Crane remote monitoring and intelligent maintenance system based on IOT and DSP

A technology of remote monitoring and intelligent maintenance, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as safety, shutdown costs, rising maintenance costs, timing methods that cannot be used by cranes, and equipment that is prone to failure. Achieve the effects of high floating-point operation precision, rich peripherals, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, preferred embodiments of the present invention are given in conjunction with the drawings to illustrate the technical solutions of the present invention in detail.

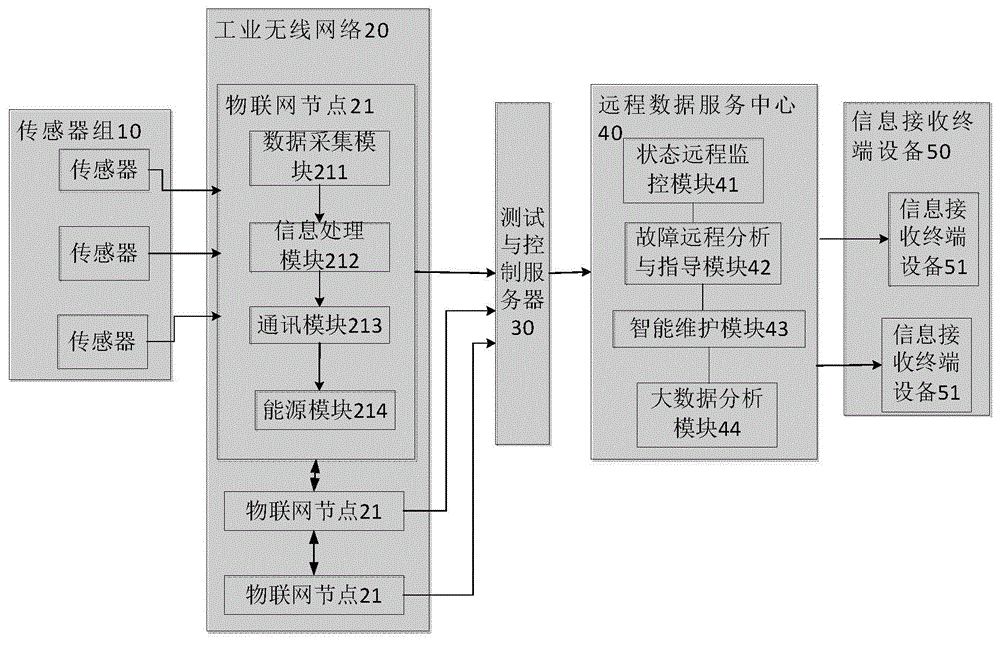

[0012] Such as figure 1 As shown, the crane remote monitoring and intelligent maintenance system based on the Internet of Things and DSP of the present invention is composed of a sensor group 10, an industrial wireless network 20, a test and control server 30, a remote data service center 40, and an information receiving terminal device 50 connected in sequence.

[0013] The sensor group 10 includes electrical sensors, optical sensors, magnetic sensors, acoustic sensors, mechanical sensors, etc., and these sensor signals are uniformly converted into electrical signals so that the data acquisition module 211 in the IoT node can perform A / D conversion.

[0014] The industrial wireless network 20 is composed of multiple IoT nodes 21. The IoT nodes include a data collection module 211, an information proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com