Petrol detergent capable of reducing deposit of gasoline engine combustion chamber

A gasoline detergent and gasoline engine technology, applied in fuel additives, fuel, petroleum industry, etc., can solve problems such as rising gas temperature, increasing mechanical interference between piston top and cylinder head, increasing engine compression ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

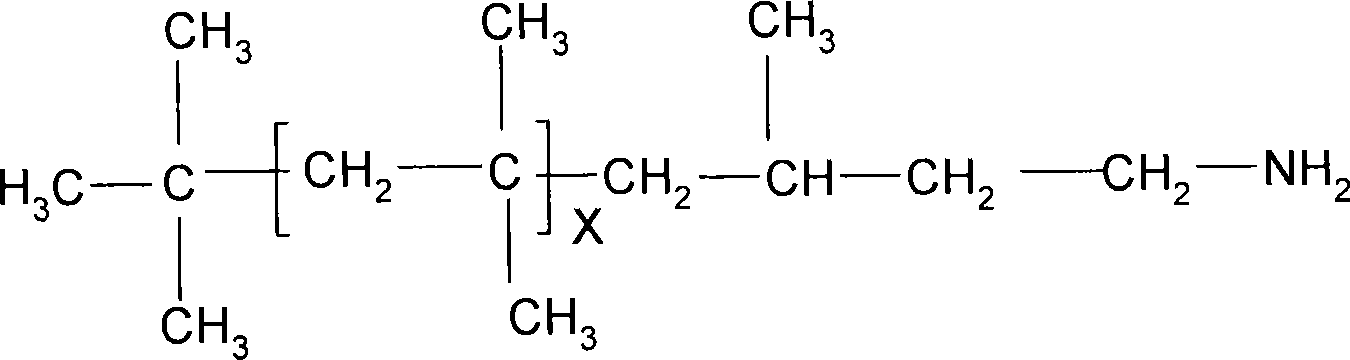

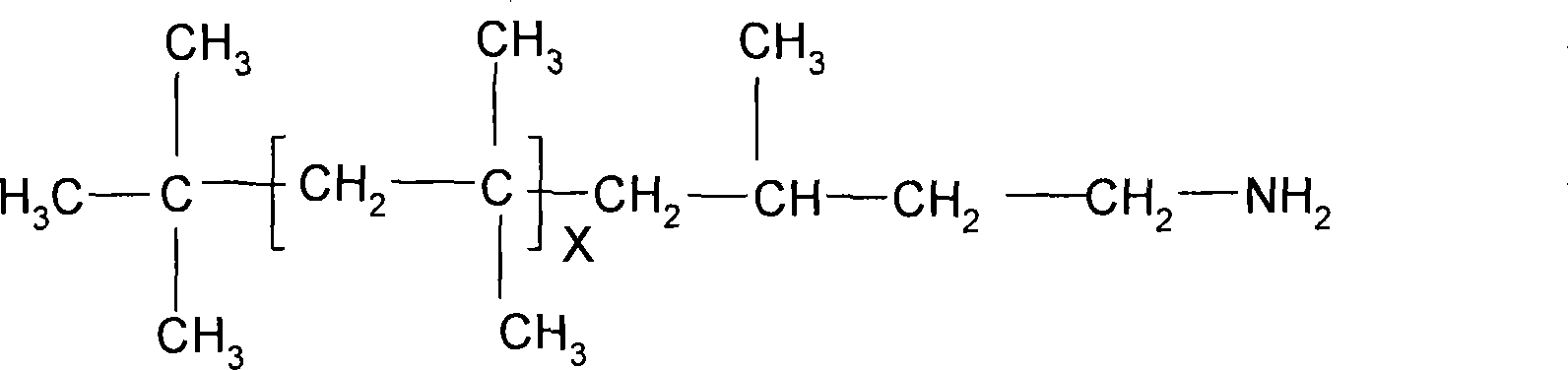

[0025] The high surface active polyisobutylene amine used is Kerocom PIBA from Basf, Germany. The oil-soluble polyether carrier liquid is a copolymer of propylene oxide with a C / O above 3.5 and a weight-average molecular weight of 800-1200. Agents, rust inhibitors, preservatives, and demulsifiers are typical commercially available products.

[0026] The mass percent of each component is:

[0027] High surface active polyisobutylamine 24%

[0028] Oil-soluble polyether carrier fluid 36%

[0029] Aromatic oil co-solvent 37%

[0030] T502 antioxidant 0.75%

[0031] T534 Antioxidant 0.75%

[0032] T747 rust inhibitor 0.8 / %

[0033] T551 preservative 0.4%

[0034] SP-169 Demulsifier 0.3%

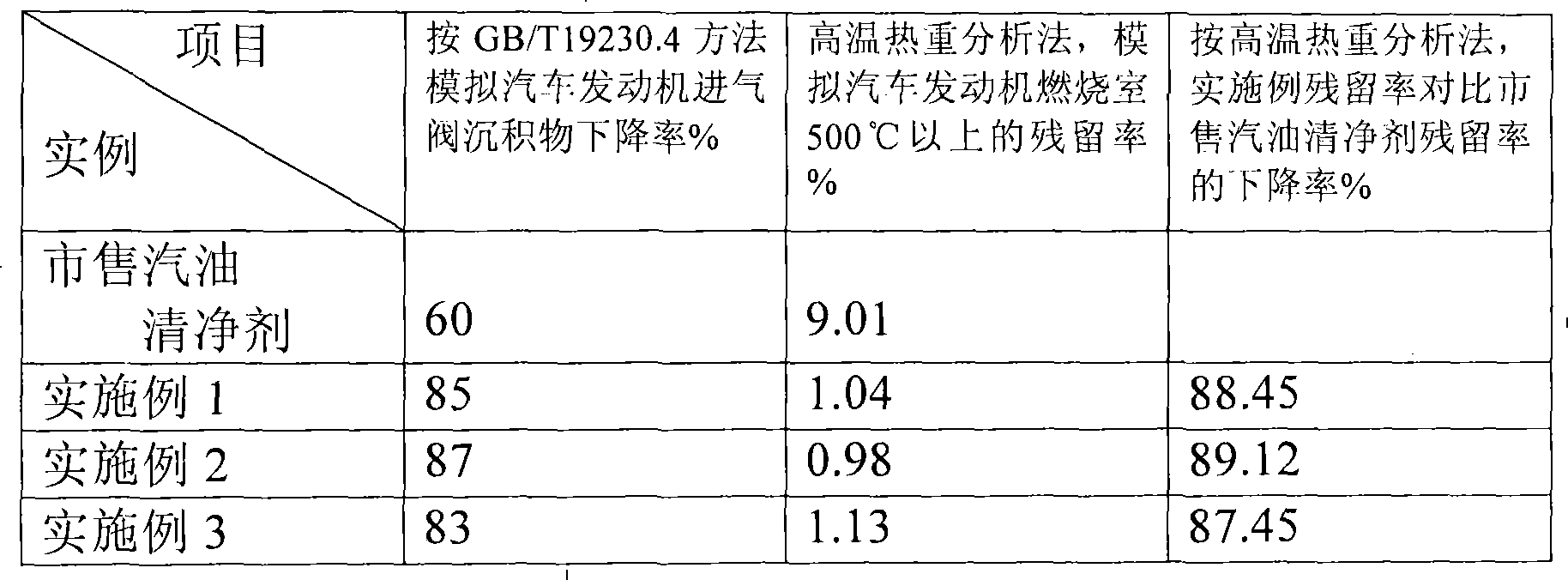

[0035] Weigh the above required components in proportion, mix them at room temperature or not higher than 60°C, and stir evenly until transparent to obtain the gasoline detergent of the present invention. Add this detergent to commercially available In 93# gasoline, the physical and chemi...

Embodiment 2

[0037] Use the high surface activity polyisobutylene amine of embodiment 1 and oil-soluble polyether carrier liquid, repeat the preparation method of embodiment 1, prepare the gasoline detergent of the present invention each component mass percentage example is as follows:

[0038] High Surface Active Polyisobutylamine 18%

[0039] Oil-soluble polyether carrier fluid 36%

[0040] Aromatic oil co-solvent 43%

[0041] T502 antioxidant 0.75%

[0042] T534 Antioxidant 0.75%

[0043] T747 rust inhibitor 0.8%

[0044] T551 preservative 0.4%

[0045] Sp-169 Demulsifier 0.3%

[0046] Add this gasoline detergent to commercially available 93# motor gasoline at a dosage of 500-550ppm. After inspection by a professional inspection department, the physical and chemical analysis data of the oil fully meet the requirements of GB17930-2006. The reduction rate of simulated intake valve deposits reached 87%. Using high-temperature (above 500°C) thermogravimetric analysis, the incremental ...

Embodiment 3

[0048] Use the high surface activity polyisobutylene amine of embodiment 1 and oil-soluble polyether carrier liquid, repeat the preparation method of embodiment 1, prepare the gasoline detergent of the present invention each component mass percentage example is as follows:

[0049] High surface active polyisobutylamine 20%

[0050] Oil-soluble polyether carrier fluid 40%

[0051] Aromatic oil co-solvent 38%

[0052] T502 antioxidant 0.5%

[0053] T534 Antioxidant 0.5%

[0054] T747 rust inhibitor 0.6%

[0055] T551 preservative 0.2%

[0056] Sp-169 Demulsifier 0.2%

[0057] Add this gasoline detergent to commercially available 93# gasoline at a dose of 550-600ppm. After inspection by a professional inspection department, the physical and chemical data of the oil product all meet the requirements of GB17930-2006. The simulated intake valve deposits drop rate is 83%. Using high temperature (above 500°C) thermogravimetric analysis, the simulated combustion chamber deposits in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com