Advanced treatment recovery technology of coking wastewater

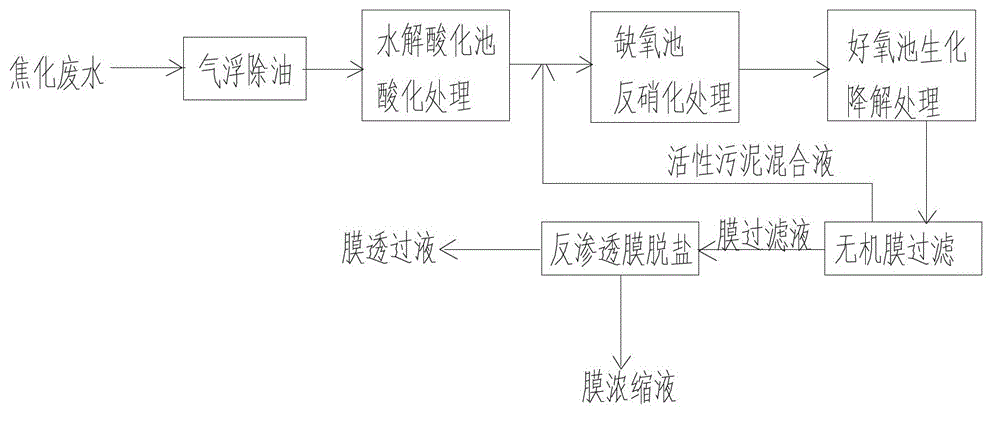

A technology for advanced treatment and coking wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply conservation, etc., can solve the problem of ineffective biological aerated filter treatment and the production of reverse osmosis concentrate Large scale, non-standard wastewater treatment and other problems, to achieve continuous and stable operation, good cleaning effect, and reduce civil construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

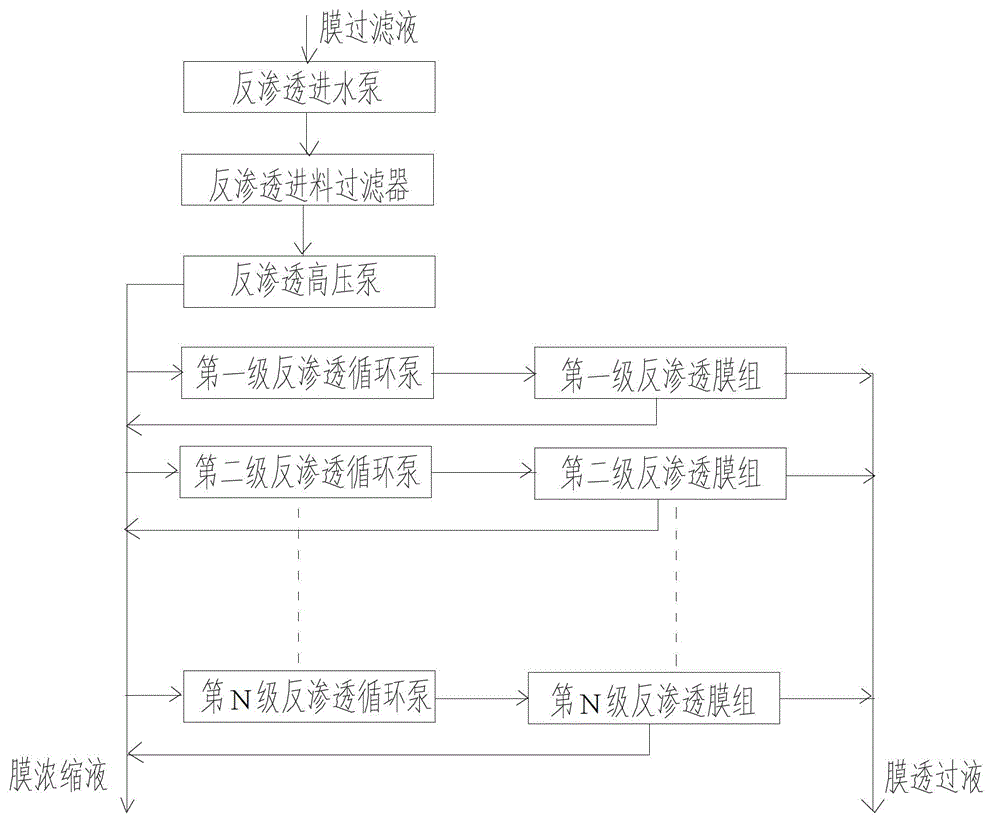

[0051] 180L of biochemically treated coking wastewater from a steel plant. Pour 180L of waste water into the circulation tank of the ceramic membrane pilot equipment, start the circulation pump, and control the pressure at the entrance and exit of the membrane at 2.0 / 1.3kg / cm 2 , start filtering at room temperature. When the filtrate is 157.5L, the concentrated liquid reaches the lowest liquid level of the equipment, and the filtration is terminated. At this time, the concentration ratio reaches 8 times. Ceramic membrane filtrate 145L, into the reverse osmosis material tank, start the RO circulation pump, operating pressure 15 / 14kg / cm 2 , start filtering at room temperature. The filtrate 109L was collected. The water recovery rate is 75%.

[0052] The water quality test results are shown in Table 1:

[0053] Table 1

[0054]

Embodiment 2

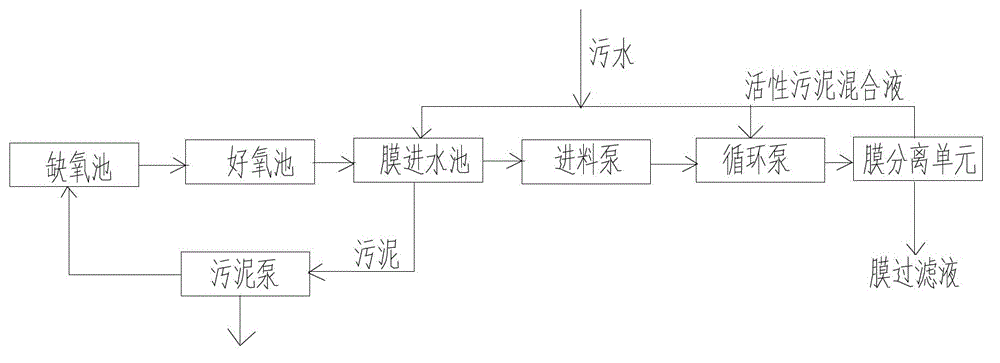

[0056] The raw water of coking wastewater from a steel plant is degreased by air flotation, then hydrolyzed and acidified, and then enters the anaerobic pool, anoxic pool, and aerobic pool in sequence. The effluent from the biochemical aerobic tank is placed in the membrane water inlet tank, and the water is transported into the membrane system through the feeding image, and the wastewater is driven by the circulating pump to provide the surface flow rate of the membrane. The pressure in and out of the membrane is controlled at 2.0 / 1.3kg / cm2, and the filtration starts at room temperature. The concentrate is returned to the anoxic pool to control the reflux ratio to be 5. The filtrate is sent to the material tank of reverse osmosis, and the water is recovered. The water recovery rate is 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com