Sulfur/vanadium disulfide/MXene composite material as well as preparation method and application thereof

A technology of vanadium disulfide and composite materials, which is applied in the direction of sulfur compounds, chemical instruments and methods, vanadium compounds, etc., and can solve problems such as poor cycle stability and safety performance, poor fixation of sulfur simple substances, and safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

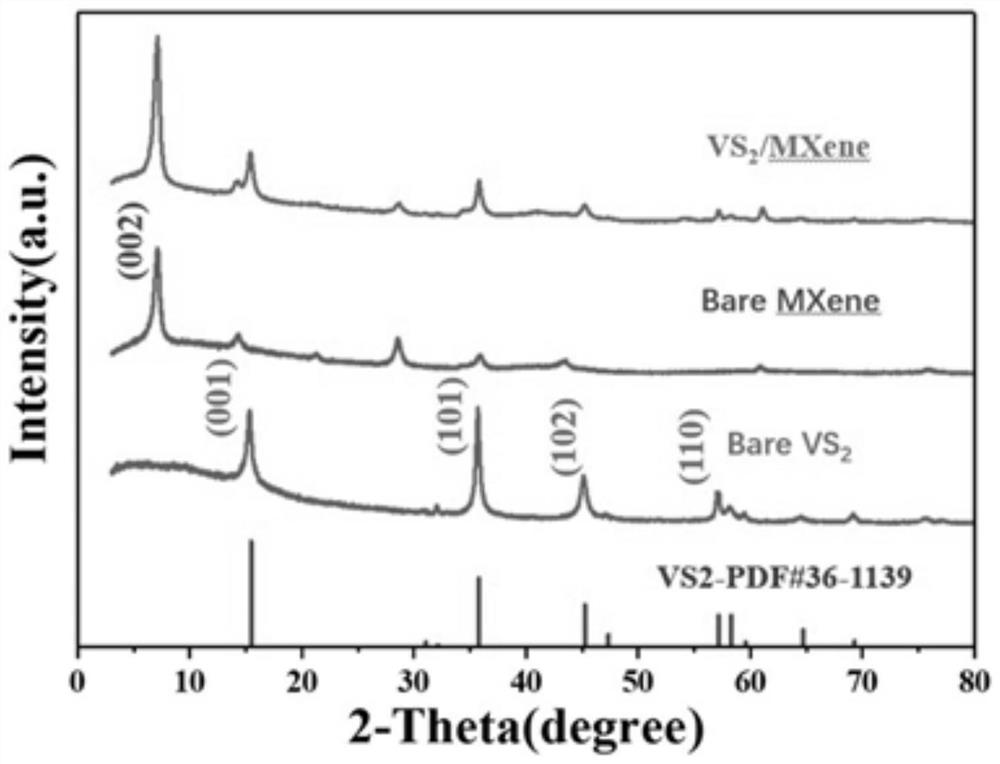

[0047] This comparative example is the preparation of vanadium disulfide, and concrete steps are as follows:

[0048] Weigh 0.232g of ammonium metavanadate and 4ml of ammonia water and stir for 15min, then add 1.504g of thioacetamide, stir and ultrasonically disperse for 1h, then transfer the solution to a 100ml hydrothermal kettle, seal it and place it in an oven at 180°C In constant temperature reaction 20h. After the reaction is naturally cooled, the vanadium disulfide can be obtained by washing with distilled water and ethanol for several times of centrifugation and then freezing and freeze-drying.

Embodiment 2

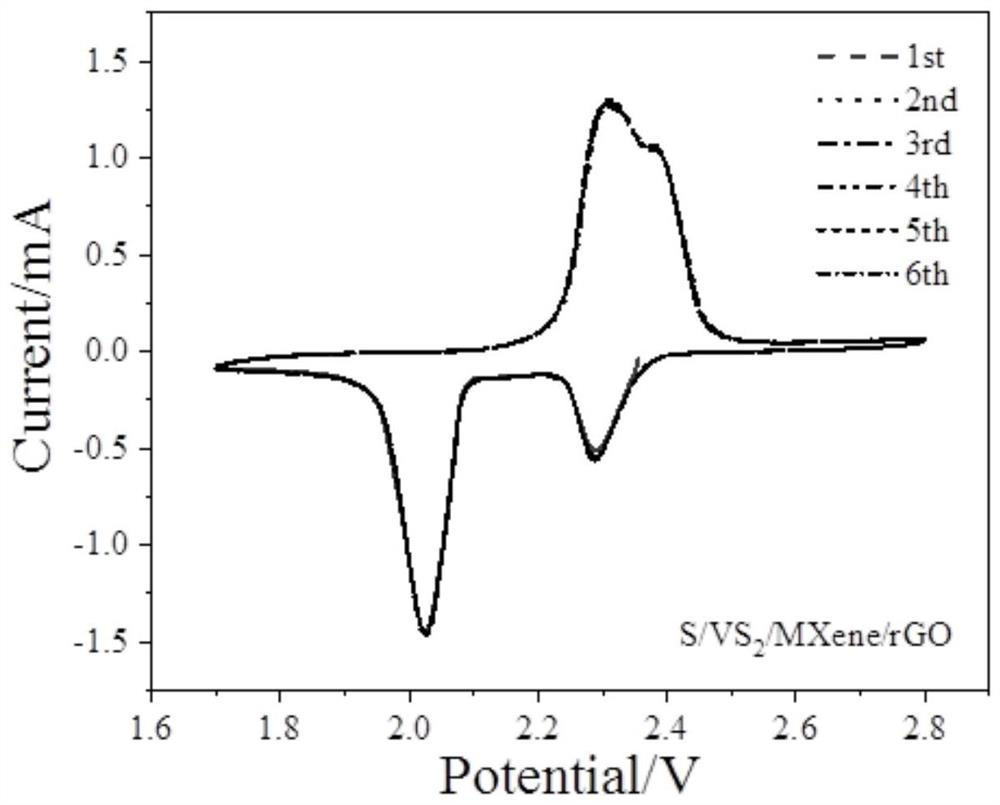

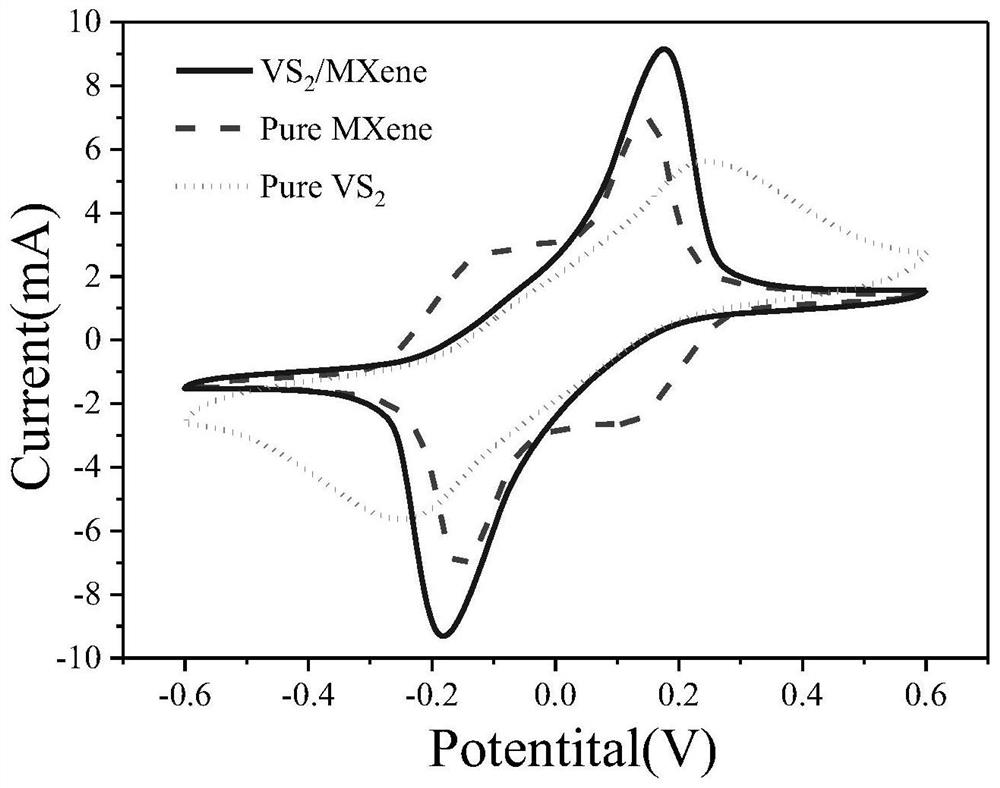

[0050] The present embodiment is sulfur / vanadium disulfide / MXene (Ti 3 C 2 ) / graphene composite material, the specific steps are as follows:

[0051] (1) Preparation of few-layer MXene(Ti 3 C 2 ): Use an electronic balance to weigh 2g of lithium fluoride, measure 40ml of HCl in a graduated cylinder, place them in a plastic beaker at a constant temperature of 35°C, stir and dissolve for 30min, and then use an electronic balance to weigh the titanium-based MAX (Ti 3 AlC 2 ) phase precursor 2g, slowly put into a plastic beaker at a constant temperature of 35°C and continue to stir for 24 hours; then use distilled water for several times to centrifuge and wash, and when the pH value is close to 7 after ultrasonication, the supernatant is collected and the final product is the few-layer MXene(Ti 3 C 2 ), and finally freeze and freeze-dry the suspension to obtain graphene-like few-layer MXene (Ti 3 C 2 ) solid powder.

[0052] (2) Preparation of vanadium disulfide / MXene(Ti ...

Embodiment 3

[0061] The present embodiment is sulfur / vanadium disulfide / MXene (Ti 3 C 2 ) / graphene composite material, the specific steps are as follows:

[0062] (1) Preparation of few-layer MXene(Ti 3 C 2 ): Use a measuring cylinder to measure 40% HF 40ml, pour it into a plastic beaker, and then use an electronic balance to weigh the titanium-based MAX (Ti 3 AlC 2) phase precursor 2g, slowly put it into a plastic beaker under magnetic stirring and continue to react for 24 hours; then use distilled water for several times to centrifuge and wash, and when the pH value is close to 7 after ultrasonication, the supernatant is collected and the final product is the few-layer MXene(Ti 3 C 2 ), and finally freeze and freeze-dry the suspension to obtain graphene-like few-layer MXene (Ti 3 C 2 ) solid powder.

[0063] (2) Preparation of vanadium disulfide / MXene(Ti 3 C 2 ) Nanocomposite material: Weigh 100mg of MXene (Ti 3 C 2 ) solid powder, which is placed in a beaker filled with 30ml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com