Remote intelligent maintenance system for direct current power supply of transformer substation and application of remote intelligent maintenance system

A DC power supply and intelligent maintenance technology, applied in battery circuit devices, information technology support systems, collectors, etc., can solve problems such as not suitable for substation use, high cost of VMS and BMS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] Specific implementation methods: the present application is not limited by the following examples, and the specific implementation manners can be determined according to the technical solutions of the application and actual conditions.

Embodiment

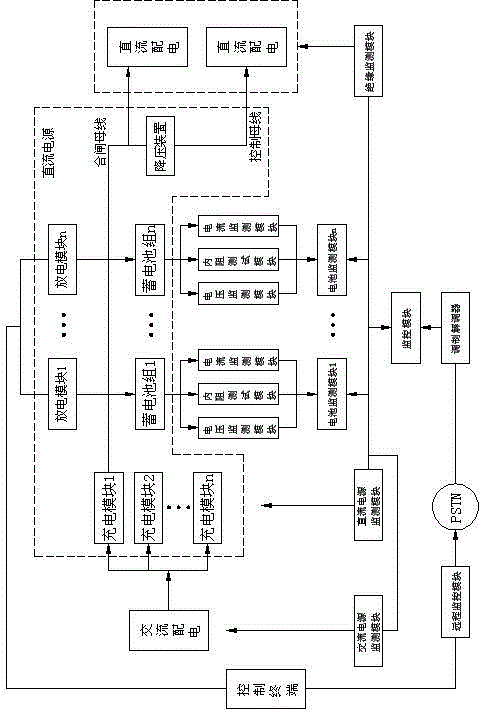

[0025] Example: such as figure 1 As shown, the remote intelligent maintenance system for substation DC power supply includes a DC power supply, the input terminal of the DC power supply is connected to the AC power distribution terminal, the output terminal of the DC power supply is connected to the DC power distribution terminal, and the DC power supply includes charging and discharging modules 1— n, the charging and discharging modules 1-n are respectively connected with the battery pack 1-n, and the battery pack 1-n is connected with the battery monitoring module 1-n, and the battery monitoring module includes a voltage monitoring module, a circuit monitoring module and an internal resistance testing module , the battery monitoring module is followed by a monitoring module, and the monitoring module is connected to the public switched telephone network PSTN through a modem and connected to the control terminal.

[0026] The function of the battery pack is mainly to provide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com