Patents

Literature

99 results about "Intelligent maintenance system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An intelligent maintenance system (IMS) is a system that utilizes collected data from machinery in order to predict and prevent potential failures in them. The occurrence of failures in the machinery can be costly and even catastrophic. In order to avoid them, there needs to be a system which analyzes the behaviour of the machine and provides alarms and instructions for preventive maintenance. Analyzing the behaviour of the machines has become possible by means of advanced sensors, data collection systems, data storage/transfer capabilities and data analysis tools. Such as those developed for prognostics. The aggregation of data collection, storage, transformation, analysis and decision making for smart maintenance is called an intelligent maintenance system (IMS).

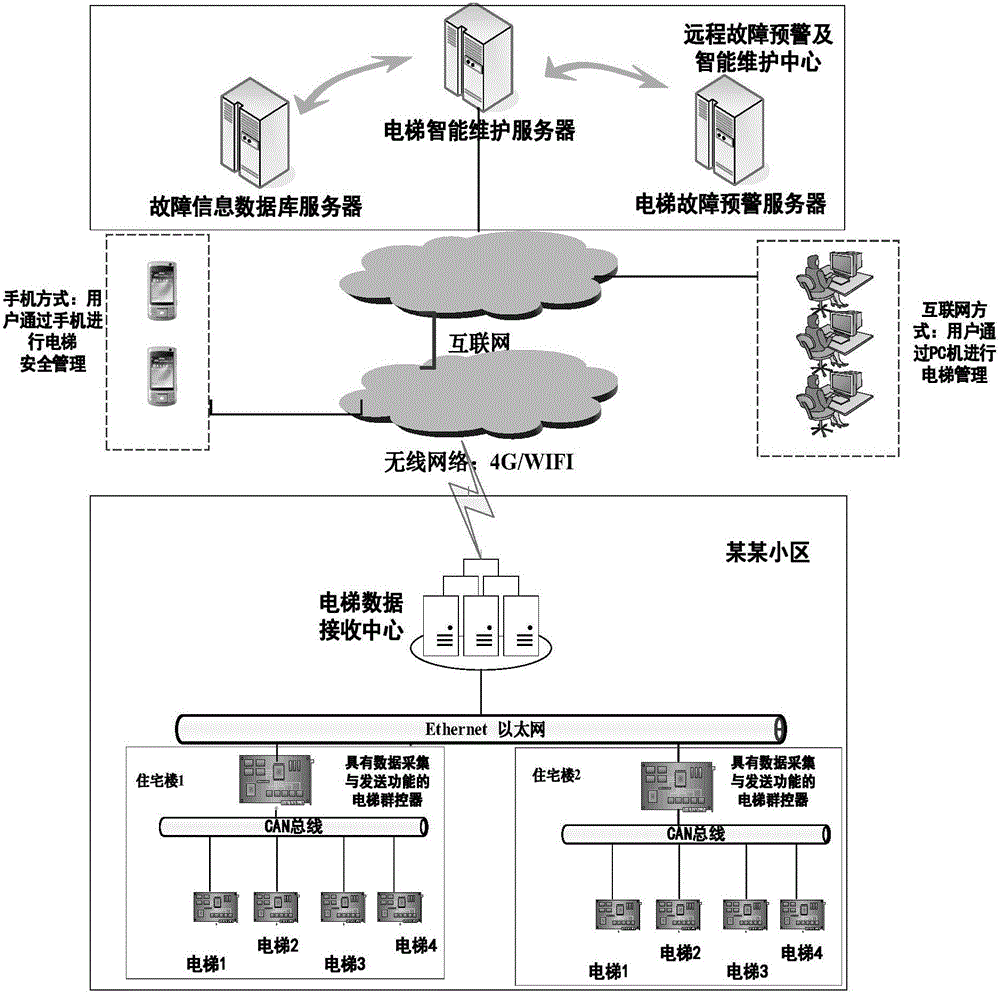

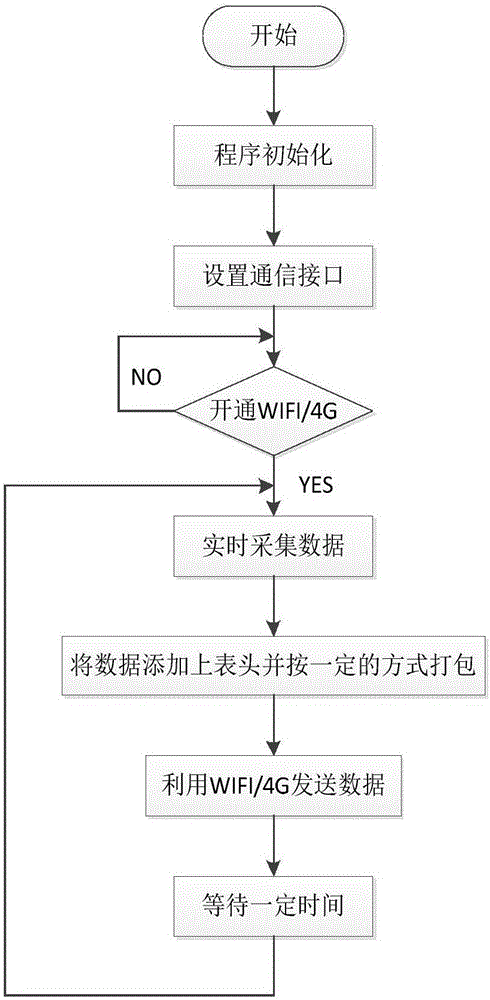

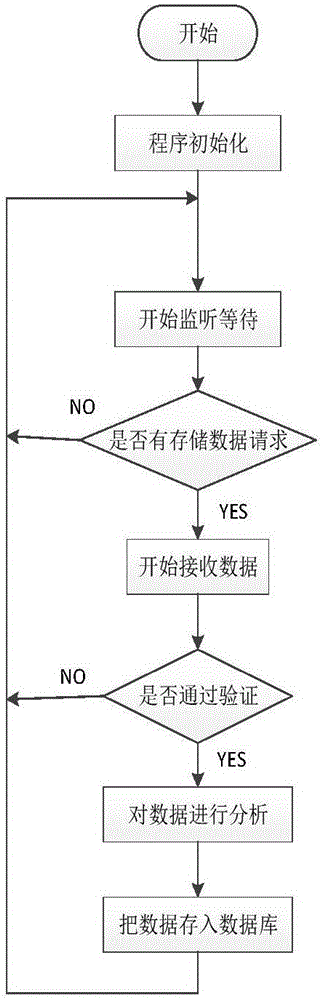

Intelligent prediction, diagnosis and maintenance method for elevator faults on basis of Internet of Things

The invention relates to the elevator control field and the field of the Internet of Things, and provides an intelligent prediction, diagnosis and maintenance system for elevator faults on the basis of the Internet of Things. The intelligent prediction, diagnosis and maintenance system can effectively shorten the time of elevator halt caused by the elevator faults, improve the reliability of elevator running and the elevator maintenance efficiency and guarantee the personal safety and the property safety. According to the technical scheme of an intelligent prediction, diagnosis and maintenance method for the elevator faults on the basis of the Internet of Things, a data acquisition module collects elevator data in real time and transmits the collected data to a server through WIFI or the 4G wireless communication technology, the data are analyzed on the server side through the big data technology, and therefore the elevator faults which are possibly to occur can be predicted; if the elevator faults occur, a fault diagnosis system on the server side can be used for analyzing the faults, then the positions and the reasons of the faults can be provided, and then an intelligent maintenance system on the server side provides solutions to the faults. The intelligent prediction, diagnosis and maintenance method is mainly applied to the elevator control occasion.

Owner:TIANJIN UNIV

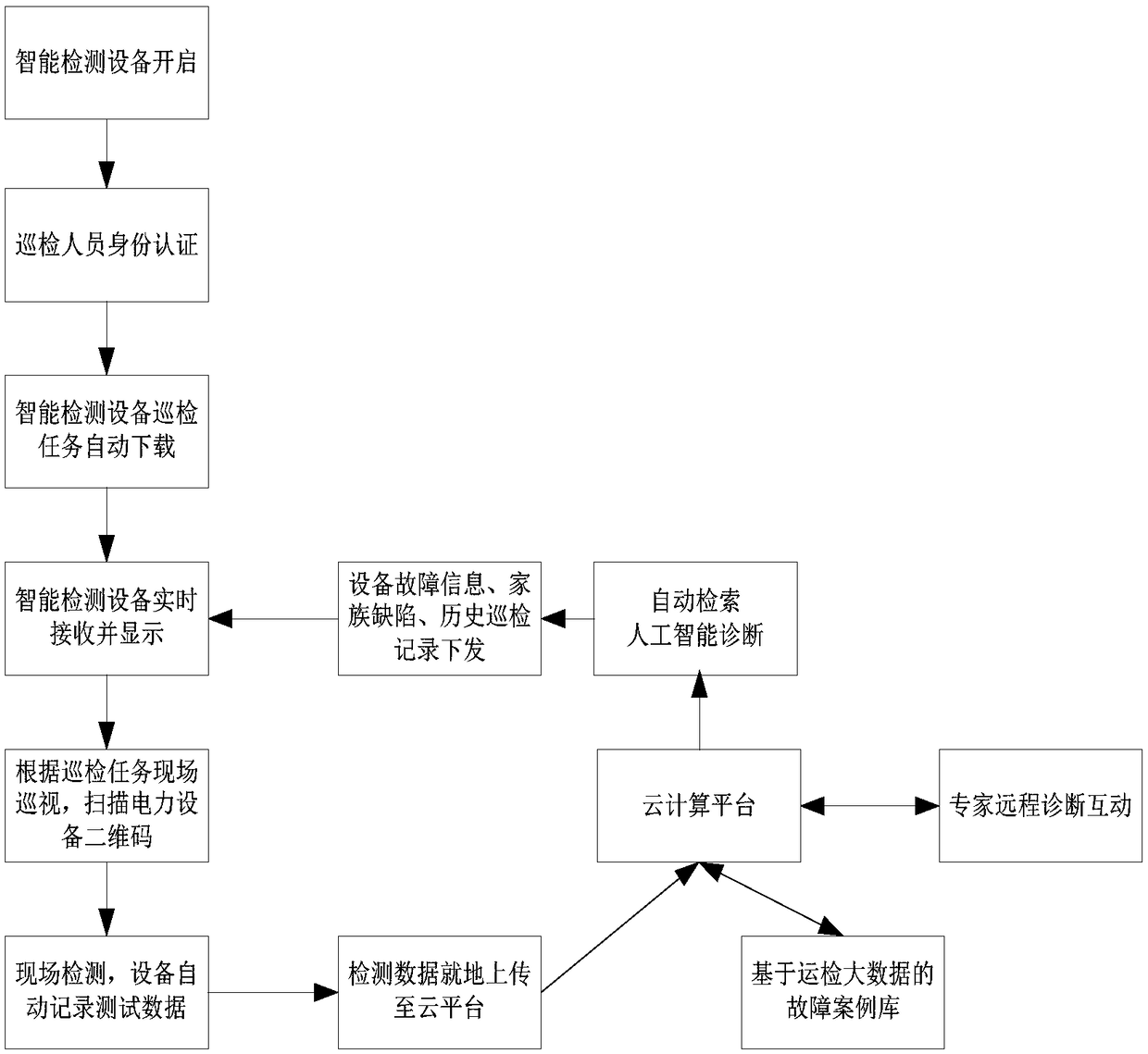

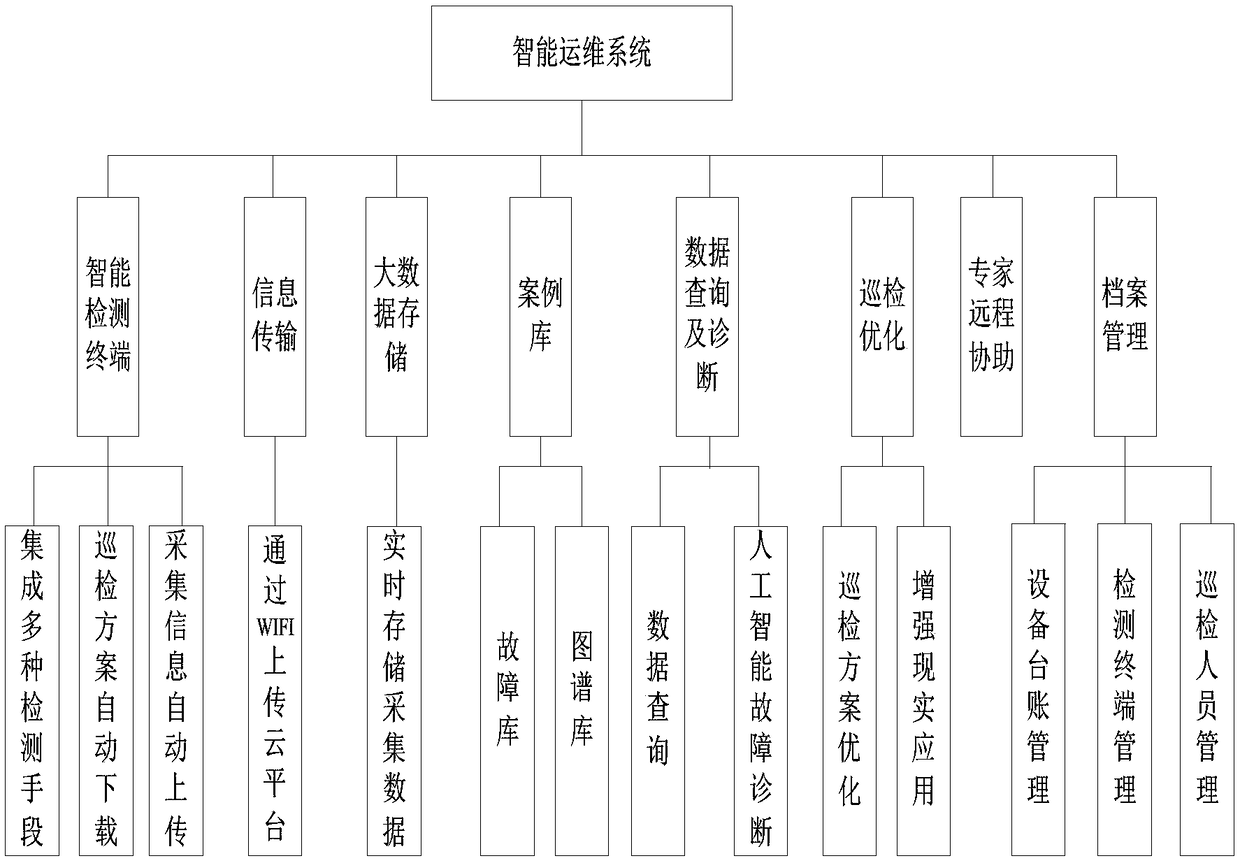

Intelligent maintenance system and method based on wearable augmented reality display terminal and cloud platform

InactiveCN108879440ARealize remote assistanceImprove predictive abilityCircuit arrangementsSustainable buildingsSimulationPower grid

The invention discloses an intelligent maintenance system and method based on a wearable augmented reality display terminal and a cloud platform. According to the intelligent maintenance system and method, an augmented reality technology-based infrared image intelligent identification, video collection and uploading of personnel operation scenarios and real-time conversation with a monitoring center on the scene are achieved, thereby guiding maintenance personnel to implement standard and normalized work process; an intelligent maintenance platform based on big data and artificial intelligenceis built to carry out inspection optimization, defect identification and fault diagnosis; and auxiliary information is transmitted to an intelligent terminal of site operation personnel to display inreal time through an augmented reality technology, so that the operation efficiency is improved, misoperation is avoided and the intelligent maintenance system and method can be applied to multiple power grid operation and maintenance scenarios.

Owner:JINING POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

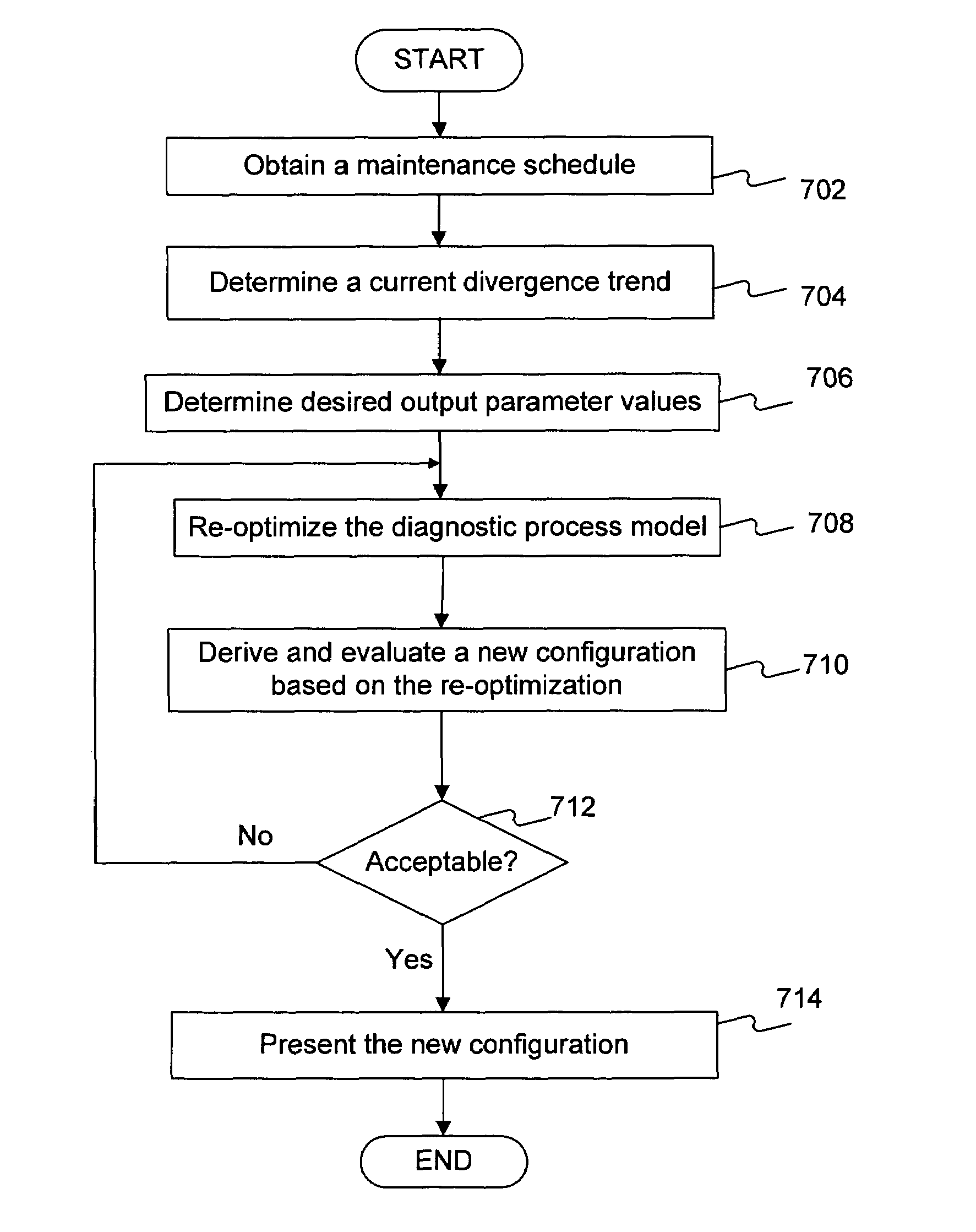

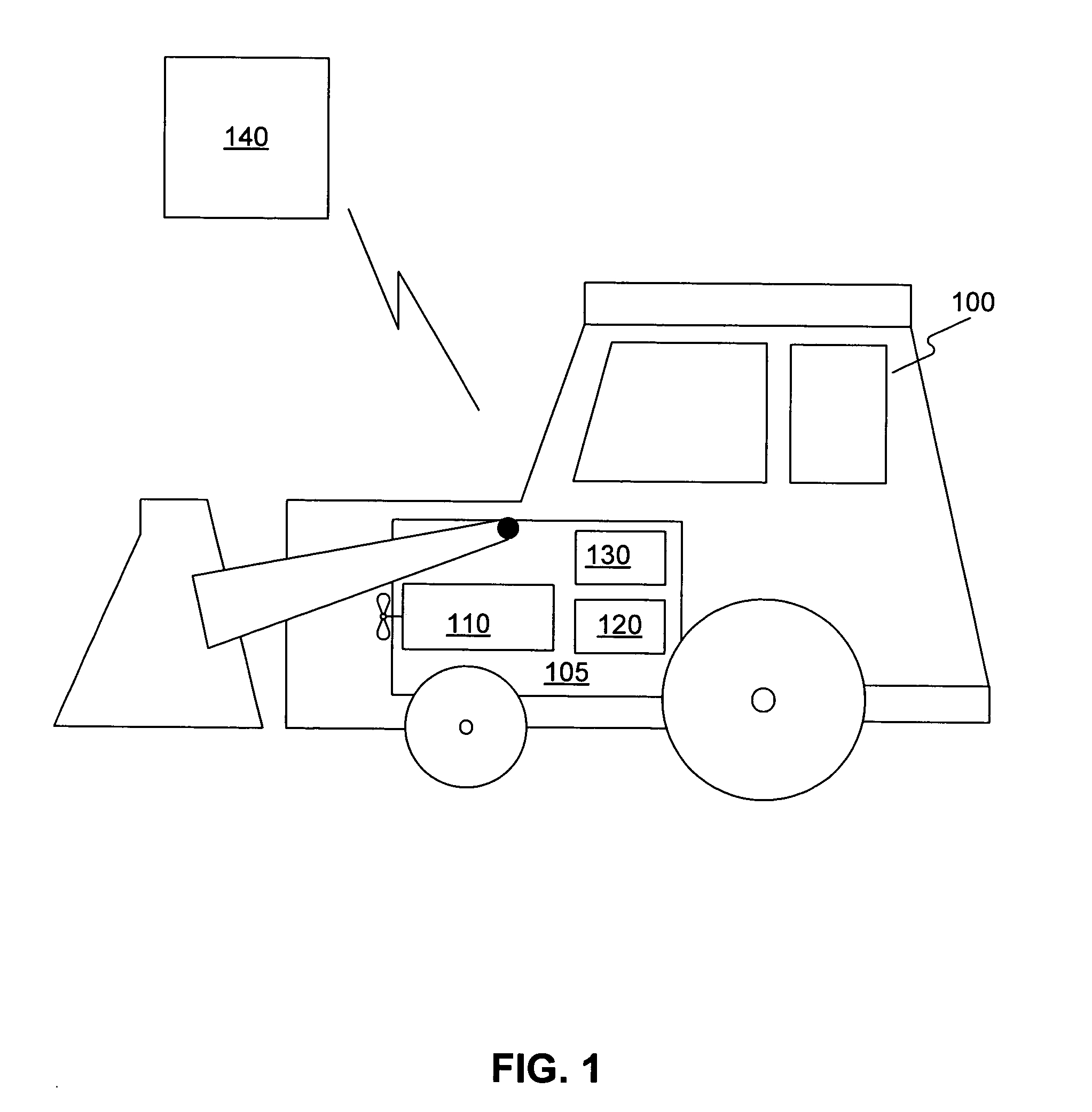

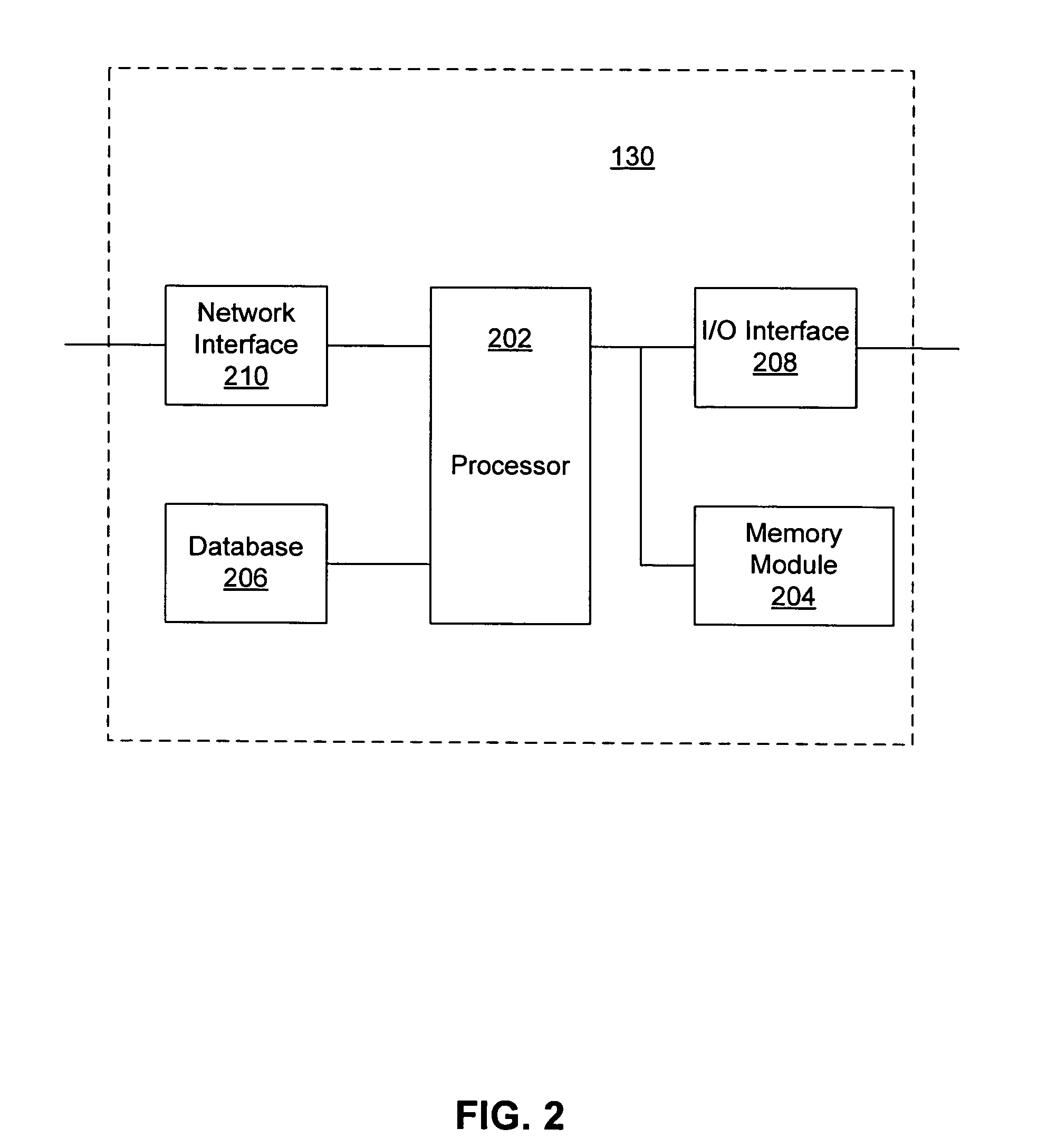

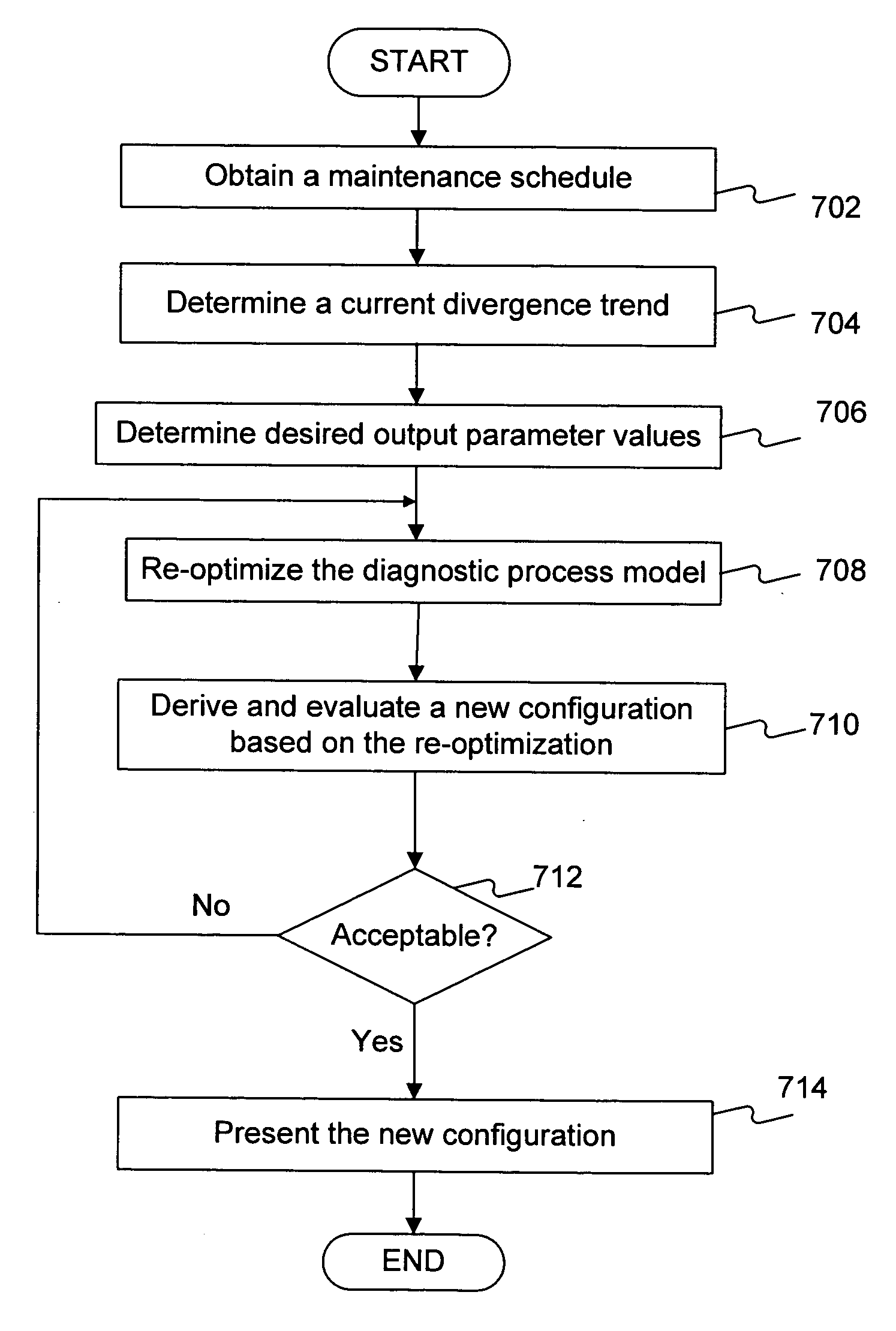

Method and system for intelligent maintenance

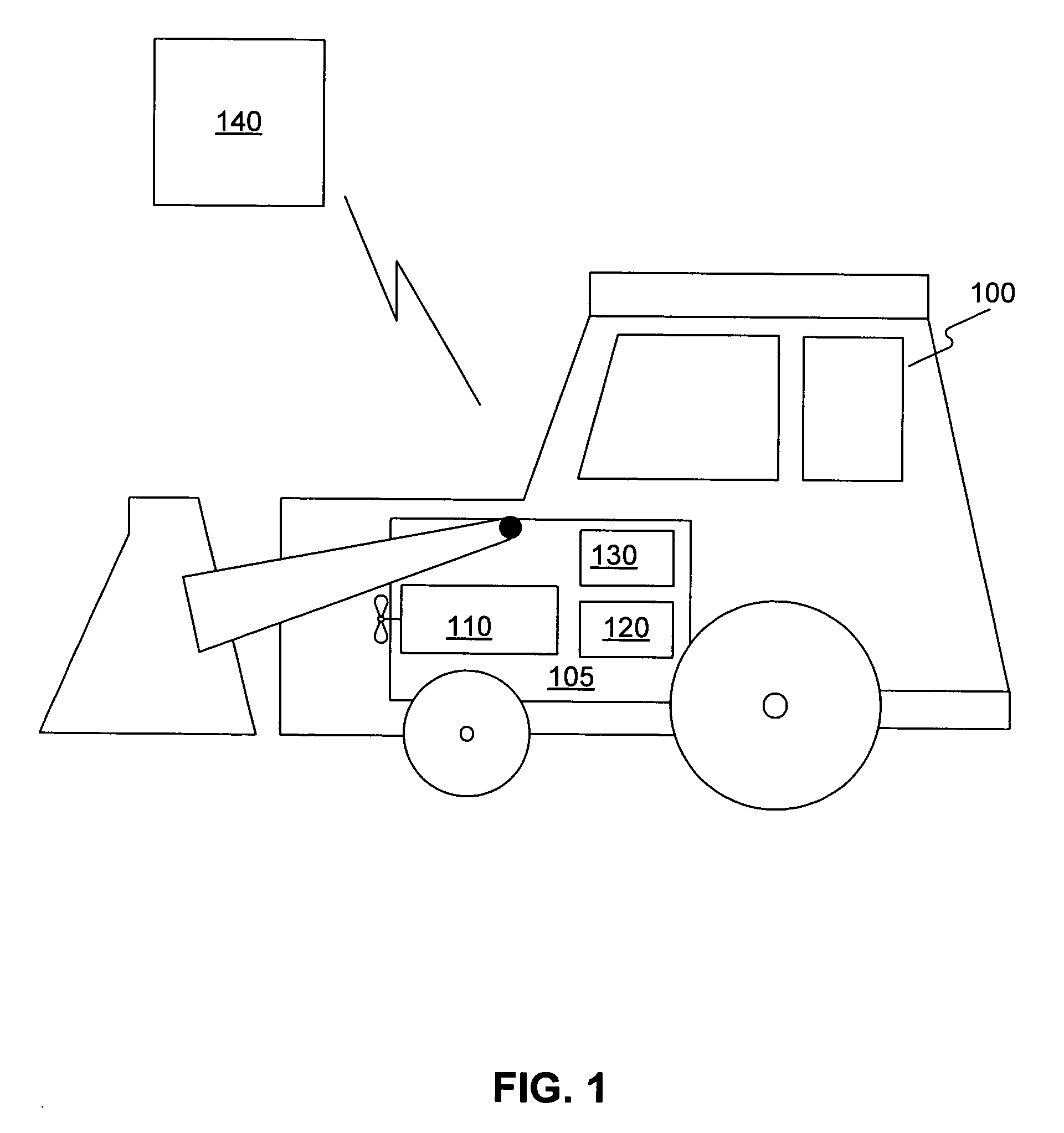

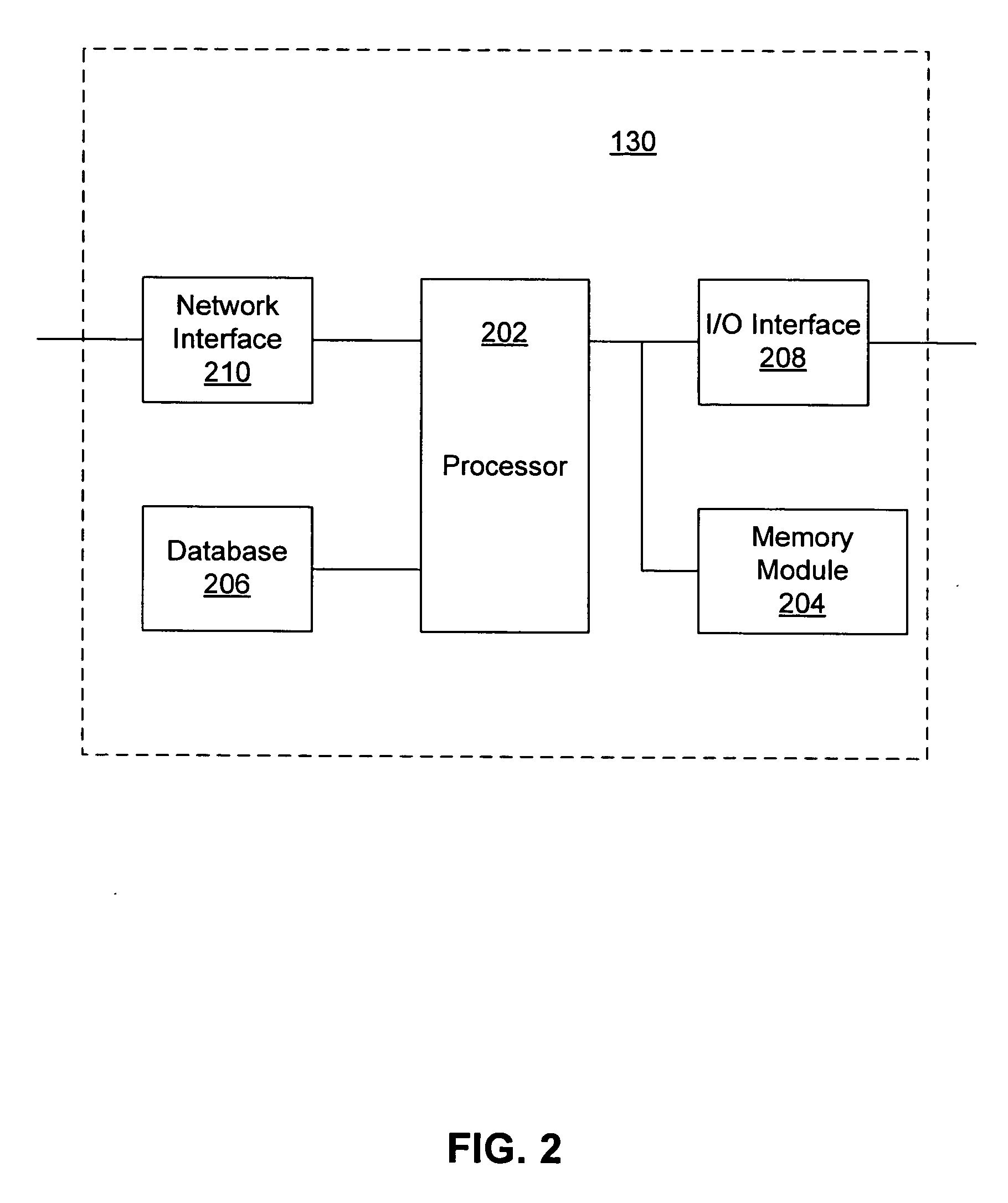

InactiveUS7483774B2Vehicle testingRegistering/indicating working of vehiclesOperational systemEngineering

A method is provided for reconfiguring an operational system having a plurality of input parameters and a plurality of output parameters. The method may include obtaining a maintenance schedule of the system and obtaining a set of actual values of the plurality of input parameters and corresponding actual values of the plurality of output parameters. The method may also include calculating corresponding model values of the plurality of output parameters based on an established process model indicative of interrelationships between the plurality of input parameters and the plurality of output parameters. Further, the method may include determining a divergence trend based on current divergences between the actual values and the model values of the plurality of output parameters and determining a desired set of values of the plurality of output parameters based on the divergence trend and the maintenance schedule. The method may also include providing a desired set of input constraints required to achieve the desired set of values of the plurality of output parameters based on the divergence trend and maintenance schedule.

Owner:CATERPILLAR INC

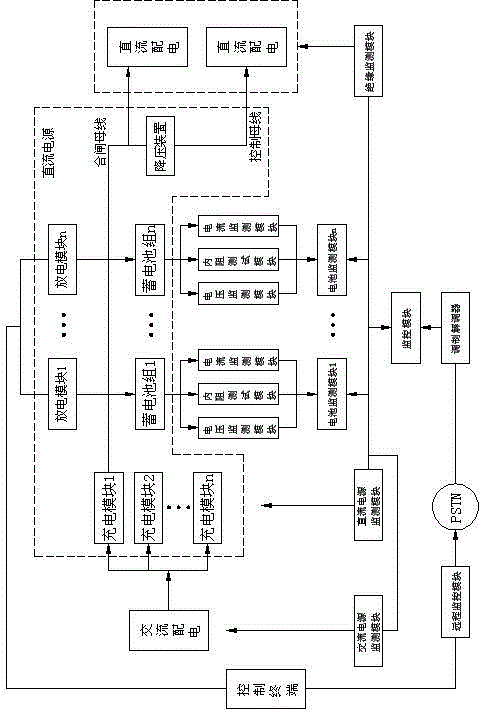

Remote intelligent maintenance system for direct current power supply of transformer substation and application of remote intelligent maintenance system

The invention relates to a remote intelligent maintenance system for a direct current power supply of a transformer substation. The remote intelligent maintenance system comprises the direct current power supply, wherein the input end of the direct current power supply is connected with an alternating current power distribution end; the output end of the direct current power supply is connected with a direct current power distribution end; the direct current power supply comprises charging and discharging modules 1-n; the charging and discharging modules 1-n are respectively connected with storage battery packs 1-n; the storage battery packs 1-n are connected with battery monitoring modules 1-n; the battery monitoring modules comprise voltage monitoring modules, circuit monitoring modules and internal resistance test modules; the battery monitoring modules are then connected with a monitoring module, and the monitoring module is connected with a control terminal. The control terminal performs remote communication with concentrated monitoring modules of all branch station direct current systems; after receiving a monitoring command sent by the control terminal, the monitoring modules of all the branch station direct current systems can complete data acquisition and control operation on direct current systems and send back results to the remote control terminal, so that unattended and real-time concentrated monitoring and remote maintenance of direct current equipment are realized.

Owner:STATE GRID CORP OF CHINA +1

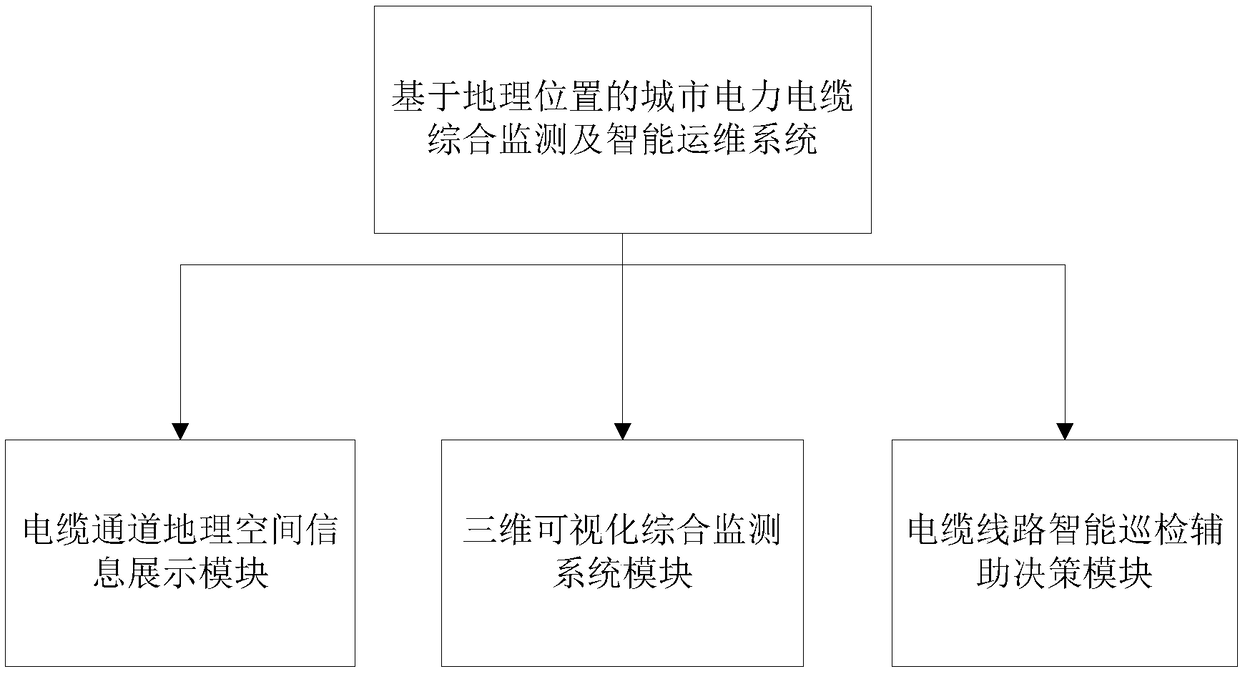

Urban power cable comprehensive Integrated monitoring and intelligent maintenance system based on geographical location

The invention discloses an urban power cable comprehensive monitoring and intelligent operation and maintenance system based on geographical position. The system comprises the following steps: the route direction of the cable channel is identified by adopting RFID technology through the geographic space position of the cable channel is found out; the geographic space information of the cable channel is displayed in the platform; the route direction of the cable channel is identified by using RFID technology. Realize the comprehensive monitoring of the cable running state, running environment and auxiliary equipment in the cable trench; Intelligent patrol and inspection assistant decision-making module of cable line: to establish and integrate the database of account data, daily operation and maintenance data and comprehensive monitoring data of cable in main network, to make intelligent operation and maintenance scheme according to equipment working condition and monitoring data of cable line, and to give reference operation and inspection scheme to the point or area prone to failure; The present invention solves the technical problems that it is difficult to accurately detect theabnormality of the equipment and brings inconvenience to the maintenance and management of the transmission cable by adopting the traditional single index and the fixed threshold judgment method in the prior art.

Owner:GUIZHOU POWER GRID CO LTD

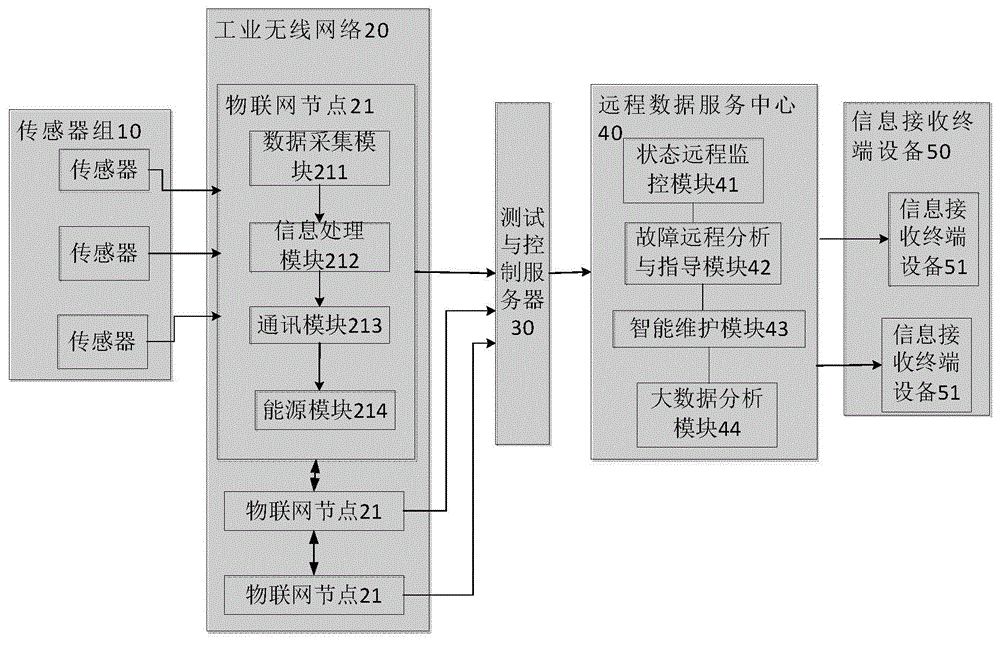

Crane remote monitoring and intelligent maintenance system based on IOT and DSP

InactiveCN105467949AFast operationMultiple data channelsTechnology managementTotal factory controlTerminal equipmentComputer terminal

The present invention discloses a crane remote monitoring and intelligent maintenance system based on an IOT and a DSP. The system is formed by the connection of a sensor group, an industrial wireless network, a test and control servers, a remote data service center, and an information receiving terminal device in order. The design and project amount can be greatly reduced, the installation cost is reduced, the DSP has the characteristics of fast computing speed, multiple data channels and high floating point operating precision, and the characteristics are very suitable for an industrial control system to carry out accurate detection and positioning.

Owner:SHANGHAI GUDE SOFTWARE ENG CO LTD

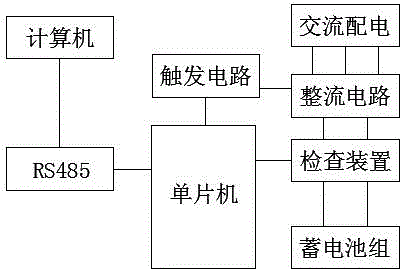

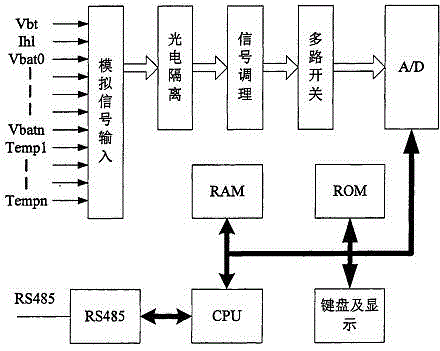

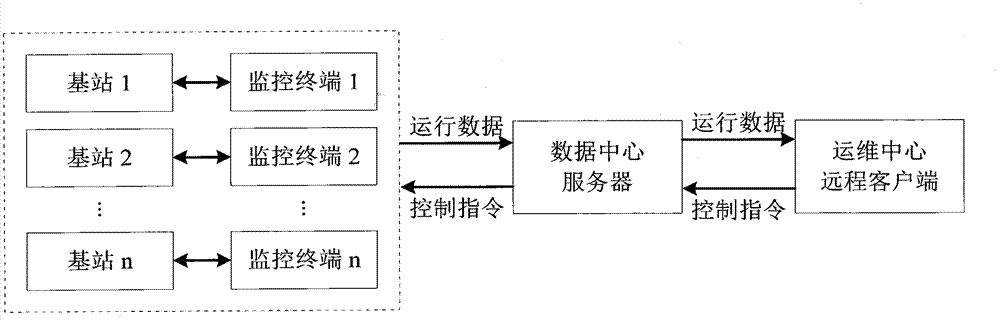

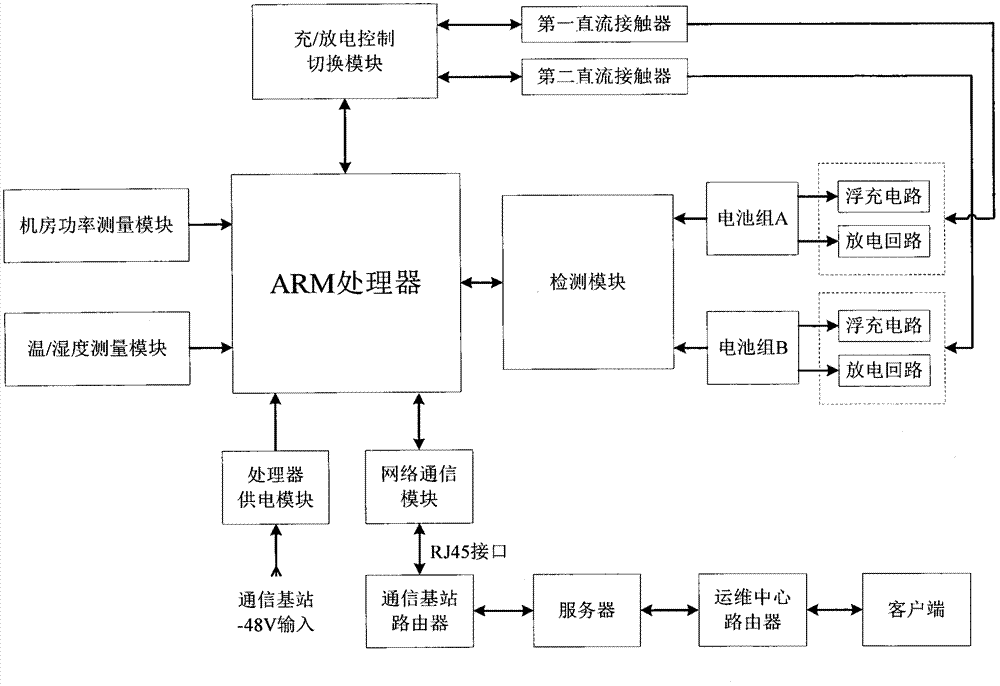

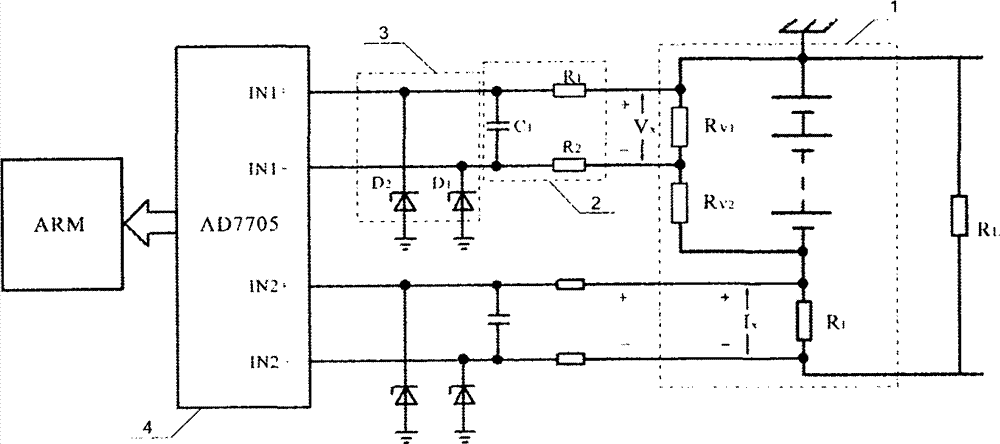

Intelligent maintenance system and method for communication base station standby power supply

InactiveCN104333059AImprove reliabilityReal-time collection of working parametersBatteries circuit arrangementsCells structural combinationEngineeringIntelligent maintenance system

The invention discloses an intelligent maintenance system and a method for a communication base station standby power supply. the system comprises one or more monitoring terminals in mutual two-way data communication, a server and a client located in a remote operation and maintenance center, wherein each monitoring terminal comprises a detection module, a charging / discharging control switching module, a temperature / humidity measurement module, a computer room power measurement module, an ARM processor and a power supply module; a battery pack is switched between a float charging circuit and a discharging loop via a DC contactor; the DC contactor is switched via the switching module; output ends of the detection module, the temperature / humidity measurement module and the computer room power measurement module are all connected with the ARM processor; and the input end of the charging / discharging control switching module is connected with the ARM processor and the output end is connected with the DC contactor. According to the system and the method of the invention, scientific maintenance and intelligent management on the base station standby power supply can be realized, the service life of the battery is prolonged, reliability of the standby power supply is improved, and the operation and maintenance cost is saved.

Owner:西安煜邦电子科技有限公司

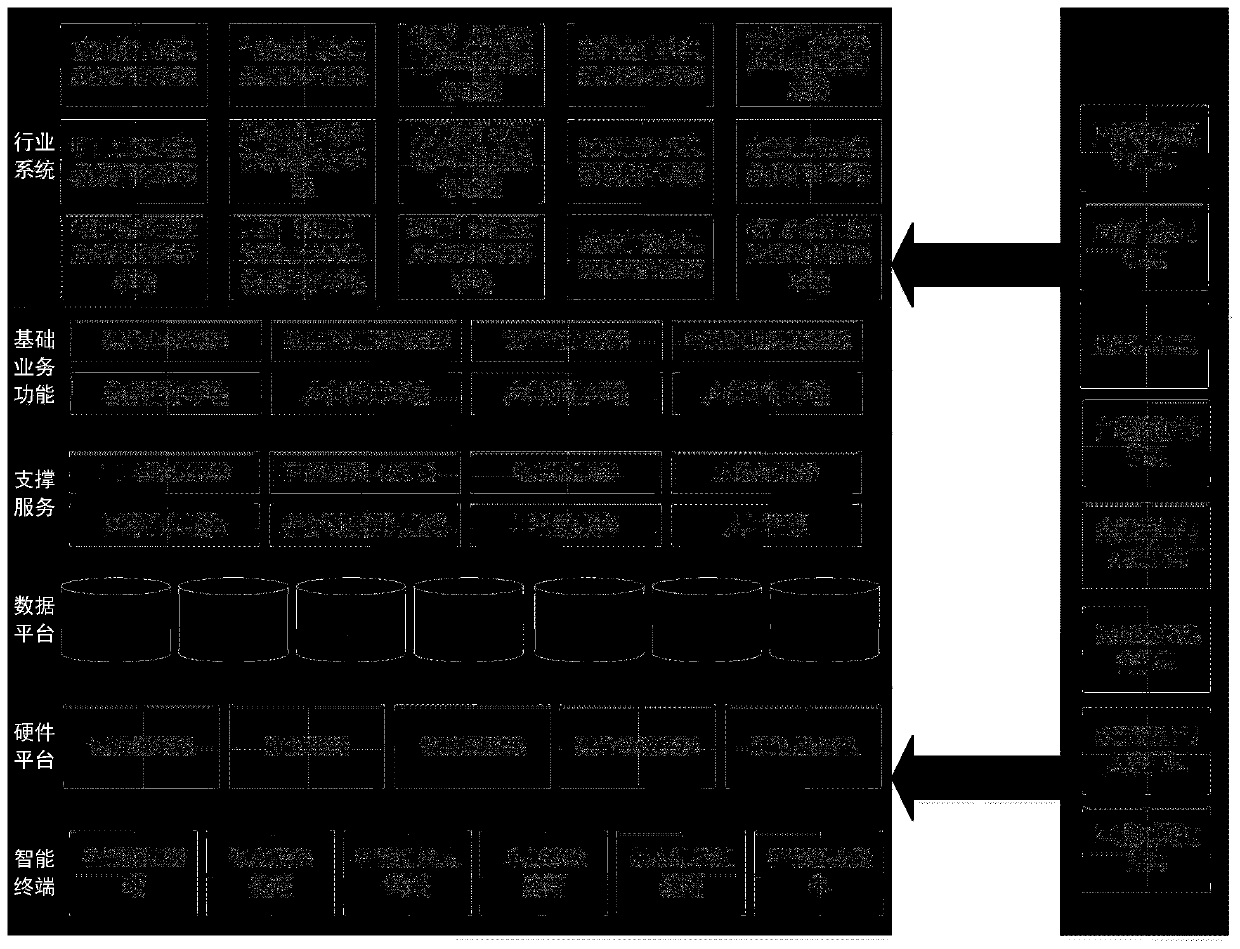

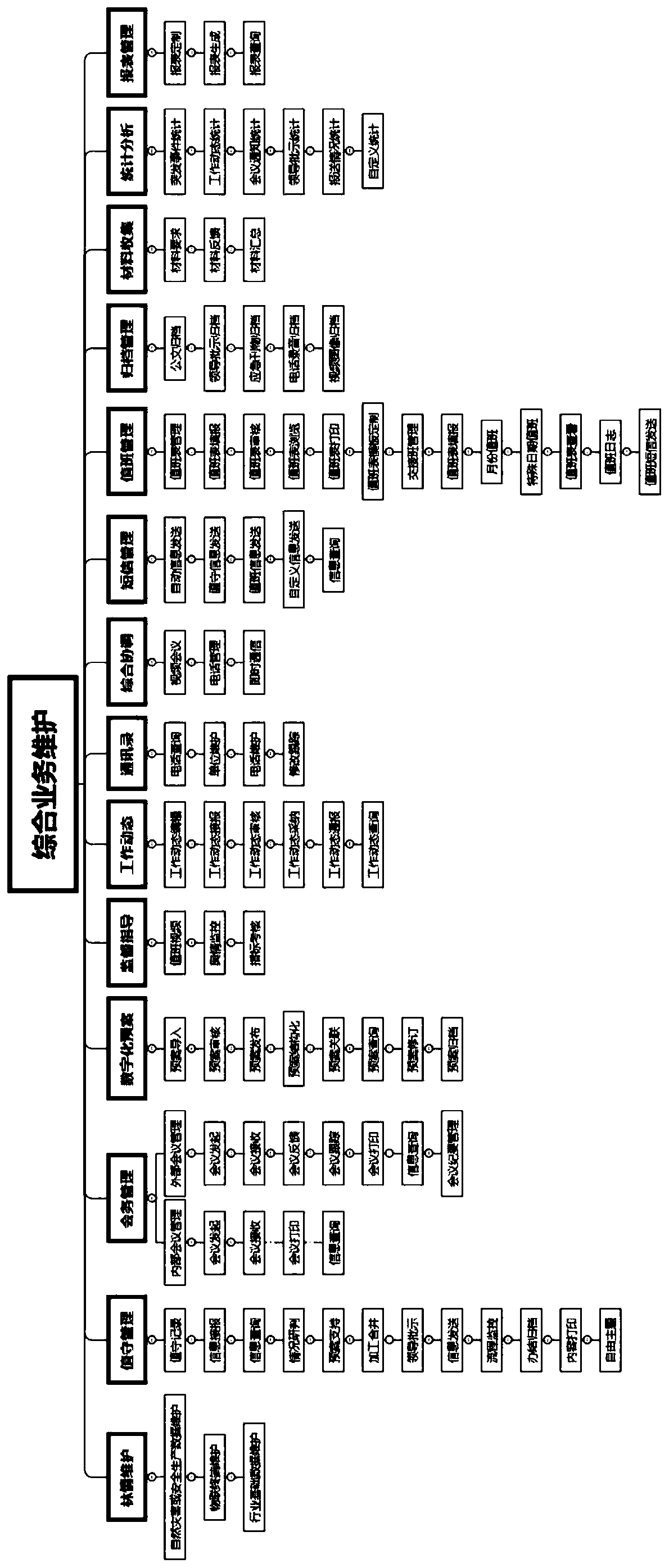

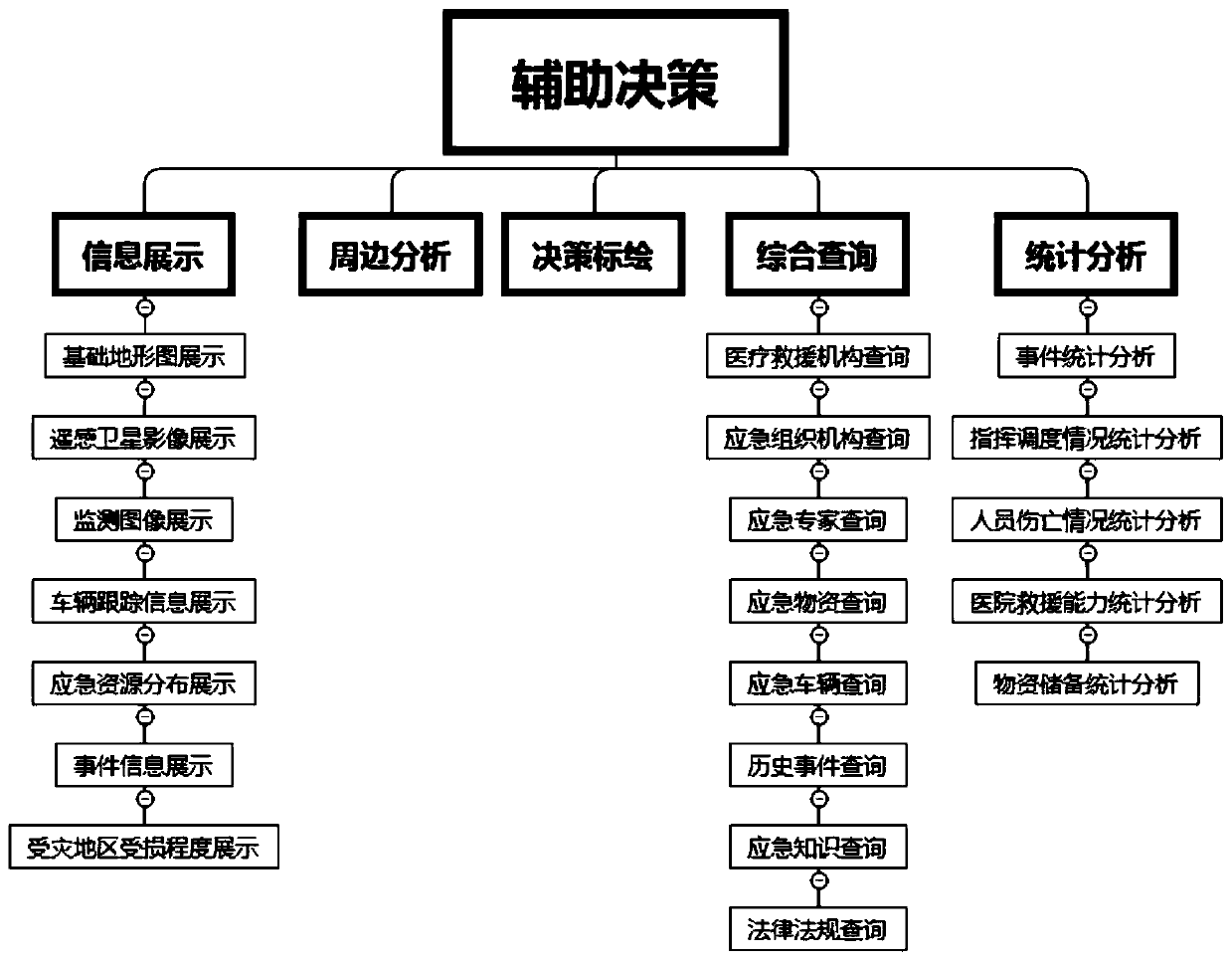

Integrated management platform of safety production emergency rescue command center

InactiveCN110059910AImprove emergency management capabilitiesPrevention and responseSatellite radio beaconingResourcesData platformEmergency rescue

The invention discloses an integrated management platform of a safety production emergency rescue command center. The integrated management platform comprises an industry system, a basic business system, a support service system, a data platform, a hardware platform and an intelligent terminal system. The management platform comprises all industry systems, all basic data are collected by the intelligent terminal, under the support of the support service system and the data platform, the basic service system is used for preventing and properly dealing with various emergencies such as natural disasters and safety production, and economic losses caused by sudden public events and losses of life and property of people are reduced. All emergency rescue command systems related to safe productionare comprehensively integrated, various data are imported in all directions and are in butt joint with an external system, various terminals are comprehensively interacted and controlled, and basic support is provided for establishing and perfecting an emergency mechanism which is unified in command, complete in function, sensitive in reaction, coordinated and ordered and efficient in operation.

Owner:北京兴泰科技有限公司

Method and system for intelligent maintenance

InactiveUS20080154459A1Vehicle testingRegistering/indicating working of vehiclesOperational systemEngineering

A method is provided for reconfiguring an operational system having a plurality of input parameters and a plurality of output parameters. The method may include obtaining a maintenance schedule of the system and obtaining a set of actual values of the plurality of input parameters and corresponding actual values of the plurality of output parameters. The method may also include calculating corresponding model values of the plurality of output parameters based on an established process model indicative of interrelationships between the plurality of input parameters and the plurality of output parameters. Further, the method may include determining a divergence trend based on current divergences between the actual values and the model values of the plurality of output parameters and determining a desired set of values of the plurality of output parameters based on the divergence trend and the maintenance schedule. The method may also include providing a desired set of input constraints required to achieve the desired set of values of the plurality of output parameters based on the divergence trend and maintenance schedule.

Owner:CATERPILLAR INC

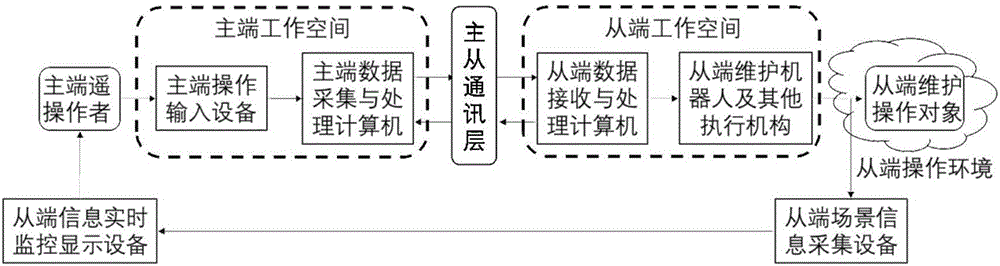

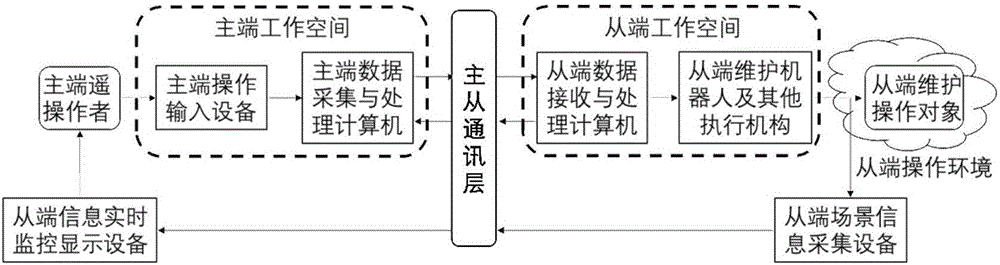

Remote control-based robot-assisted intelligent maintenance system

InactiveCN106375421AEfficient assistance with maintenance tasksEffectively complete auxiliary maintenance tasksTransmissionManipulatorProcess moduleRemote control

The present invention provides a remote control-based robot-assisted intelligent maintenance system. The system comprises a master end control platform module, a master end input signal acquisition and processing module, a signal transmission and communication module, and a slave end control execution module. The master end control platform module provides a platform and an operation environment in accordance with man-machine engineering for an operation by a remote control system master end remote operator. The master end input signal acquisition and processing module collects and processes motion data of an action instruction of the remote operator. The signal transmission and communication module transmits input data of a master operator collected by a master end and a processing result to a remote slave end. The slave end control execution module receives the data of the master end, then analyzes the data and drives a slave end robot execution mechanism to execute a corresponding action. According to the remote control-based robot-assisted intelligent maintenance system, a robot can be controlled remotely online in real time, the system is applicable to multiple operation environments that are inconvenient for people to perform tasks directly, and auxiliary maintenance tasks of the remote control intelligent maintenance system can be completed.

Owner:SHANGHAI JIAO TONG UNIV

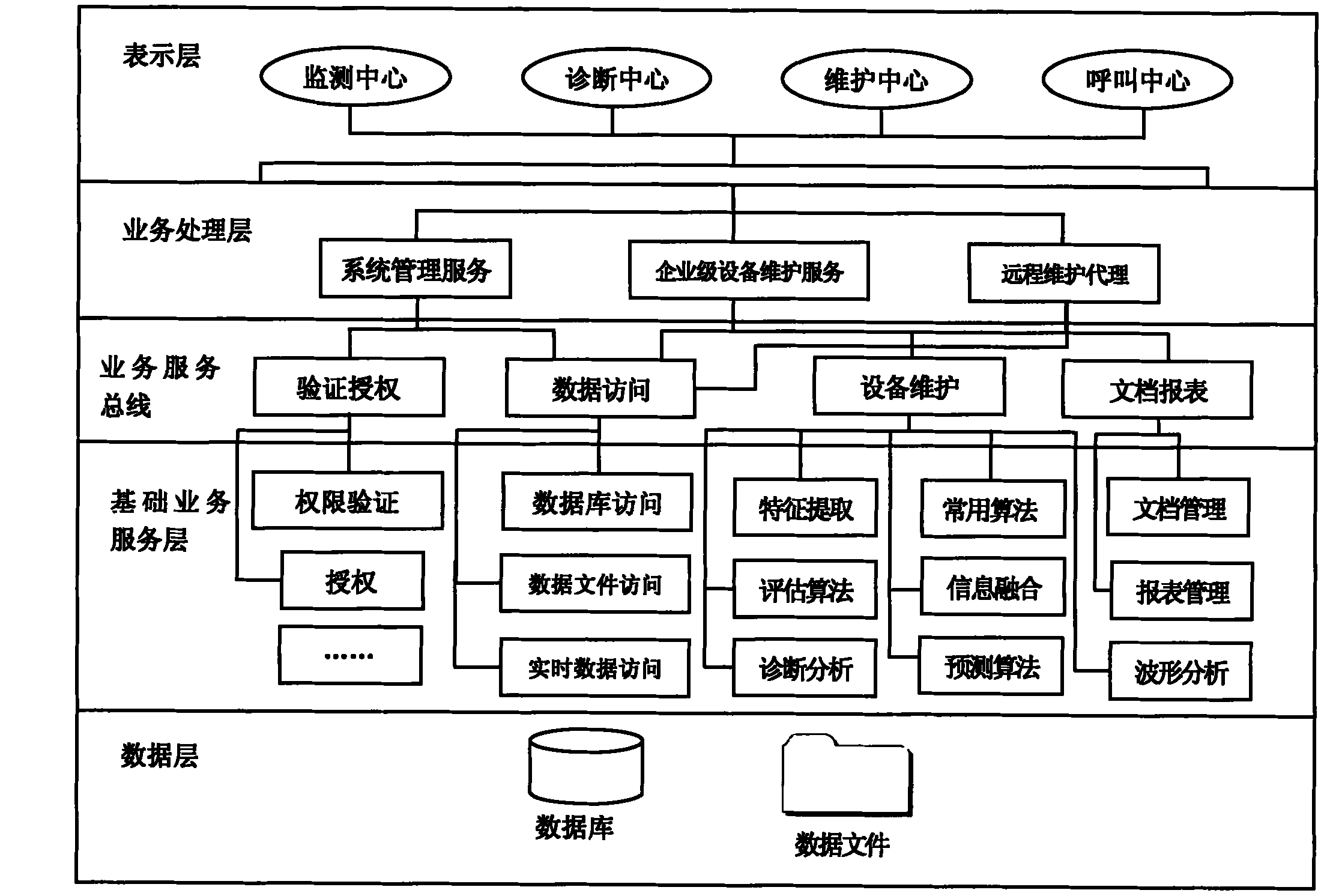

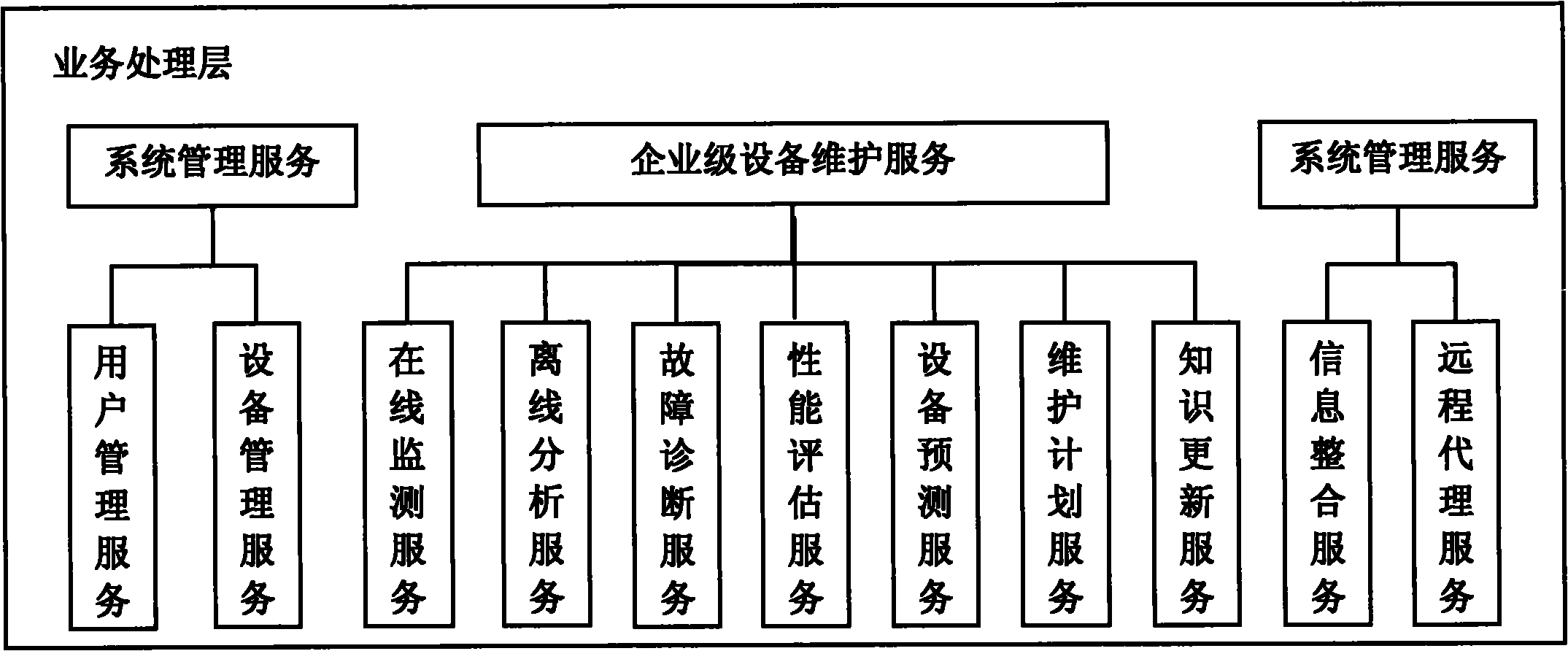

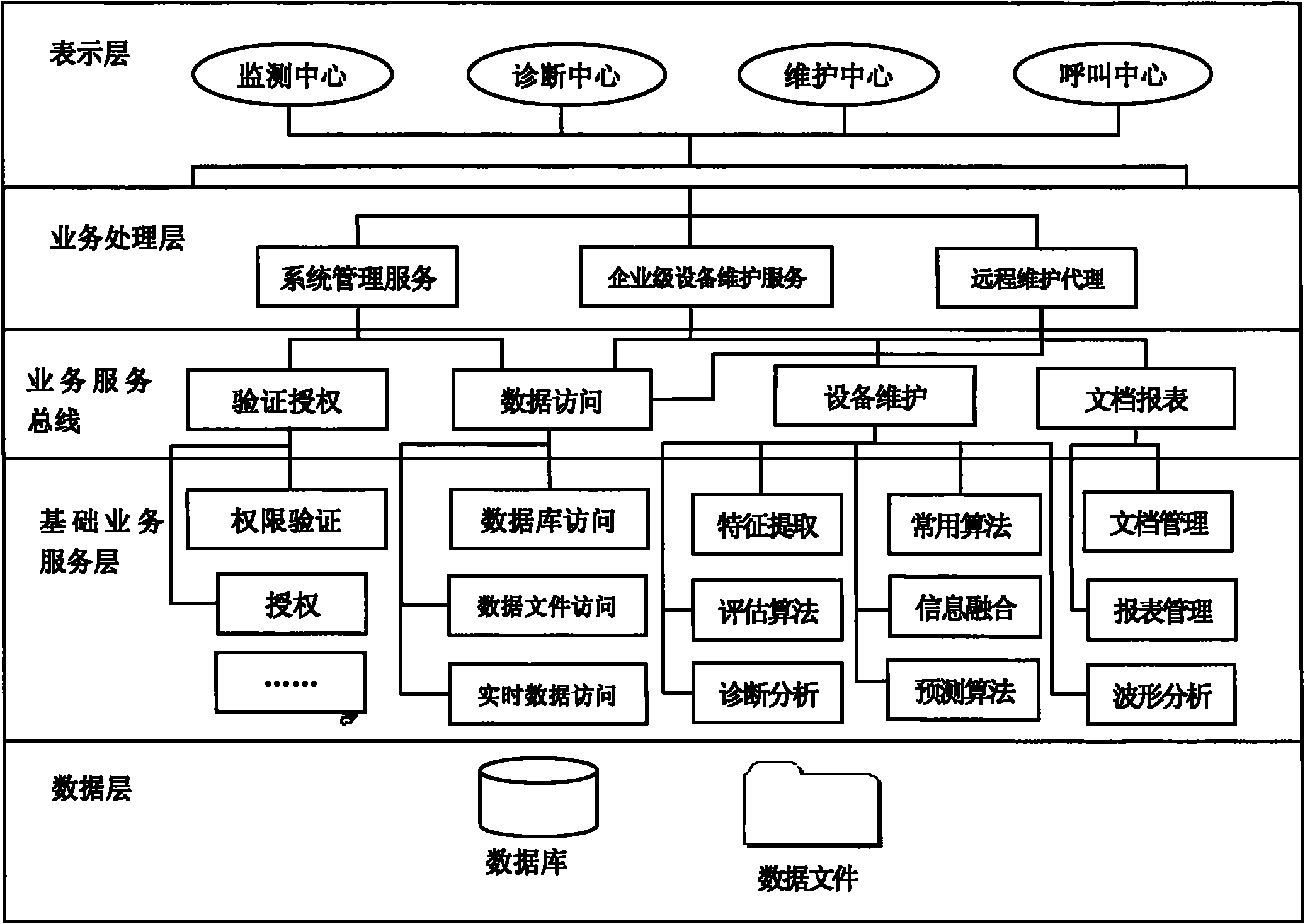

Architecture method for SOA-based intelligent enterprise equipment maintenance system and system

InactiveCN102033750ASpecific program execution arrangementsSystems managementIntelligent maintenance system

The invention provides an architecture method for a service oriented architecture (SOA)-based intelligent enterprise equipment maintenance system, which is characterized by comprising the following steps of: 1) constructing a data layer, wherein the data layer comprises a plurality of database systems; 2) constructing a basic service layer, wherein the basic service layer comprises a plurality of fine-grained basic services; 3) constructing a service bus; 4) constructing a service processing layer, wherein the service processing layer comprises a system management service module, an enterprise-level equipment maintenance service module and a remote maintenance agent module; and 5) constructing a presentation layer, wherein the presentation layer comprises a user interface (UI) processing module for verifying user information and loading user configuration files. The invention also provides a system for realizing the method. The system comprises the data layer, the basic service layer, the service bus, the service processing layer and the presentation layer which are connected mutually from top to bottom by an SOA frame. By the method and the system, enterprise-level information management application programs which are loosely coupled, easy to expand and convenient to deploy are constructed.

Owner:DONGGUAN GOSCIEN ELECTRICAL & MECHANICAL TECH SERVICES

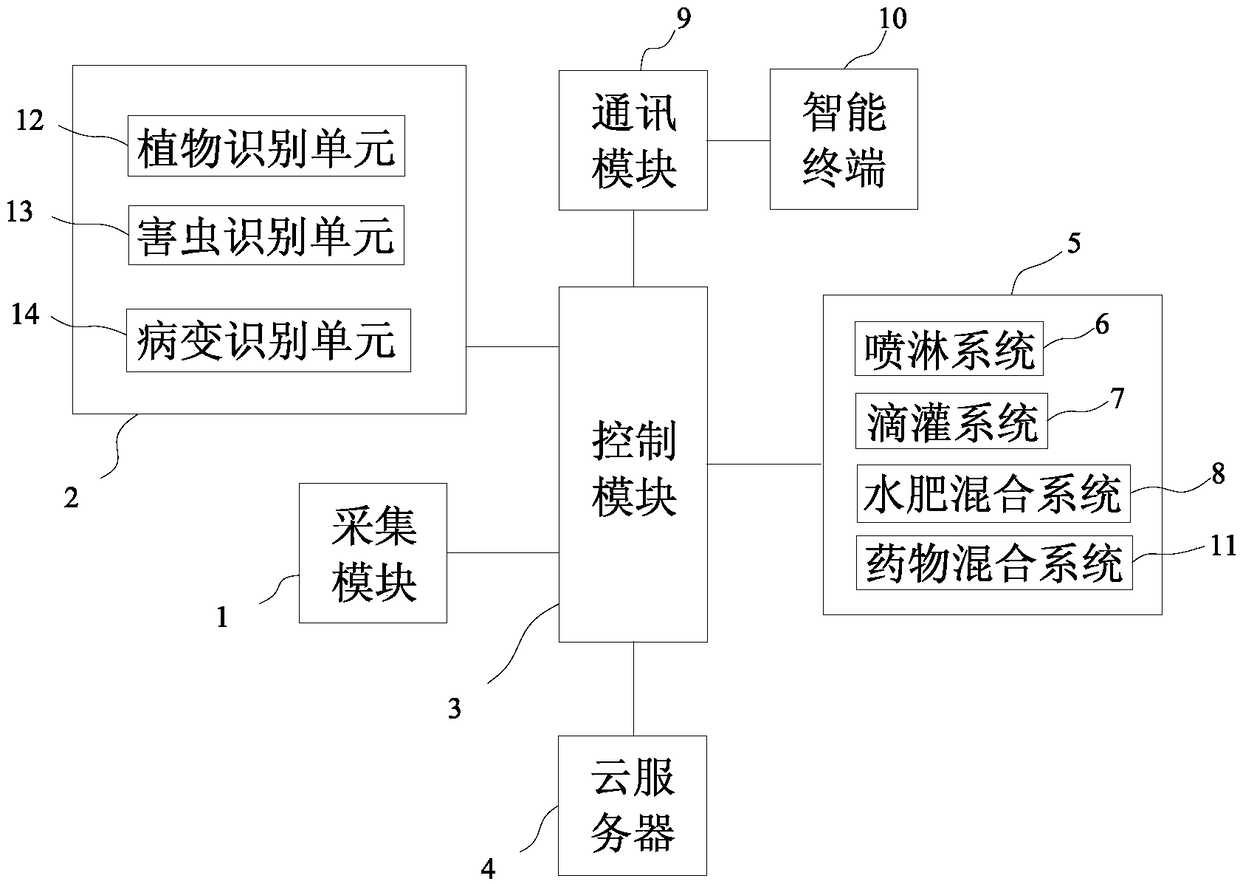

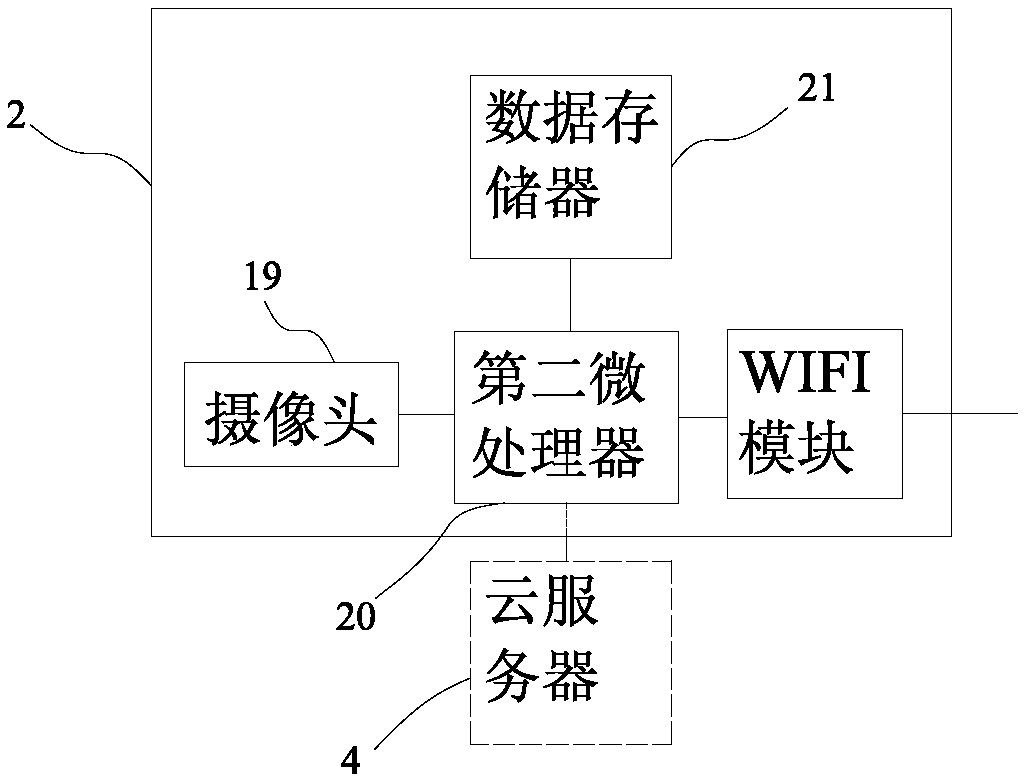

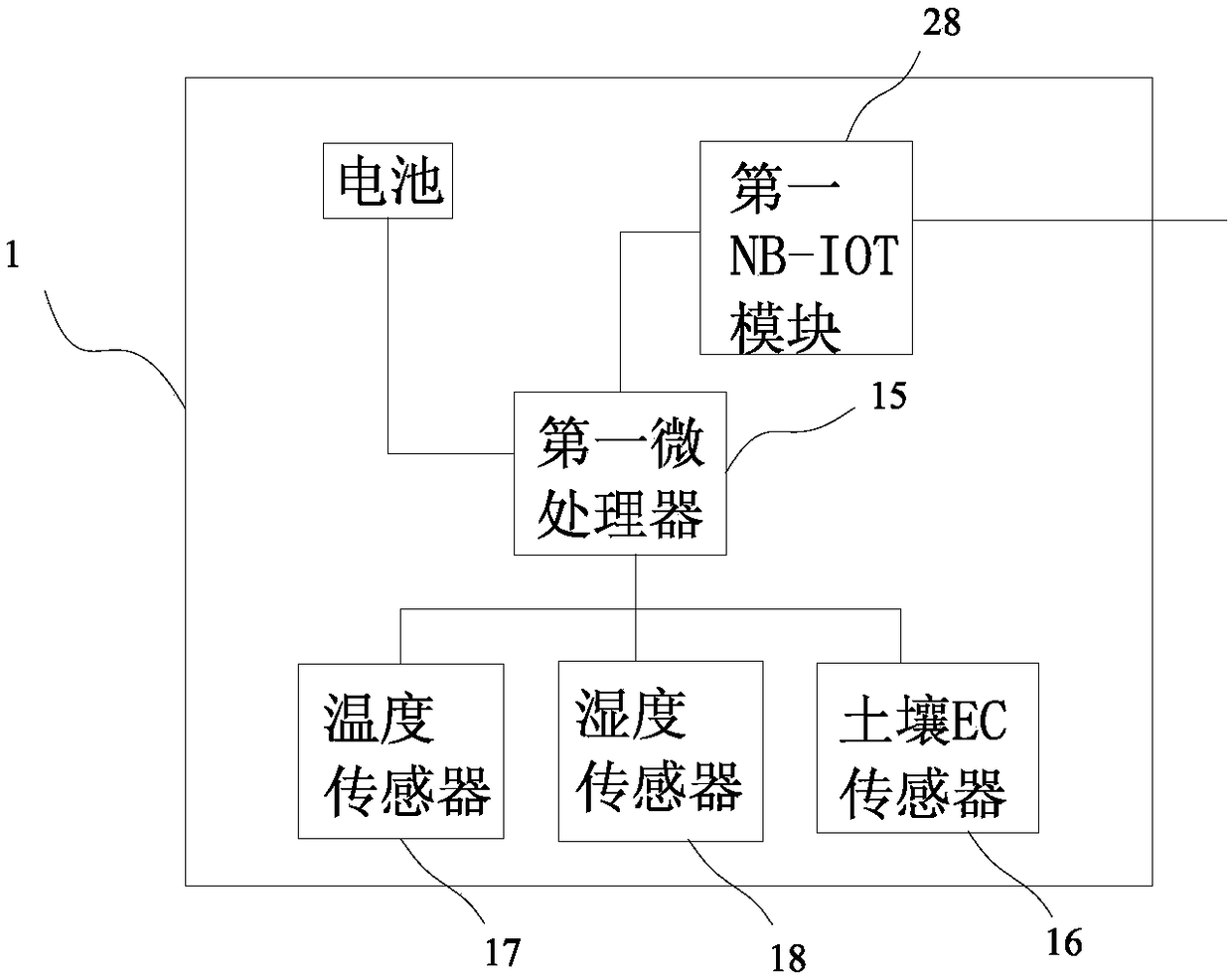

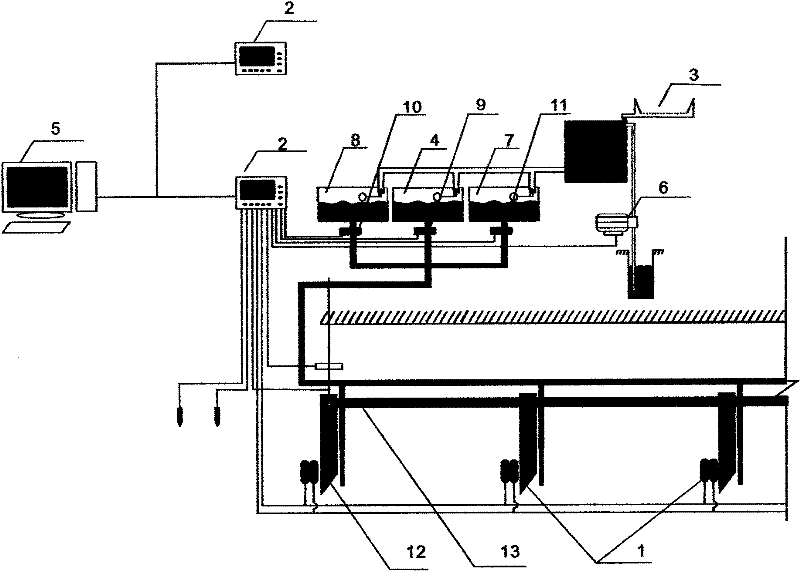

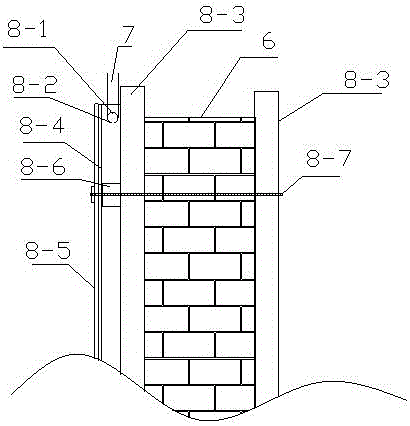

Internet of Things-based intelligent maintenance system for roof garden and control method of intelligent maintenance system

InactiveCN109197531AAvoid death from dehydrationAvoid root rotManure treatmentTransmission systemsDrip irrigationThe Internet

The invention belongs to the technical field of plant cultivation and relates to an Internet of Things-based intelligent maintenance system for a roof garden and a control method of the intelligent maintenance system. The Internet of Things-based intelligent maintenance system for the roof garden comprises an acquisition module (1), an image recognition module (2), a control module (3), a cloud server (4) and an execution module (5); the execution module (5) comprises a spraying system (6), a drip irrigation system (7), and a water and fertilizer mixing system (8). According to the control method of the Internet of Things-based intelligent maintenance system for the roof garden, a plant identification unit (12) is used for identifying plant species in the roof garden and the growth cyclesof the plant species; the acquisition module obtains the soil temperature value, soil moisture value, and soil electrolyte content value of the roof garden; the control module (3) compares the data and controls the operation of the execution unit; and therefore, death caused by dehydration and root rotting can be avoided.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

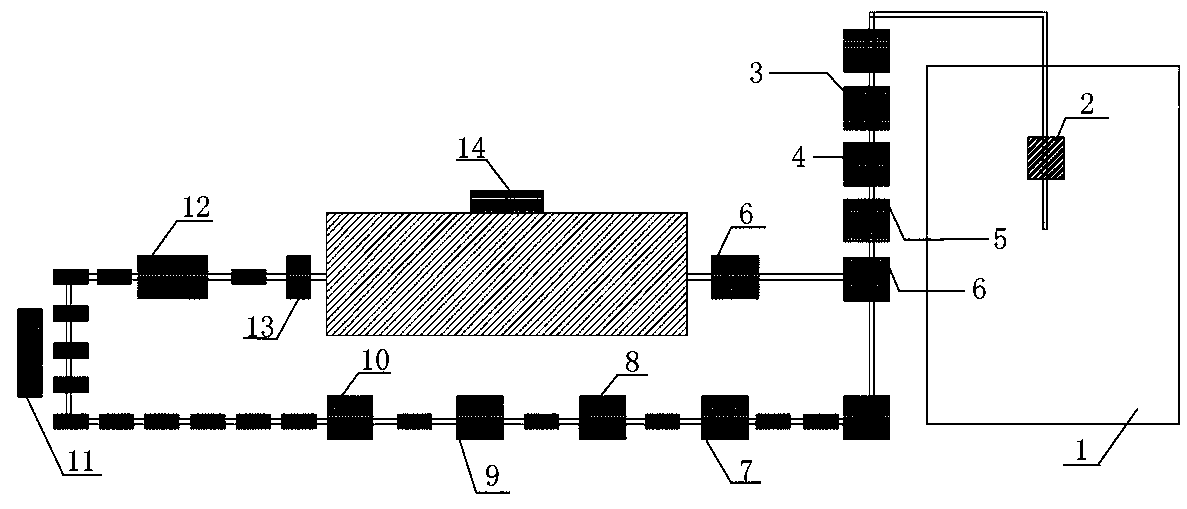

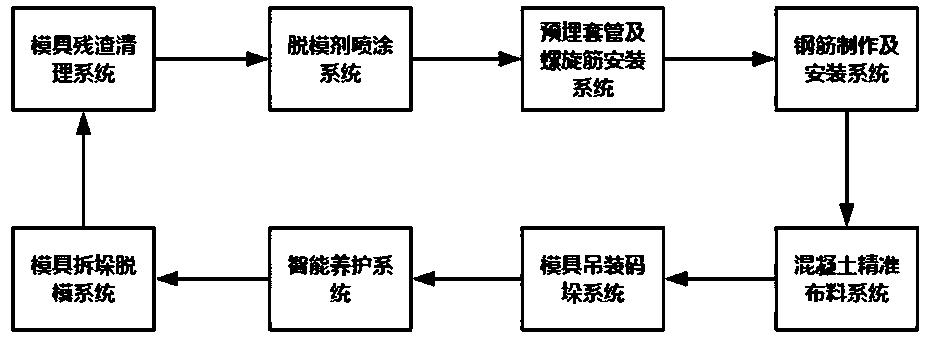

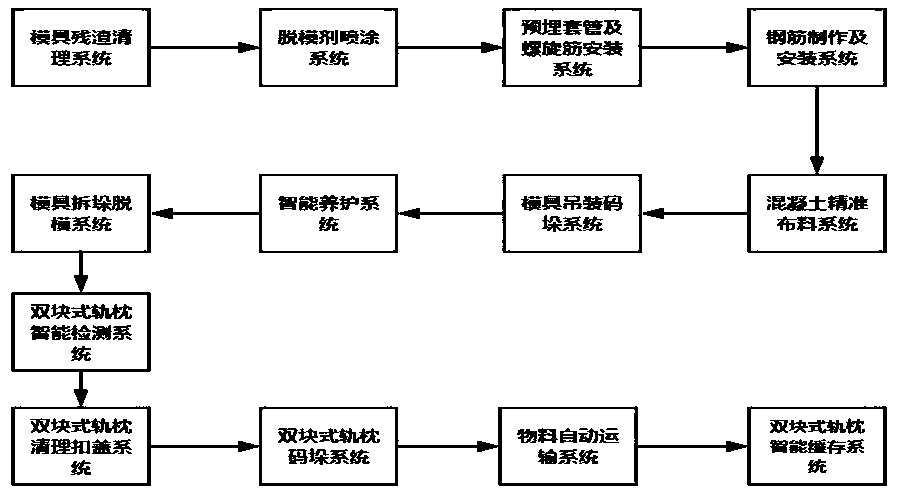

Automatic intelligent unmanned production line for CRTSI type double-block sleepers

PendingCN111098401ASimple structureReasonable designDischarging arrangementCeramic shaping plantsDistribution systemRebar

The invention belongs to the technical field of automatic prefabrication of double-block sleepers, and particularly relates to an automatic intelligent unmanned production line for CRTSI type double-block sleepers. A mold unstacking and demolding system, a mold residue cleaning system, a demolding agent spraying system, an embedded sleeve and spiral rib mounting system, a steel bar manufacturing and mounting system, a concrete precise distribution system, a mold hoisting and stacking system and an intelligent maintenance system are sequentially connected to form a closed loop, the mold unstacking and demolding system is further sequentially connected with a double-block sleeper cleaning and cover buckling system, a double-block sleeper stacking system and a double-block sleeper intelligenttemporary storage system, and all the systems are connected through an automatic material conveying system. The automatic intelligent unmanned production line is convenient to mount and arrange, highin turnover utilization rate and good in use effect, personnel injuries and potential safety hazard factors can be effectively avoided while the sleeper production efficiency is improved and the construction cost is reduced, the defects of a double-block sleeper mechanical and manual operation mode are eliminated, pollution is reduced, and the purposes of energy conservation and emission reduction are achieved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

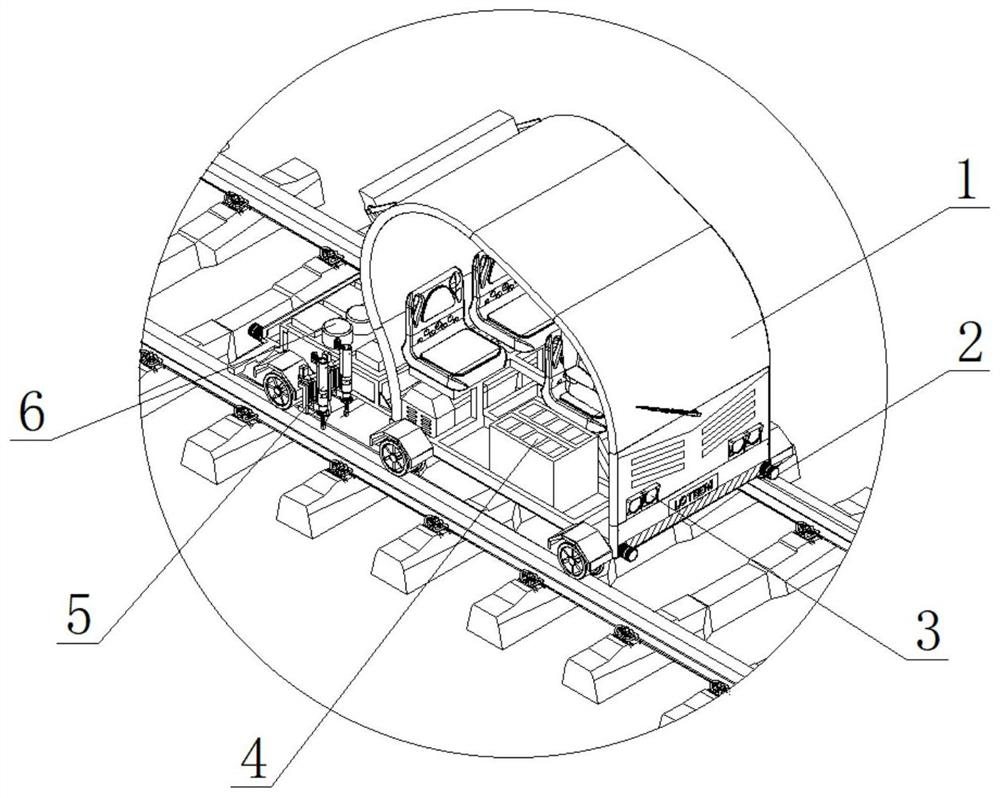

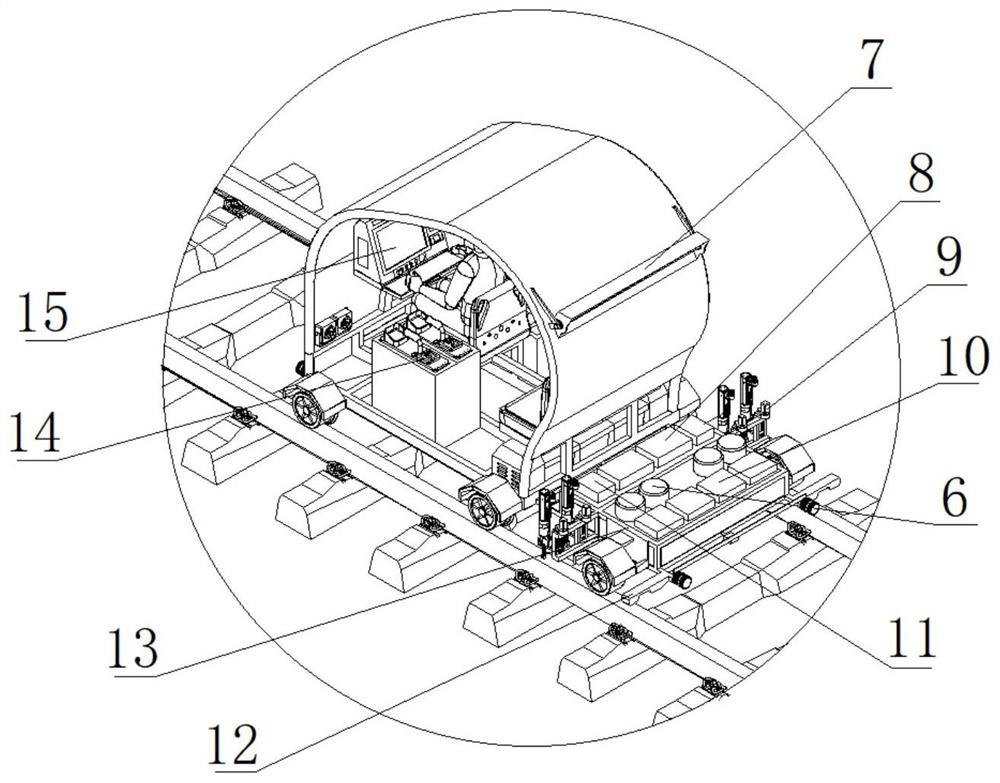

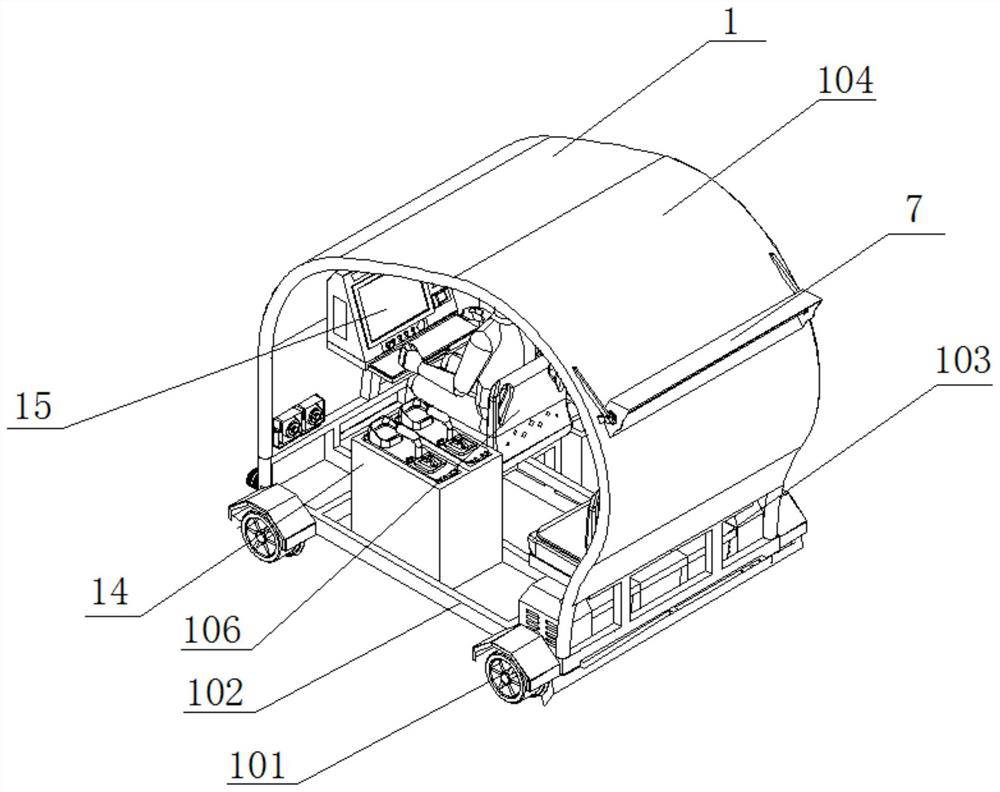

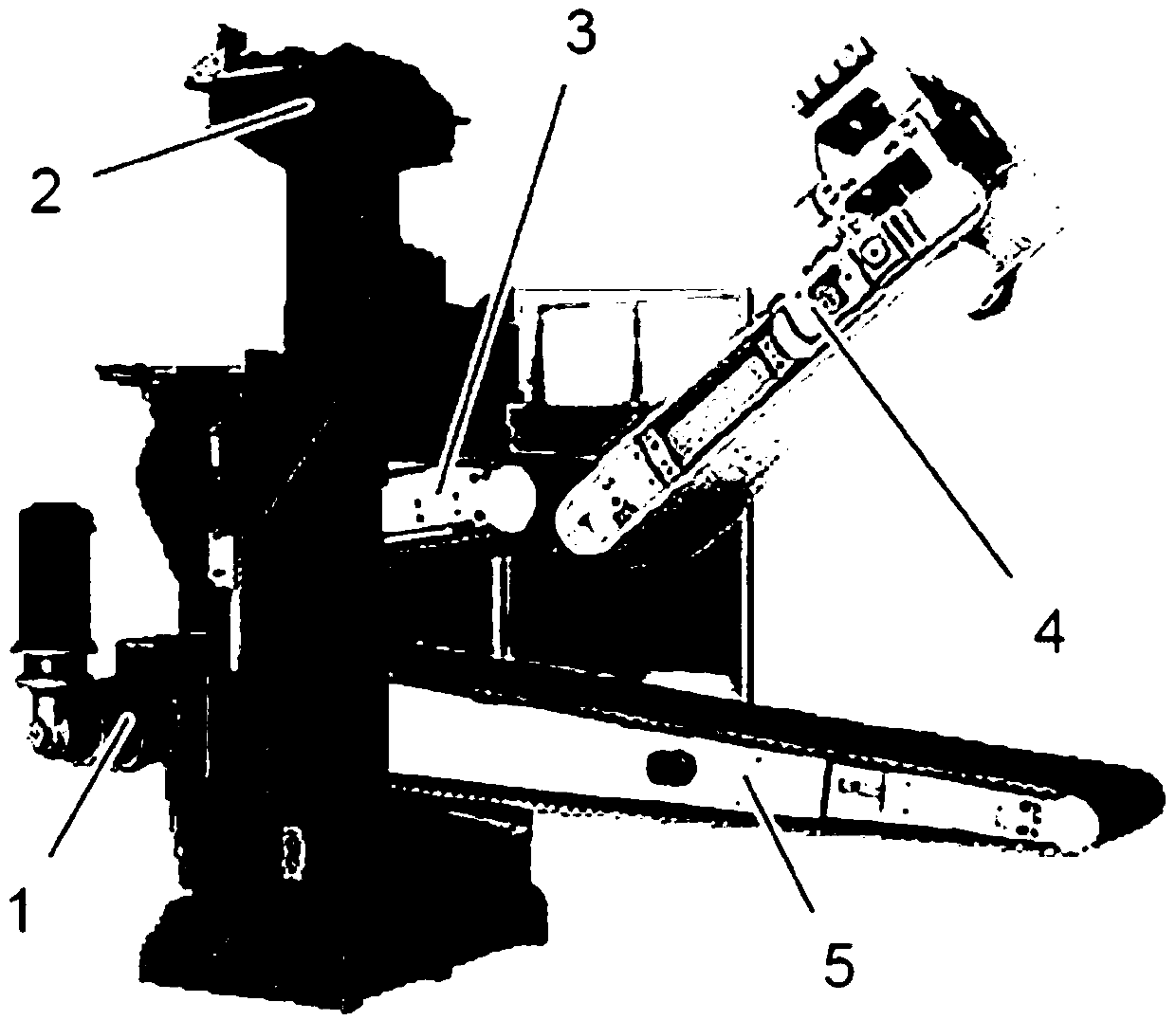

Intelligent maintenance system and method for track fasteners of track maintenance division

ActiveCN112061172ARealize automated detectionImprove work efficiencyRailway inspection trolleysTrack superstructureIn vehicleControl engineering

The invention discloses an intelligent maintenance system and method for track fasteners of a track maintenance division. The intelligent maintenance system comprises a track car (1) running along a track, a tightening machine bearing vehicle (13) and a vehicle-mounted workstation (15). The tightening machine bearing vehicle (13) is connected with the track car (1) in a hanging manner, an intelligent tightening mechanism and an automatic nail feeding mechanism (6) are arranged on the tightening machine bearing vehicle (13), a fastener and track detection sensor (12) is arranged at one end of the intelligent tightening mechanism, the intelligent tightening mechanism comprises a tightening shaft controller (8), a tightening shaft control motor (9) in communication connection with the tightening shaft controller (8) and a servo fastener tightening shaft (5) connected with the tightening shaft control motor (9), and the vehicle-mounted workstation (15) is arranged in the track car (1). According to the system, a vehicle-mounted manual driving operation mode is adopted, a track flaw detection and track fastener locking torque sensor is installed on the track car, the image recognition technology is adopted in a combined manner, automatic detection of the track flaw detection and track fastener state and the bolt locking torque is achieved, and the working efficiency and the operation precision are improved.

Owner:LOTEEM BEIJING RAIL TRANSIT TECH CO LTD

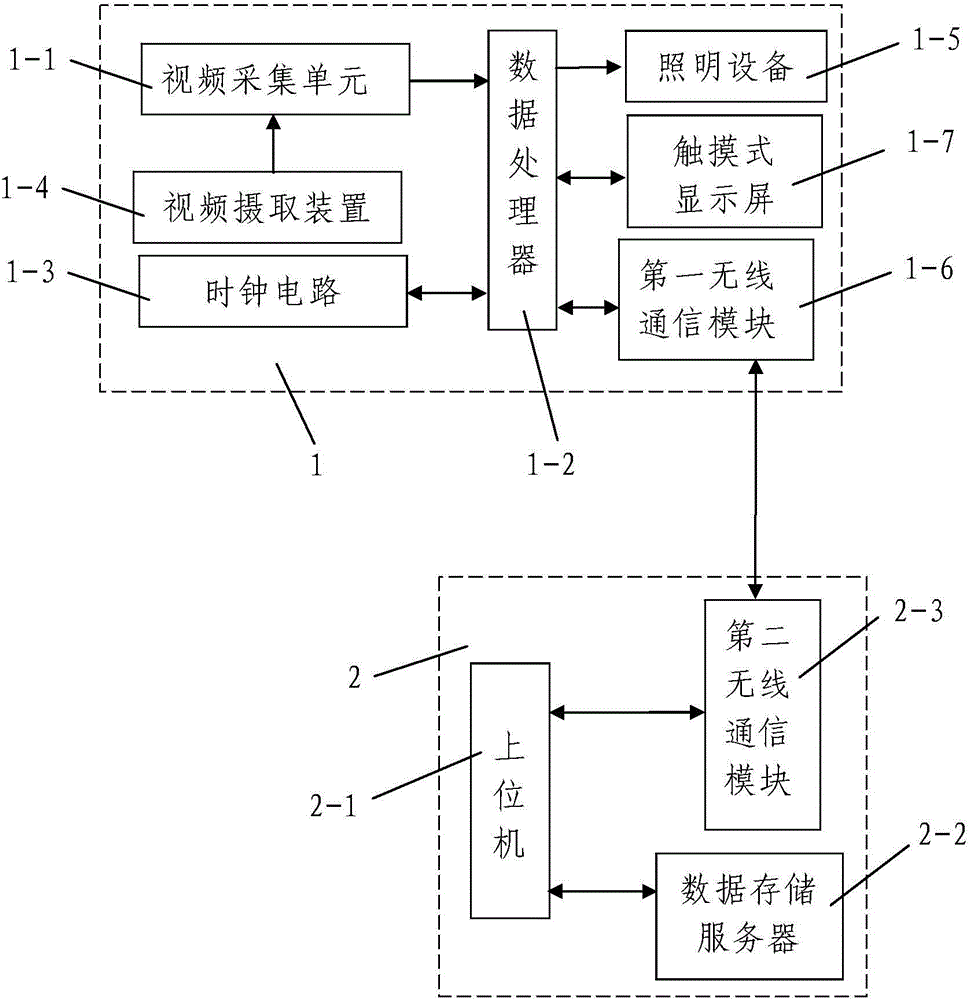

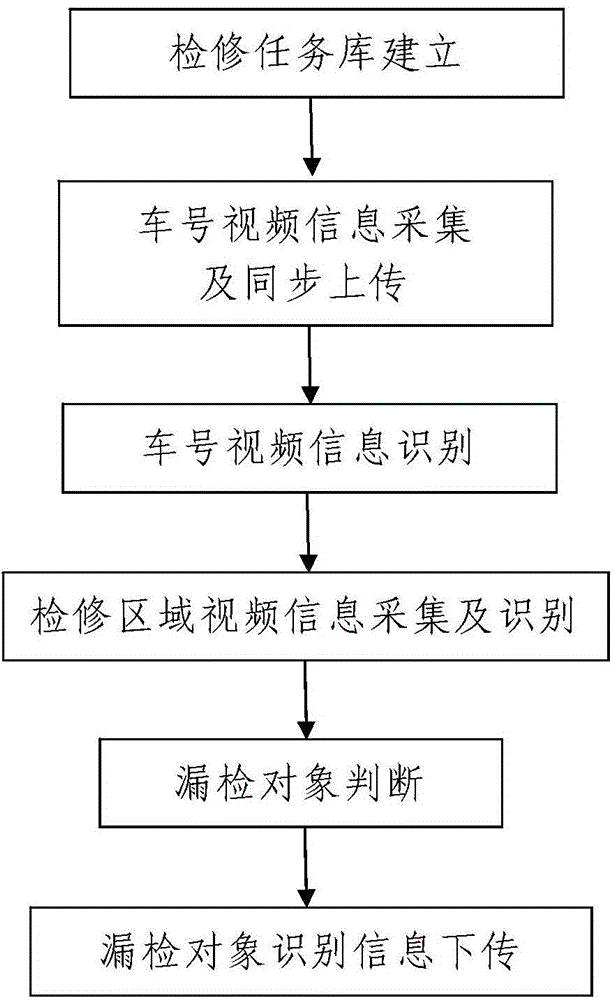

Locomotive vehicle intelligent maintenance system and method based on video identification

ActiveCN104787009ASimple structureReasonable designVehicle servicing/repairingAcquisition apparatusComputer terminal

The invention discloses a locomotive vehicle intelligent maintenance system based on video identification. The system comprises an upper monitoring terminal and a movable video collecting device used for collecting video information of each maintenance object of a maintained locomotive vehicle; the movable video collecting device comprises a shell, a video capture device and an electric circuit board, and the electric circuit board is provided with a data processor, a video collecting unit and a clock circuit. According to the system, the structure is simple, the operation is easy and convenient, the using effect is good, and the maintenance process of the locomotive vehicle can be completed simply, conveniently and rapidly. Meanwhile, the invention further discloses a locomotive vehicle intelligent maintenance method. The method comprises the steps that 1, a maintenance task library is established; 2, the video information of the maintained object is collected, the maintenance records are synchronously uploaded, and the specific process comprises the steps of collecting and synchronously uploading vehicle number video information, identifying the vehicle number video information and collecting and identifying video information of a maintenance area; 3, objects which are left out in maintenance are judged. The method is simple, reasonable in design and convenient to achieve, the maintenance speed is fast, and the maintenance effect is good.

Owner:XIAN YINSHI TECH DEV CO LTD

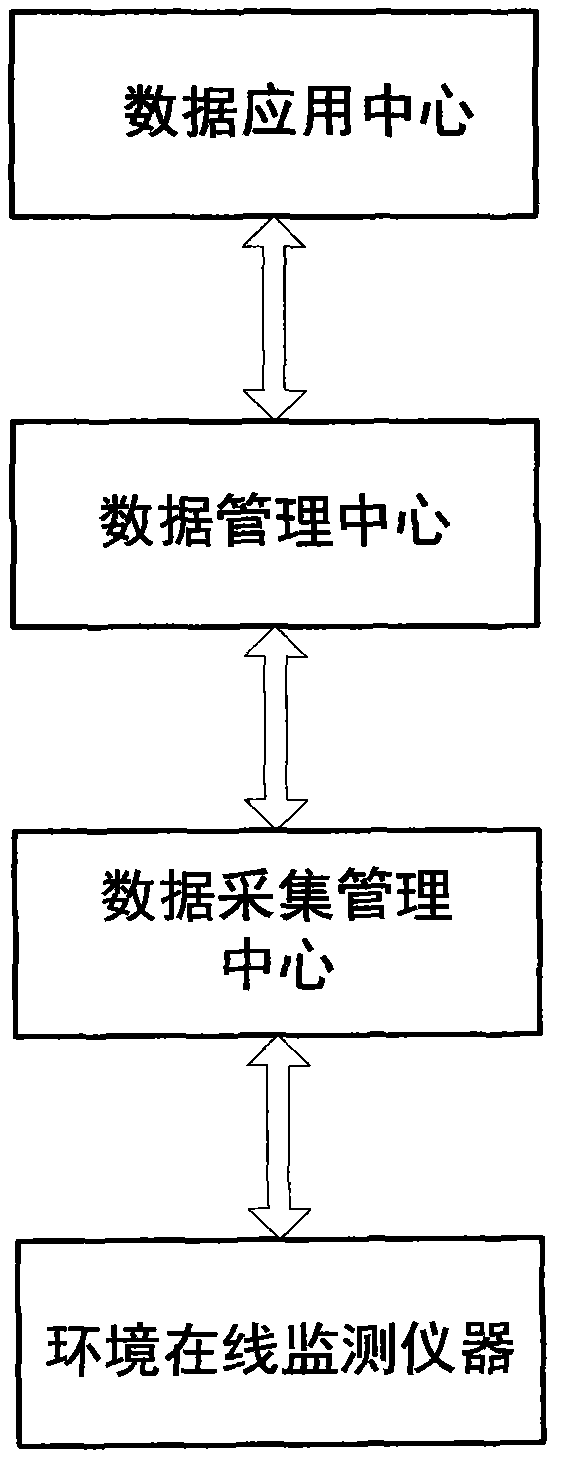

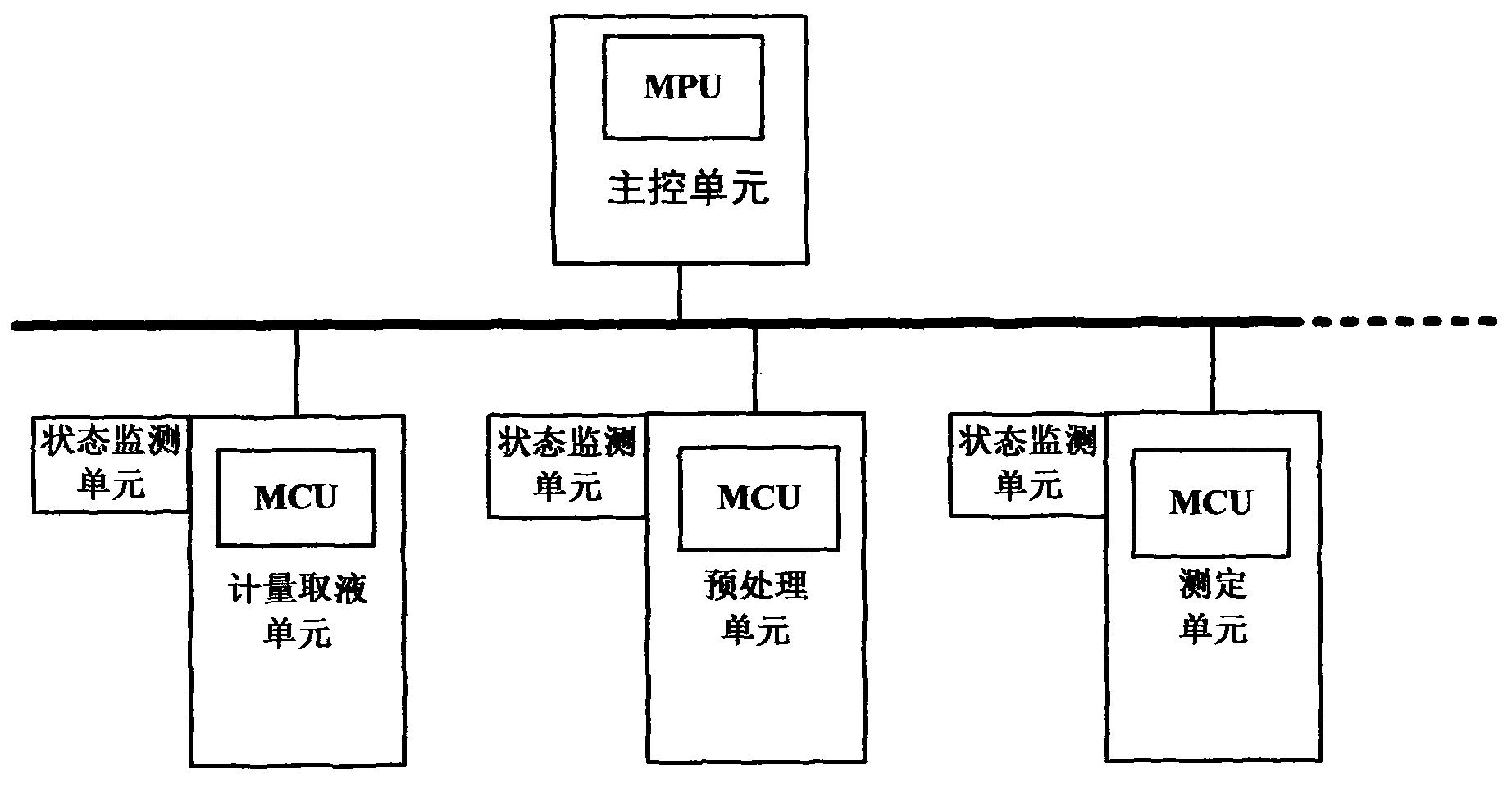

Remote intelligent maintenance system for online environment monitoring instrument

ActiveCN102841589ATotal factory controlProgramme total factory controlData acquisitionHuman monitoring

The invention discloses a remote intelligent maintenance system for an online environment monitoring instrument. The system comprises the online environment monitoring instrument, a data acquisition and management center, a data management center and a data application center, wherein the data acquisition and management center collects monitoring results of the online environment monitoring instrument, stores the collected monitoring results and uploads the monitoring results to the data management center; and the data management center receives the monitoring results, carries out data analysis on the monitoring results and uploads the data results to the data application center. According to the invention, aiming at solving the problems that errors of equipment and system cannot be monitored in real time by human monitoring to cause the uploading of wrong data so as to make a misjudgment on environmental change, the method for remotely monitoring and maintaining the online environment monitoring instrument is provided.

Owner:YIWEN ENVIRONMENTAL SCI & TECH GUANGZHOU

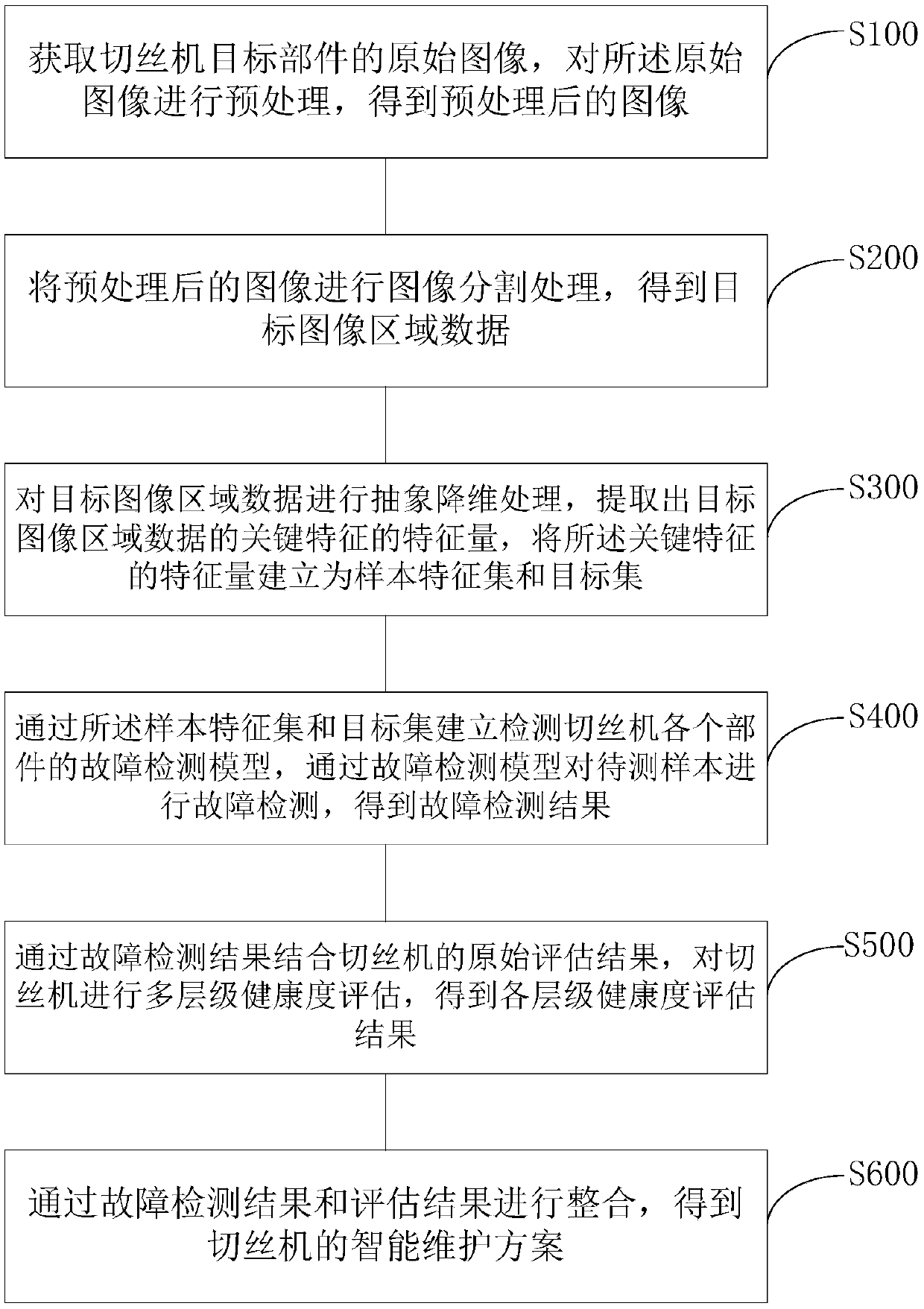

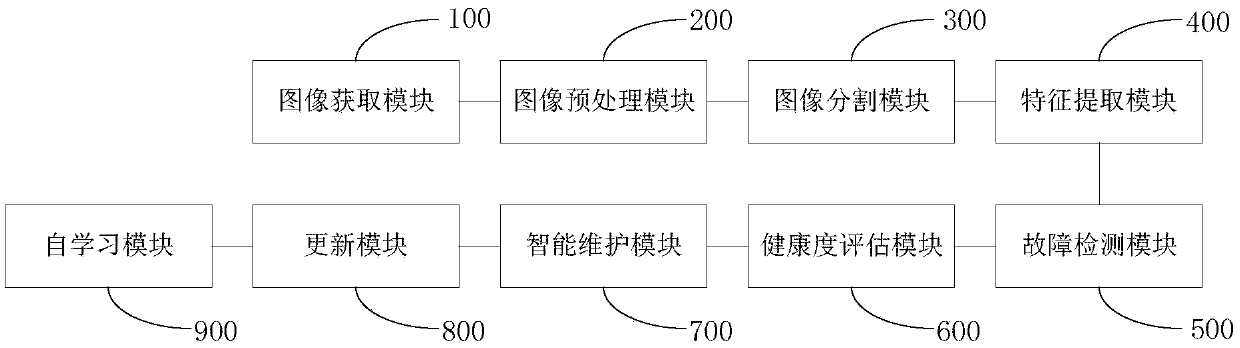

Intelligent maintenance method and system for tobacco cutter based on automatic optical inspection technology

ActiveCN108685158AGood technical effectHigh precisionImage enhancementImage analysisEvaluation resultMaintenance strategy

The invention discloses an intelligent maintenance method for a tobacco cutter based on an automatic optical inspection technology. The method comprises the following steps that an original image of atarget component of the tobacco cutter is acquired and preprocessed; the preprocessed image is identified and segmented to obtain target image region data; the target image region data is processed,characteristic quantities of key characteristics of the target image region data are extracted to be built into a sample characteristic set and a target set; a fault detection model detecting each component of the tobacco cutter is established through the sample characteristic set and the target set, and fault detection is performed to obtain a fault detection result; the fault detection result iscombined with an original evaluation result of the tobacco cutter to perform multi-level health assessment on the tobacco cutter so as to obtain the health assessment results of multiple levels; andthe fault detection result is integrated with the health assessment results to obtain an intelligent maintenance scheme for the tobacco cutter; and an intelligent maintenance strategy can be providedtimely, clearly and efficiently.

Owner:HANGZHOU ANMAISHENG INTELLIGENT TECH CO LTD

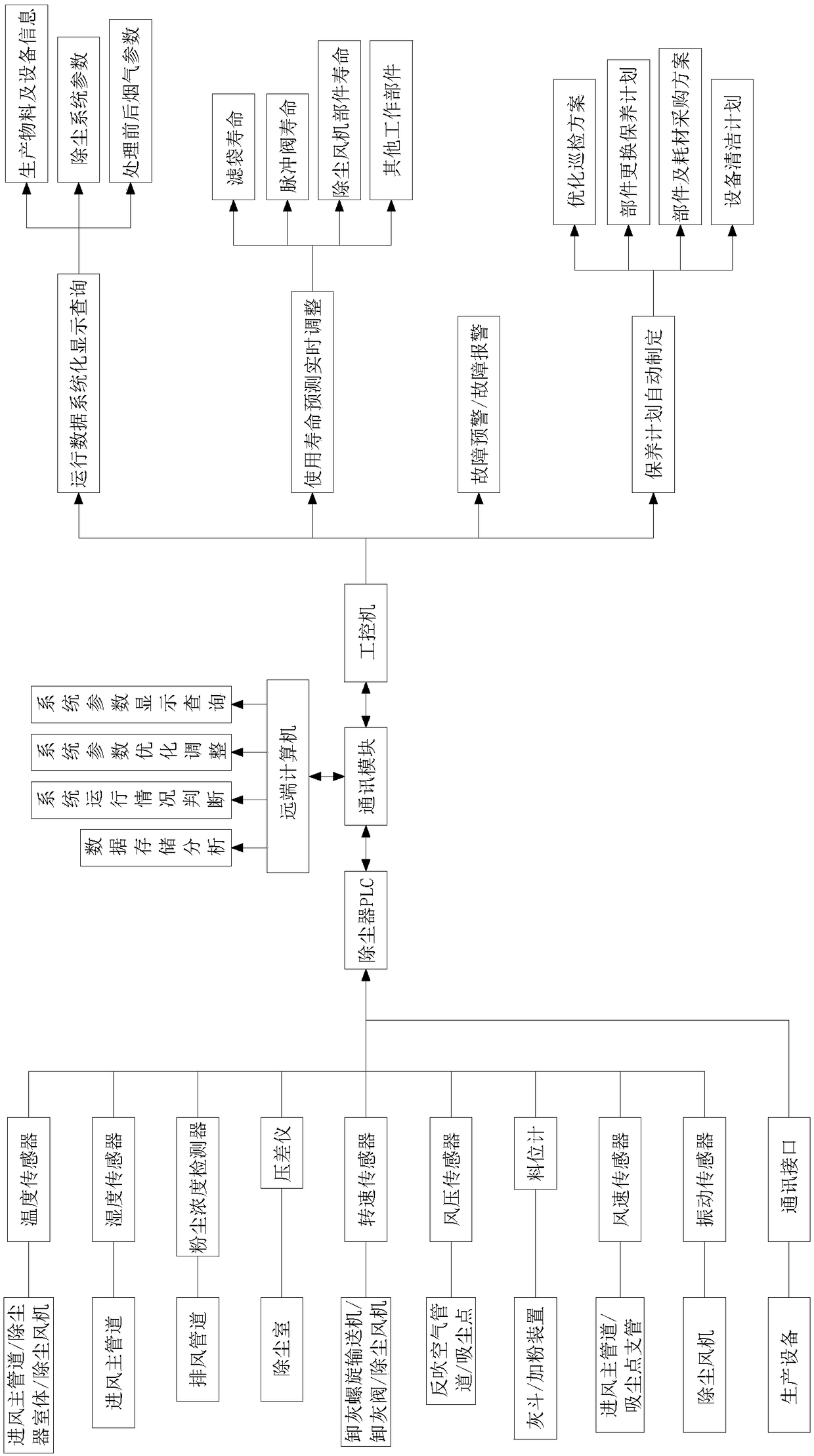

Deduster intelligent maintenance system and maintenance method

InactiveCN108549335AOptimize inspection planReduce the frequency of spot checksTechnology managementTotal factory controlComputer moduleData acquisition

The invention discloses a deduster intelligent maintenance system comprising a data acquisition module, a communication module, an industrial control computer and a far-end computer; the data acquisition module is connected each work part of the deduster, used for gathering work state data of the work parts, and transmitting the gathered work state data to the industrial control computer and the far-end computer via the communication module. The invention also discloses a deduster intelligent maintenance method comprising the steps of predicting service lives of the work parts and making maintenance plans. The deduster intelligent maintenance system and method are high in intelligent level, more comprehensive and reliable in maintenance and analysis, fast and accurate in responses on problems, can realize scientific prevention and maintenance of the deduster, can improve the deduster reliability, can prolong the deduster service life, can make reasonable maintenance plans, are more effectively in maintenance works, and timely and accurate in consumable purchases.

Owner:尼欧迪克(青岛)环保科技有限公司

Ground screen comprehensive monitoring and intelligent maintenance system

InactiveCN102412623AParameter adjustmentWill not harmCircuit arrangementsFault locationElectrical resistance and conductanceGeneral Packet Radio Service

The invention discloses a ground screen comprehensive monitoring and intelligent maintenance system. The system is composed of a front-end detector (1), a ground screen comprehensive monitor (2), a rainwater collector (3), an ion supplying device (4), a superior industrial digging machine (5), an electric control water pump (6), an electric control valve (9), a PH (potential of hydrogen) modifier (7) and a ration pool (8), wherein a ground screen and an instrument, the ground screen and monitoring as well as a GPRS (general packet radio service) module are mutually combined, thus whole-screen intellectualized remote monitoring and seamless data transmission are realized, the operating condition of the ground screen is remotely monitored in real time (on a national scale), and the monitoring condition is reported in real time through a prewarning and warning device; and according to the reported monitoring information, an attendant can set parameters for an intellectualized system according to corresponding conditions, comprising setting resistance prewarning, an alarm value and automatic-start regulating equipment.

Owner:吴兴杰 +1

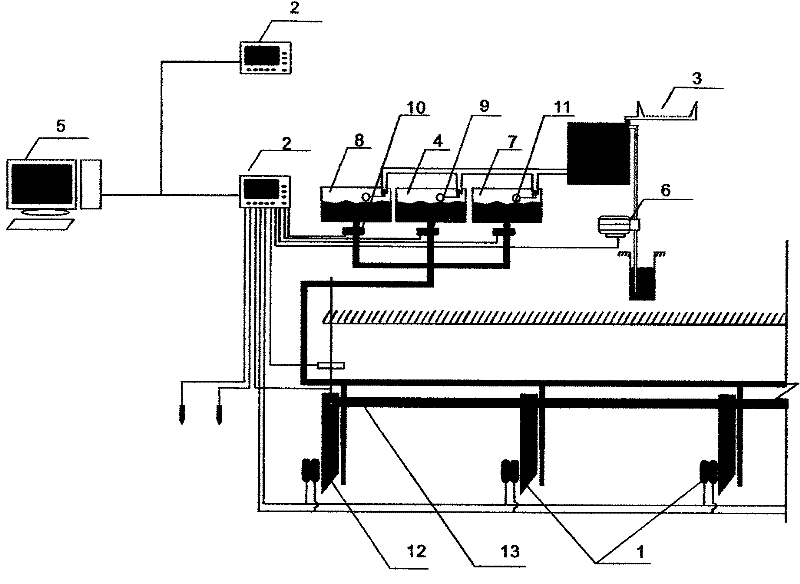

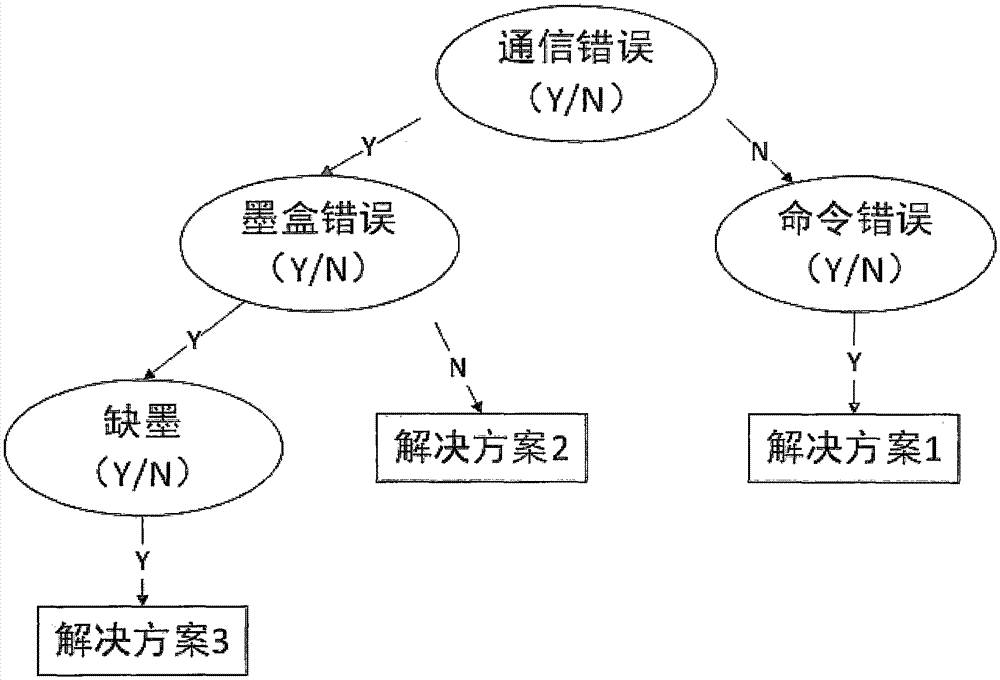

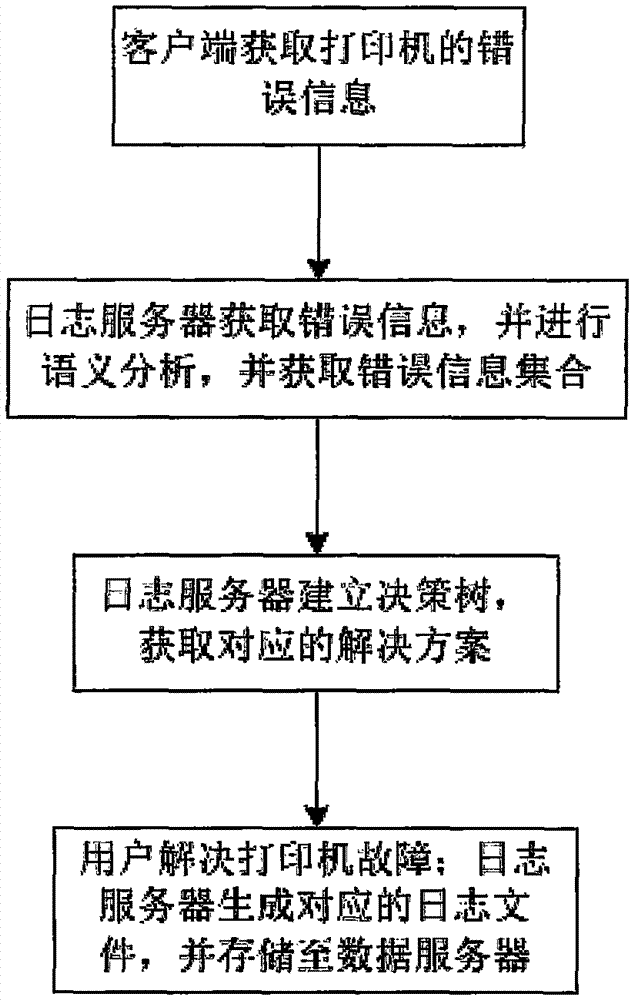

Intelligent maintenance system based on WMI technique and decision tree classification algorithm

InactiveCN106909478AAutomatic analysisAchieve learningSpecial data processing applicationsDetecting faulty hardware using fault dictionariesDatabase serverInternet access

The invention provides an intelligent maintenance system based on a WMI technique and a decision tree classification algorithm. The intelligent maintenance system comprises a client, a control terminal, a log server and a database server, wherein the client and the control terminal achieve data communication with the log server through the Internet, and the log server is in communication connection with the database server. According to the intelligent computer accessory maintenance system based on the WMI technique and the decision tree classification algorithm, an application directly acquires error information of a computer accessory or manual input error information of a user through the WMI technique, the client accesses the server through the Internet, and the server accurately acquires a wrong solution through the decision tree algorithm and feeds the solution to the client; meanwhile, after the user solves a failure of the computer accessory, the server automatically generates a maintenance log file for being used in next-time maintenance, the precise solution is provided for maintenance of the computer accessory, and meanwhile extensive expenditure is saved.

Owner:曹圣航

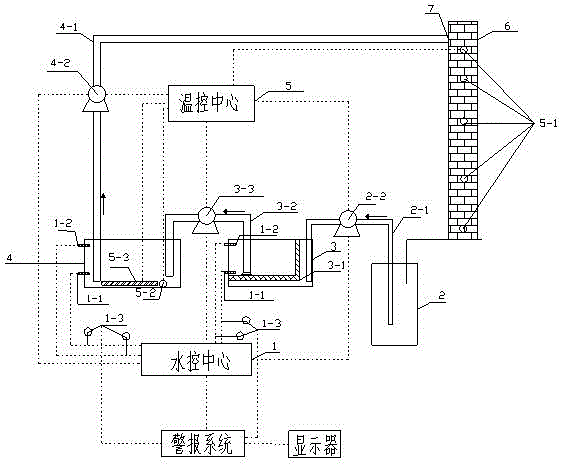

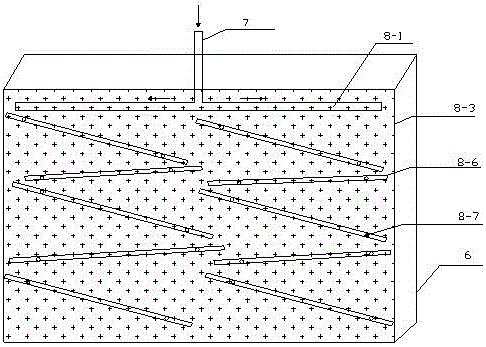

Intelligent maintenance system for concrete outer wall

ActiveCN106368442AImprove thermal conductivityImprove insulation effectBuilding material handlingTemperature controlDisplay device

The invention discloses an intelligent maintenance system for a concrete outer wall. The intelligent maintenance system comprises a water collection tank, a heat-preservation tank, an intelligent water level system, an intelligent temperature control system, an alarm system and a wall maintenance system. The intelligent water level system comprises a water control center, a flow controller and a water level sensor; the intelligent temperature control system comprises a temperature control center, a temperature detection device and a heating device; the alarm system comprises a display and an alarm; and the alarm system is in feedback connection with the temperature control center and the water control center. According to the intelligent maintenance system for the concrete outer wall, intelligent water level control and intelligent temperature control are adopted in the whole course, the labor cost is largely saved, and the outer wall is fully maintained; and the temperature and the flow of maintenance water are adjusted along with the changes of the outer wall temperature, the maintenance quality of the concrete outer wall is improved, the crack risk of the concrete outer wall is reduced, and the durability of a concrete structure is improved.

Owner:WUHAN YUANJING READY MIXED CONCRETE CO LTD

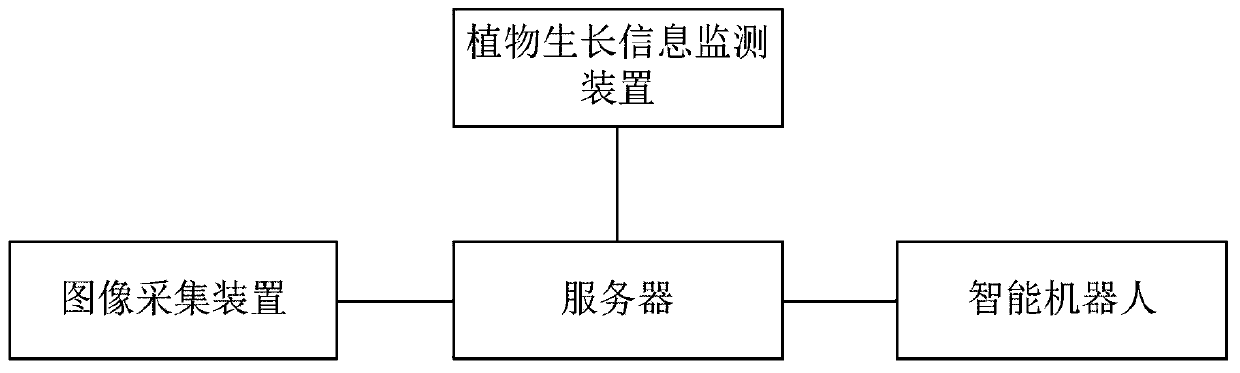

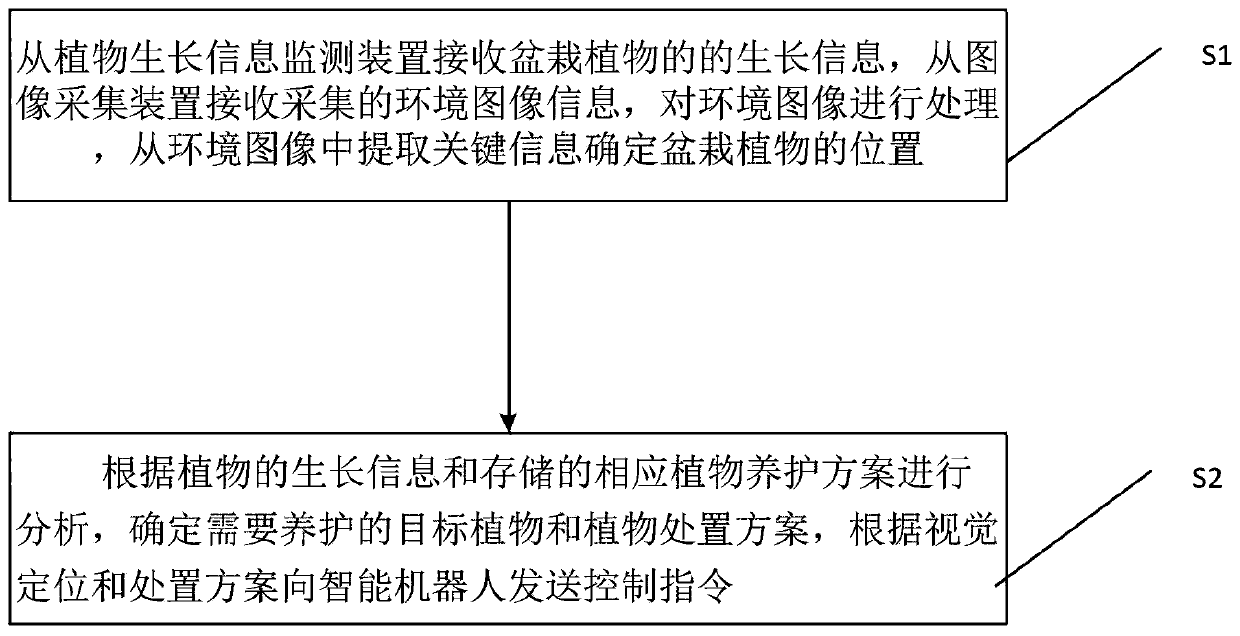

Machine-vision-based intelligent maintenance system of potted plants and data processing method thereof

InactiveCN110199844ARealize automatic monitoringRealize automatic maintenanceMeasurement devicesSelf-acting watering devicesGrowth plantMachine vision

The invention provides a machine-vision-based intelligent maintenance system of potted plants, which comprises a plant growth information monitoring device, an image acquisition device, a server and an intelligent robot. The plant growth information monitoring device is used for acquiring growth information of potted plants; the image acquisition device is used for acquiring ambient image information of the potted plants; the server is intended for processing the received information to obtain plant treatment plans; the intelligent robot is intended for receiving and executing control commandssent by the server. The ambient image information of the vicinity of the potted plants is acquired through the image acquisition device; the growth condition of the potted plants is analyzed by the server according to the growth information and the ambient image information so as to determine target plants to be maintained and plant treatment plans; control commands are sent to the intelligent robot according to visual positioning and the treatment plans; the intelligent robot moves to the target plants for maintenance. The whole process of automatic monitoring and automatic maintenance is achieved; manual workload is reduced.

Owner:QINGDAO UNIV OF SCI & TECH

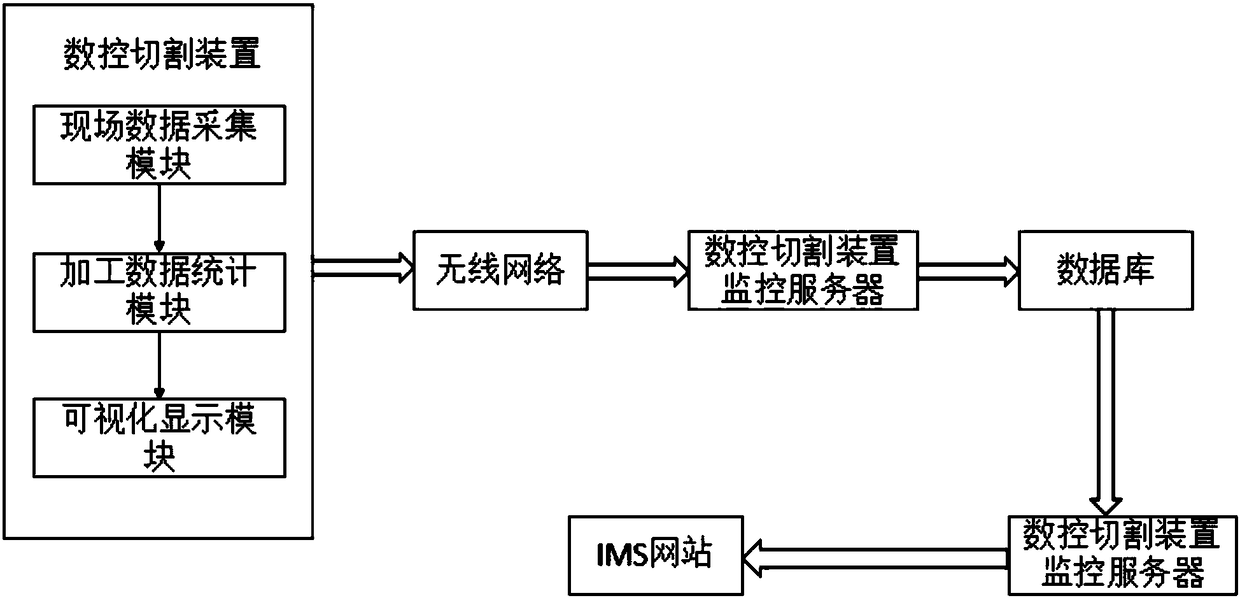

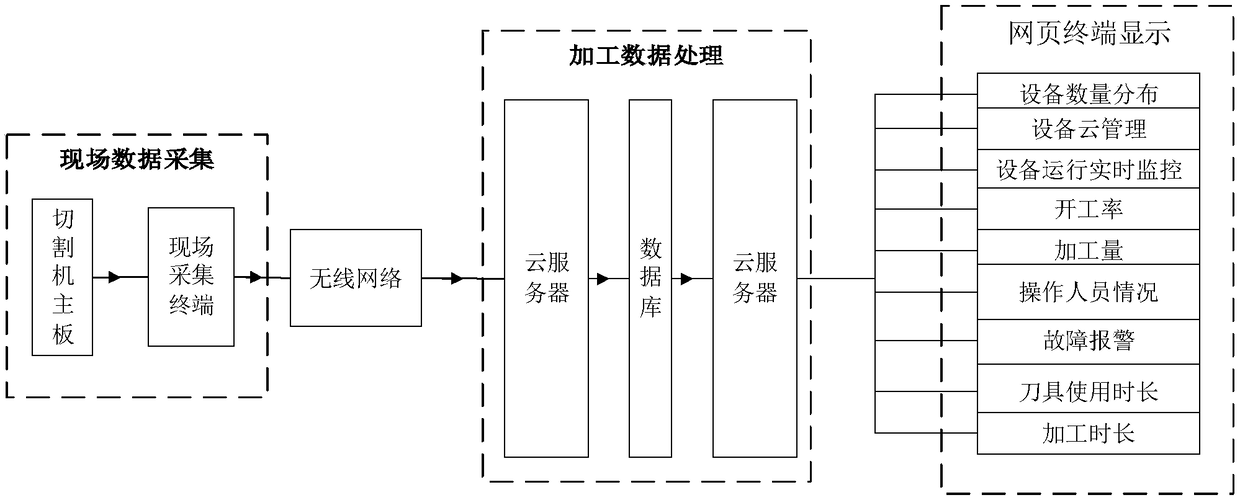

Intelligent maintenance apparatus of flexible material processing equipment

PendingCN108415373AQuality improvementImplementation track recordProgramme controlComputer controlNumerical controlReal-time data

The invention discloses an intelligent maintenance apparatus of flexible material processing equipment, comprising a numerical control cutting device, a numerical control cutting device monitoring server, a database, and an intelligent maintenance system (IMS) website; the numerical control cutting device acquires equipment processing real-time data and field state data by a cutting device mainboard through a field embedded device, and transmits the acquired processing equipment data to the numerical control cutting device monitoring server; the numerical control cutting device monitoring server is used for processing and analyzing the acquired data to provide processing equipment operation monitoring and core parameter statistics; the database is used for storing processing equipment operation monitoring parameters, and transmitting the processing parameters to the IMS website through the numerical control cutting device monitoring server; the IMS website judges, in real time, workingcondition of the numerical control cutting device and working efficiency and quality of working staff of the numerical control cutting device according to the received processing equipment operationdata.

Owner:FOSHAN SHIKE INTELLIGENT TECH CO LTD +1

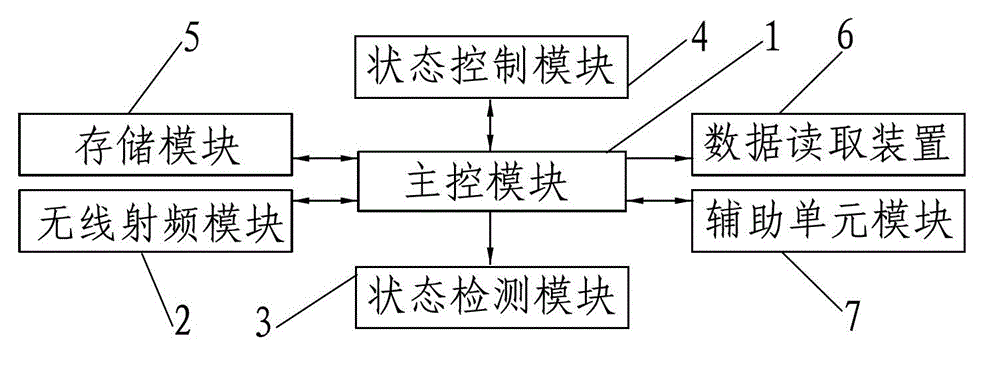

Refrigeration device intelligent maintenance system based on radio frequency technology

ActiveCN102981476AAvoid lostEfficient and correct assemblyRefrigeration safety arrangementTotal factory controlIdentity recognitionComputer module

The invention relates to the technical field of refrigeration device control, in particular to a refrigeration device intelligent maintenance system based on radio frequency technology. The refrigeration device intelligent maintenance system based on the radio frequency technology comprises a master control module, a radio frequency module, a state monitoring module and a state control module, wherein the radio frequency module, the state monitoring module and the state control module are connected with the master control module in action mode. In a production process, the radio frequency module has an identity recognition function, and a manual radio frequency reader-writer reads assembly information in the radio frequency module. If the information is unmatched, and the radio frequency module returns to a station starting stage to perform inspection and verification until assembly is correct. When a refrigeration device product is operated, the state monitoring module acquires operation information of a refrigeration device and sends the operation information to the master control module, faults of the device can be found in real time or in advance through analysis processing of the master control module, the faults can be found in time, and loss is avoided. In a whole life cycle, the radio frequency reader-writer reads the radio frequency module in the system, the information is uploaded to a feed-back system of a manufacturer, and follow-up service of sold products is performed well.

Owner:DG HUST MFG ENG RES INST +2

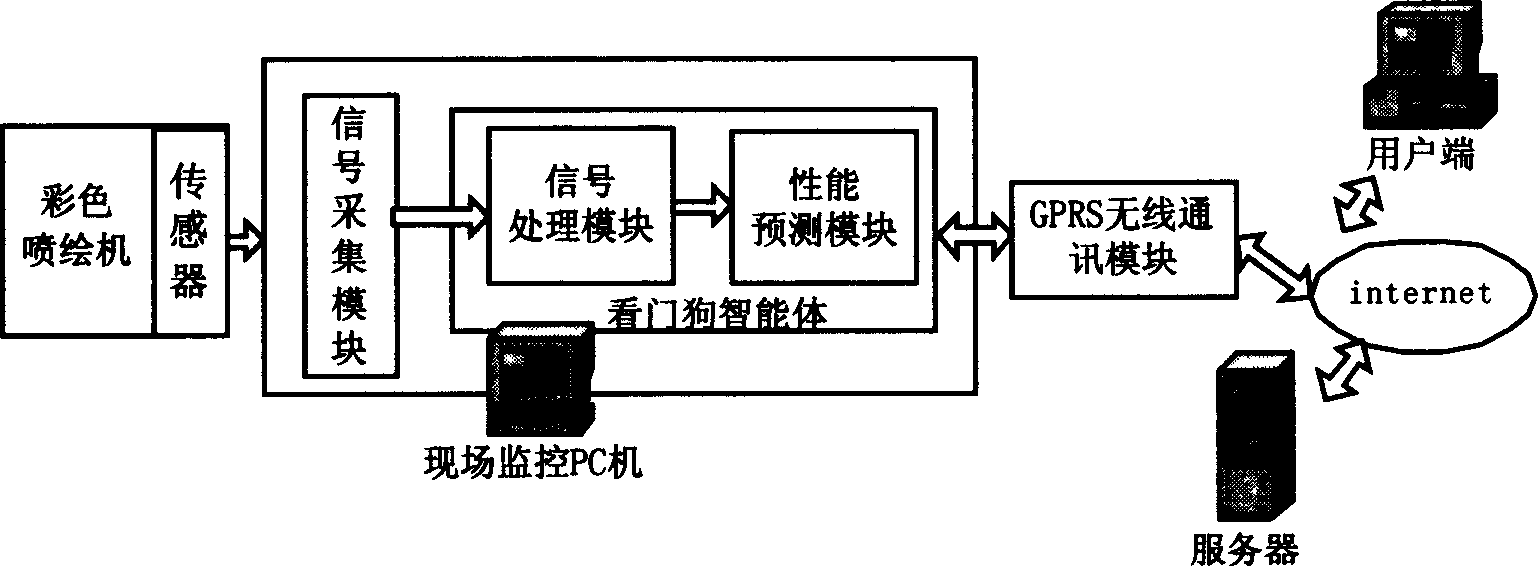

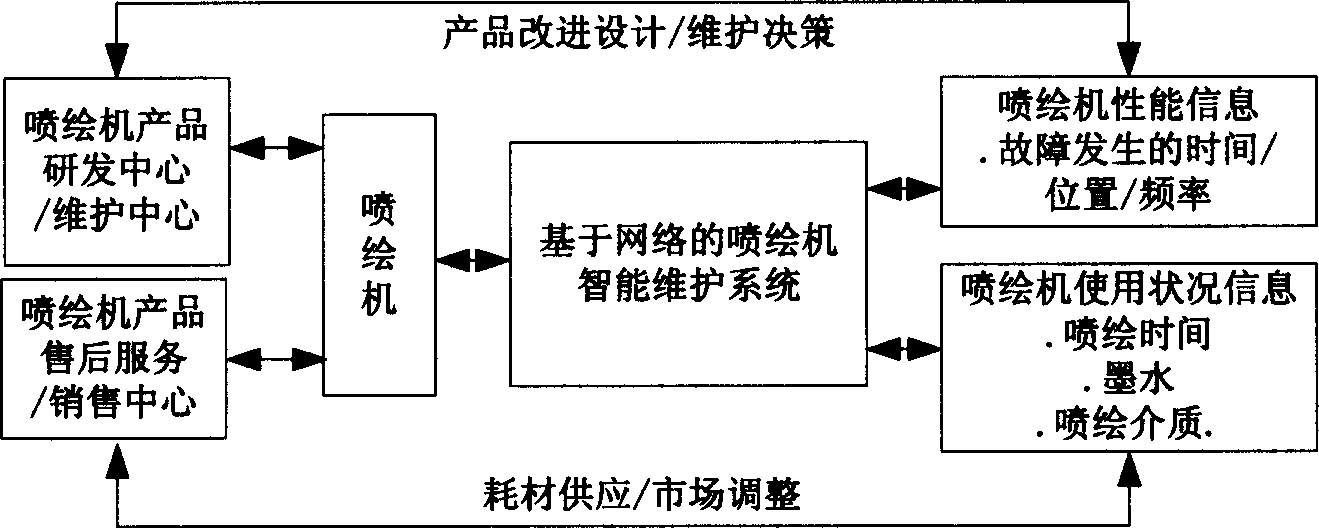

Intelligent maintenance system of colour spraying draught machine based on network

InactiveCN1564557ARealize intelligent maintenanceAvoid failureSubstation remote connection/disconnectionData informationPrincipal component analysis

The system comprises: the module for collection of signals from sensor, the signal process module, the performance prediction module, the wireless communication module and the sever. The module for collection of signal from sensor takes charge of collecting signals from multi-path sensor. The signal process module analyzes the signals from sensor and extracts the feature of time-domain or frequency-domain. The performance prediction module first uses the principle component analysis method to extract the feature vector presenting the performance of large format color inkjet printer, then uses neural net method to make data fusion of the feature vector, and to predict and recognize the state of the large format color inkjet printer. The wireless communication module sends the data information to the database in the server by using GPRS wireless transmission mode.

Owner:SHANGHAI JIAO TONG UNIV

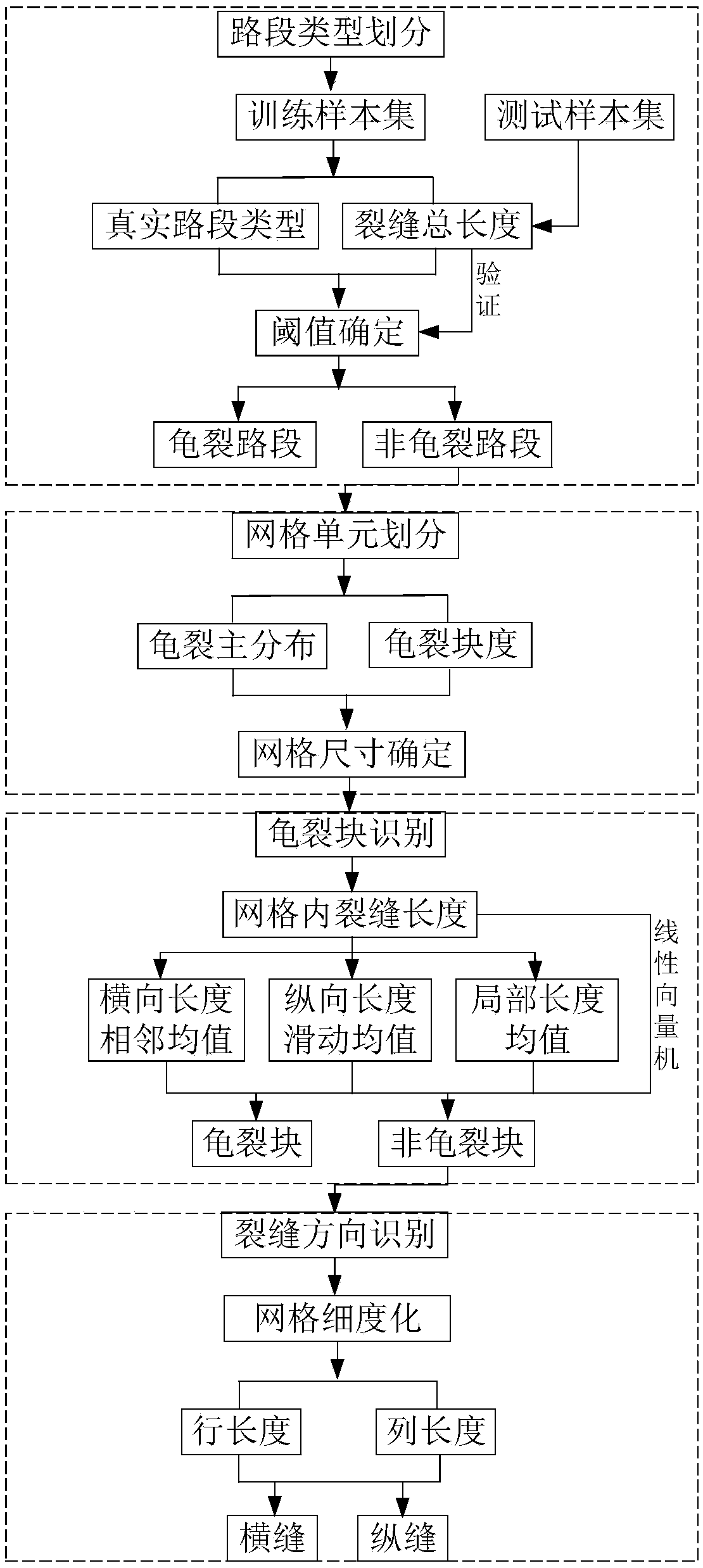

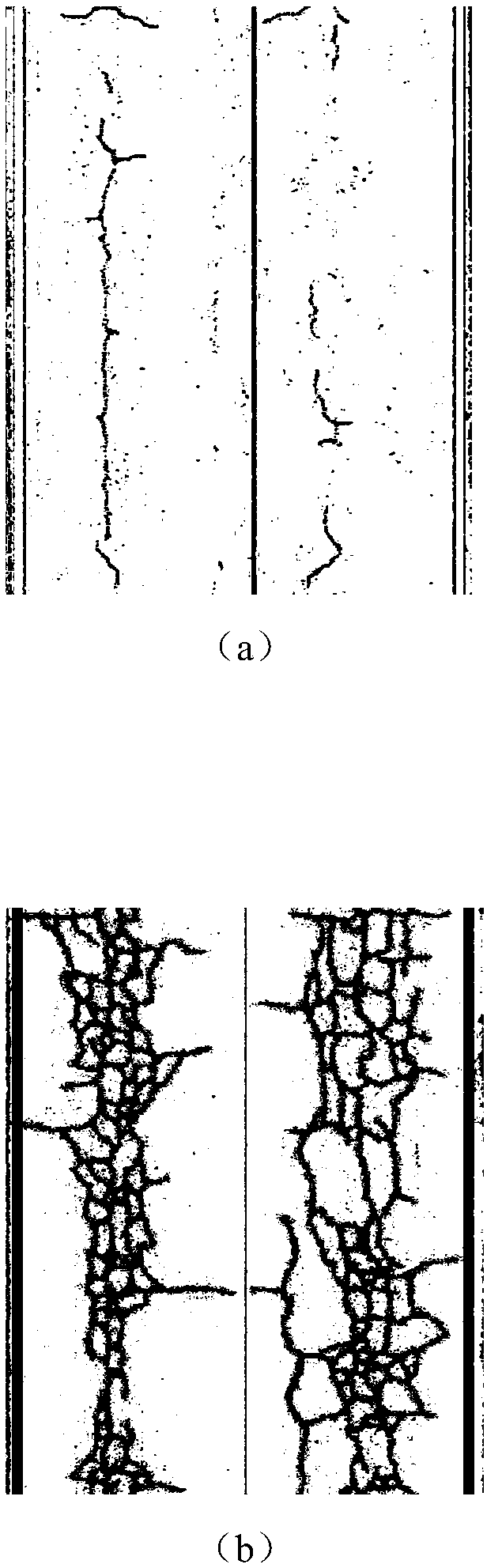

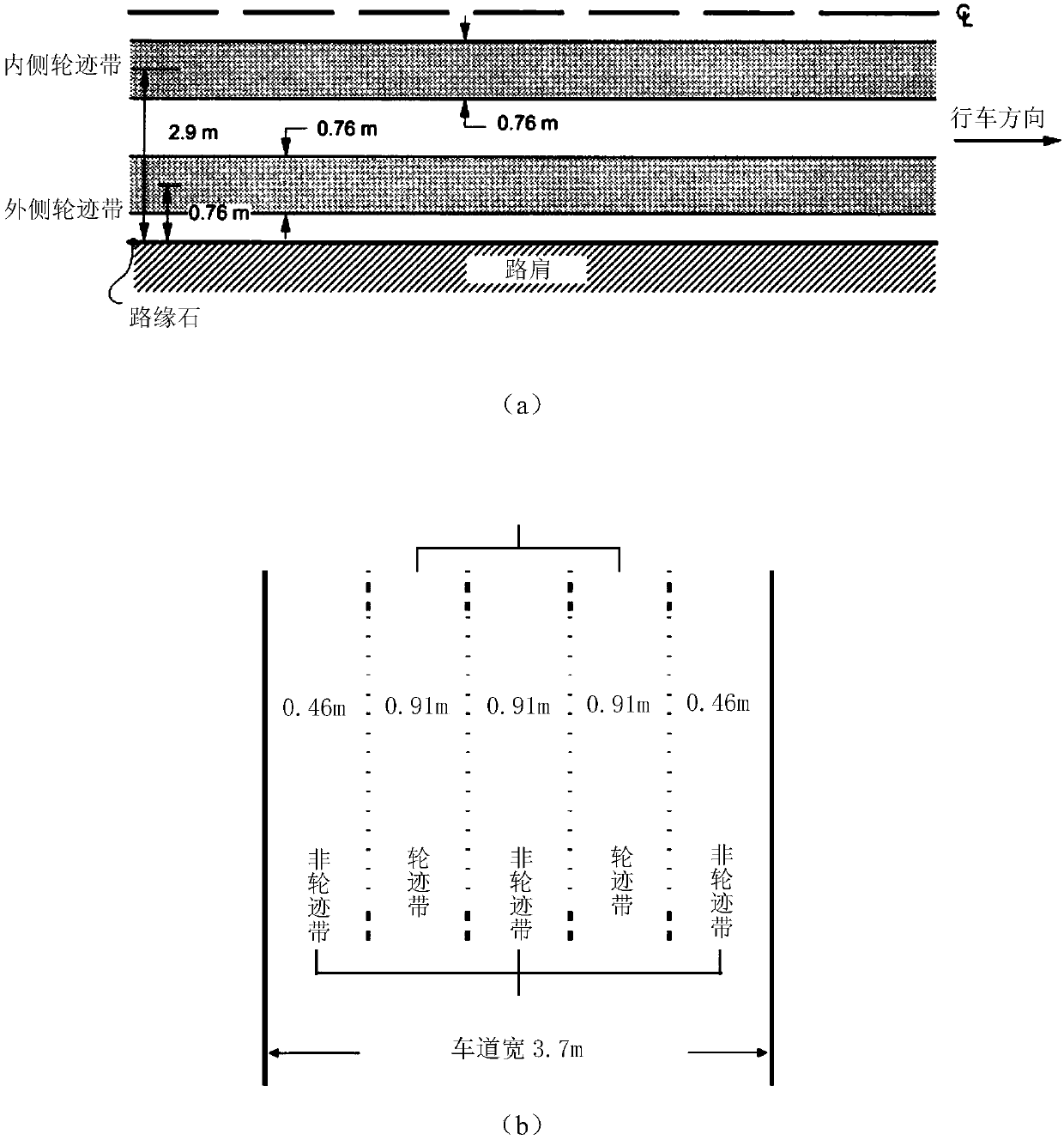

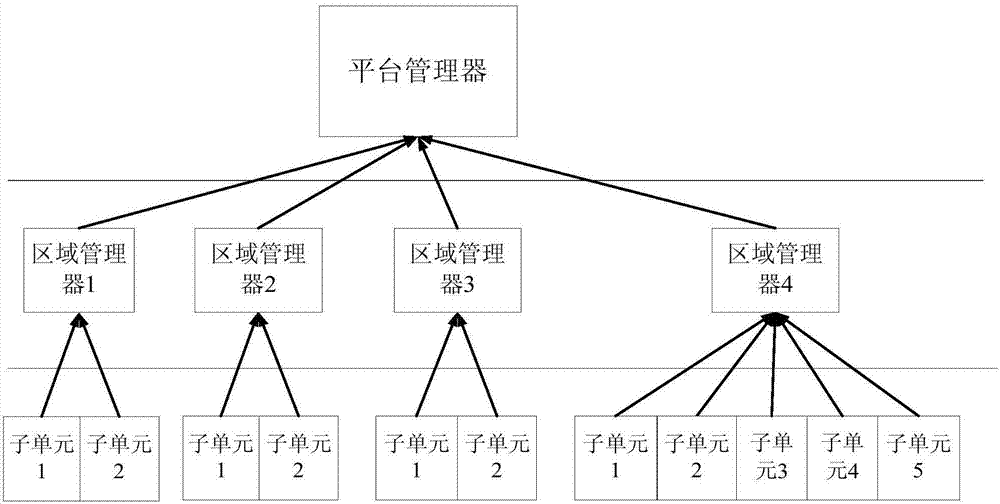

Automatic recognition method of bituminous pavement crack type

ActiveCN108166362AOptically investigating flaws/contaminationRoads maintainenceRoad surfaceComputer vision

The invention discloses an automatic recognition method of a bituminous pavement crack type. Firstly, crack information is artificially measured, crack data are obtained through 3D detection, after chap blocks and crack directions are divided into respective mesh sizes, characteristic indexes of unit meshes are calculated, secondly, the direction of each crack is determined according to the sum ofthe crack lengths in each row and each line in the meshes, and finally distribution of chaps, transverse joints and longitudinal joints in each unit road segment are calculated. A set of systematizedtheories are provided for determination of the chap degree and judgment and determination of the crack directions through a specific quantization method, and a basic procedure is provided for automatic recognition of the crack type; and meanwhile, the procedure lays a foundation for further discussion of crack failure characteristic information and the development law and has great significance in scientific maintenance of a joint filling and sealing road segment, and development of an intelligent maintenance system through the three-dimensional laser detection technology is further facilitated.

Owner:CHANGAN UNIV

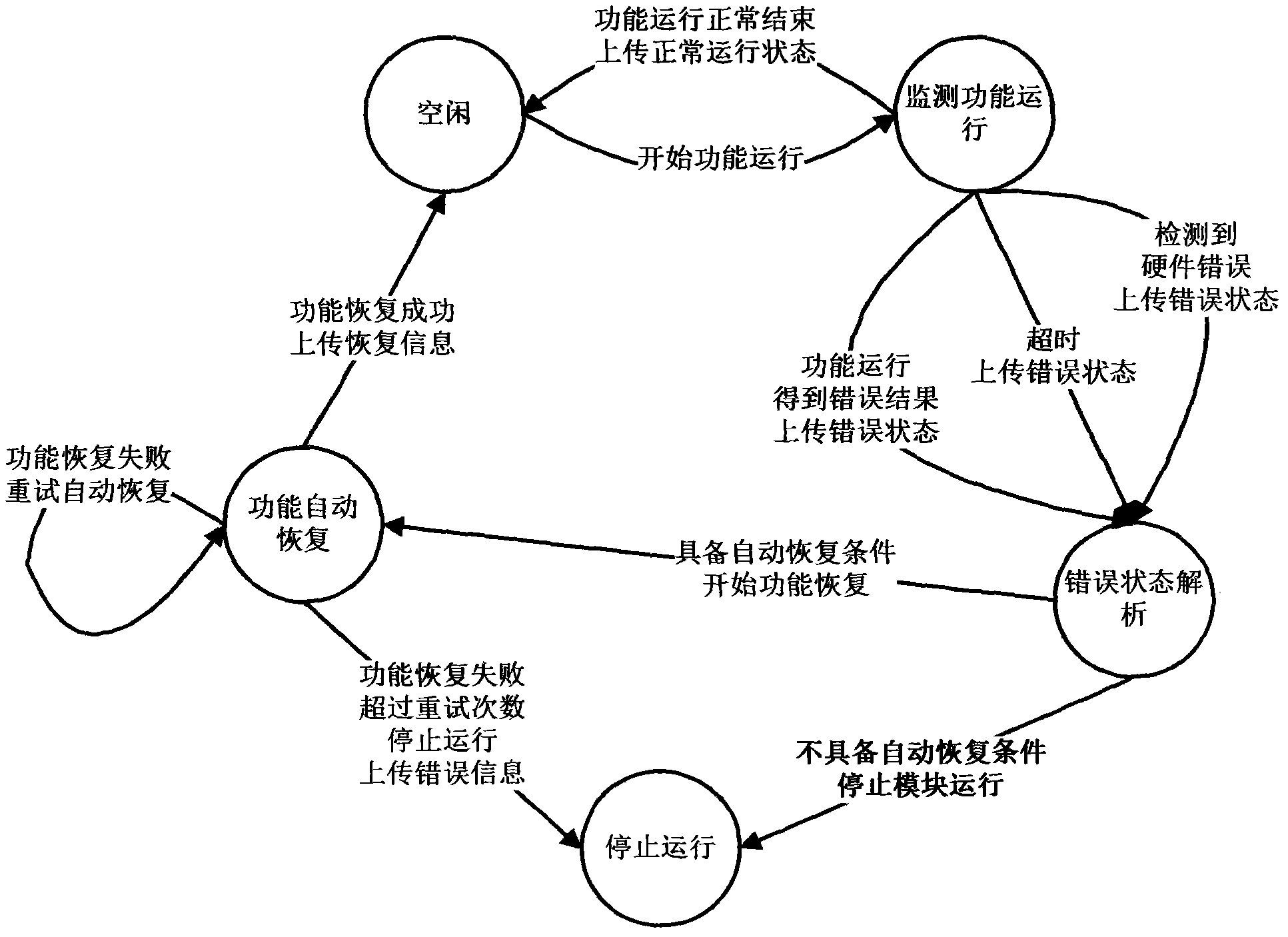

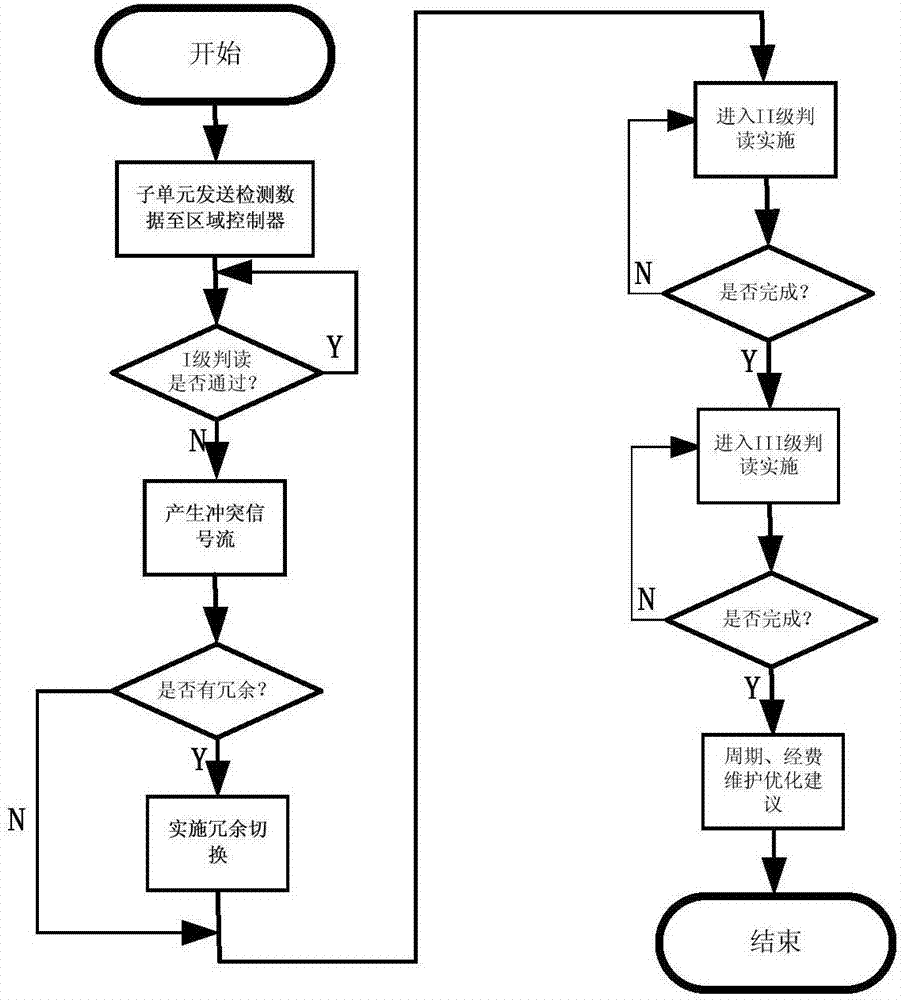

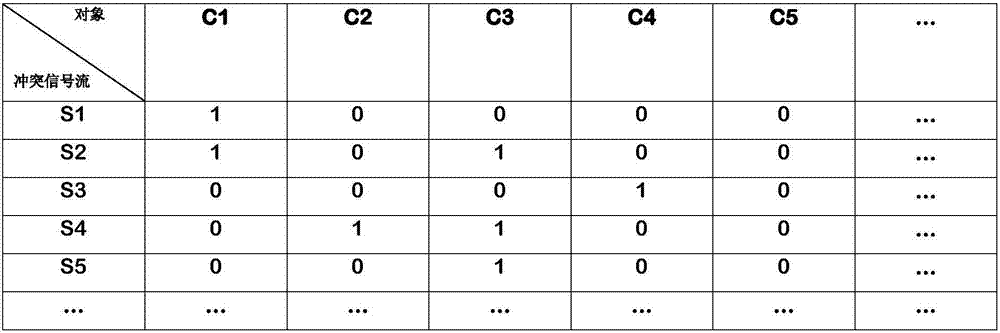

Autonomous failure diagnosing and intelligent maintenance system and method for carrier capable of being used repeatedly

ActiveCN107963240ALay the foundation of independent fault diagnosis technologyReduce workloadCosmonautic vehiclesCosmonautic partsIntelligent maintenance systemSpacecraft

The invention relates to an autonomous failure diagnosing and intelligent maintenance system and method for a carrier capable of being used repeatedly based on a plurality of signal flows, and belongsto the technical field of spacecraft failure diagnosis and maintenance security. According to a failure diagnosis result, a maintenance method with the period and the expenditure being optimized is intelligently reckoned, intelligent maintenance is achieved, accordingly the problems that ''a manual loop'' for diagnosing failures of the carrier capable of being used repeatedly is large in participation quantity, has a certain hysteretic nature, long in maintenance period and high in cost are solved, rapid online failure diagnosis and intelligent maintenance of the carrier capable of being usedrepeatedly are achieved, and the autonomous failure diagnosing and intelligent maintenance system and method are beneficial for providing technical support for achieving rapid and repeated usage of the carrier.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

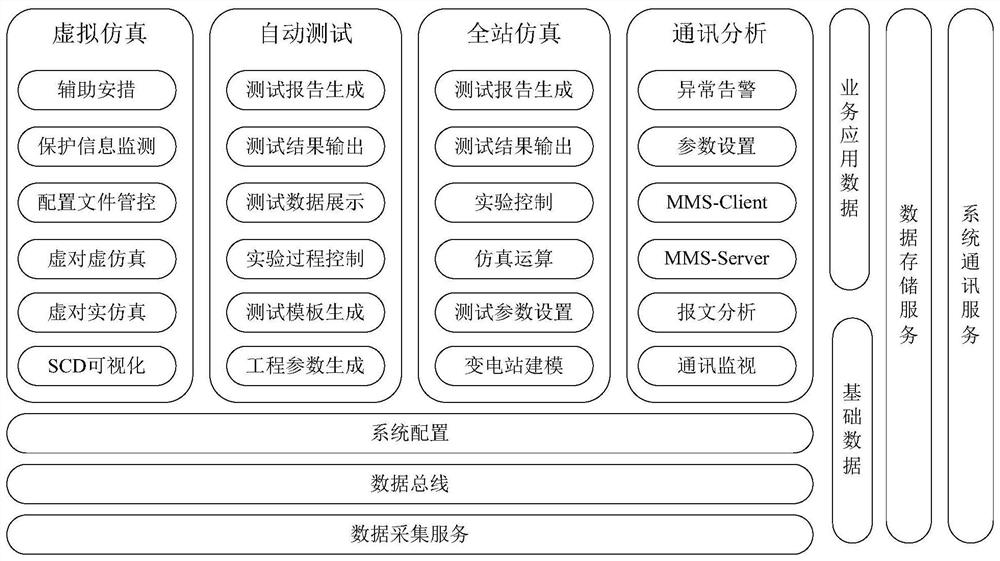

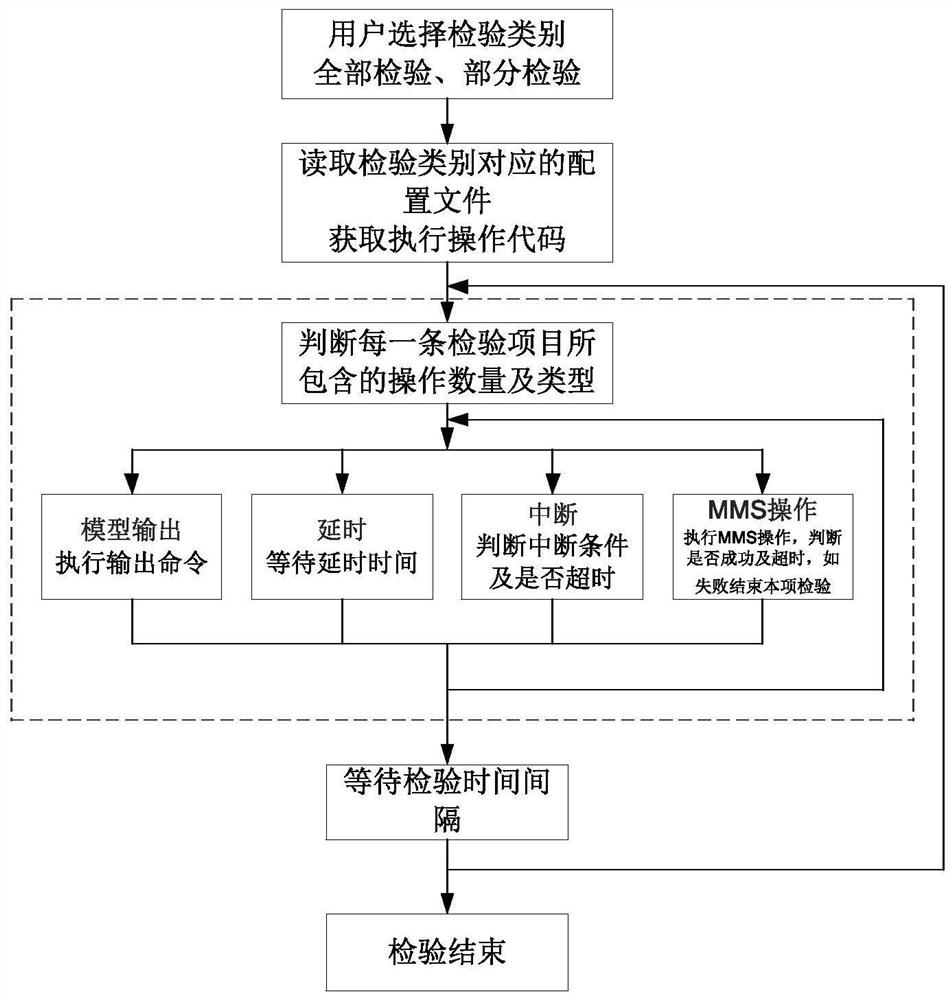

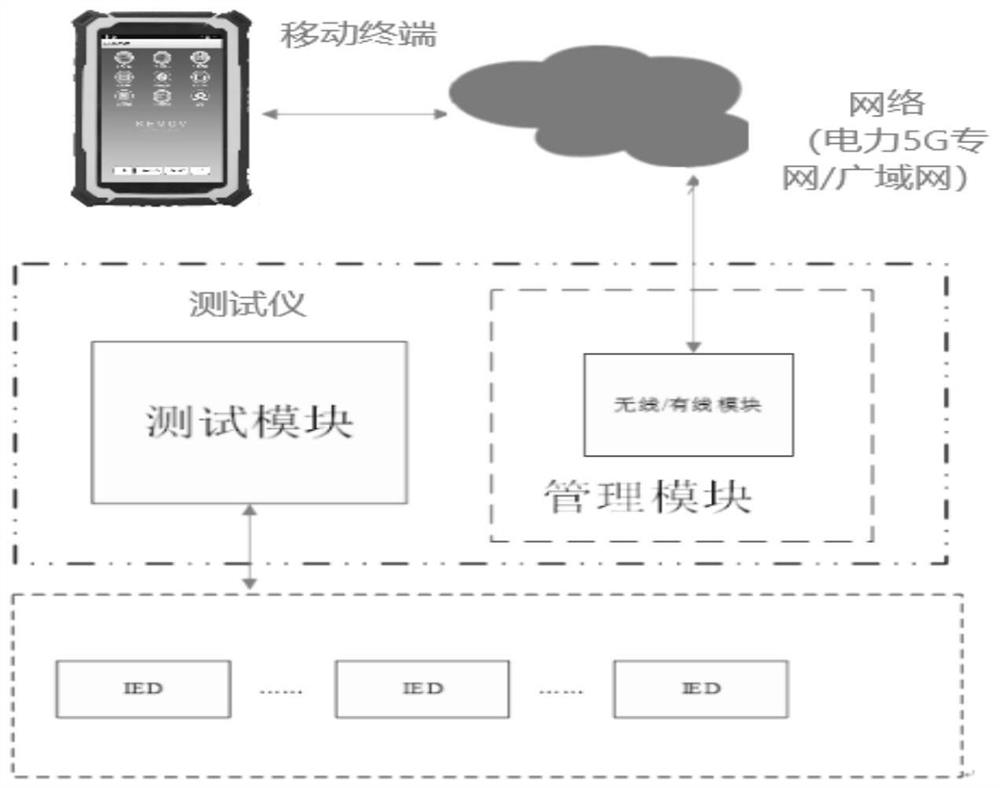

Factory-like intelligent maintenance system for secondary equipment of intelligent substation

InactiveCN112711829AImprove carrying capacityImprove operation and maintenance efficiencyData processing applicationsCircuit arrangementsData displayField tests

The invention provides an intelligent substation secondary equipment factory intelligent maintenance system comprising a virtual simulation module which is used for providing SCD visualization, virtual-to-real simulation test, virtual-to-virtual simulation test, configuration file management and control, protection information monitoring and auxiliary safety measure functions; the automatic test module is used for automatic test report generation, automatic test result output, automatic test data display, experimental process control, test template generation and engineering parameter generation; the full-station simulation module is used for generating a simulation test report, outputting a simulation test result, carrying out experiment control, carrying out simulation operation, setting test parameters and carrying out substation modeling; the communication analysis module is used for abnormal alarm, parameter setting, MMSClient, MMSServer, message analysis and communication monitoring; and the public service part is used for realizing data sharing and high integration of the system. Operation and maintenance efficiency can be improved, power grid operation efficiency and reliability are improved, debugging and testing efficiency is improved, and remote synchronous visualization of field testing is achieved.

Owner:AKSU POWER SUPPLY COMPANY STATE GRID XINJIANG ELECTRIC POWER +1

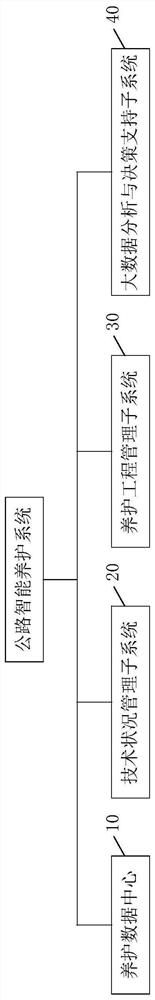

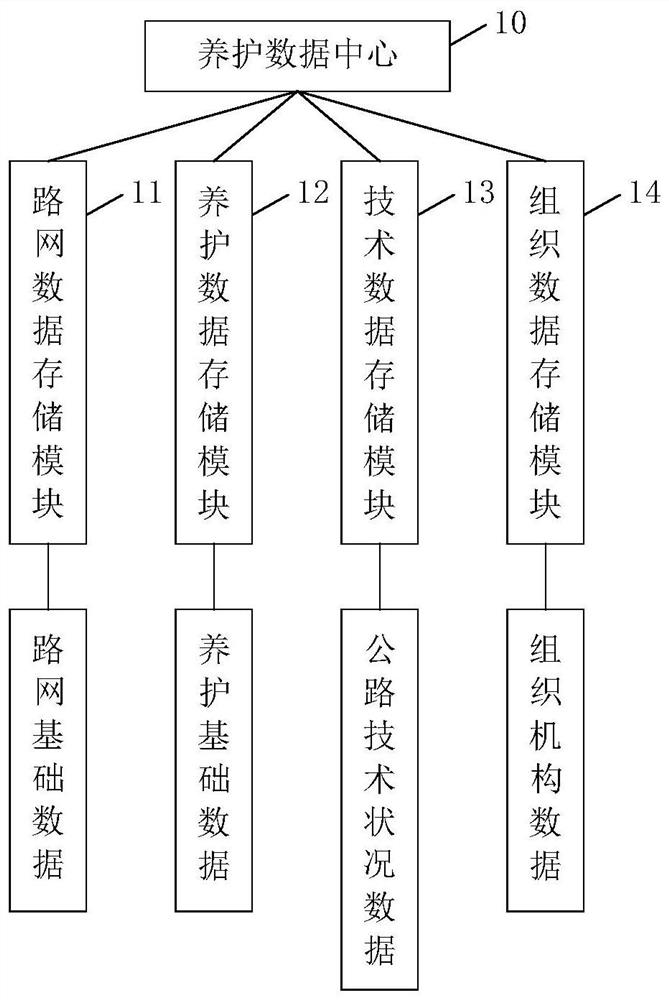

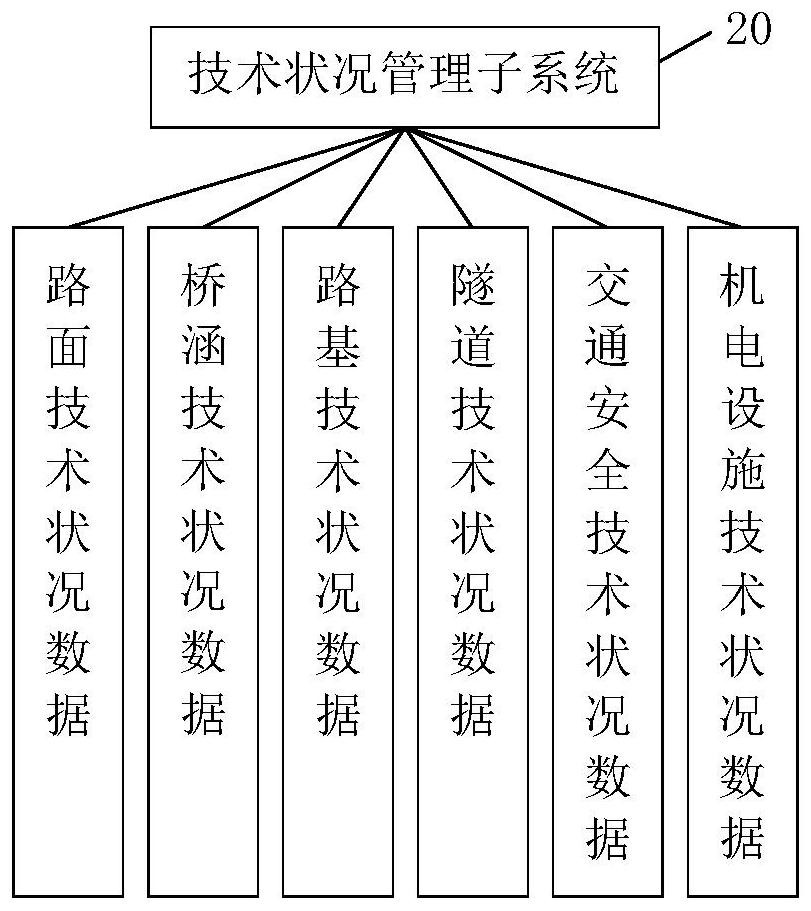

Highway intelligent maintenance system

PendingCN111860896AAchieve sharingReduce redundancyForecastingResourcesData storeIntelligent maintenance system

The invention relates to an intelligent road maintenance system. The system comprises a maintenance data center, a technical condition management subsystem, a maintenance engineering management subsystem and a big data analysis and decision support subsystem; the maintenance data center comprises a road network data storage module used for storing road network basic data. The maintenance data storage module is used for storing maintenance basic data, maintenance disease data and maintenance data, a technical data storage module which is used for storing road technical condition data, and an organization data storage module which is used for storing organization data; wherein the road network basic data, the maintenance basic data and the organization data are associated with one another; the road network basic data, maintenance basic data, highway technical condition data and organization data are stored and managed by the unified maintenance data center and are associated with one another, so an information island phenomenon can be avoided, each unit participating in highway maintenance realizes information sharing, and data redundancy is reduced.

Owner:广东华路交通科技有限公司

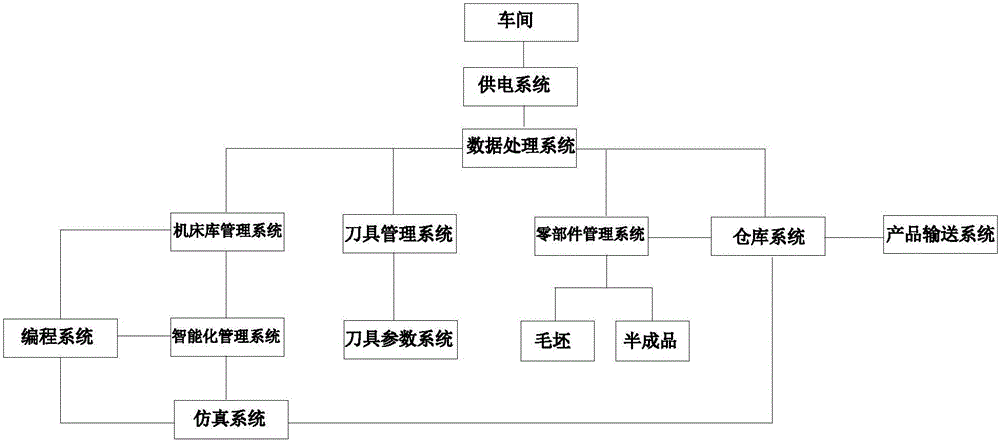

Intelligent workshop management system

InactiveCN106203850AProduction preparation in advanceQuickly grasp online inventoryResourcesLogisticsData processing systemIntelligent management

The invention discloses an intelligent workshop management system including a plurality of machine tool database management systems for managing lathes, a cutter management system for managing machine tool cutters and machine tool clamps, a component management system for managing and machining blanks and semi-finished products, a warehouse for storing and transporting finished products, a data processing system for processing the information of the machine tool database management systems, the cutter management system, the component management system, and the warehouse, an intelligent management system connected with the machine tool database management systems and used for managing the machine tool database management systems, a simulation system for simulating the operation steps of the machine tool database management systems, the intelligent management system, and the warehouse, and a power supply system for supplying power for the intelligent workshop management system. Through the close connection of the system, the problems that the workshop management system in the prior art is not intelligent and is lack of unified management.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com