Method for preparing B4C/17-4PH high-strength steel composite material through SLM

A composite material and high-strength steel technology, which is applied in the field of preparing B4C/17-4PH high-strength steel composite materials, can solve the problems of high cost, affecting the overall performance of materials, and cumbersome procedures, and achieve short cycle times, resource saving, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

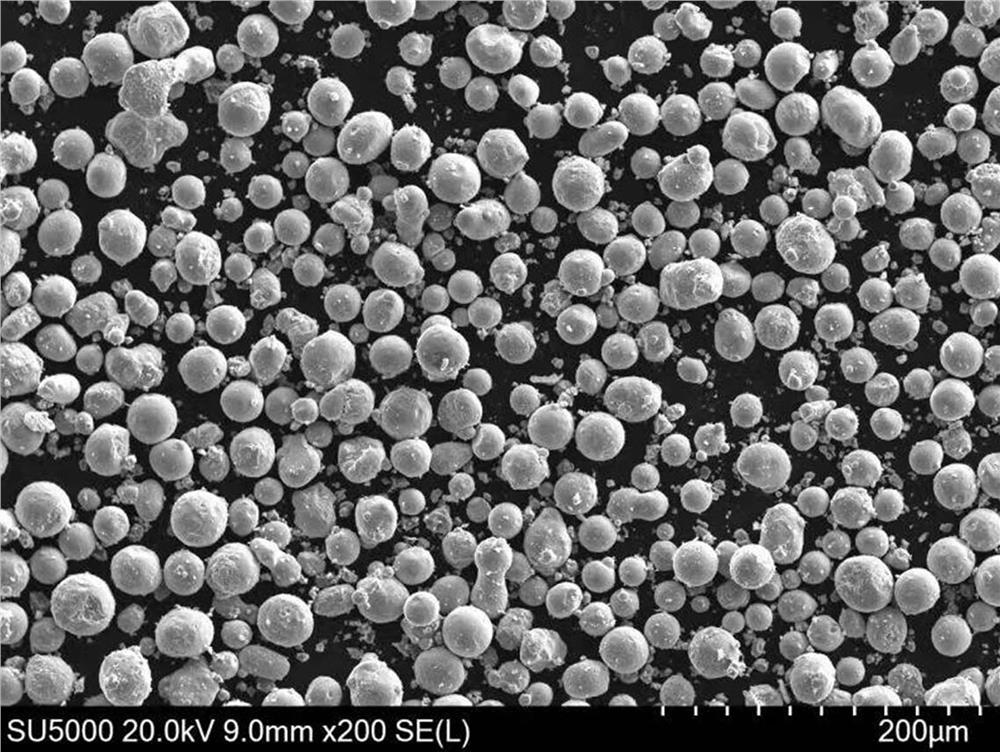

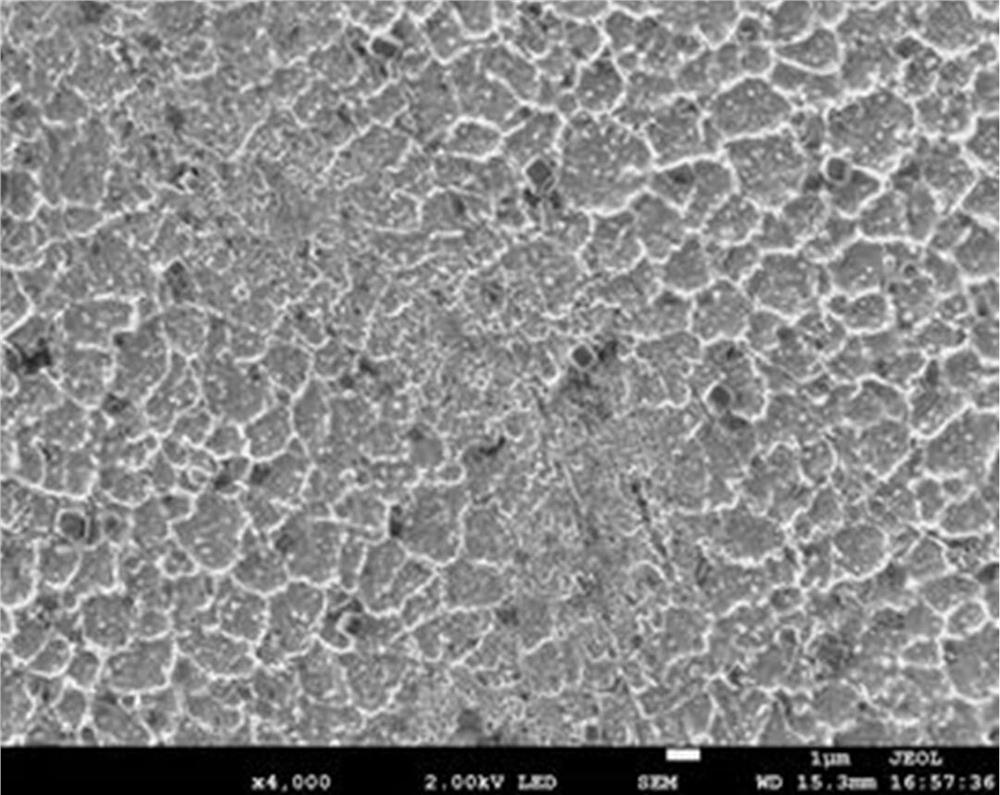

[0025] A method for preparing B4C / 17-4PH high-strength steel composite material by using SLM, comprising the following steps: (1) Pretreatment of 17-4PH high-strength steel powder: the concentration is 0.06 g / L, the density is 1.055 g / cm3 (20° C. ), the sodium cetyl sulfonate aqueous solution with a viscosity of 0.02 Pa s (20°C) was evenly distributed in the 17-4PH high-strength steel powder, and then ultrasonic cleaning and magnetic stirring were performed, and the cleaning temperature was set to 60°C, The cleaning time was 2 hours, and after cleaning, it was left to stand for 10 minutes, and then ultrasonic cleaning and magnetic stirring were used for cleaning with monododecyl phosphate triethanolamine aqueous solution. The cleaning temperature was set to 60 °C, and the cleaning time was 1 hour. Dry in a hot atmosphere furnace (XQ) to finally obtain pretreated 17-4PH high-strength steel powder.

[0026] (2) Pretreatment of B4C powder: The prepared B4C powder with an average ...

Embodiment 2

[0032] A method for preparing B4C / 17-4PH high-strength steel composite material by using SLM, comprising the following steps: (1) Pretreatment of 17-4PH high-strength steel powder: the concentration is 0.07g / L, the density is 1.055g / cm3 (20°C ), the sodium cetyl sulfonate aqueous solution with a viscosity of 0.02Pa s (20℃) was evenly distributed in the 17-4PH high-strength steel powder for ultrasonic cleaning and magnetic stirring treatment. The cleaning temperature was set to 60℃, and the cleaning time was 2.5h, let stand for 20min after cleaning, and then use the monododecyl phosphate triethanolamine aqueous solution to carry out ultrasonic cleaning and magnetic stirring treatment cleaning, and set the cleaning temperature to 60 ° C and the cleaning time to 1.5h. Type atmosphere furnace (XQ) drying, and finally get pretreated 17-4PH high-strength steel powder.

[0033] (2) Pretreatment of B4C powder: The prepared B4C powder with an average grain size of 40 μm was uniformly d...

Embodiment 3

[0039] A method for preparing B4C / 17-4PH high-strength steel composite material by using SLM, comprising the following steps: (1) pretreatment of 17-4PH high-strength steel powder: the concentration is 0.08g / L, the density is 1.055g / cm3 (20°C ), the sodium cetyl sulfonate aqueous solution with a viscosity of 0.02Pa s (20℃) was evenly distributed in the 17-4PH high-strength steel powder for ultrasonic cleaning and magnetic stirring treatment. The cleaning temperature was set to 60℃, and the cleaning time was 3h, let stand for 30min after cleaning, and then perform ultrasonic cleaning and magnetic stirring treatment cleaning with monododecyl phosphate triethanolamine aqueous solution, and set the cleaning temperature to 60 °C and the cleaning time to 2h, after filtration, in an endothermic atmosphere Dry in furnace (XQ) to obtain 17-4PH high-strength steel powder after pretreatment.

[0040] (2) Pretreatment of B4C powder: The prepared B4C powder with an average grain size of 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com