Processing method of water electret melt-blown fabric

A processing method and technology of melt-blown cloth, which are applied in the directions of non-woven cloth, single-component polyolefin rayon, chemical characteristics of fibers, etc., can solve the problem of reduced filtration efficiency, low filtration efficiency, and fast falling speed of melt-blown cloth materials. To achieve the effect of enhancing the ability to release negative ions and store charges, improve filtration performance, and enhance filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

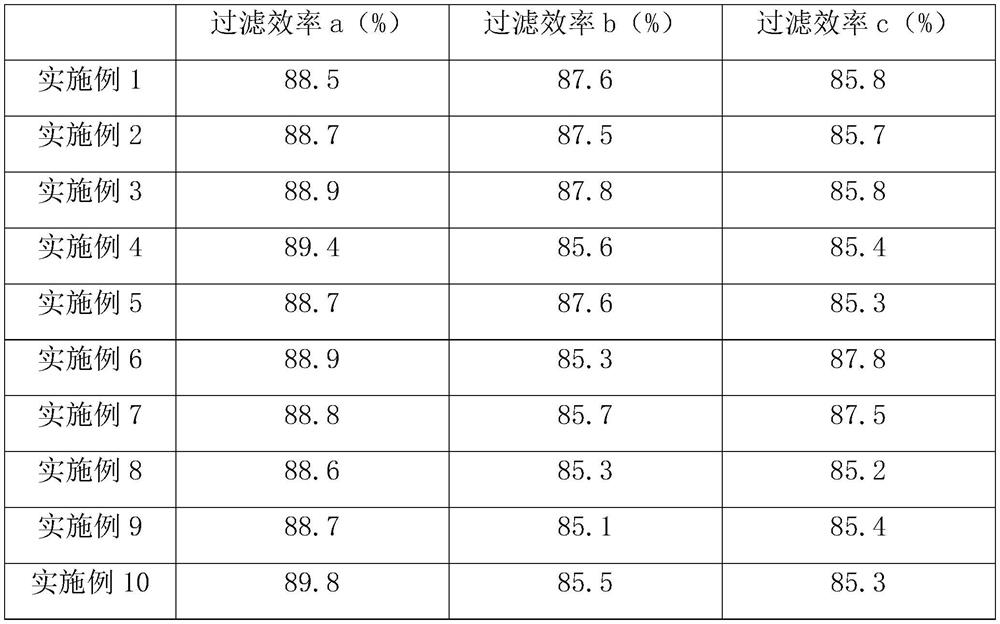

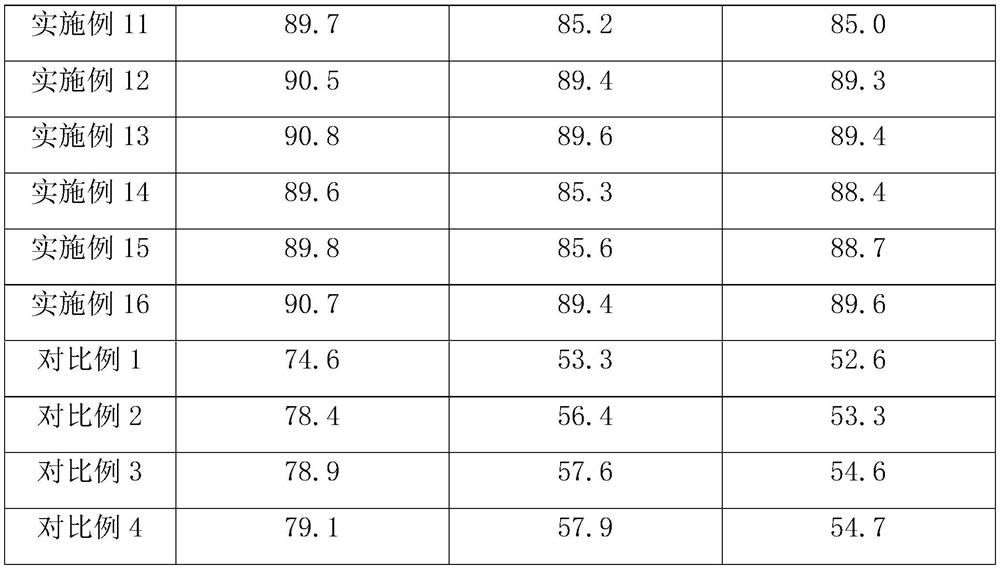

Embodiment 1

[0042] A processing method of water electret meltblown cloth, comprising the following steps:

[0043] Step 1) Prepare modified polypropylene melt-blown cloth:

[0044] Step 1-1) Add 85kg of polypropylene, 3kg of soluble polytetrafluoroethylene, 3kg of nano-titanium dioxide, 5kg of nano-silicon dioxide, and 1kg of nano-alumina into the mixer, and turn on the speed of 300r / min. Mix for 10min to obtain the mixture;

[0045] Step 1-2) Add 0.1kg of antioxidant and 0.1kg of additives, and put them together with the mixture into a twin-screw extruder at a speed of 100kg / h and a temperature of 170°C in each zone for melt blending and extrusion. Convergence, the screw speed is 15rpm, stretched under the airflow of 240°C, and cooled to room temperature to obtain a modified polypropylene melt-blown cloth;

[0046] In this embodiment, the antioxidant is triethyl phosphite; the auxiliary agent is an antibacterial agent, specifically polyhexamethylene biguanide hydrochloride,

[0047] S...

Embodiment 2

[0055] Compared with Example 1, the difference is only in:

[0056] In step 1-1), the addition of polypropylene is 95kg, the addition of soluble polytetrafluoroethylene is 5kg, the addition of nano-titanium dioxide is 5kg, the addition of nano-silicon dioxide is 8kg, the addition of nano-alumina The amount added is 3kg;

[0057] In step 1-2), the addition amount of antioxidant is 1 kg, and the addition amount of auxiliary agent is 1 kg.

Embodiment 3

[0059] Compared with Example 1, the difference is only in:

[0060] In step 1-1), the addition of polypropylene is 90kg, the addition of soluble polytetrafluoroethylene is 4kg, the addition of nano-titanium dioxide is 4kg, the addition of nano-silicon dioxide is 6kg, the addition of nano-alumina The amount added is 2kg;

[0061] In step 1-2), the addition amount of antioxidant is 0.5kg, and the addition amount of auxiliary agent is 0.5kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com