Internal fiber integration type miniature Michelson interferometric sensor and manufacturing method thereof

An integrated sensor technology, applied in instruments, optics, scientific instruments, etc., can solve the problems of high assembly precision, low temperature sensitivity, small thermal expansion, etc., and achieve low cost, small size, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

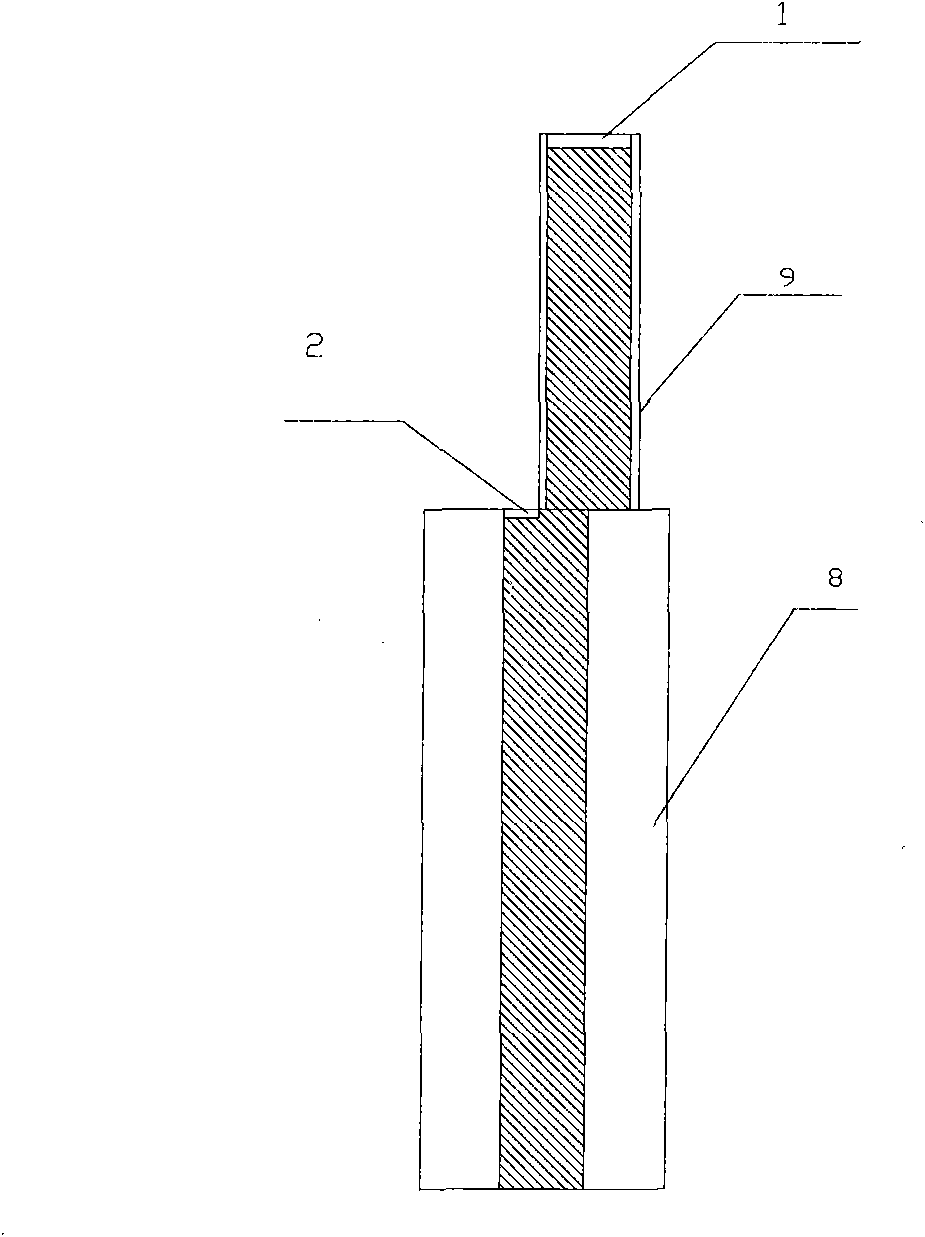

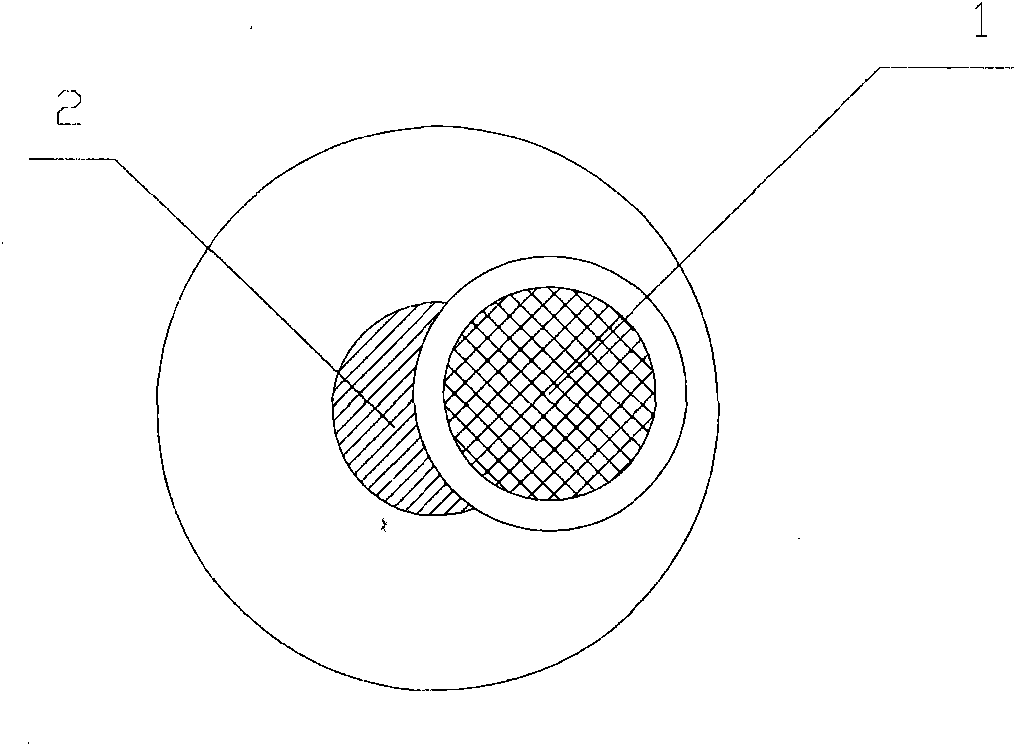

[0015] see figure 1 , 2 , as shown in the figure, the optical fiber integrated miniature Michelson interference sensor 3 of the present invention is composed of two single-mode fibers with different outer diameters and the same core diameter; On the large outer diameter single-mode fiber 8, the core parts of the two single-mode fibers overlap; the uncovered part of the core end face of the large outer diameter single-mode fiber 8 is the reference arm reflection surface 2, and the small outer diameter single-mode fiber The core end face of the bare end of the optical fiber 9 is the reflection surface 1 of the measuring arm.

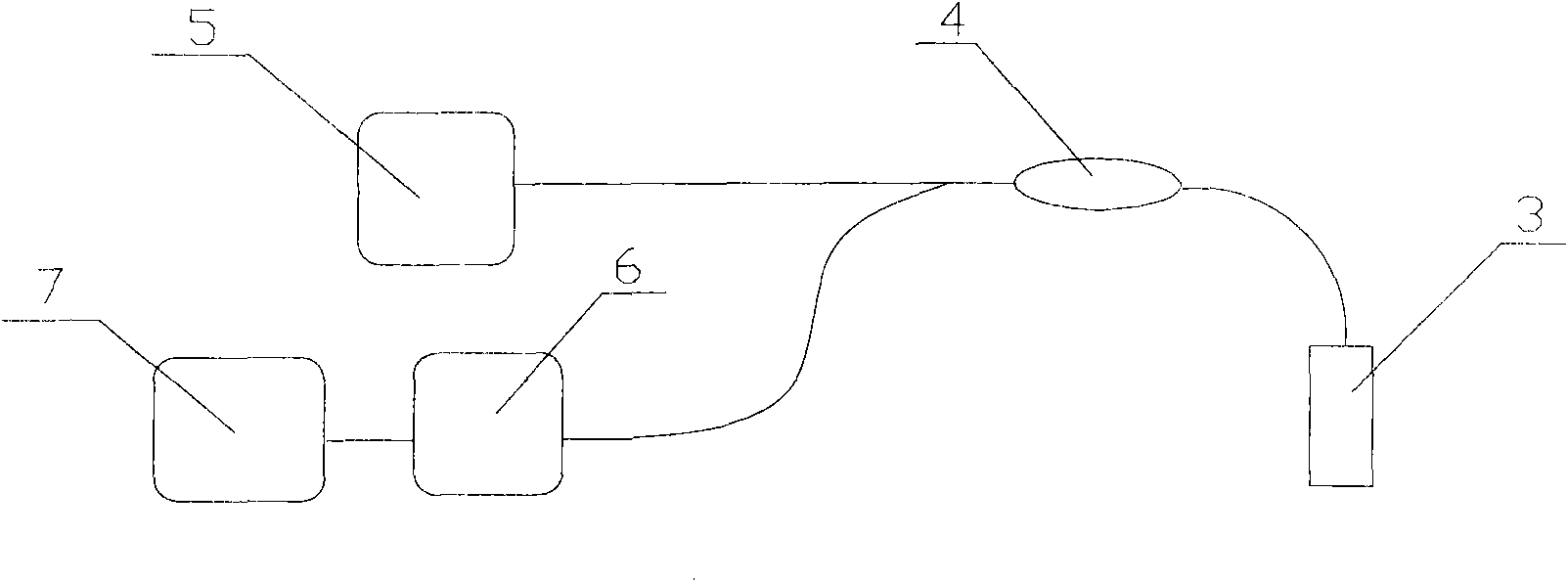

[0016] see image 3 , the structure of the detection device composed of the sensor of the present invention includes: a broadband light source 5, a 1×2 coupler 4, a spectrometer 6, a computer 7 and an integrated micro-Michelson interference sensor 3 in an optical fiber; the broadband light source 5 is connected to One end of the 1×2 coupler 4 and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com