Radioactive waste drying method and system

A radioactive waste and drying method technology, which is applied in the direction of radioactive purification, drying solid materials, and method combination to dry solid materials, etc., can solve the problems of hindering water evaporation, long time, migration, etc., and achieve the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

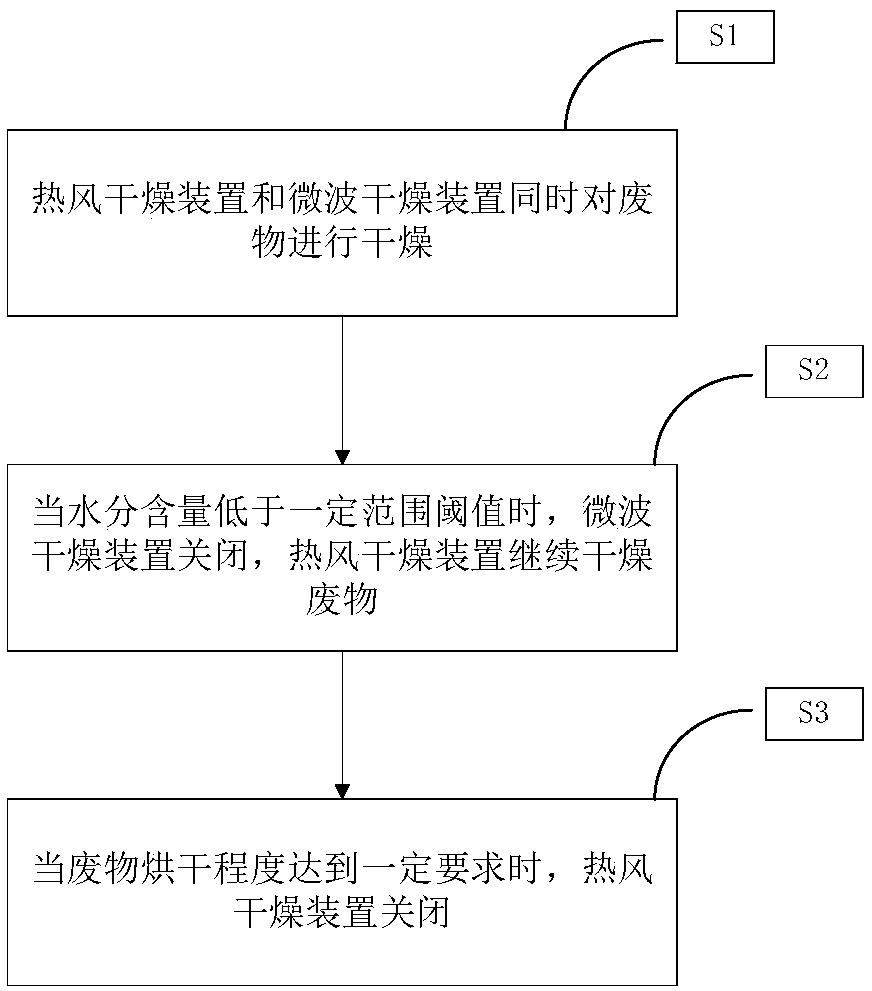

[0039] The flow chart of the drying method of radioactive waste in the embodiment of the present invention is as follows figure 1 shown, including the following steps:

[0040] S1 hot air drying device and microwave drying device simultaneously dry radioactive waste.

[0041] It should be noted that before the drying treatment, it is necessary to detect the moisture content of the radioactive waste through a moisture monitoring device to obtain the total water content data of the radioactive waste.

[0042] Randomly pre-dry a small amount of waste (about 1 / 10 of the total waste) to estimate the total water content of radioactive waste. Assuming that about 50 barrels of wet radioactive waste are produced in a certain inspection, 3-5 barrels of waste can be extracted for conventional drying such as hot air drying, and the quality change of the waste before and after drying can be detected, and the remaining radioactive waste of the same batch can be estimated based on this moi...

Embodiment 2

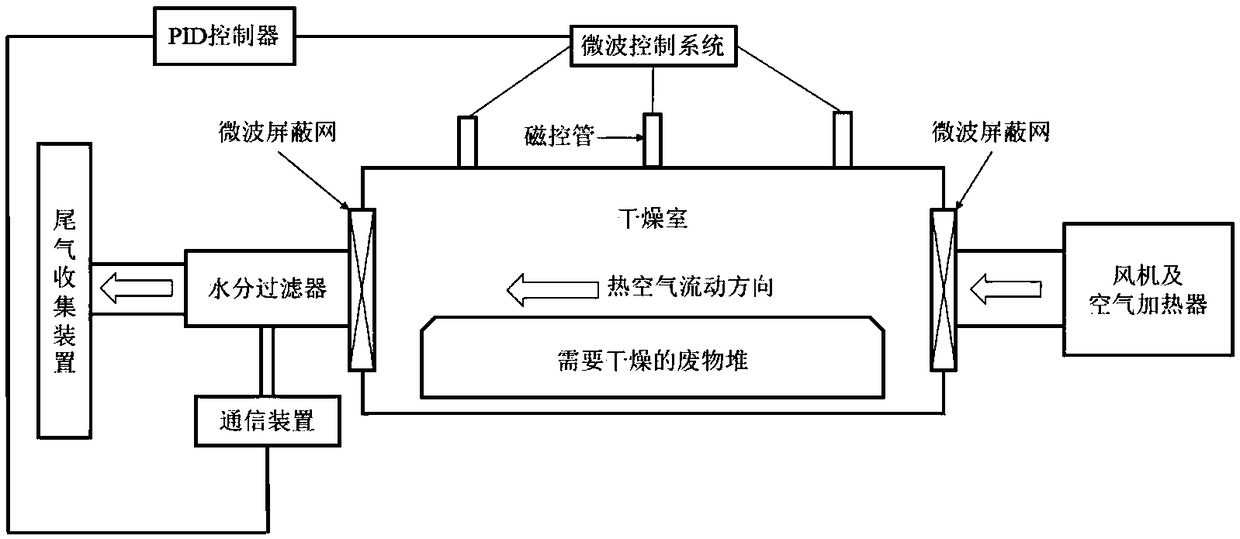

[0054] figure 2 A schematic structural diagram of a drying system for radioactive waste is disclosed, including a drying device, a moisture monitoring device and a PID (proportional, integral, differential) controller;

[0055] The drying device includes a hot air drying device and a microwave drying device for drying the radioactive waste. The hot air drying device includes a fan and an air heater. The microwave drying device includes: a wave source, a magnetron, a drying chamber and a microwave shielding net. The moisture monitoring device includes a moisture filter, a communication device and an exhaust gas collection device.

[0056] The drying process of the drying system of the radioactive waste is:

[0057] Screen the solid radioactive waste, remove the metal radioactive waste, and detect the moisture content of the radioactive waste through the moisture monitoring device to obtain the total water content data of the radioactive waste.

[0058] Spread a small amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com