Strong acid corrosion resistant color master batch and preparation method thereof

A technology of color masterbatch and strong acid resistance, which is applied in the field of color masterbatch, which can solve the problems of poor corrosion resistance and acid resistance, and achieve the effects of reducing crystallinity, easy processing, improving impact toughness and surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

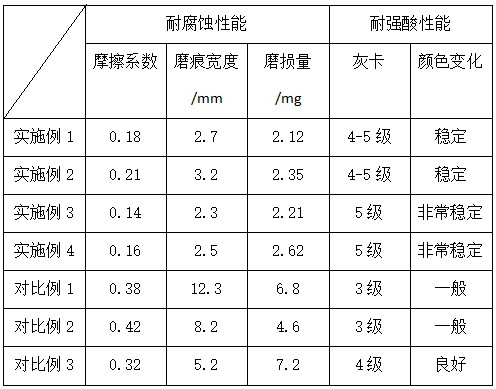

Examples

Embodiment 1

[0035] This embodiment discloses a color masterbatch resistant to strong acid corrosion, comprising the following steps:

[0036] Step 1: Weigh the following raw materials in weight percentage, 47 parts of PC resin, 2 parts of HIPS resin, 6 parts of titanium dioxide, 0.5 part of silicon carbide, 0.05 part of methyl silicone oil, 0.05 part of antioxidant DNP, 0.1 part of phthalic acid Esters, 0.2-0.4 parts of silica;

[0037] Step 2: Add PC resin, HIPS resin and 30% methyl silicone oil to the mixer in turn to mix and stir until uniform;

[0038] Step 3: Add titanium dioxide, silicon carbide, antioxidant DNP, phthalate, silicon dioxide and the remaining amount of methyl silicone oil to the above mixer in sequence and mix until uniform;

[0039] Step 4: Put the mixed raw materials into a kneader and knead them into shapes, and extrude the shaped raw materials through a twin-screw extruder to obtain Example 1.

Embodiment 2

[0041] This embodiment discloses a color masterbatch resistant to strong acid corrosion, comprising the following steps:

[0042] Step 1: Weigh the following raw materials in weight percentage, 75 parts of PC resin, 5 parts of HIPS resin, 12 parts of titanium dioxide, 1 part of silicon carbide, 0.1 part of simethicone, 0.1 part of antioxidant DNP, 0.2 part of fatty acid ester, 0.4 parts of silicon dioxide;

[0043] Step 2: Add PC resin, HIPS resin and 40% simethicone oil to the mixer in turn to mix and stir until uniform;

[0044] Step 3: Add titanium dioxide, silicon carbide, antioxidant DNP, fatty acid ester, silicon dioxide and the remaining amount of simethicone oil to the above mixer in sequence and mix until uniform;

[0045] Step 4: Put the mixed raw materials into a kneader and knead them into shapes, and extrude the shaped raw materials through a twin-screw extruder to obtain Example 2.

Embodiment 3

[0047] This embodiment discloses a color masterbatch resistant to strong acid corrosion, comprising the following steps:

[0048] Step 1: Weigh the following raw materials by weight, 60 parts of PC resin, 3 parts of HIPS resin, 8 parts of titanium dioxide, 0.8 part of silicon carbide, 0.07 part of ethyl silicone oil, 0.07 part of antioxidant DNP, 0.15 part of polyol ester, 0.3 parts silica;

[0049] Step 2: Add PC resin, HIPS resin and 35% ethyl silicone oil to the mixer in sequence to mix and stir until uniform;

[0050] Step 3: Add titanium dioxide, silicon carbide, antioxidant DNP, polyol ester, silicon dioxide and the remaining amount of ethyl silicone oil to the above mixer in sequence and mix until uniform;

[0051] Step 4: Put the mixed raw materials into a kneader and knead them into shapes, and extrude the shaped raw materials through a twin-screw extruder to obtain Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com