Aluminium plate strip AFC hot spray control system of aluminium foil mill

A technology of aluminum foil rolling mill and control system, applied in the direction of profile control, etc., can solve the problem of not being able to respond dynamically to pressure load changes in a timely manner, to reduce the unqualified scrap of aluminum sheets, strips and foils, solve the problem of cracked edges and broken strips, and improve control effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

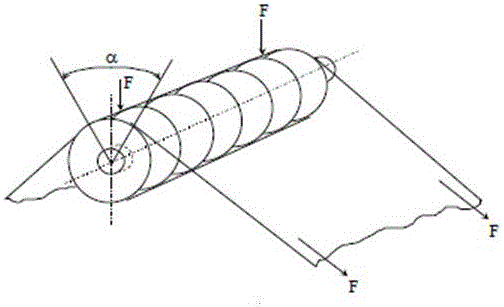

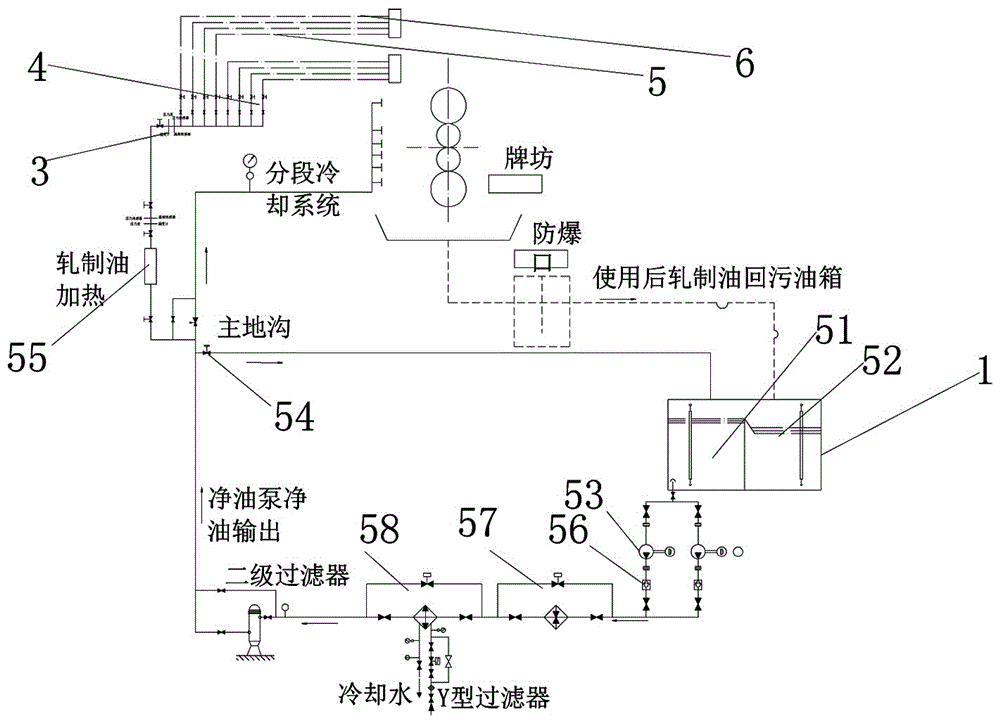

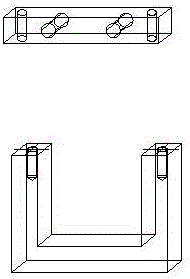

[0021] Such as Figure 1-5 As shown, the aluminum foil rolling mill aluminum strip AFC thermal spray control system includes oil supply system 1, rolling oil heating and cooling system 2, temperature control system 3, electrical adjustment drive control system 4, rolling oil thermal spray system 5, The oil supply system 1 is connected to the rolling oil heating and cooling system 2 through pipelines, and then connected to the rolling oil thermal spray system 5 through pipelines. The oil supply system is equipped with a clean oil tank 51, a dirty oil tank 52, a clean oil pump 53, and a motor , the oil supply pipeline and the valve, the net oil tank is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com