One-step controllable preparation method and application of a high-capacity, high-dispersion supported gold nanocatalyst

A support type, gold nanotechnology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of large particle size, low loading capacity and complicated preparation process of gold nanoparticles, and achieve good catalytic activity and loading range Wide, high-load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Au / Graphene (16.5wt%)

[0041] Graphene (10mg) was added to dodecyl polyethylene glycol ether aqueous solution (10mL, 1mM), ultrasonically dispersed, then added chloroauric acid aqueous solution (10mL, 1mM), further ultrasonically dispersed, and then added freshly prepared boron Sodium hydride aqueous solution (10mL, 5mM), control the reaction temperature at 16°C, react for 2h, wash and dry to obtain an Au / Graphene catalyst with a theoretical loading value of 16.5wt%.

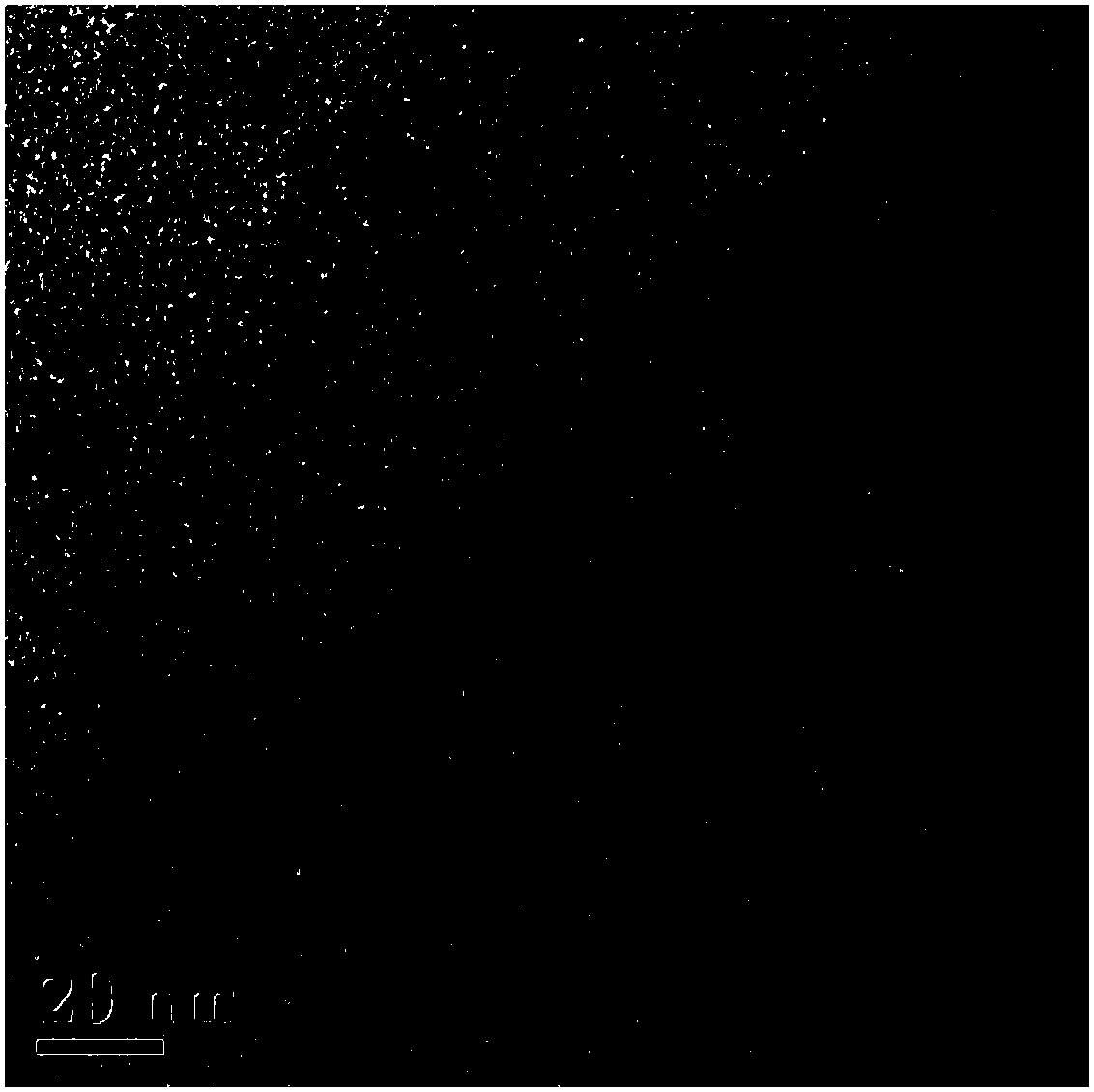

[0042] figure 1 It is a transmission electron microscope picture (TEM) of the Au / Graphene (16.5wt%) catalyst obtained in Example 1 of the present invention. Depend on figure 1 It can be seen that the gold nanocatalyst is highly dispersed on the surface of the carrier, and the particle size is small, with an average particle size of 2.5nm.

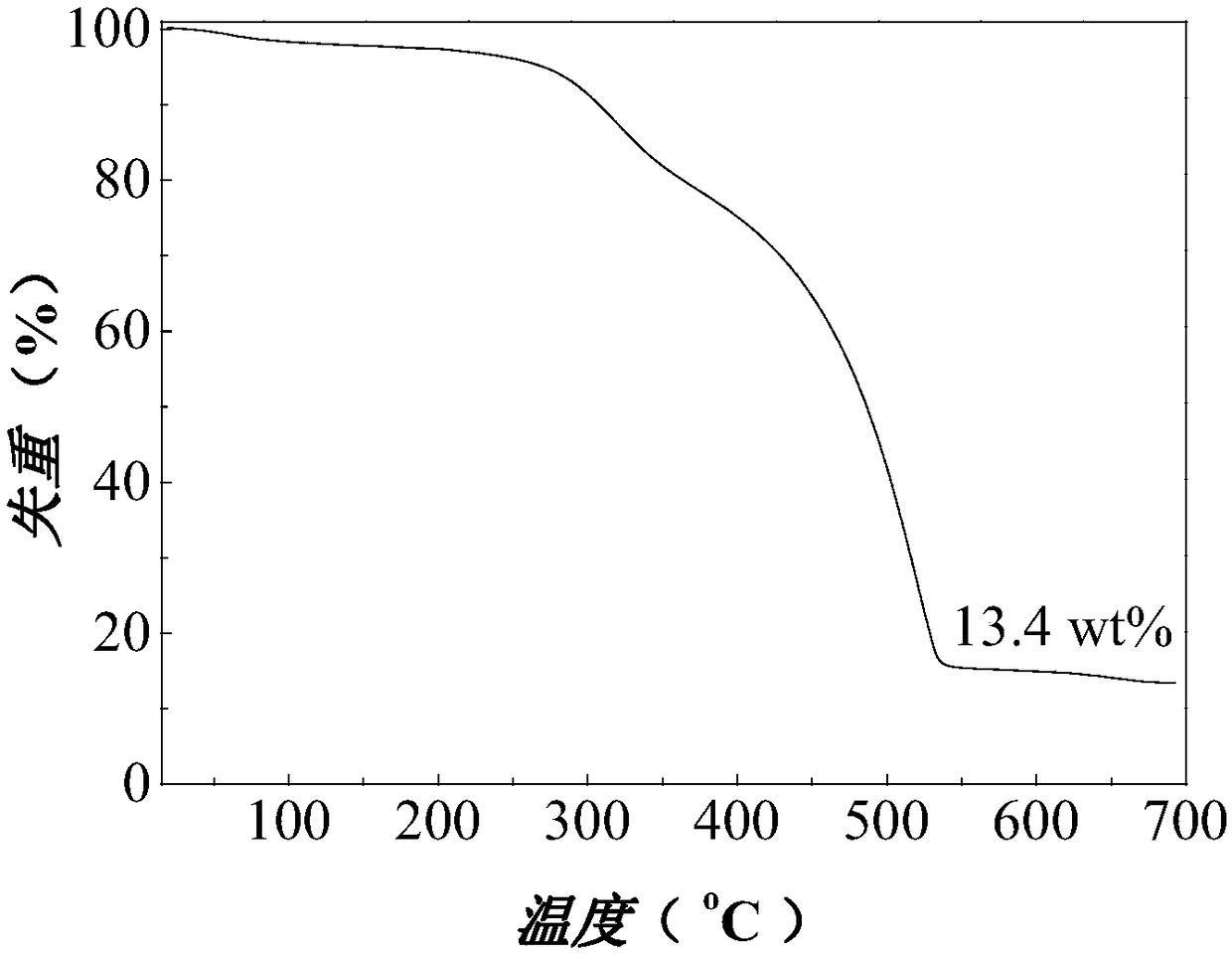

[0043] figure 2 It is the thermogravimetric analysis curve of the Au / Graphene (16.5%) catalyst obtained in Example 1 of the present invention, and ...

Embodiment 2

[0044] Embodiment 2: Au / EC600 (16.5wt%)

[0045] Activated carbon EC600 (10mg) was added to lauryl polyethylene glycol ether aqueous solution (10mL, 1mM), ultrasonically dispersed, then added chloroauric acid aqueous solution (10mL, 1mM), further ultrasonically dispersed, and then added freshly prepared boron Sodium hydride aqueous solution (10mL, 5mM), control the reaction temperature at 16°C, react for 2h, wash and dry to obtain Au / EC600 catalyst with a theoretical loading value of 16.5wt%.

[0046] image 3 It is a transmission electron microscope picture (TEM) of the Au / EC600 (16.5wt%) catalyst obtained in Example 2 of the present invention. Depend on Figure 4 It can be seen that the gold nanocatalyst is highly dispersed on the surface of the carrier, and the particle size is small, with an average particle size of 2.4nm.

[0047] Figure 4 The thermogravimetric analysis curve (TGA) of the Au / EC600 (16.5wt%) catalyst obtained in Example 2 of the present invention show...

Embodiment 3

[0050] Embodiment 3: polyethylene glycol octylphenyl ether

[0051] Graphene (10mg) was added to polyethylene glycol octylphenyl ether aqueous solution (10mL, 1mM), ultrasonically dispersed, then added chloroauric acid aqueous solution (10mL, 1mM), further ultrasonically dispersed, and then added freshly prepared boron Sodium hydride aqueous solution (10mL, 5mM), control the reaction temperature at 16°C, react for 2h, wash and dry to obtain an Au / Graphene catalyst with a theoretical loading value of 16.5wt%.

[0052] Figure 7 It is a transmission electron microscope picture (TEM) of the Au / Graphene (16.5wt%) catalyst obtained in Example 3 of the present invention. Depend on Figure 7 It can be seen that the gold nanocatalysts are highly dispersed on the surface of the support, and the particle size is small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com