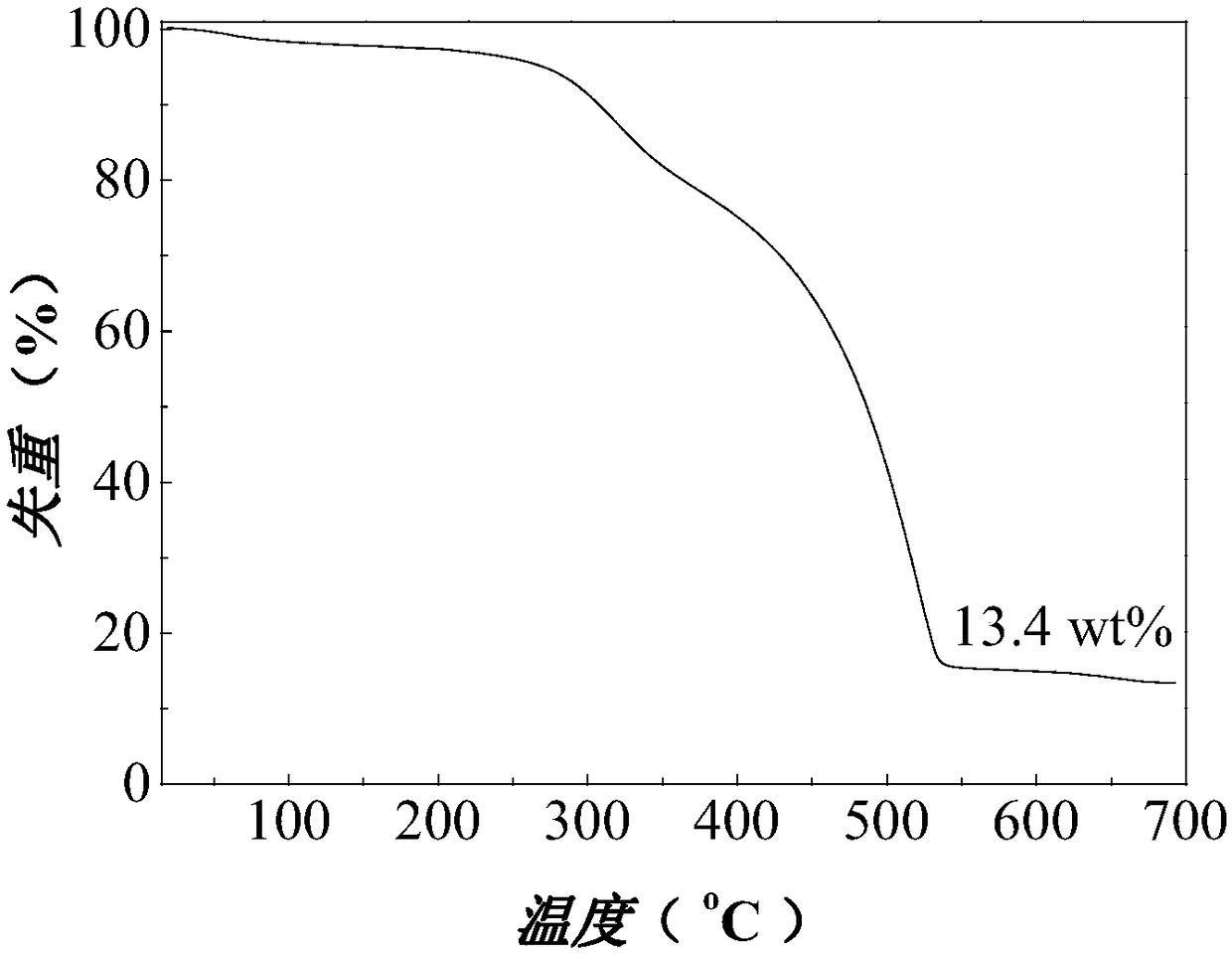

One-step controllable preparation method and application of high-capacity and high-dispersity supported nano-gold catalyst

The invention relates to a one-step controllable preparation method and application of a high-capacity and high-dispersity supported nano-gold catalyst. The preparation method of the catalyst comprises the following steps: adding a carrier to a water solution containing a surfactant and carrying out ultrasonic dispersion; adding the water solution of a gold compound for ultrasonic treatment and then adding the water solution of a reducing agent; controlling the reaction temperature, and reacting for 0.5-5 hours; and then carrying out washing and drying to obtain the high-dispersity supported nano-gold catalyst. According to the preparation method, gold nanoparticles evenly grow on the carrier surface by the ultrasonic dispersion effect, so that controllable preparation of the high-dispersity supported nano-gold catalyst is achieved; and the preparation method is simple in step, mild in condition, short in preparation time, free of calcination and suitable for large-scale synthesis. The capacity range of gold in the prepared catalyst is wide (1wt%-80wt%); the electrocatalytic activity is high; and particularly, the supported nano-gold catalyst demonstrates good catalytic performance in the aspect of alcohol oxidation and can be applied to the fields of a fuel cell, an electrochemical sensor and the like.

Owner:DALIAN UNIV OF TECH

Atomizing desuperheater shutoff apparatus and method

ActiveUS8333329B2Accelerated operational failure and premature wearLarge capacitySuperheating controlFlow mixersSpray nozzleEngineering

The present invention is directed to a desuperheater spraying valve assembly. More particularly, the invention provides a new and improved valve assembly, whereby cooling liquid may be controllably injected into a gas or a liquid stream, typically steam, to selectively maintain the gas or liquid at a predetermined temperature level. In a possible embodiment of the present invention, a class V valve assembly is disclosed. It comprises an actuator coupled to a plug with a valve seat in the proximity of said plug. The plug is affixed to an actuator rod which transverses the body of the valve assembly. A spray tube may be affixed to said valve seat and at least one spray nozzle is affixed to a to the spray tube. The plug and said valve seat are conical in shape as to when said plug is inserted into said valve, they form a seal.

Owner:CELEROS FLOW TECH LLC

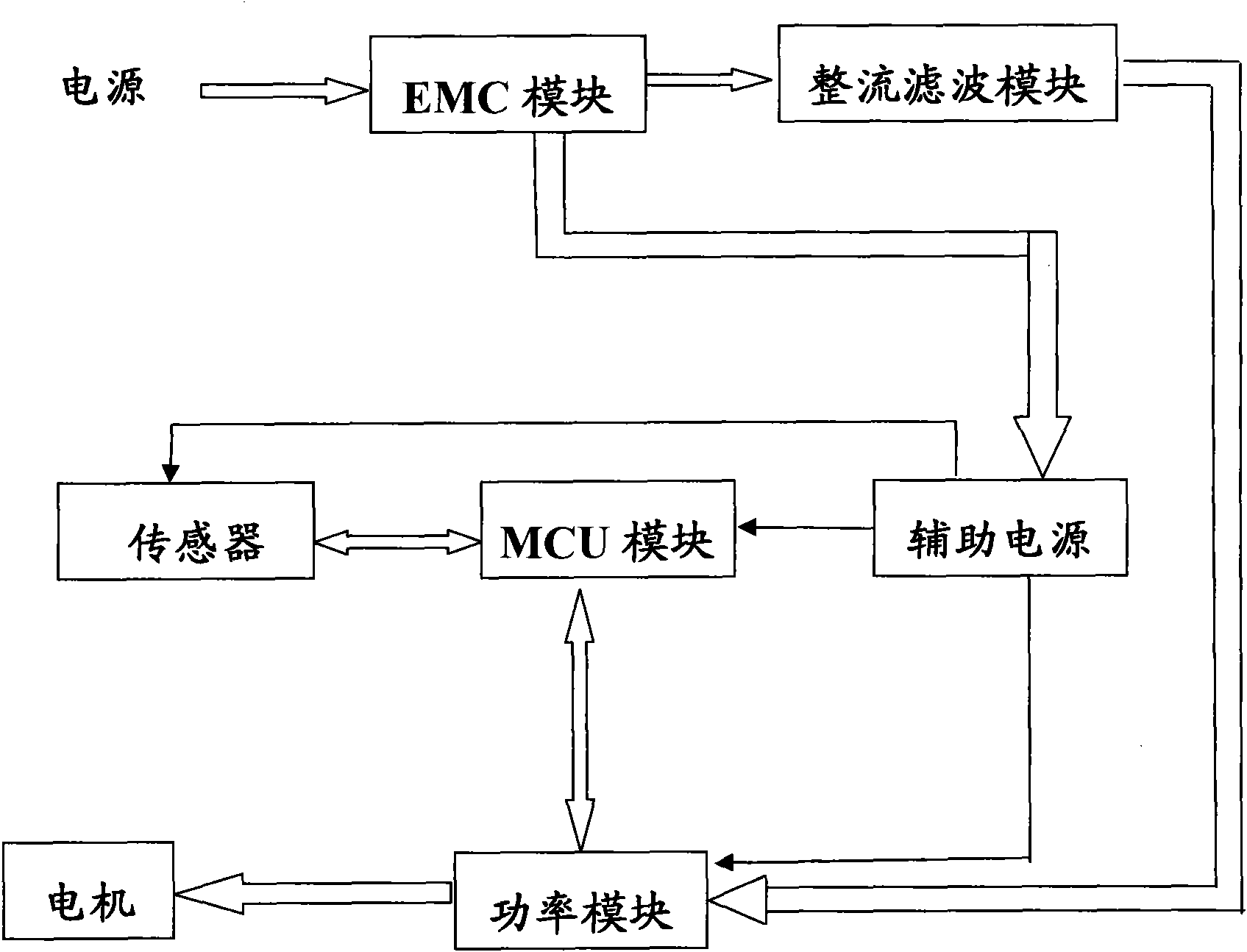

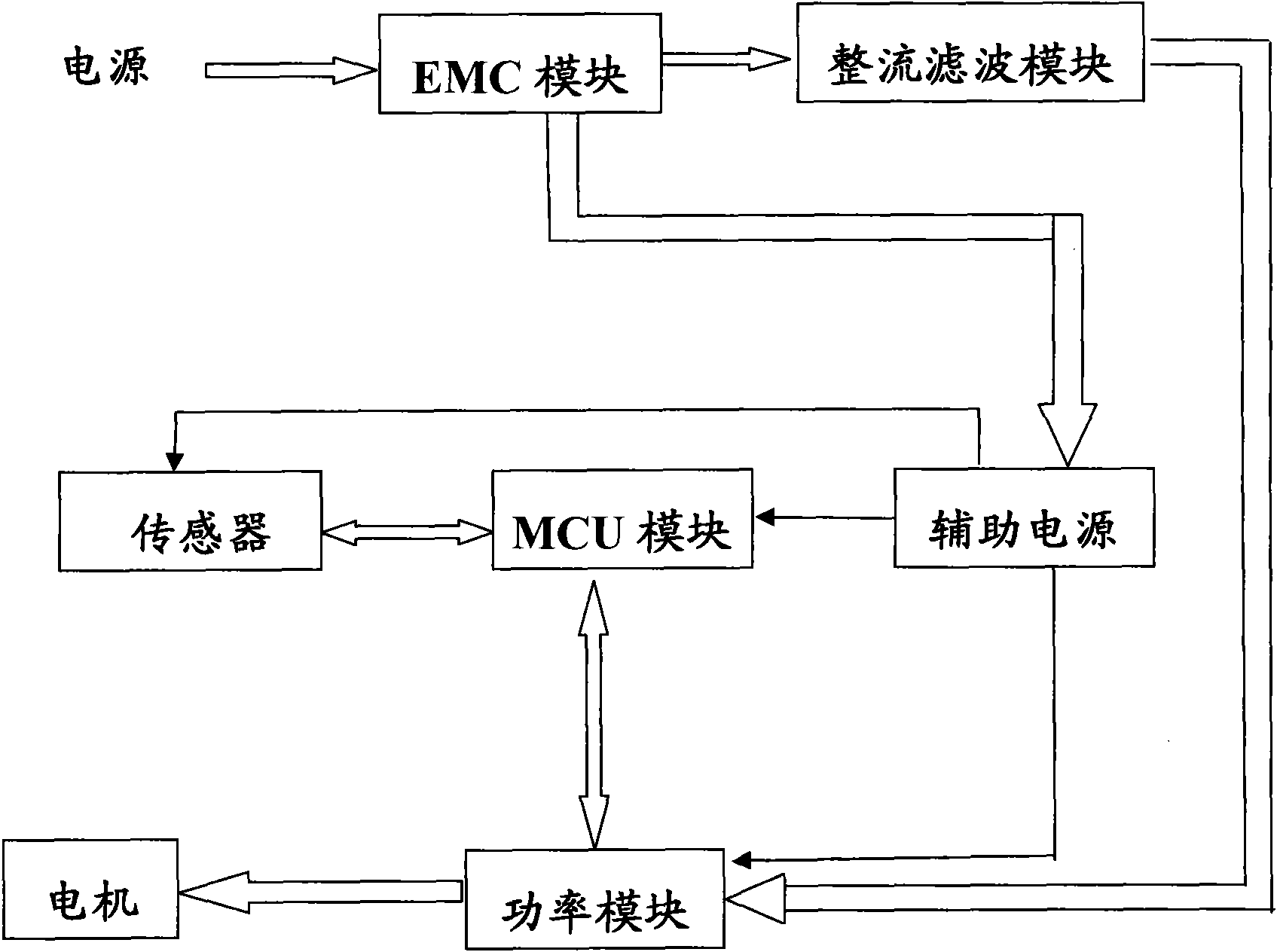

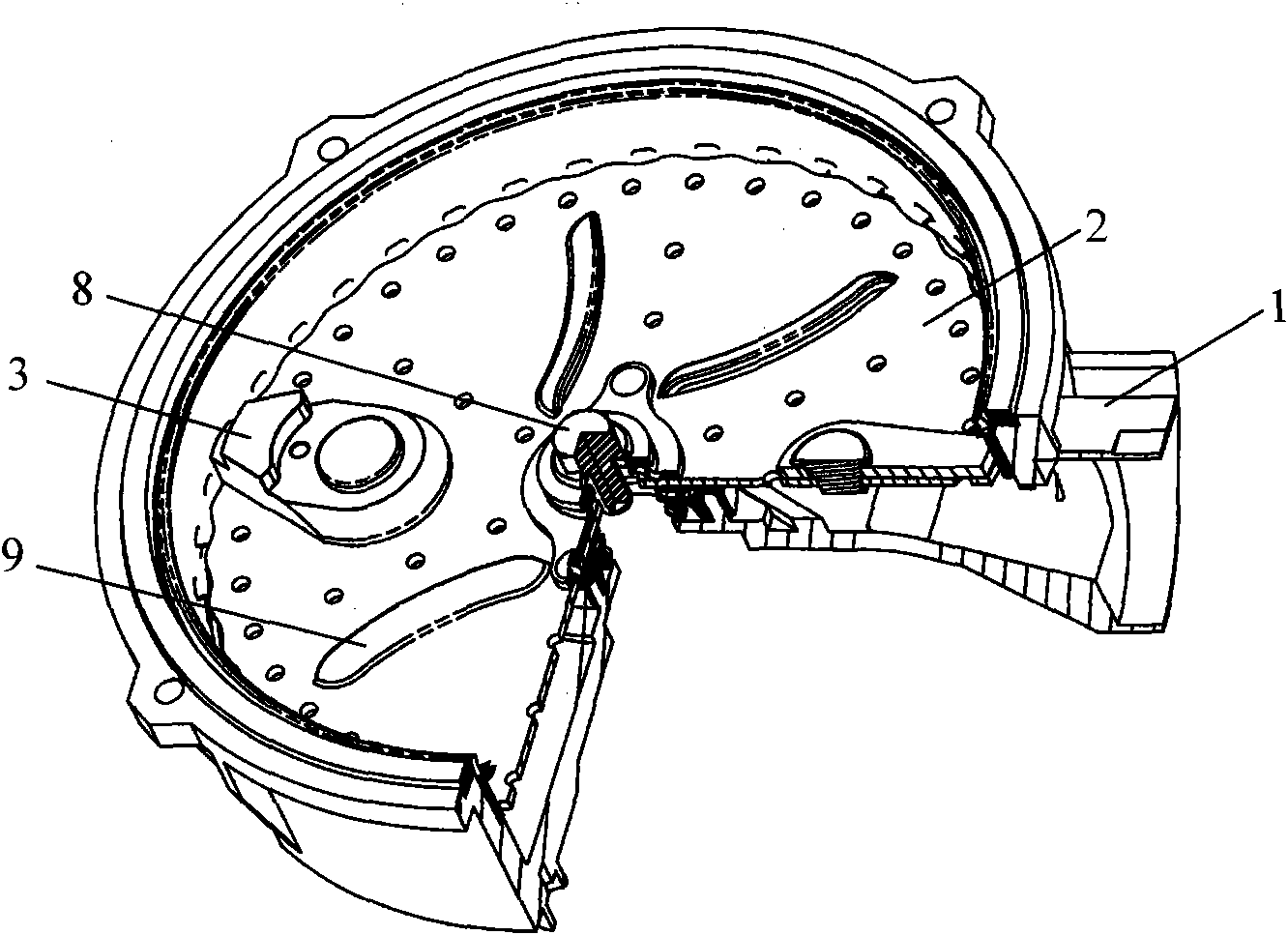

Intelligent food waste disposer

ActiveCN101890421AEasy to operateThe operation is cumbersome and not energy-savingSolid waste disposalBrushless motorsLow noise

The invention relates to an intelligent food waste disposer. The intelligent food waste disposer comprises a shell, a grinding disc positioned in the shell, a grinding head arranged on the grinding disc, a driving mechanism for driving the grinding disc, a control mechanism, an induction mechanism and an automatic water outlet mechanism. The control mechanism is respectively in line connection with the driving mechanism, the induction mechanism and the automatic water outlet mechanism. The induction mechanism is arranged at a joint of the shell. Preferably, an EMC module in the control mechanism is in line connection with a power module by a rectifier filter module; the power module is respectively in line connection with the driving mechanism, an MCU module and the automatic water outlet mechanism; the MCU module is in line connection with the induction mechanism; the induction mechanism is a sensor; the driving mechanism is a DC permanent magnet brushless motor; the grinding head is a grinding impact head; the grinding disc is radially provided with an arc barrier strip; and the shell is a streamline shell. The intelligent food waste disposer has the advantages of ingenious design, simple and convenient operation, good grinding effect, lightness, energy saving, safety, durability, low noise and high reliability.

Owner:SHANGHAI ONEDEAR ENVIRONMENT TECH

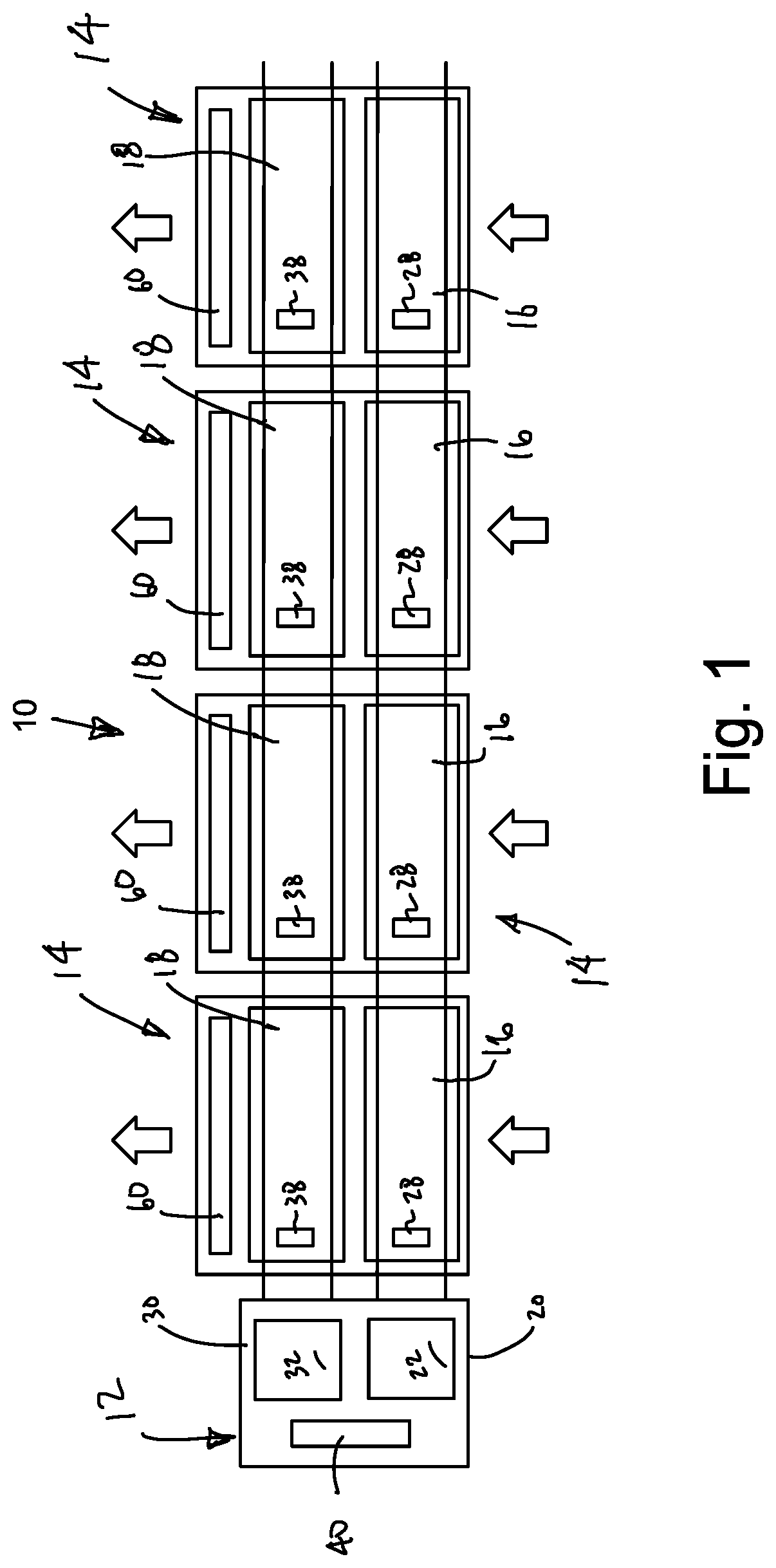

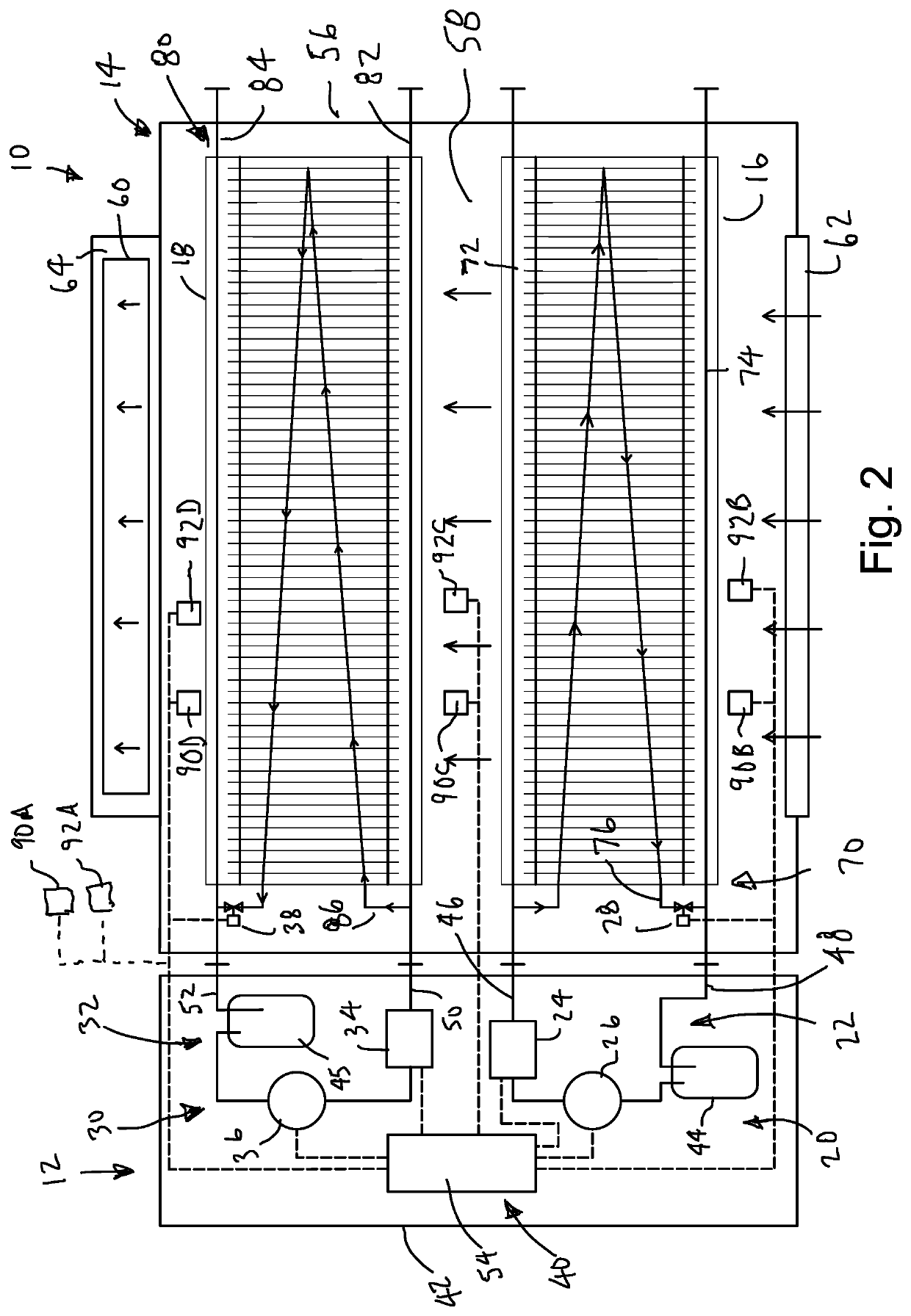

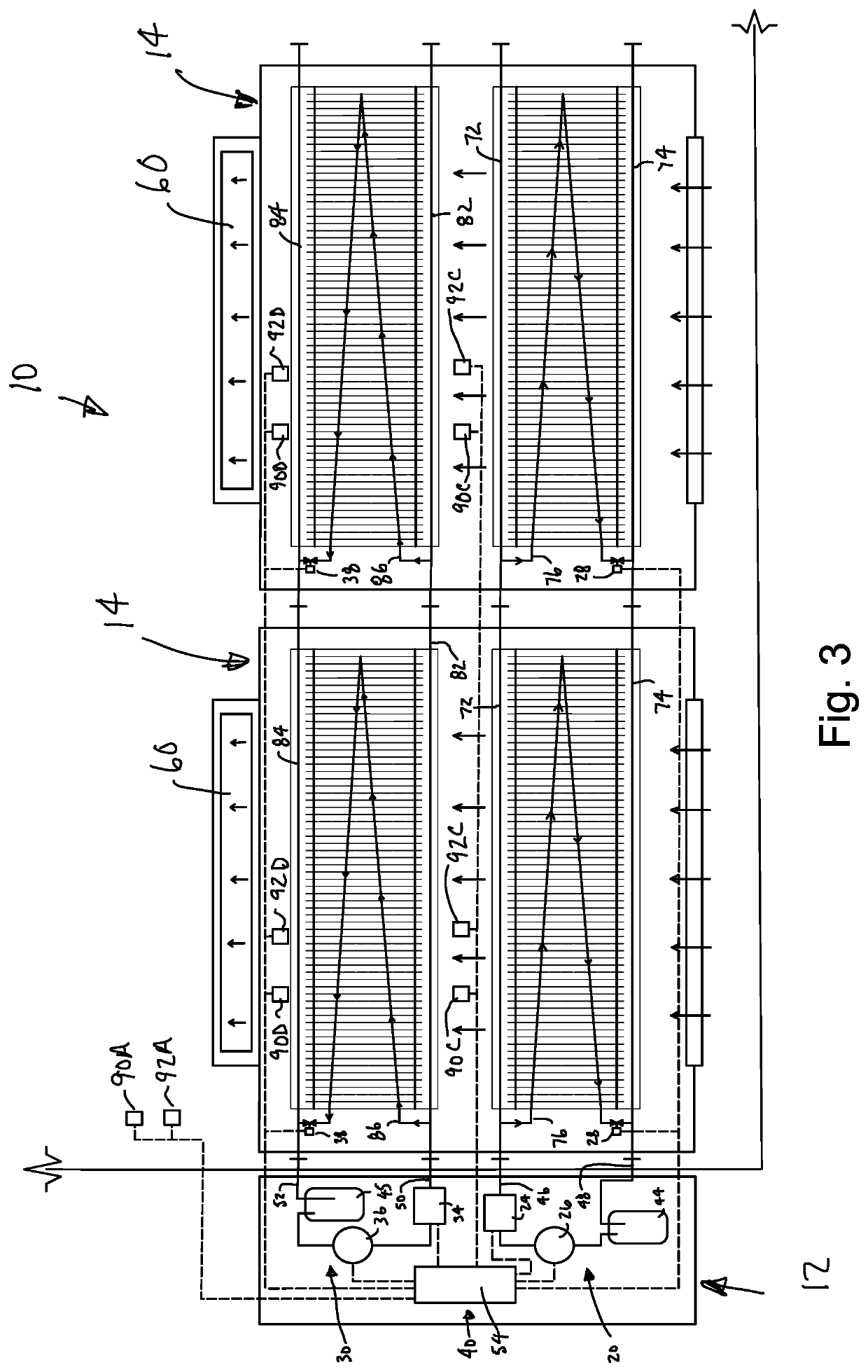

Dehumidification system with variable capacity

ActiveUS20220178559A1Improve efficiencyCompensation for heat lossLighting and heating apparatusAir conditioning systemsThermodynamicsControl system

A multi-use system for influencing organic matter in an environmentally controlled room is provided with a modular dehumidification system. The modular dehumidification system includes a head unit, with separate cooling and heating subcircuits, and multiple modular dehumidifier units. Each modular dehumidifier unit has a cooling coil operable to cool and / or dehumidify the air and a heating coil operable to heat the air, for example, to raise room temperature and / or offset heat loss arising during dehumidification. The cooling coils are connected to the head unit in parallel to one another and the heating coils are connected to the head unit in parallel to one another. The number of modular dehumidifier units installed in the system is selected to provide the system with the desired maximum capacity. The control system may be configured to activate the appropriate number of cooling and heating coils, and to control the operation of each active coil.

Owner:COIL RES LLC

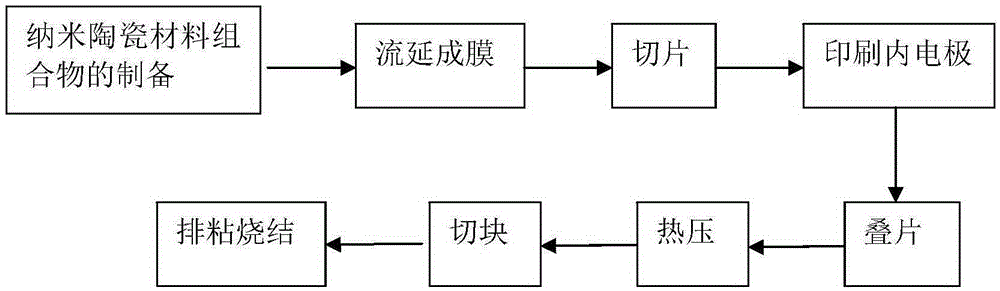

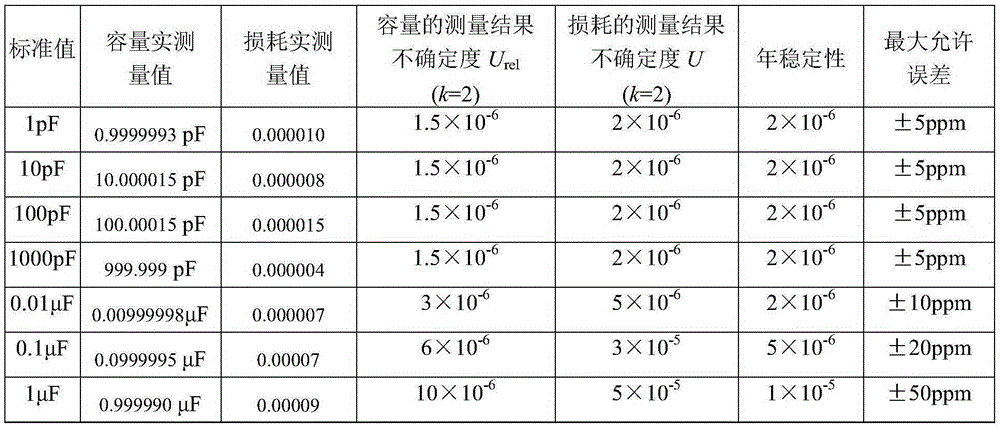

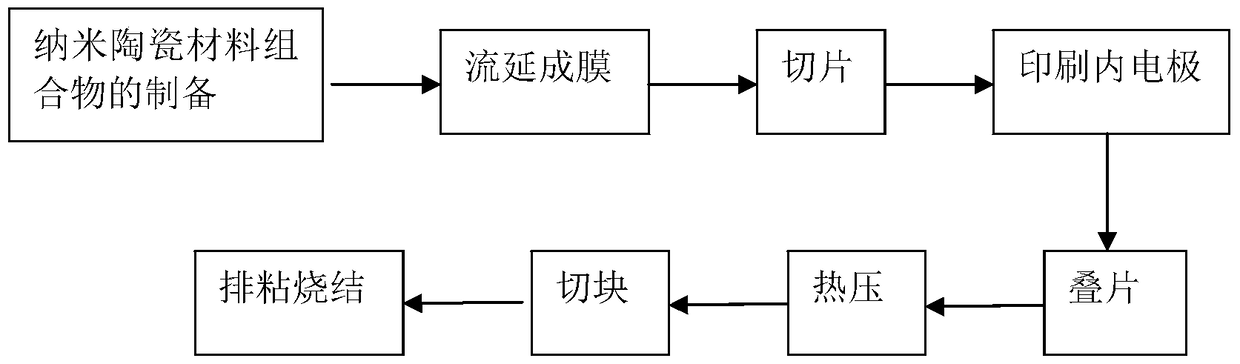

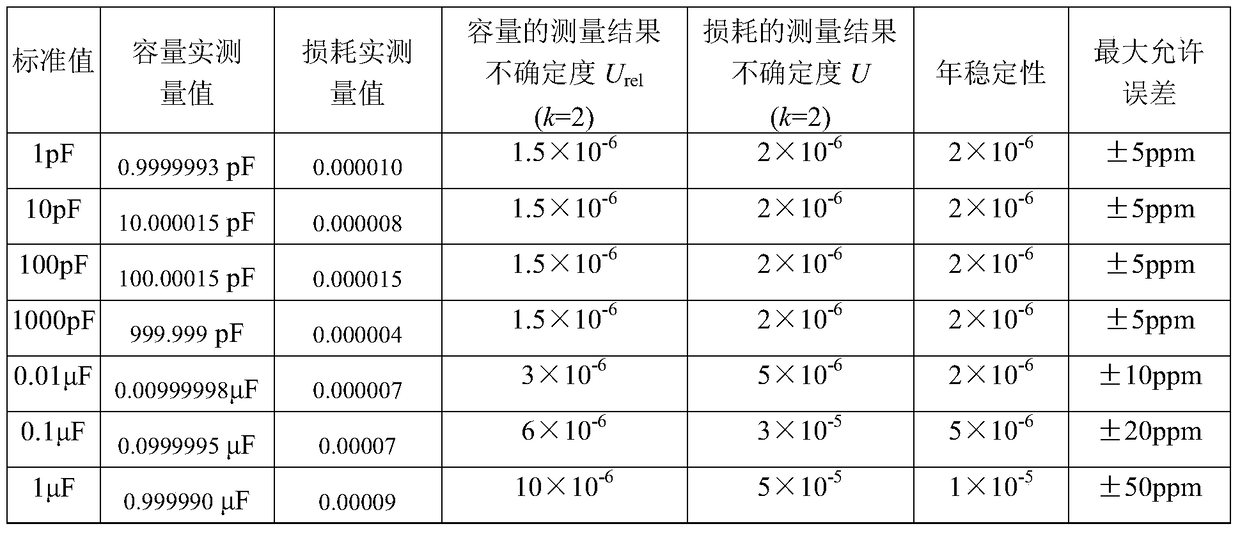

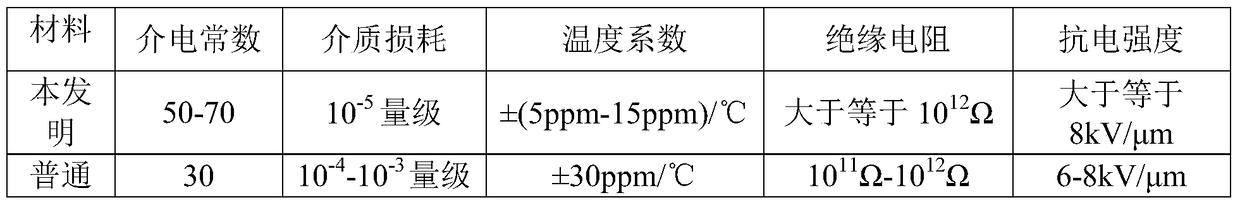

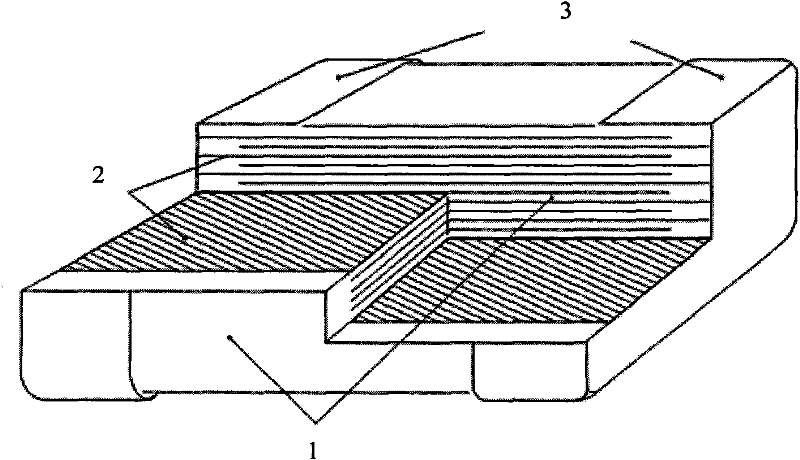

Nano ceramic material composition, standard capacitor, and preparation method of nano ceramic material composition and standard capacitor

The invention provides a nano ceramic material composition, and a preparation method thereof. The nano ceramic material composition comprises a nano ceramic material, a nanometer substance additive, and a glass frit sintering aid; the nanometer substance additive comprises at least one ingredient selected from Sm2O3, CeO2, Nd2O3, BiO2, SiO2, MnCO3, and MnO2. The invention also provides a standard capacitor, and a preparation method thereof. The nano ceramic material composition is taken as a medium of the standard capacitor. The standard capacitor prepared by taking the nano ceramic material composition as the medium is high in accurate, low in loss factor, wide in capacity range, and high in stability and reliability.

Owner:NAT INST OF METROLOGY CHINA

Centrifugal compressor assembly and method

InactiveUS20160273549A1Improve performanceReduce physical sizeEngine manufacturePump componentsMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

A kind of nano ceramic material composition and standard capacitor and preparation method thereof

The invention provides a nano ceramic material composition, and a preparation method thereof. The nano ceramic material composition comprises a nano ceramic material, a nanometer substance additive, and a glass frit sintering aid; the nanometer substance additive comprises at least one ingredient selected from Sm2O3, CeO2, Nd2O3, BiO2, SiO2, MnCO3, and MnO2. The invention also provides a standard capacitor, and a preparation method thereof. The nano ceramic material composition is taken as a medium of the standard capacitor. The standard capacitor prepared by taking the nano ceramic material composition as the medium is high in accurate, low in loss factor, wide in capacity range, and high in stability and reliability.

Owner:NAT INST OF METROLOGY CHINA

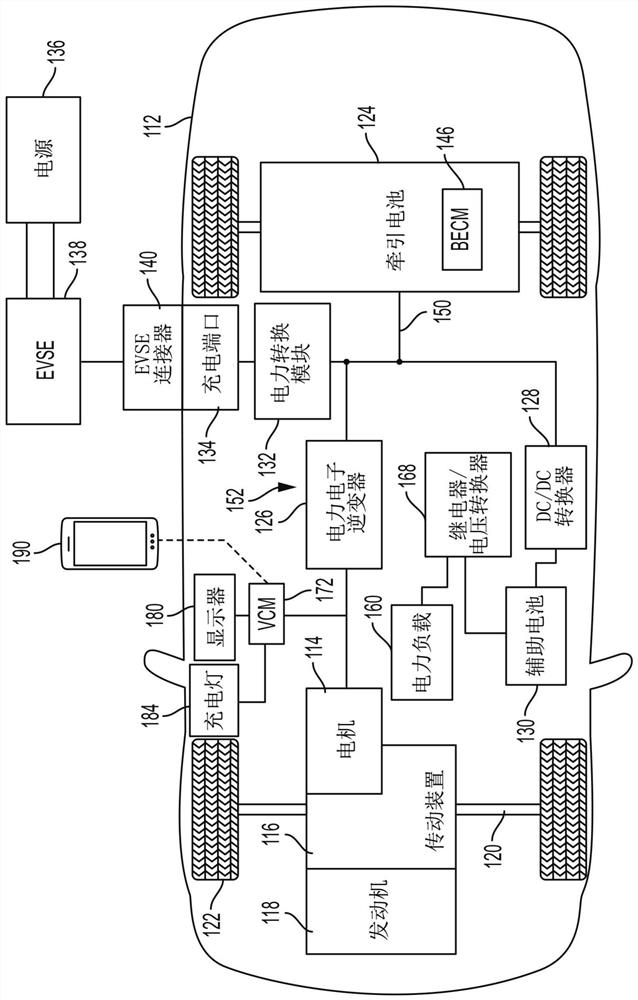

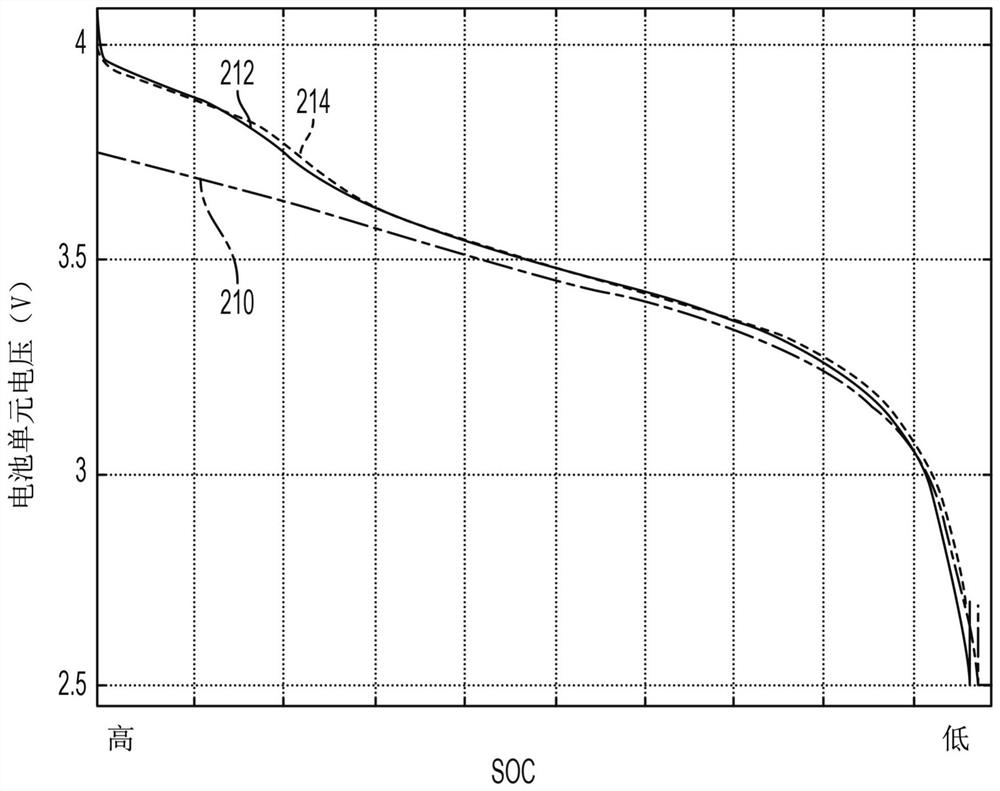

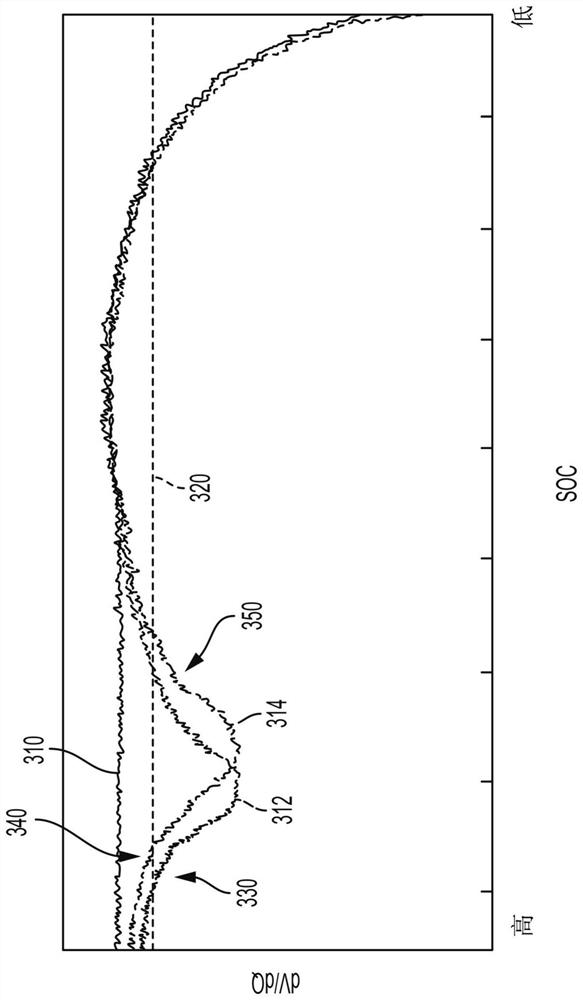

Charging strategies for mitigating lithium plating in electrified vehicle batteries

ActiveCN106985683BReduce performanceEasy to operateCharging stationsSecondary cellsControl theoryBattery cell

The present disclosure relates to a charging strategy for mitigating lithium plating in electrified vehicle batteries. A vehicle includes a traction battery and a controller in communication with the traction battery and configured to control the traction battery in response to a user selected charging strategy of a plurality of charging strategies having different charging rates. Charging of the battery, the user selected charging strategy is based on the detection of lithium plating in the traction battery. A method implemented by a vehicle controller in a vehicle having a traction battery may include controlling, by the controller, charging of the traction battery in response to a user selected charging strategy selected from a plurality of available charging strategies, Each of the plurality of available charging strategies has a different charging rate and is displayed on the user interface in response to detection of lithium plating in the traction battery, at least one charging strategy being selected with additional lithium plating is associated.

Owner:FORD GLOBAL TECH LLC

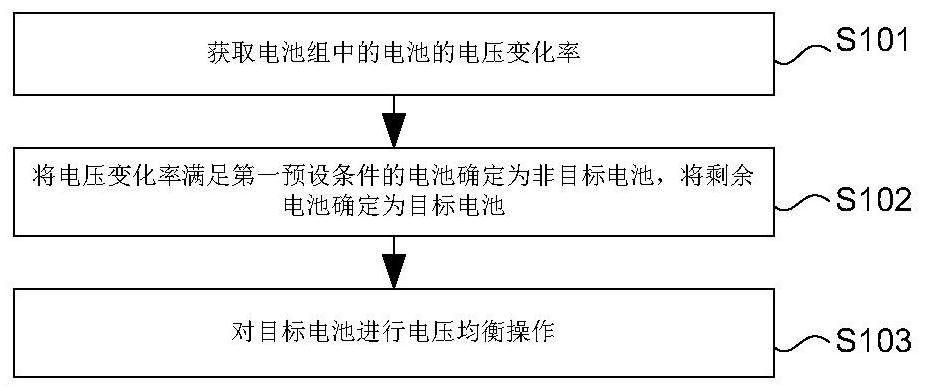

Battery equalization method and device

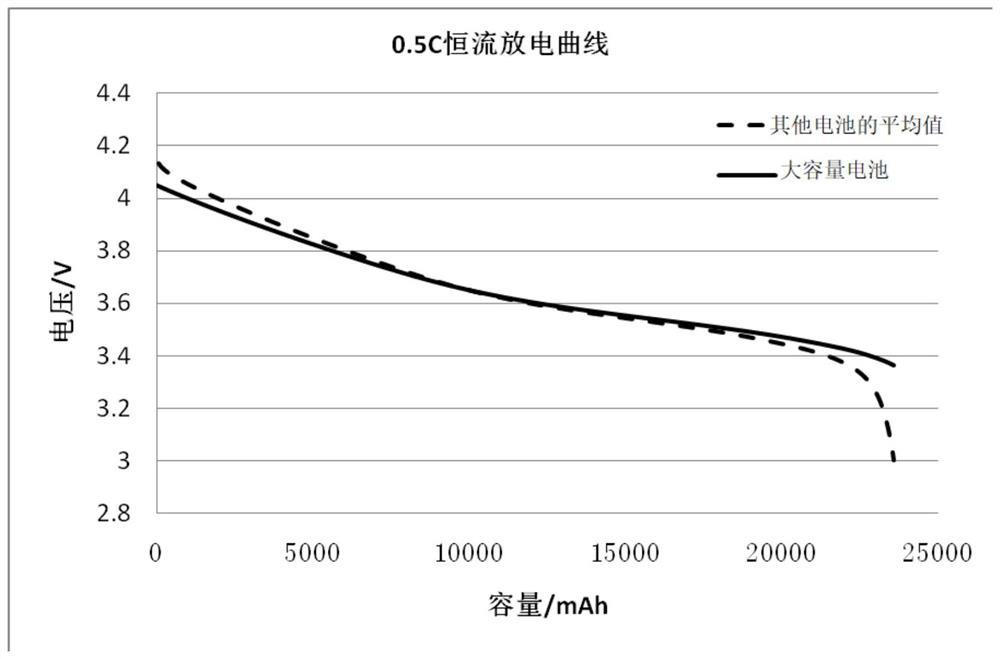

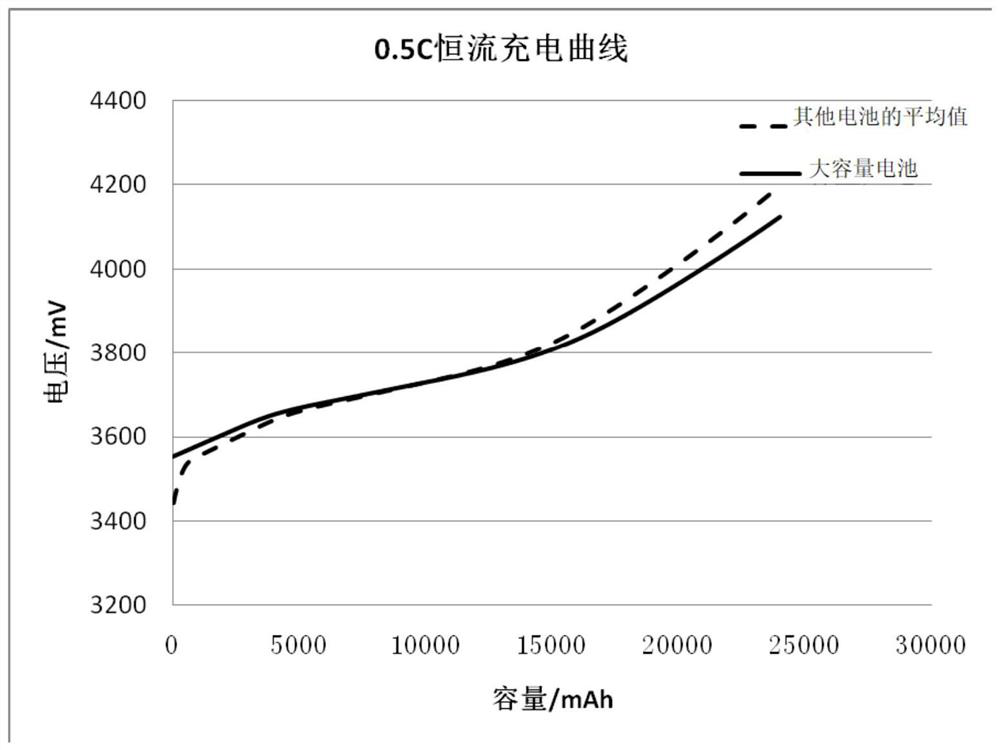

PendingCN112653209AReduce capacityLarge capacityCharge equalisation circuitElectric powerBattery cellBattery pack

The invention discloses a battery equalization method and device. The battery equalization method comprises the following steps of: acquiring a voltage change rate of a battery in a battery pack; determining the battery of which the voltage change rate meets a first preset condition as a non-target battery, and determining the remaining battery as a target battery; and performing voltage equalization operation on the target battery. According to the battery equalization method and the device, the capacity range of the alternative batteries can be widened, the grouping rate is improved, the waste of the batteries is reduced, and the cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Intelligent food waste disposer

ActiveCN101890421BEasy to operateThe operation is cumbersome and not energy-savingSolid waste disposalLow noiseBrushless motors

Owner:SHANGHAI ONEDEAR ENVIRONMENT TECH

One-step controllable preparation method and application of a high-capacity, high-dispersion supported gold nanocatalyst

The invention relates to a one-step controllable preparation method and application of a high-capacity and high-dispersity supported nano-gold catalyst. The preparation method of the catalyst comprises the following steps: adding a carrier to a water solution containing a surfactant and carrying out ultrasonic dispersion; adding the water solution of a gold compound for ultrasonic treatment and then adding the water solution of a reducing agent; controlling the reaction temperature, and reacting for 0.5-5 hours; and then carrying out washing and drying to obtain the high-dispersity supported nano-gold catalyst. According to the preparation method, gold nanoparticles evenly grow on the carrier surface by the ultrasonic dispersion effect, so that controllable preparation of the high-dispersity supported nano-gold catalyst is achieved; and the preparation method is simple in step, mild in condition, short in preparation time, free of calcination and suitable for large-scale synthesis. The capacity range of gold in the prepared catalyst is wide (1wt%-80wt%); the electrocatalytic activity is high; and particularly, the supported nano-gold catalyst demonstrates good catalytic performance in the aspect of alcohol oxidation and can be applied to the fields of a fuel cell, an electrochemical sensor and the like.

Owner:DALIAN UNIV OF TECH

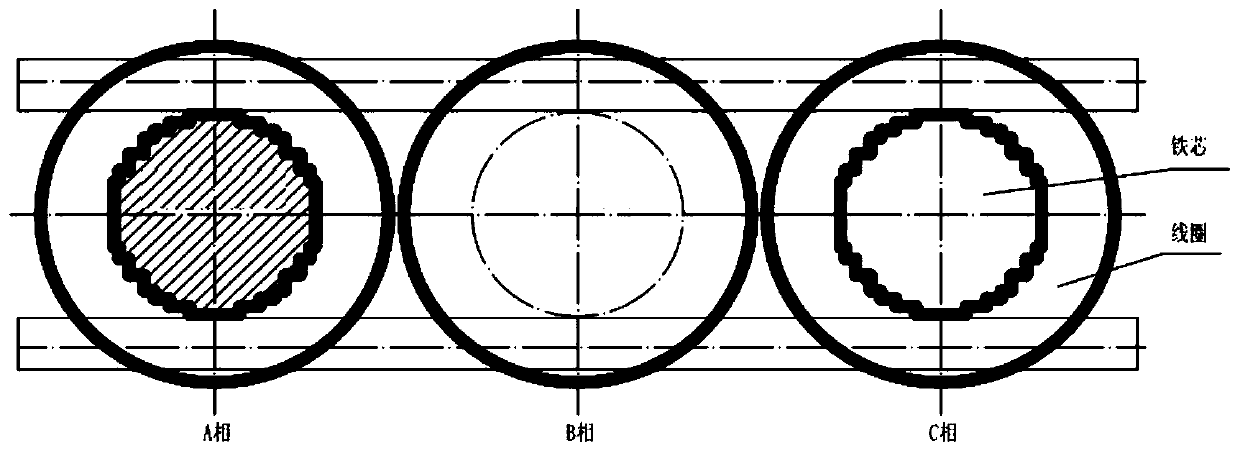

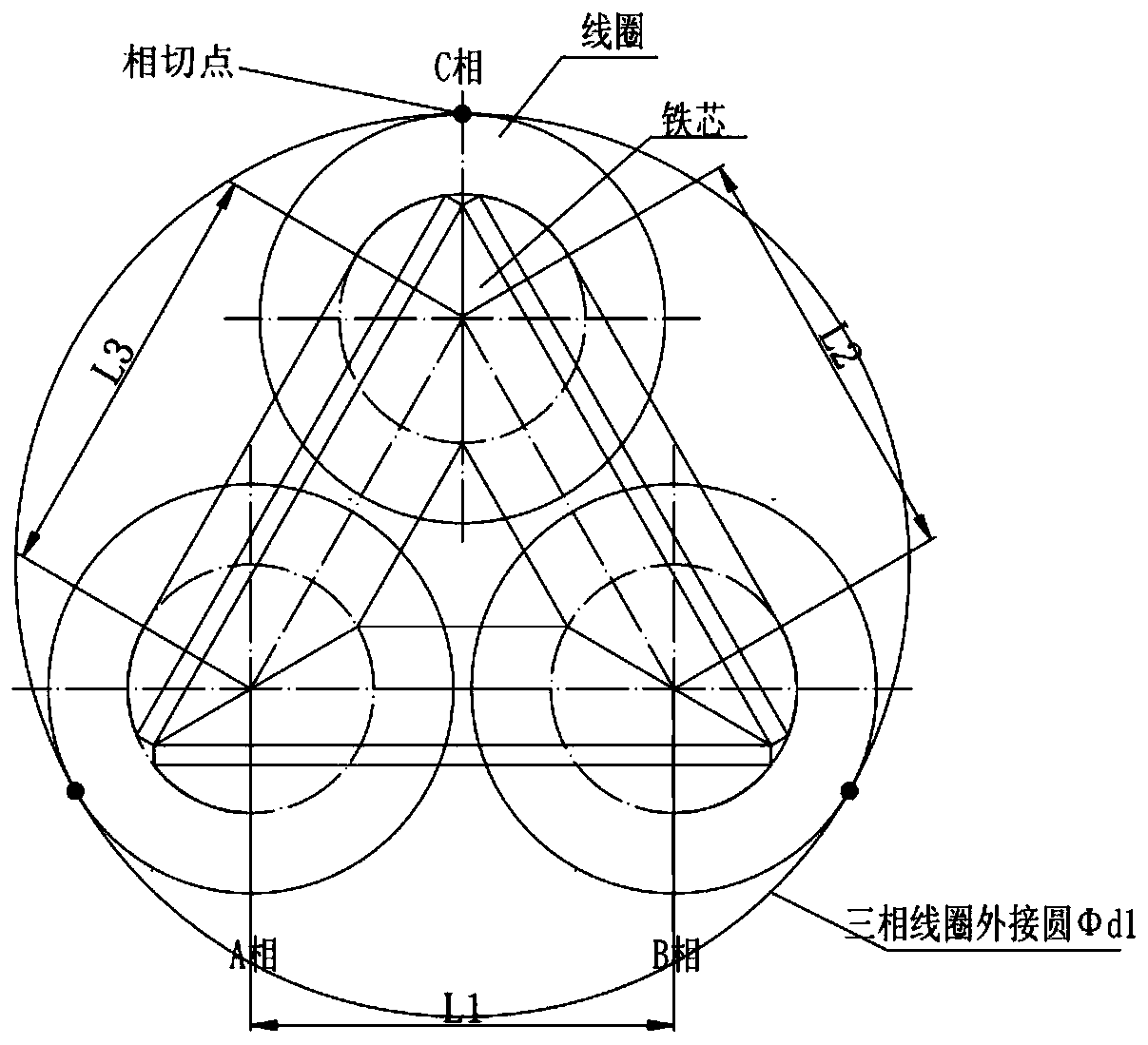

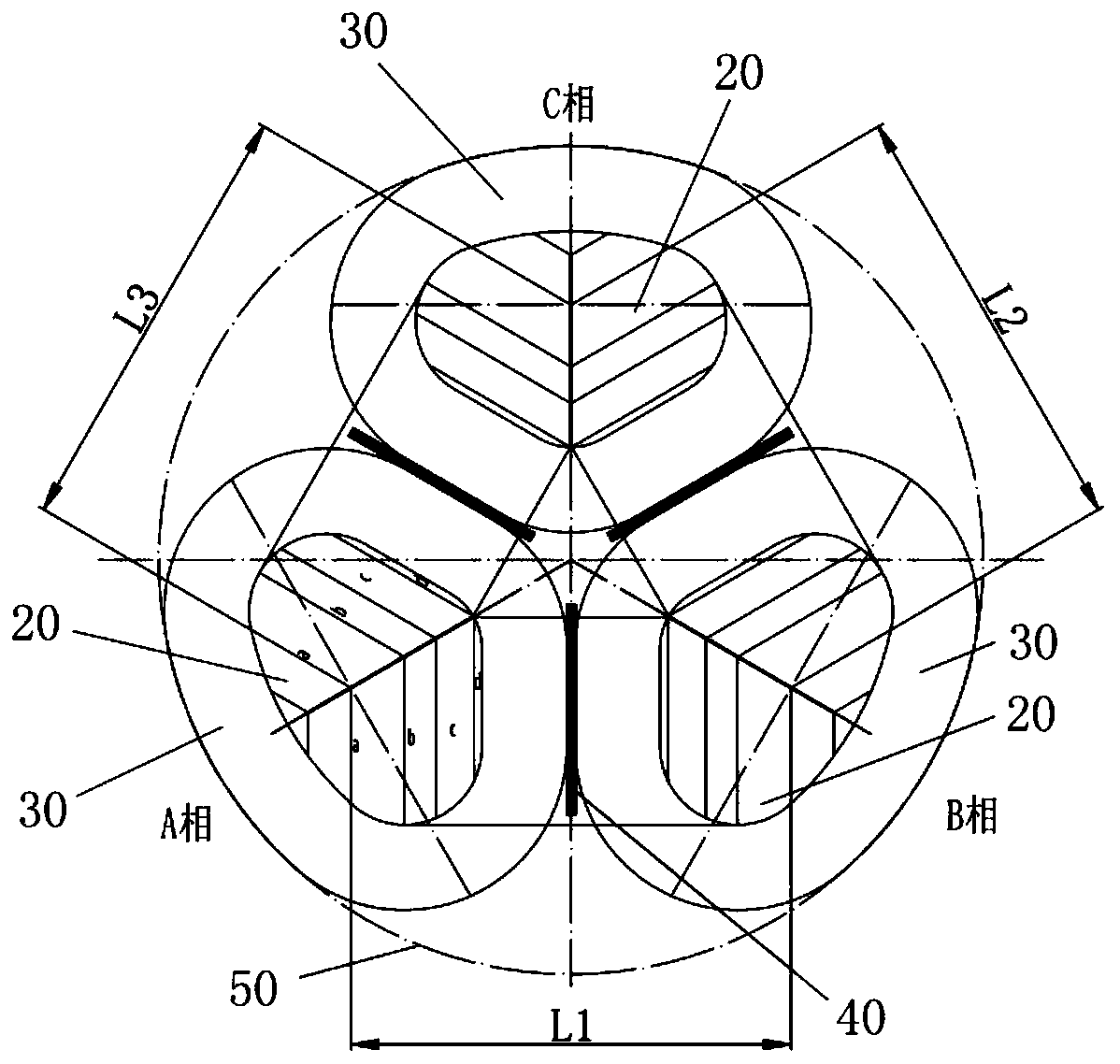

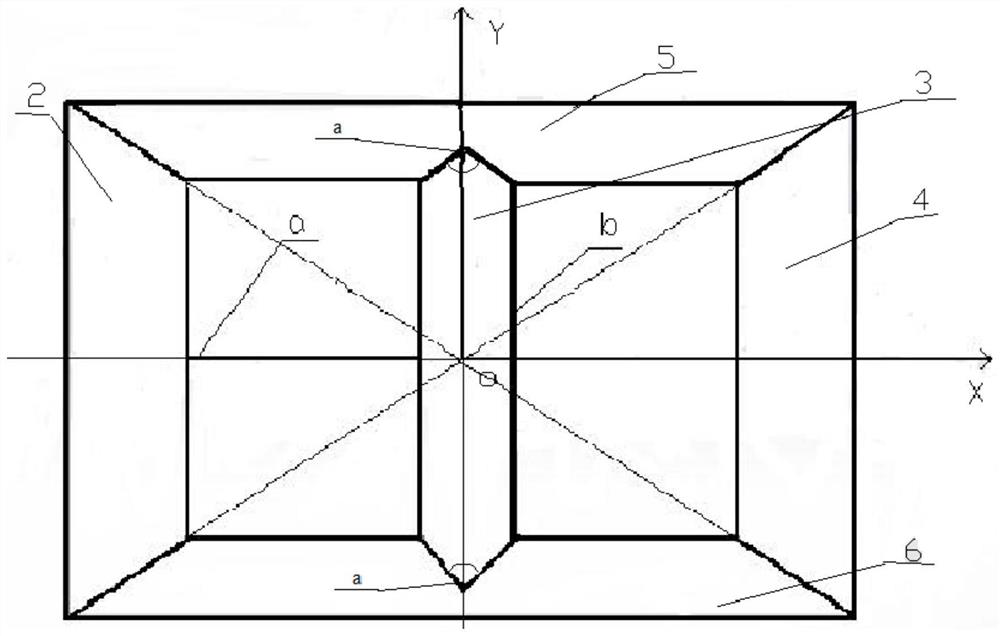

Three-phase three-dimensional non-circular transformer body structure

PendingCN110136934AWide capacity rangeReduce volumeTransformers/inductances coils/windings/connectionsCoil structureEngineering

The invention discloses a three-phase three-dimensional non-circular transformer body structure which comprises an iron core and three coils. The iron core comprises three non-circular iron core columns with horizontal cross sections, the three coils surround the three iron core columns, the three coil structures are the same in size, the horizontal sections of the three coils are all non-circularshapes, each of the horizontal sections of the three coils has a curved side, a circumscribed circle is defined by the peripheries of the three coils, and the curved sides of the three coils are tangent to the circumscribed circle. The various performances of a transformer can be effectively improved by using the three-phase three-dimensional non-circular transformer body structure, and the manufacturing cost is reduced.

Owner:BAODING TIANWEI GRP JIANGSU WUZHOU TRANSFORMER

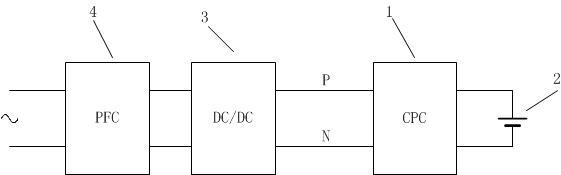

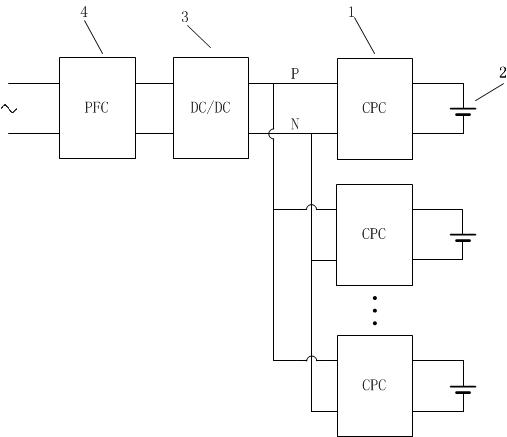

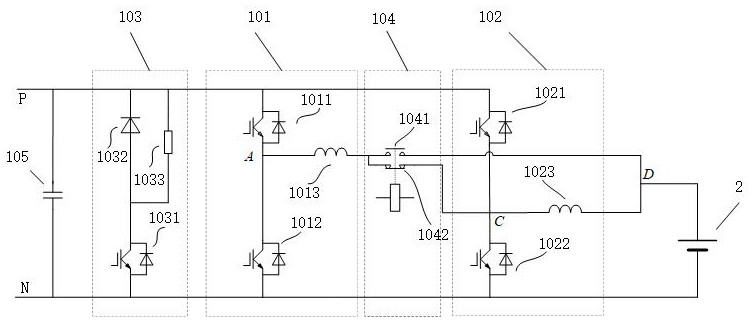

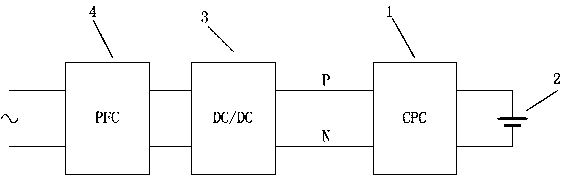

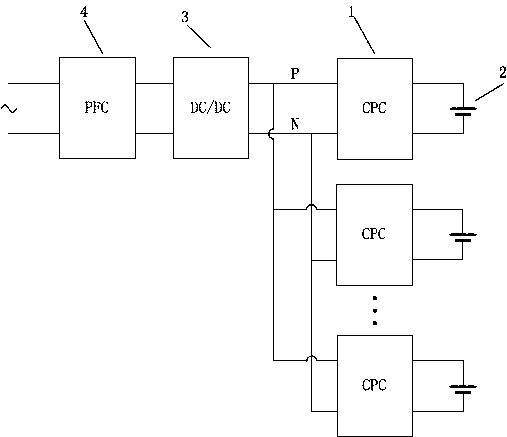

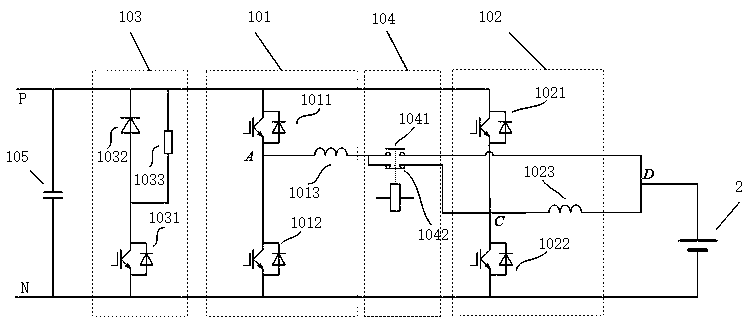

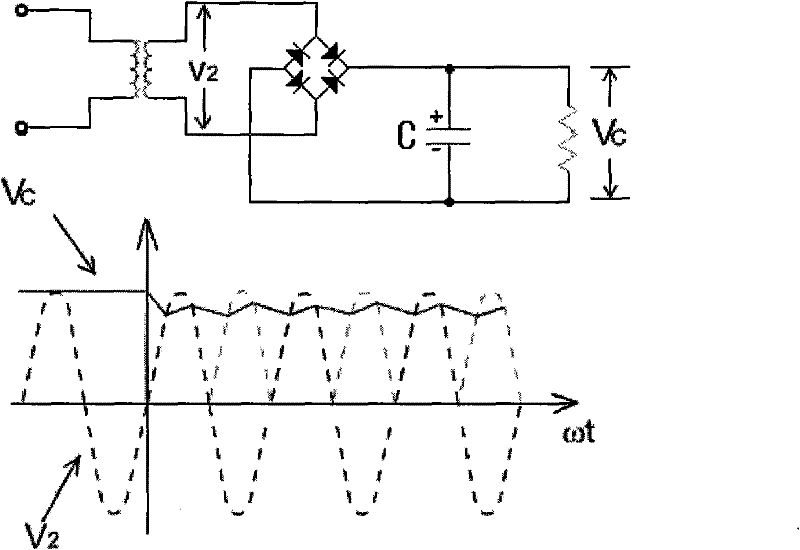

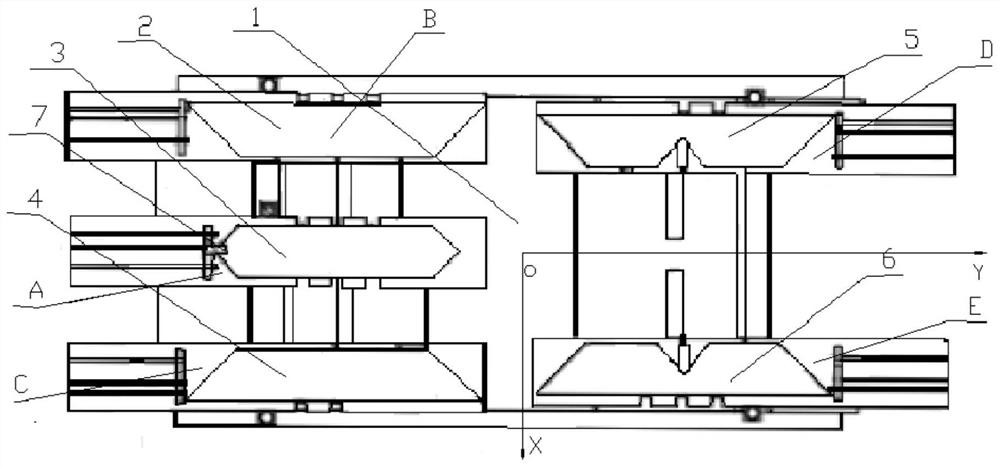

Wide capacity range battery charging and repairing integrated device

ActiveCN111293761BWide capacity rangeImprove adaptabilitySecondary cells charging/dischargingElectric powerBattery chargeControl theory

The invention provides a wide-capacity-range battery charging and repairing integrated device. The integrated device comprises an integrated module, a storage battery, a DC / DC module and a rectification module, wherein the output of the integrated module is connected with the storage battery to control charging, discharging and repairing of the storage battery, and the integrated module comprisesa first bridge arm, a second bridge arm and a third bridge arm. The three bridge arms are connected to the positive and negative end of the direct-current bus, namely, the PN end; and the first bridgearm and the second bridge arm can be connected in series and output to the storage battery, and the first bridge arm and the second bridge arm can also be connected in parallel and output to the storage battery. According to the invention, the adaptive capacity range of the storage battery is wider, the charging, discharging and repairing functions can be completed, and the storage batteries of different types, different batches, different models and different aging states can be repaired more flexibly, so that the repairing effect is improved; and the amplitude, the frequency, the positive polarity and the negative polarity of the applied pulse current can be randomly controlled, and the flexibility of repair control is improved.

Owner:北京理工大学唐山研究院

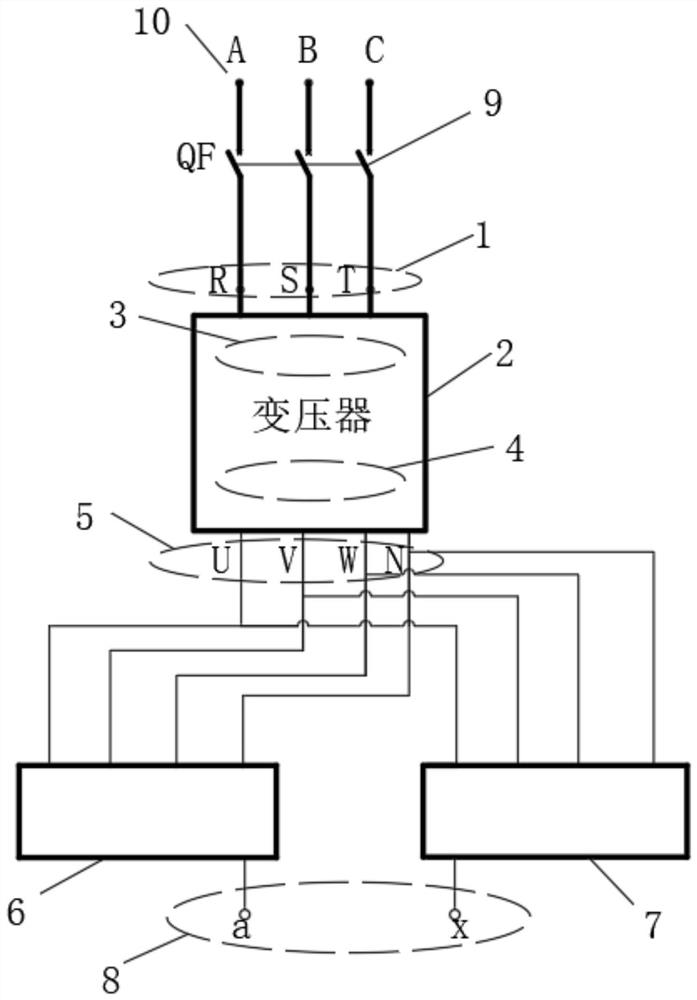

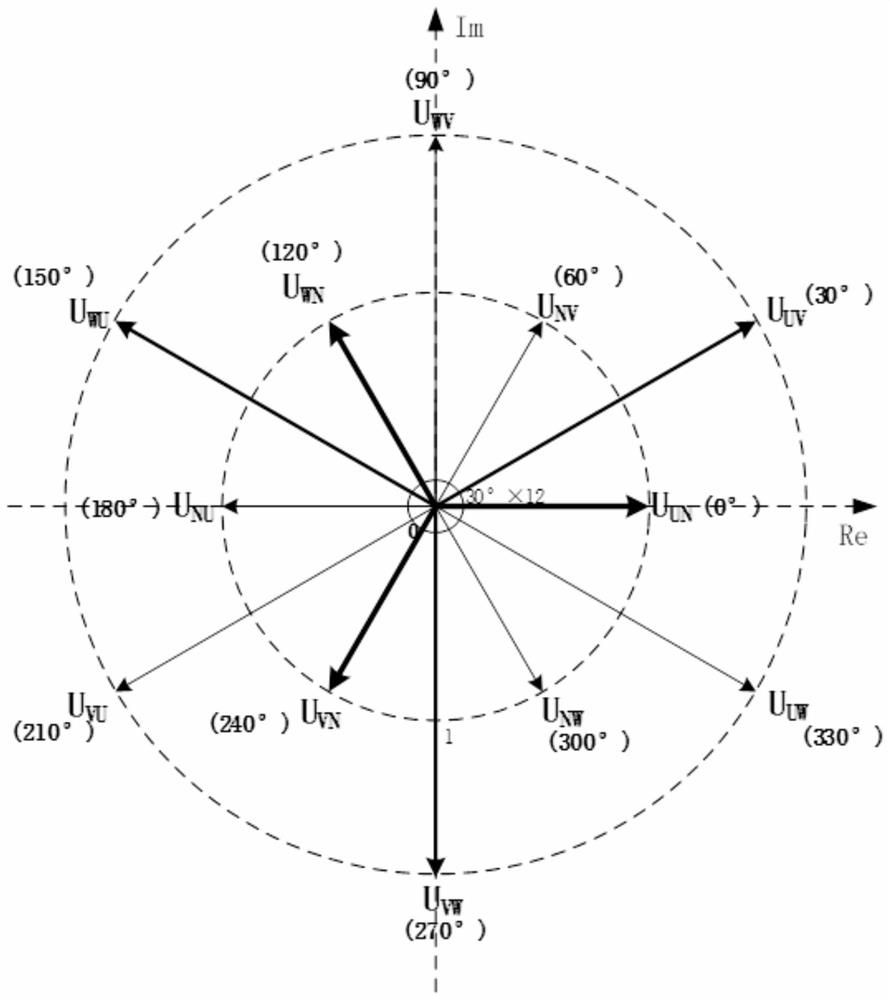

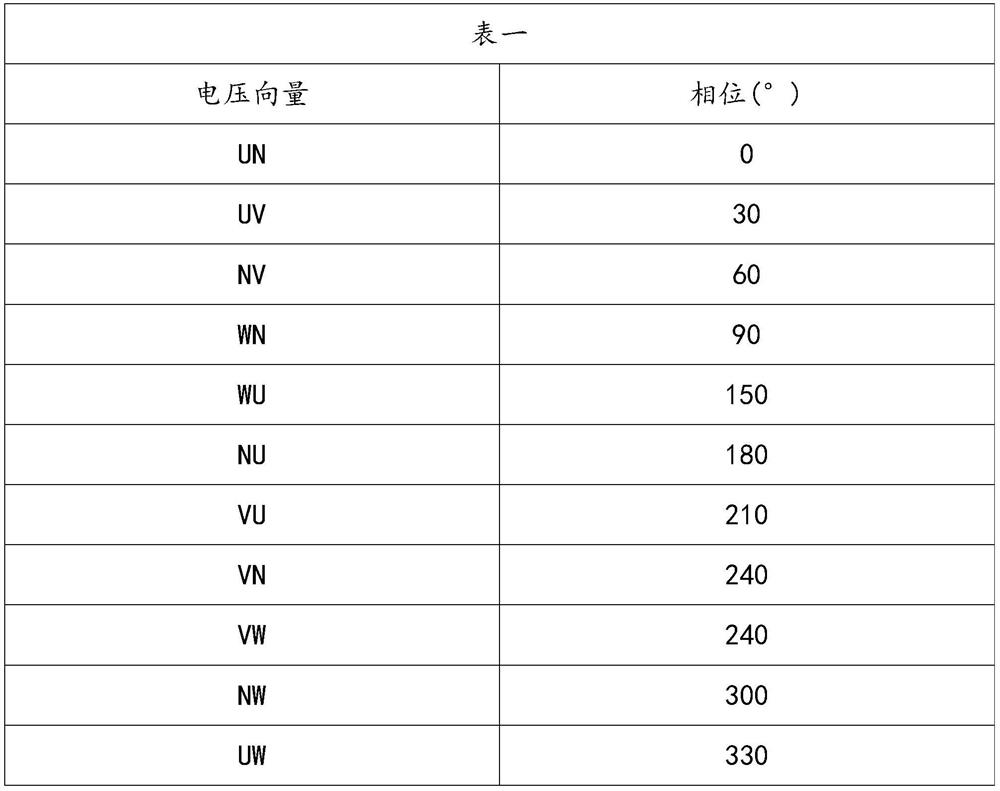

System and method for generating uniformly distributed twelve-phase discrete phase modulation single-phase voltage

PendingCN113691143AFlexible useFlexible regulationConversion without intermediate conversion to dcAC - Alternating currentControl engineering

The invention provides a system and method for generating uniformly distributed twelve-phase discrete phase modulation single-phase voltage, and relates to the technical field of alternating current power supplies. According to the system and method for generating uniformly distributed twelve-phase discrete phase modulation single-phase voltage, the system comprises a three-phase transformer, a primary winding is arranged in the three-phase transformer, a secondary winding is arranged in the three-phase transformer, the input end of the primary winding is connected with the input end of the transformer, and the secondary winding is electrically connected with a three-phase four-wire output end of the transformer. The three-phase transformer of the three-phase four-wire system power supply system formed by the three-phase symmetrical power supply and the three-phase power supply is used for generating uniformly-distributed twelve-phase discrete phase modulation single-phase voltage, so that the cost is low, the impact resistance is high, high-capacity output can be realized, the operation is stable and reliable, and the practicability is high.

Owner:南京普源电气有限公司

Wide-capacity-range battery charging and repairing integrated device

ActiveCN111293761AWide capacity rangeImprove adaptabilitySecondary cells charging/dischargingElectric powerBattery chargeControl theory

The invention provides a wide-capacity-range battery charging and repairing integrated device. The integrated device comprises an integrated module, a storage battery, a DC / DC module and a rectification module, wherein the output of the integrated module is connected with the storage battery to control charging, discharging and repairing of the storage battery, and the integrated module comprisesa first bridge arm, a second bridge arm and a third bridge arm. The three bridge arms are connected to the positive and negative end of the direct-current bus, namely, the PN end; and the first bridgearm and the second bridge arm can be connected in series and output to the storage battery, and the first bridge arm and the second bridge arm can also be connected in parallel and output to the storage battery. According to the invention, the adaptive capacity range of the storage battery is wider, the charging, discharging and repairing functions can be completed, and the storage batteries of different types, different batches, different models and different aging states can be repaired more flexibly, so that the repairing effect is improved; and the amplitude, the frequency, the positive polarity and the negative polarity of the applied pulse current can be randomly controlled, and the flexibility of repair control is improved.

Owner:北京理工大学唐山研究院

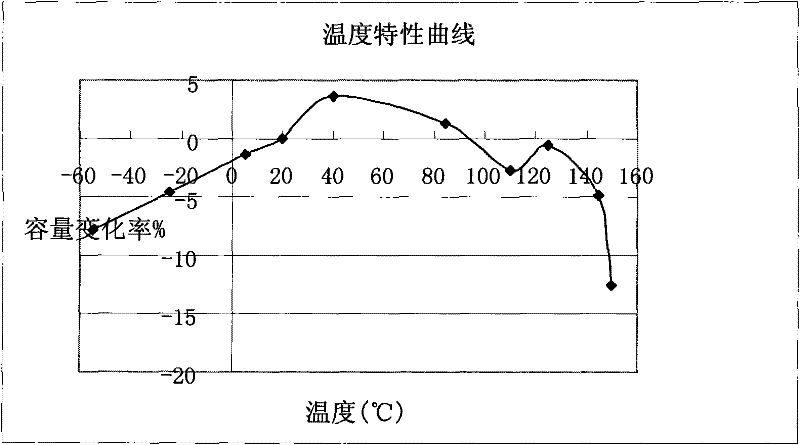

Preparation method of X8R-property slice type multilayer ceramic capacitor

ActiveCN101908415BImprove reliabilityReduce manufacturing costFixed capacitor electrodesStacked capacitorsBarium titanateDielectric membrane

The invention discloses a preparation method of an X8R-property slice type multilayer ceramic capacitor, comprising the following steps of: preparing ceramic slurry, making a dielectric membrane, alternately overprinting inner electrodes and dielectric layers, cutting, discharging glue, sintering, sealing ends and burning ends, wherein the used ceramic slurry in a barium titanate structure also comprises 0.1-5wt% of auxiliary components apart from BaTiO3 as a main component; the inner electrodes are made of nickel inner electrode materials; end electrodes are made of copper end electrode materials; and the sintering temperature is 1220 DEG C-1300 DEG C, and the sintering process comprises a temperature rise section, a high-temperature burning section, a temperature reducing section and a tempering section. As the X8R-property slice type multilayer ceramic capacitor is prepared by using materials of a base metal system for replacing expensive materials of a palladium silver system, theperformance reaches the level of X8R products of the palladium silver system, the upper-limit use temperature of the product reaches +150 DEG C, the change rate of the inner capacity in the temperature range of -55 DEG C-+150 DEG C is not greater than + / -15%, and the ceramic capacitor has high reliability and can effectively replace the X8R products of the palladium silver system; the method greatly reduces the production cost and saves scarce noble metal resources, and the producible capacity range of the product is wider than that of the materials of the palladium silver system.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

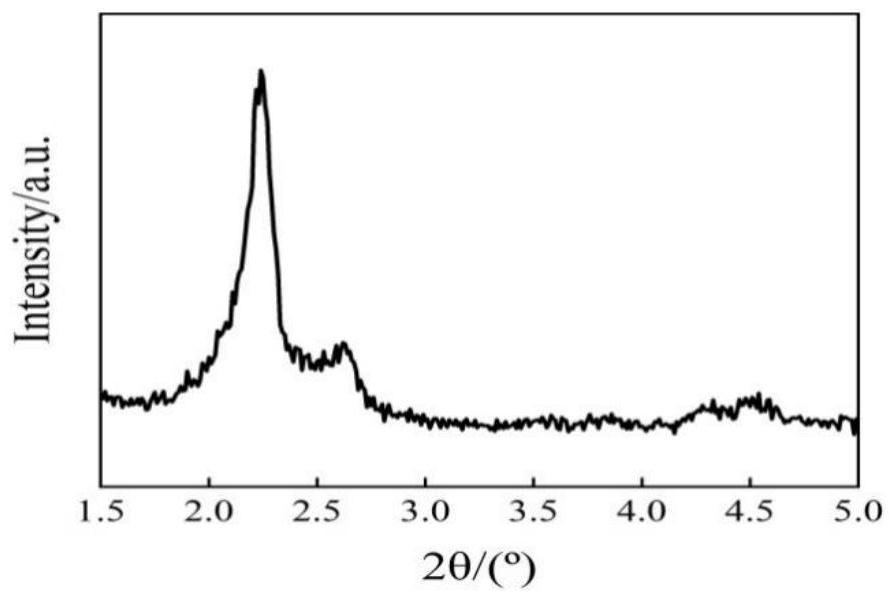

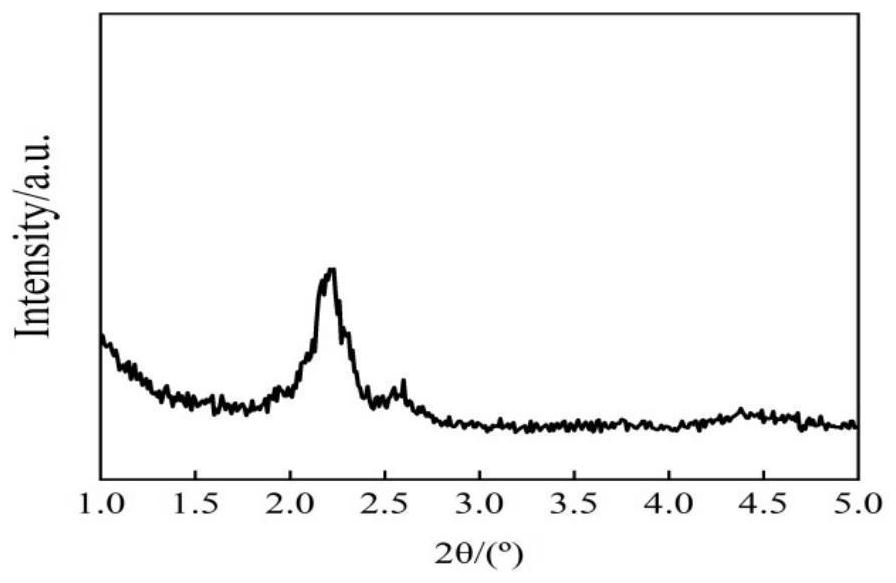

Pd/Ce-F/MCM-48 catalyst as well as preparation method and application thereof

ActiveCN114632538AWide capacity rangeImproved pore size distributionHydrocarbon by isomerisationMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a Ce-F / MCM-48 mesoporous material and a Pd catalyst with the Ce-F / MCM-48 mesoporous material as a carrier. According to the invention, Ce-F / MCM-48 is synthesized by using a NaF and Ce in-situ doping hydrothermal synthesis method, and the Pd-loaded Pd / Ce-F / MCM-48 bimetallic catalyst taking Ce-F / MCM-48 as a carrier is prepared by using an impregnation method. The catalytic performance of the catalyst on the n-heptane isomerization reaction is investigated. Results show that the molecular sieve prepared after NaF doping has the advantages that the specific surface area and the pore volume are increased, the pore size distribution tends to be uniform, and the acidity is mild and moderate. When the optimal loading capacity of the noble metal Pd is 0.4% by mass, the reaction temperature is 280 DEG C and the reaction time is 120 min, the catalytic performance is relatively stable, the conversion rate of n-heptane isomerization is 79.7%, and the selectivity of isoheptane is 91.5%. The catalyst is expected to be an important catalyst for hydroisomerization of n-heptane.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com