Preparation method of X8R-property slice type multilayer ceramic capacitor

A technology of multilayer ceramics and capacitors, which is applied in the direction of laminated capacitors, fixed capacitor electrodes, fixed capacitor parts, etc., can solve the problems of decreased density of dielectric ceramics, decreased product competitiveness, and decreased reliability of finished products, achieving The effect of promoting development, reducing production cost, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

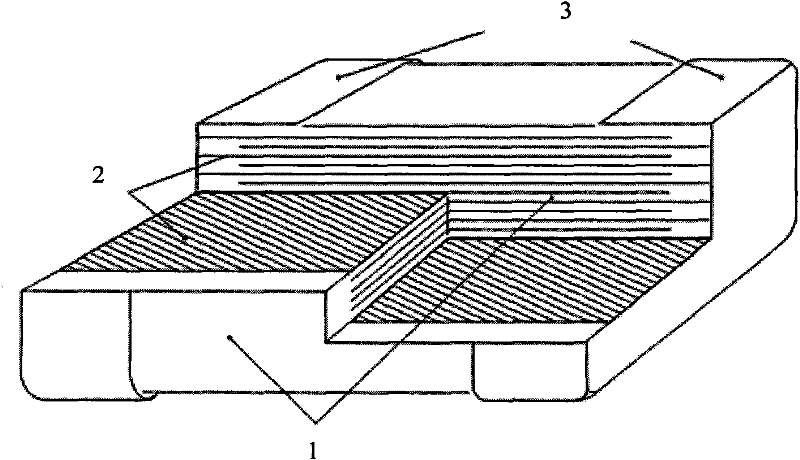

[0025] A method for preparing an X8R characteristic chip multilayer ceramic capacitor of the present invention includes preparation of porcelain slurry, making dielectric diaphragms, alternately overprinting inner electrodes and dielectric layers, drying blocks, laminating, cutting, debinding, sintering, pouring Steps such as cornering, capping, and burning.

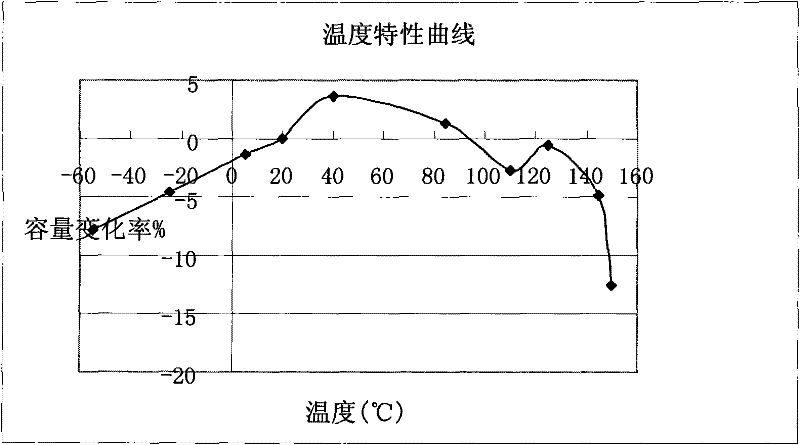

[0026] In the preparation step of porcelain slurry, the porcelain material used adopts barium titanate structure porcelain material, and the main component is 95-99.9wt% of Ba, Ti composite oxide BaTiO 3 , the secondary component is 0.1-5wt% of one or more of Ca, Mg, Ce, La, Si, Y, Zr, Er, Ni, Nb oxides, which can be adjusted according to the actual situation, taking into account the temperature characteristics of the product, Insulation, withstand voltage, service life, etc., should also consider the impact on the sintering temperature of the product, and the total amount should be controlled at 0.1-5wt%. For example, ...

Embodiment

[0033] Specifically select the porcelain slurry of No. 1 to No. 5 formulations in Table 1, and the above-mentioned binders, plasticizers, dispersants, and defoamers are all substances commonly used by those skilled in the art. The solvents used were the formulations in Table 3. The performance parameters of the ceramic material after silk screen printing are shown in Table 2 corresponding to test numbers 1 to 5. Make 250V 1206-inch products with superior performance as shown in Table 4.

[0034] Table 1: Porcelain slurry formula (mass ratio of each component to porcelain powder)

[0035]

[0036] Table 2: Performance Parameters of Porcelain Cast Diaphragms

[0037]

[0038] From the ratios in Table 1 and the diaphragm comparison results in Table 2, the ratio corresponding to Test No. 4 is the best ratio.

[0039] Table 3: Formulation selection of solvents

[0040]

[0041] From the analysis of the above test results, it can be seen that when the ratio of toluene a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com