Adjustable ultralow-frequency vertical eddy current tuned mass damper (TMD)

A tuned mass damping, ultra-low frequency technology, applied in protective buildings/shelters, building components, anti-vibration, etc., can solve the problems of reducing TMD, reducing static elongation of springs, small dynamic stiffness, etc., to improve vibration reduction effect, improve energy consumption efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

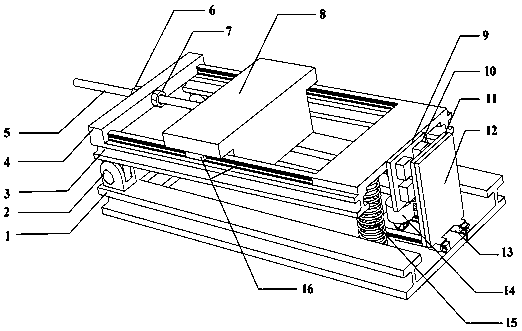

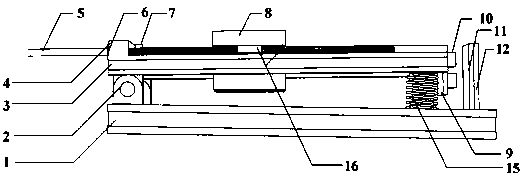

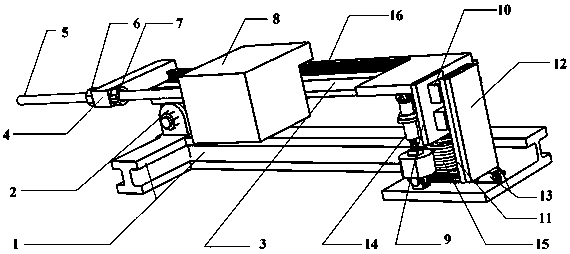

[0027] The present invention will be further clarified below in conjunction with the drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer" "Respectively refers to the direction toward or away from the geometric center of a particular component.

[0028] Such as Figure 1-3 As shown, an adjustable ultra-low frequency vertical eddy current tuned mass damper of this embodiment includes a base 1, a fixed hinge 2, a rigid rod 3, a rigid rod beam 4, a mass position adjustment rod 5, and a first nut 6. The second nut 7, the mass 8, the permanent magnet fixing plate 9, the permanent magnet group 10, the conductor copper plate 11, the magnetic steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com