Monocrystalline solar cell texturing process

A solar cell and single-crystal-like technology, which is applied in the field of photovoltaics, can solve the problems of low power conversion efficiency of cells, uneven distribution of impurities and grain boundaries, and uneven grain size, so as to improve power conversion efficiency and avoid manpower consumption , the effect of reducing the difference in reflectance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

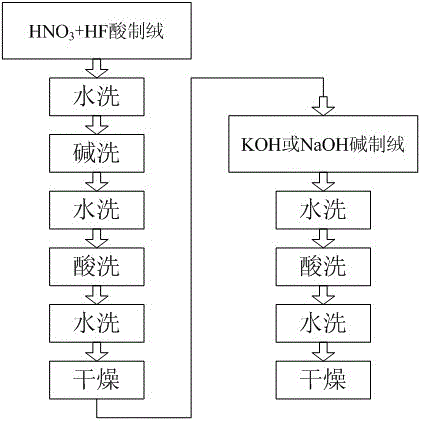

[0017] like figure 1 As shown, the monocrystalline solar cell texturing process includes two steps of acid texturing and alkali texturing, in which acid texturing includes HNO 3 And HF acid texturing - washing - alkali washing - washing - pickling - washing - drying; alkali texturing includes KOH or NaOH alkali texturing - washing - pickling - washing - drying. Among them, the specific process of acid texturing is: put the silicon wafer into HNO at a temperature of 5-10°C 3 Etch in the mixed acid solution of HF and HF, and take it out from the mixed acid solution when the etching depth of the silicon chip reaches 2-2.5um; put the silicon chip taken out of the mixed acid solution into KOH or NaOH with a concentration of less than 5% after washing with water solution, and then wash the silicon wafer with water and then put it into the HCl solution with a concentration of less than 10% and the HF solution with a concentration of less than 5% for cleaning; finally, wash and dry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com