Pd/Ce-F/MCM-48 catalyst as well as preparation method and application thereof

A catalyst and reagent technology, applied in the field of Pd/Ce-F/MCM-48 catalyst and its preparation, can solve the problems of low concentration of surface acid centers and lack of catalytic oxidation reaction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

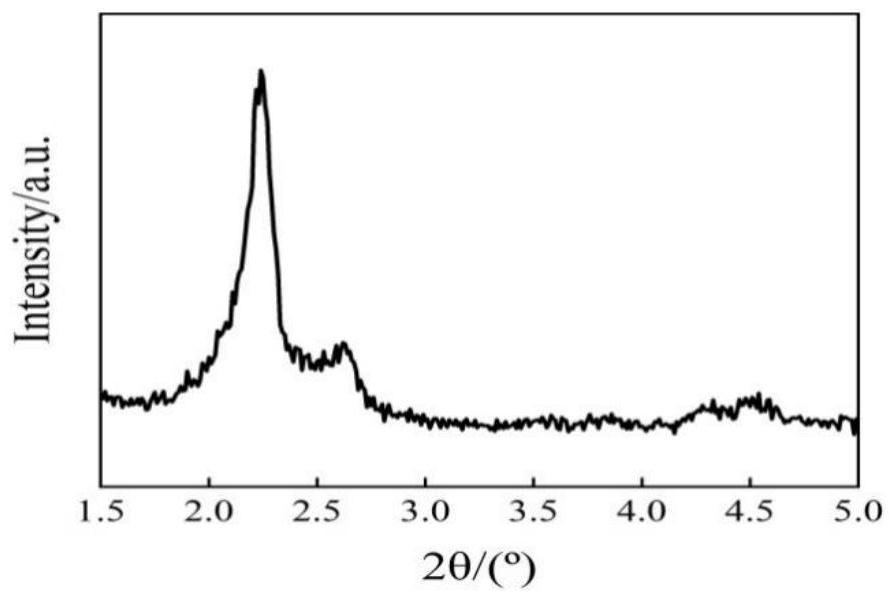

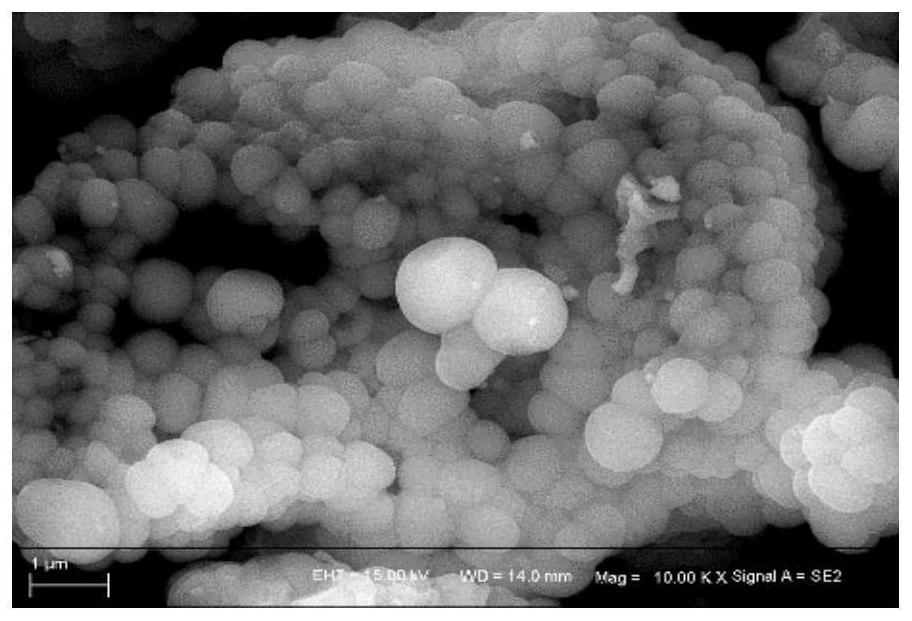

[0053] Example 1. Preparation of anion-doped mesoporous material Ce-F / MCM-48 with high degree of order

[0054] Using CTAB as a template, NaF and Ce(NO 3 ) 6H 2 O is an additive reagent, prepared by hydrothermal synthesis under alkaline conditions.

[0055] First, dissolve NaOH in deionized water and stir well, then add NaF and Ce(NO 3 ) 6H 2 Stir for 30min, add CTAB to the mixture in small amounts and stir for 90min under heating in a water bath at 35°C, the solution is transparent at this time, and then use a 3mL long pasteurized plastic pipette to slowly add TEOS (ethyl silicate) dropwise and intermittently. In this solution, continue stirring for 60min, and the molar ratio of the reaction mixture raw materials is n(TEOS):n(CTAB):n(H 2 O):n(NaOH):n(Ce):n(NaF)=1.0:0.65:62:0.5:0.02:0.10. The prepared initial gel was transferred into a stainless steel reaction kettle lined with PTFE, and then placed in a drying oven for 72h at 110°C for constant temperature crystallizatio...

Embodiment 2

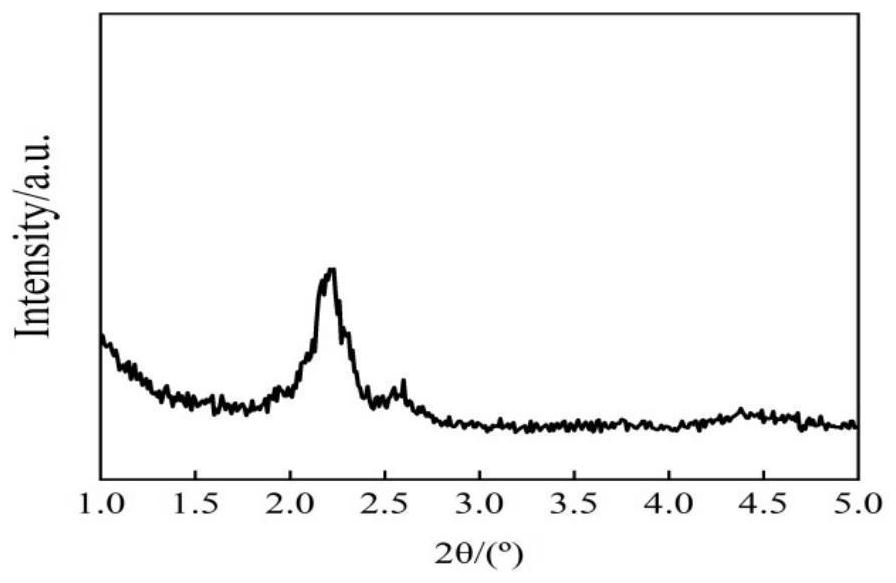

[0056] Example 2. Preparation of a catalyst supporting metal active components

[0057] In the catalyst supporting metal active components, the active component is precious metal palladium, and the carrier is the mesoporous material Ce-F / MCM-48 prepared in Example 1; the catalyst is Pd-Ce-F / MCM-48.

[0058] The catalyst was prepared by impregnation method, and the loading (mass fraction) of Pd was 0.4%. Pd was dissolved in a porcelain crucible of deionized water, and Ce-F / MCM-48-0.10 was then immersed in it. Ultrasonic dispersion at 50°C for 20min. After standing at room temperature for more than 6 hours, drying at 90°C for 4 hours on an electric hot plate, drying at 105°C for 5 hours in a drying oven, and calcining at 400°C for 4 hours, a Pd-supported catalyst was obtained, denoted as 0.4% Pd-Ce-F / MCM-48.

Embodiment 3、0

[0061] Example 3. Evaluation of catalytic reaction performance of 0.4% Pd-Ce-F / MCM-48 for catalyzing the isomerization of n-heptane

[0062] The evaluation of catalytic reaction performance was carried out on a fixed-bed micro-reaction device, and the prepared catalyst was tableted and sieved to obtain 60-80 mesh particles, which were used for later use. The filling amount is 0.3 g, which is mixed with quartz sand and then loaded into a reaction tube, and the inner diameter of the reaction tube is 6 mm. Before the reaction, the catalyst was activated in a hydrogen atmosphere at a pressure of 1.0 MPa and 300 °C for 4 h, and then cooled to a temperature in the range of 220-360 °C for modulation. The reaction evaluation process conditions are pressure n-C 7 Flow rate 6.0mL / h, n-H 2 Flow rate 30mL / min, MHSV is 7.6h -1 . Sampling was started after 30 minutes of stability, and the product was separated by a chromatographic column and analyzed on-line with a gas chromatograph FID...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com