Sulfur/copper sulfide/MXene positive electrode material and preparation method and application thereof

A positive electrode material, copper sulfide technology, applied in the field of nanomaterials, can solve the problems of unsatisfactory firmness, cumbersome steps, and unsuitability for large-scale production, and achieve good adsorption, increased specific capacity, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

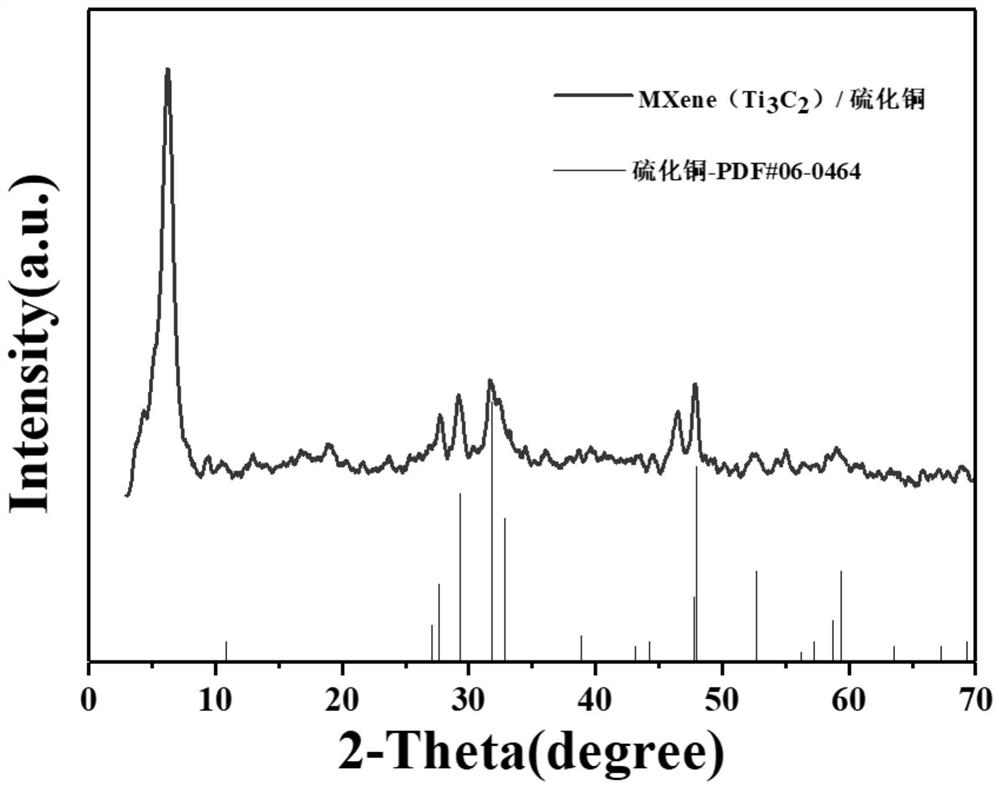

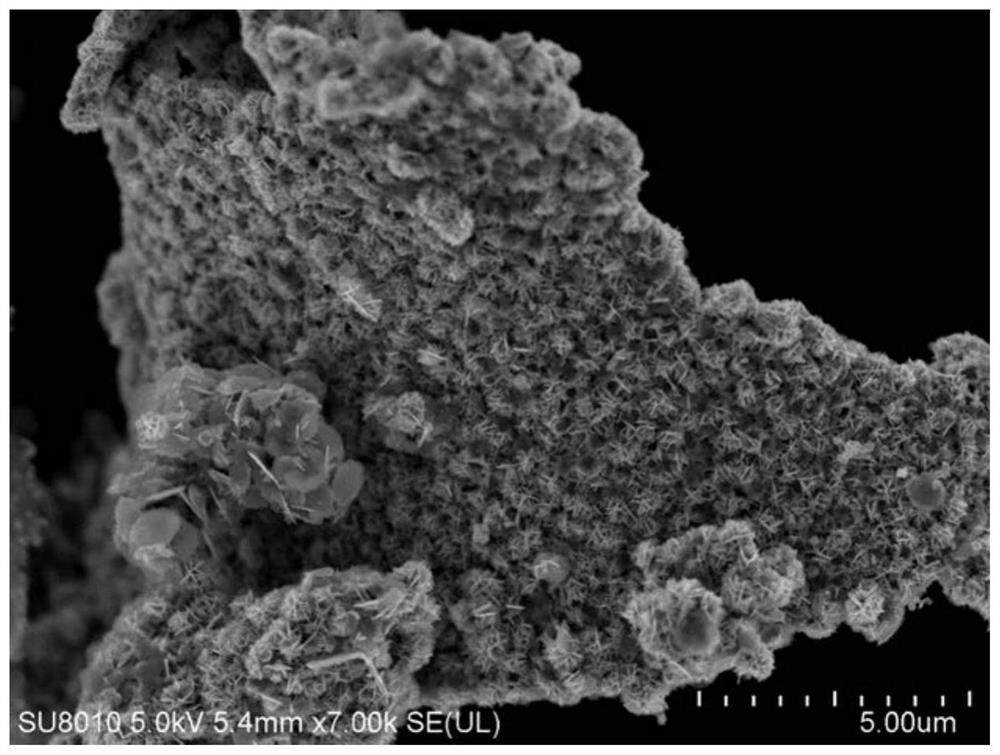

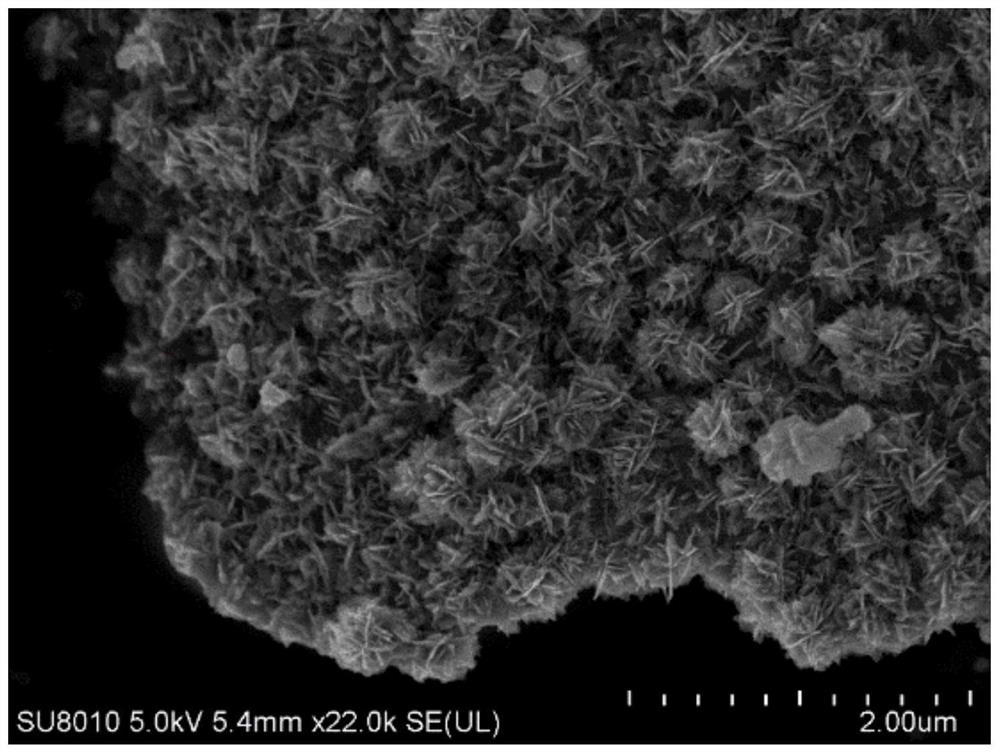

[0039] The invention provides a method for preparing a sulfur / copper sulfide / MXene positive electrode material, which can solve the technical problems of low sulfur loading, poor conductivity, low specific capacity, and poor cycle stability of lithium-sulfur batteries.

[0040] The technical solution is:

[0041] A preparation method of sulfur / copper sulfide / MXene cathode material, comprising the following steps:

[0042] Disperse MXene, copper salt and sulfur source in a solvent to obtain a mixed solution;

[0043] The mixed solution is placed in a closed pressure system, and the solvothermal reaction is carried out at 100°C to 180°C for 18h to 24h to prepare a copper sulfide / MXene nanocomposite material;

[0044] Mixing the copper sulfide / MXene nanocomposite material with elemental sulfur, and after grinding, place it at 155°C-180°C for 10h-18h to prepare the sulfur / copper sulfide / MXene positive electrode material;

[0045] The MXene is Ti 3 C 2 .

[0046] In some preferr...

Embodiment 1

[0076] This embodiment provides a sulfur / copper sulfide / MXene positive electrode material and a preparation method thereof, the specific steps are as follows:

[0077] Preparation of few-layer MXene(Ti 3 C 2 ): Weigh 2g of lithium fluoride with an electronic balance, measure 40ml of HCl aqueous solution with a concentration of 9mol / L in a graduated cylinder, place them in plastic beakers at a constant temperature of 35°C, stir and dissolve for 30min, and then use an electronic balance to weigh the titanium-based MAX ( Ti 3 AlC 2 ) phase precursor 2g, slowly put into a plastic beaker at a constant temperature of 35°C and continue to stir for 24 hours; then use distilled water to wash centrifugally and ultrasonically for several times, until the pH value is close to 7, collect the supernatant, which is the final product of few-layer MXene(Ti 3 C 2 ), and finally freeze-dry the suspension to obtain graphene-like few-layer MXene (Ti 3 C 2 ) solid powder.

[0078] Preparatio...

Embodiment 2

[0086] This embodiment provides a sulfur / copper sulfide / MXene positive electrode material and a preparation method thereof, the specific steps are as follows:

[0087] Preparation of few-layer MXene(Ti 3 C 2 ): use a graduated cylinder to measure 40ml of HF aqueous solution with a mass fraction of 40%, pour it into a plastic beaker, and then use an electronic balance to weigh the titanium series MAX (Ti 3 AlC 2 ) phase precursor 2g, slowly put it into a plastic beaker with a constant temperature of 35°C under magnetic stirring and continue to react for 24h; then use distilled water to wash centrifugally and ultrasonically for several times, until the pH value is close to 7, collect the supernatant which is the final product few-layer MXene ( Ti 3 C 2 ), and finally freeze and freeze-dry the suspension to obtain graphene-like few-layer MXene (Ti 3 C 2 ) solid powder.

[0088] Preparation of copper sulfide / MXene(Ti 3 C 2 ) nanocomposite material: the above-mentioned MXe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com