A control method and device for precise positioning of transformer iron core silicon steel sheet

A transformer core and precision positioning technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of high error rate of manual selection, difficulty in wide application, and poor accuracy of manual positioning laminations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

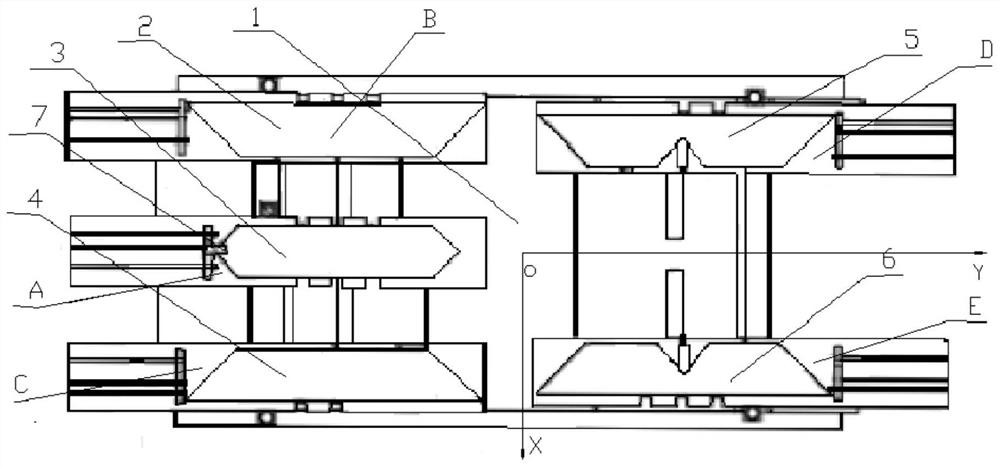

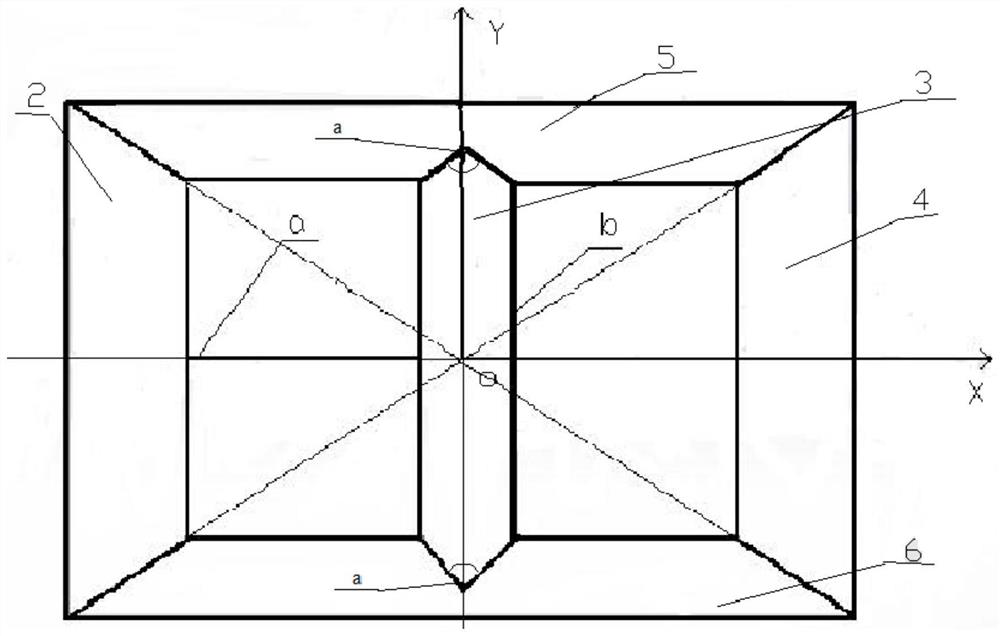

[0031] A control device for precise positioning of transformer iron core silicon steel sheets, characterized in that:

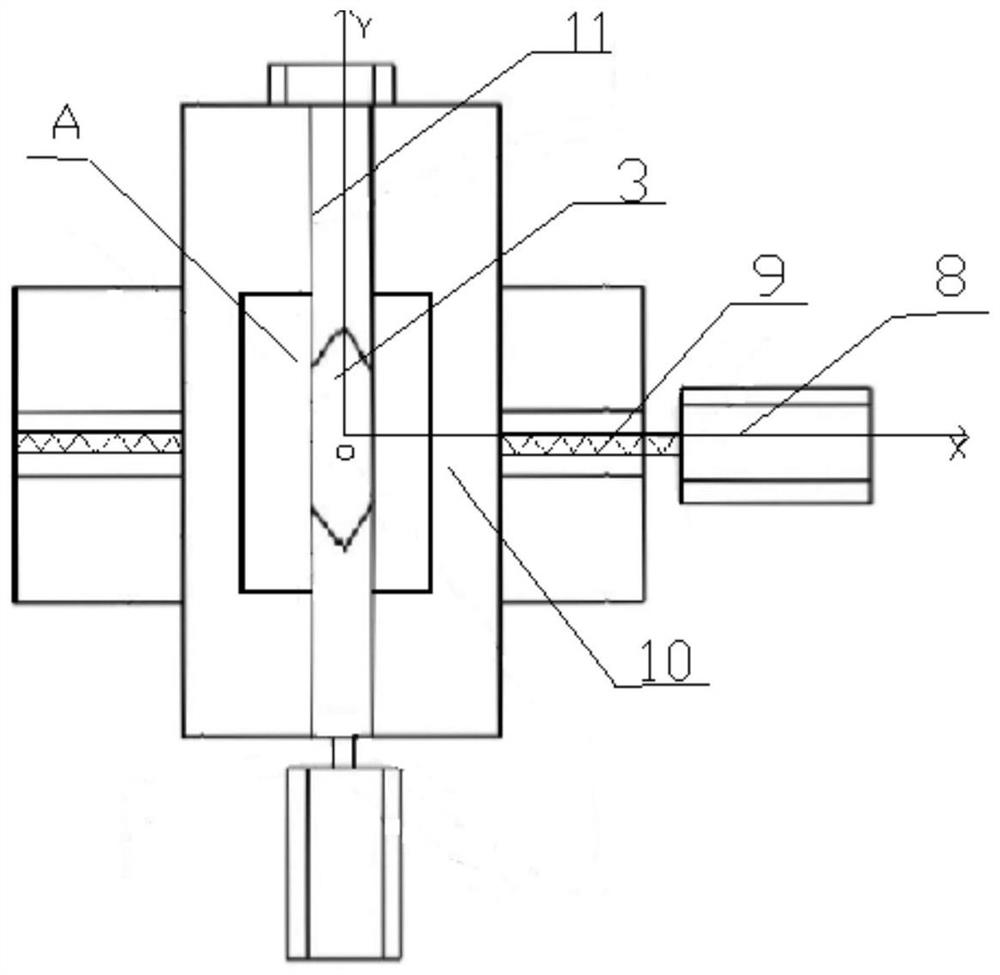

[0032] Five sets of CNC cross slides are installed on the positioning platform 1, and each set of CNC cross slides includes upper and lower stages, and each stage includes a servo motor 8, a driving screw 9, a slider 10 and a guide rail 11; the servo motor 8 is connected to the driving lead screw 9, the leading screw 9 is connected to the slider 10, and the guide rail 11 is arranged on the slider 10 (the cross slide belongs to the prior art; the servo motor 8 of the lower platform (X-direction slide) is connected to the lower driving screw 9. The lower driving screw 9 is connected to the lower slider 10, and the slider 10 is driven to move along the guide rail 11 through the rotation of the driving screw 9; the structure of the upper platform (Y-direction platform) is the same as that of the lower platform; the upper slider 10 is set It is on the lower slider...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com