Deduster intelligent maintenance system and maintenance method

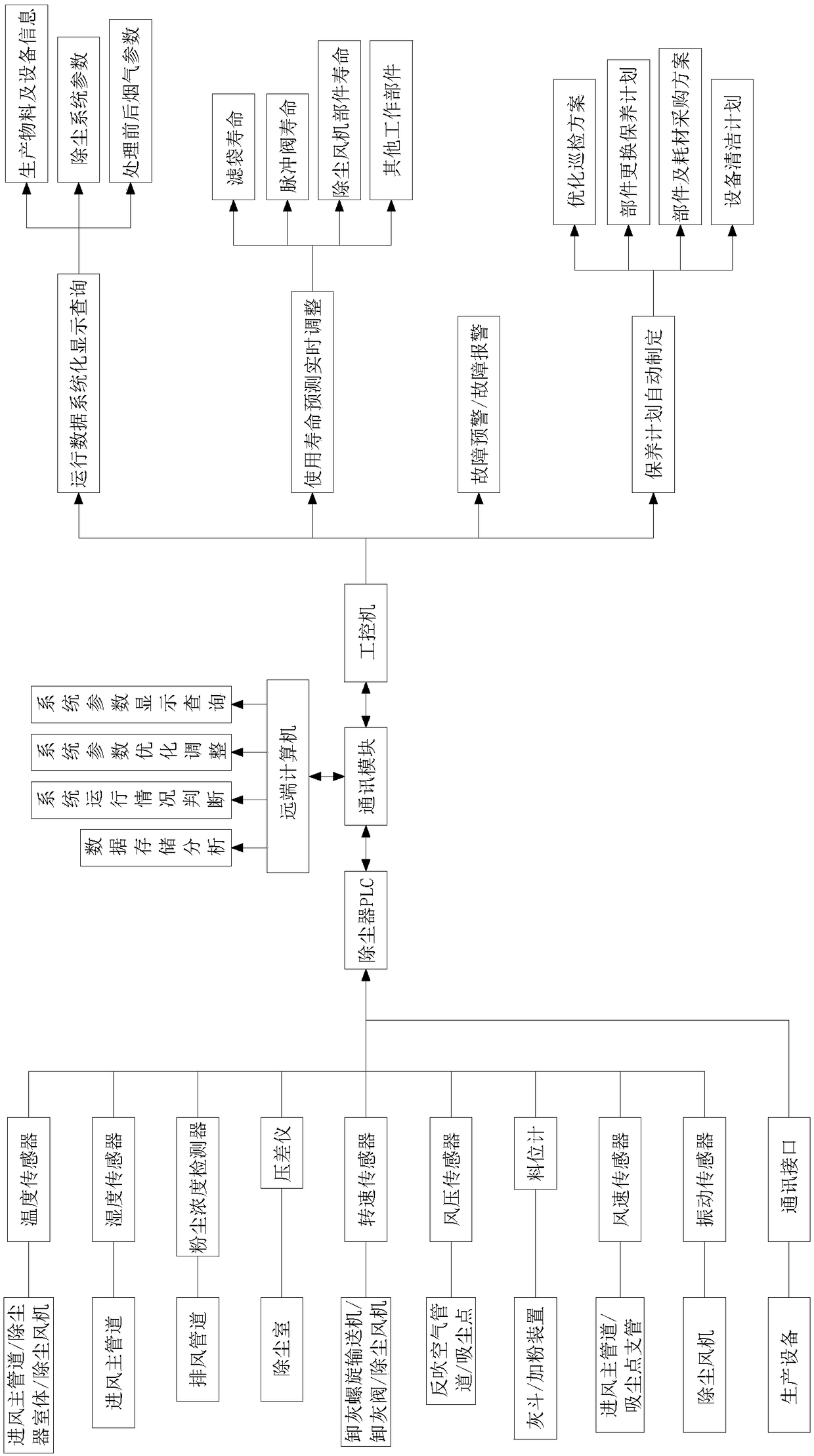

A dust collector and intelligent technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve problems such as unsound equipment maintenance measures, improper equipment maintenance, low efficiency, etc., and achieve scientific prevention and maintenance, and problem response Quick and reduce the effect of error probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Embodiment one: (life prediction of dust collector chamber body filter bag)

[0097] Through the all-round evaluation of the filter bag, the prediction of the life of the filter bag is realized. The specific method is to monitor and control the operation status of the dust collector, comprehensively consider the influence of various factors, and combine with regular inspections to estimate the life of the filter bag more reasonably. Prediction, in order to carry out early warning and replacement in time before the filter bag has a problem.

[0098] First, pre-enter the material information of the filter bag in the industrial computer, including the rated service life of the filter bag, technical agreement, instruction manual, certificate of conformity and factory inspection report, etc.; Operation and maintenance information such as operating parameters, abnormal handling records, start-up and shutdown maintenance, etc. are automatically collected or manually entered. ...

Embodiment 2

[0103] Embodiment two: (life prediction of pulse valve)

[0104] First, pre-enter the material information of the product in the industrial computer, including the rated service life of the pulse valve, technical agreement, instruction manual, certificate of conformity and factory inspection report; at the same time, for the installation of the pulse valve, compressed air pressure, and body pressure Automatic data collection or manual entry of operation and maintenance information such as faults, daily operating parameters, abnormal handling records, start-up and shutdown maintenance, etc.

[0105] Predicted remaining lifetime T of pulse valve at first use 0 =(Rated use times×Comprehensive life factor R 0 ) / Average times of use per day; where, R=R t × R p , R t is the compressed air temperature life coefficient, R p Parameters such as compressed air pressure life coefficient, compressed air temperature, compressed air pressure, and pulse valve action times are collected o...

Embodiment 3

[0109] Embodiment three: (formulation of filter bag maintenance plan)

[0110] The formulation of filter bag maintenance plan mainly includes early warning of filter bag replacement, automatic formulation of regular inspection plan, inventory status and procurement plan.

[0111] First, set a warning time T in advance through the industrial computer 警 , the filter bag predicts the remaining service life T 剩 ≤Warning time T 警 , the system will issue an early warning message to remind the staff to detect and replace the filter bag in advance.

[0112] The automatic formulation of the regular inspection plan means that under normal circumstances, the filter bag needs to be randomly inspected every 1-2 months, and the system will make judgments based on the previous operating parameters. If the parameters are normal and the equipment is running well, the sampling interval will be extended; if the parameters are abnormal on all sides, the sampling interval will be shortened. If...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com