Antistatic, anti-dazzle and anti-reflection optical film and manufacture method for the same and application thereof

An anti-static, anti-reflection technology, applied in optics, optical components, instruments, etc., can solve the problems of glare, poor anti-glare effect, low haze value, etc., and achieve good scratch resistance, excellent anti-glare and anti-reflection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

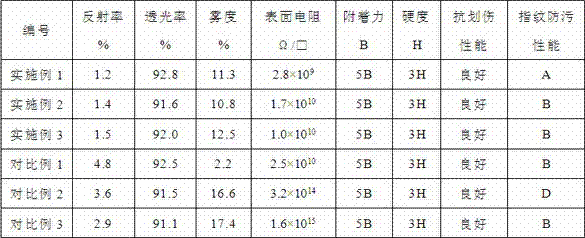

Examples

Embodiment 1

[0047] Mix and stir various antistatic and antiglare hard coating raw materials according to the following proportions to make them uniform:

[0048] 40 parts by weight of UV curing resin

[0049] 15 parts by weight of pentaerythritol triacrylate

[0050] 10 parts by weight of transparent anti-glare particles

[0051] 6 parts by weight of photoinitiator

[0052] Antistatic agent 2 parts by weight

[0053] Thinner 90 parts by weight

[0054] Add 4 parts by weight of polymethyl methacrylate resin particles (brand MBX-2H, average particle size 2 μm, refractive index 1.49, water Kasei Co.) and 6 parts by weight of polymethyl methacrylate resin particles (brand MB20X-5, average particle size 5 μm, refractive index 1.49, Sekisui Kasei Co.), stirred and mixed evenly.

[0055] Add 40 parts by weight of UV curable resin (brand name CN9010, refractive index 1.48, functionality 6, American Sartomer product), 15 parts by weight of pentaerythritol triacrylate (brand name SR444, refrac...

Embodiment 2

[0068] Mix and stir various antistatic and antiglare hard coating raw materials according to the following proportions to make them uniform:

[0069] 50 parts by weight of UV curing resin

[0070] 20 parts by weight of trimethylolpropane triacrylate

[0071] 8 parts by weight of transparent anti-glare particles

[0072] 8 parts by weight of photoinitiator

[0073] 1 part by weight of antistatic agent

[0074] Thinner 100 parts by weight

[0075] Add 4 parts by weight of polymethyl methacrylate resin particles (brand SSX-102, average particle size 2 μm, refractive index 1.49, water Kasei Co.) and 4 parts by weight of polystyrene resin particles (brand SBX-6, average particle size 6 μm, refractive index 1.59, Sekisui Kasei Co.), stirred and mixed evenly.

[0076] Add 50 parts by weight of UV curable resin (brand CN9013, refractive index 1.49, functionality 9, American Sartomer product), 20 parts by weight of trimethylolpropane triacrylate (brand SR350, refractive index 1.47...

Embodiment 3

[0087] Mix and stir various antistatic and antiglare hard coating raw materials according to the following proportions to make them uniform:

[0088] 55 parts by weight of UV curing resin

[0089] 20 parts by weight of trimethylolpropane triacrylate

[0090] 15 parts by weight of transparent anti-glare particles

[0091] 8 parts by weight of photoinitiator

[0092] Antistatic agent 2 parts by weight

[0093] Thinner 140 parts by weight

[0094] Add 8 parts by weight of polymethyl methacrylate resin particles (brand SSX-102, average particle size 2 μm, refractive index 1.49, water Chemical Company) and 7 parts by weight of polystyrene resin particles (brand SBX-3, average particle size 3 μm, refractive index 1.59, Sekisui Chemical Company), stirred and mixed evenly.

[0095] Add 55 parts by weight of UV curable resin (brand CN9013, refractive index 1.49, functionality 9, American Sartomer product), 20 parts by weight of trimethylolpropane triacrylate (brand SR350, refractive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com