Circuit board plating line intelligent board feeding and discharging method capable of achieving accurate positioning

A precise positioning and circuit board technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems that the electroplating clip cannot clamp the circuit board, affect the plating quality of the circuit board, and the board drop rate, etc., to reduce the time, The effect of reducing the impact and reducing the drop rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described further, so that understand the technical thought that the present invention claims protection more clearly. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

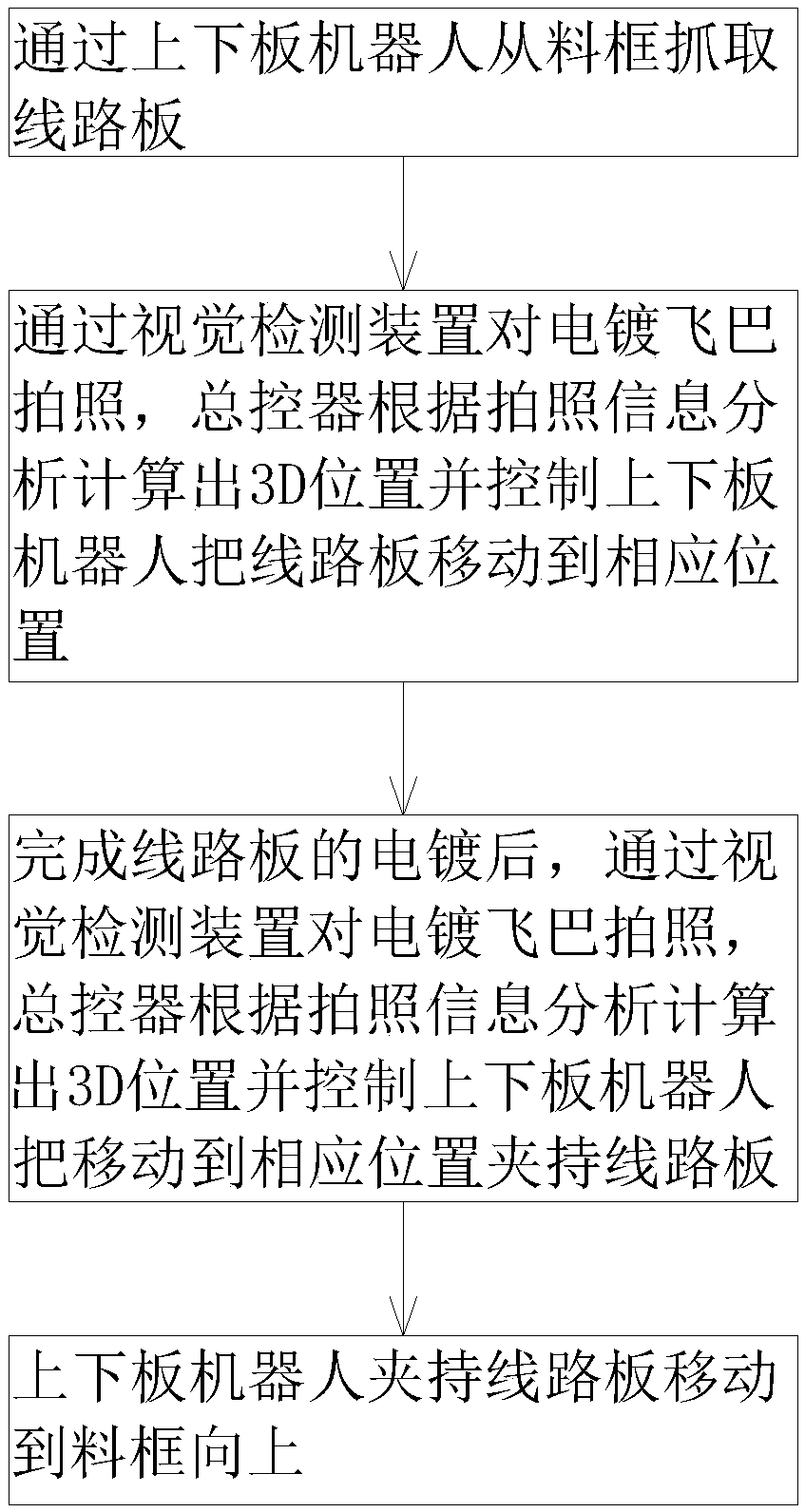

[0053] Such as Figure 1-8 Shown, a kind of circuit board 9 electroplating lines intelligent upper and lower plate methods that can be precisely positioned in the embodiment of the invention may further comprise the steps:

[0054] A, Grab the circuit board 9 on the material frame 2 through the clamping device 5 at the end of the upper and lower board robot 3;

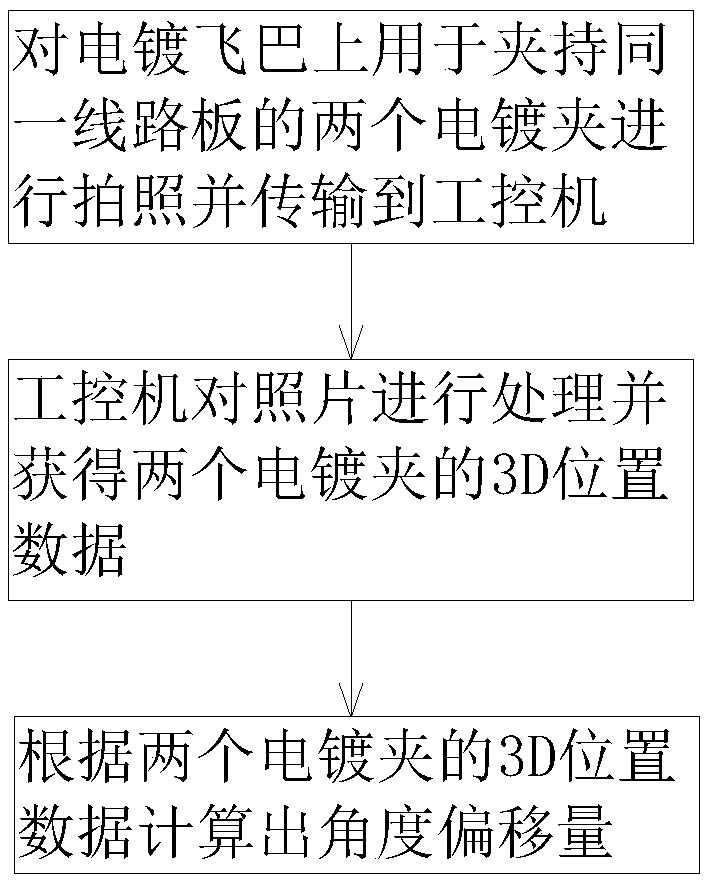

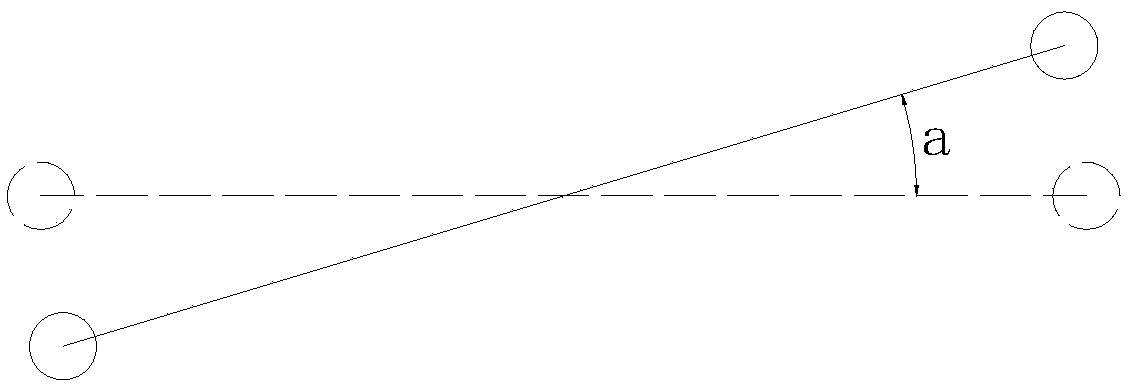

[0055] B. The electroplating clip 11 on the electroplating flying bus 1 is photographed by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com