Vibration damper for boom system, boom system and pumping machinery

The technology of a vibration damping device and a boom is applied to the vibration damping device of the boom system and the field of pumping machinery, which can solve the problems of complex movement mode and structure, and unsatisfactory vibration damping effect, so as to offset the initial vibration and ensure the stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

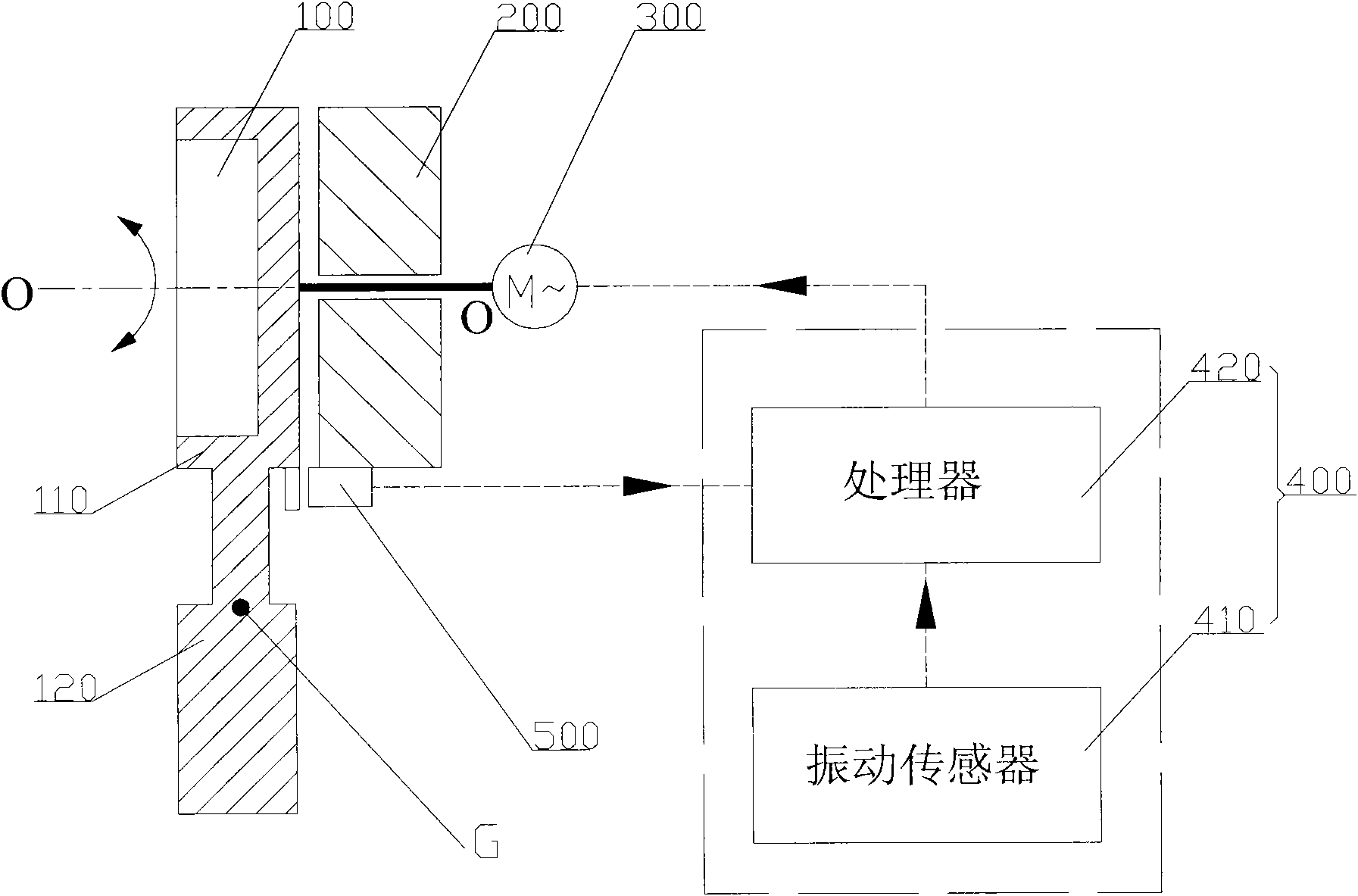

[0039] The vibration damping device provided in Embodiment 1 includes a rotating body 100, a main body 200, a speed-regulating motor 300 and a control mechanism 400; the main body 200 is installed on the jib system, specifically, it can be installed on the corresponding section arm of the jib system; the rotating body 100 It is rotatably installed on the body 200, so that the rotating body 100 can rotate around the rotation axis O-O relative to the body 200; the speed regulating motor 300 is relatively fixed with the body 200, and its output shaft is connected with the rotating body 100. When the speed motor 300 rotates, it can drive the rotating body 100 to rotate around the rotation axis O-O relative to the main body 200 . At the same time, the center of gravity G of the rotating body 100 deviates from the rotating axis O-O to form a suitable eccentricity; in this way, during the rotation of the rotating body 100, a pulsating impact will be generated on the main body 200, res...

Embodiment 2

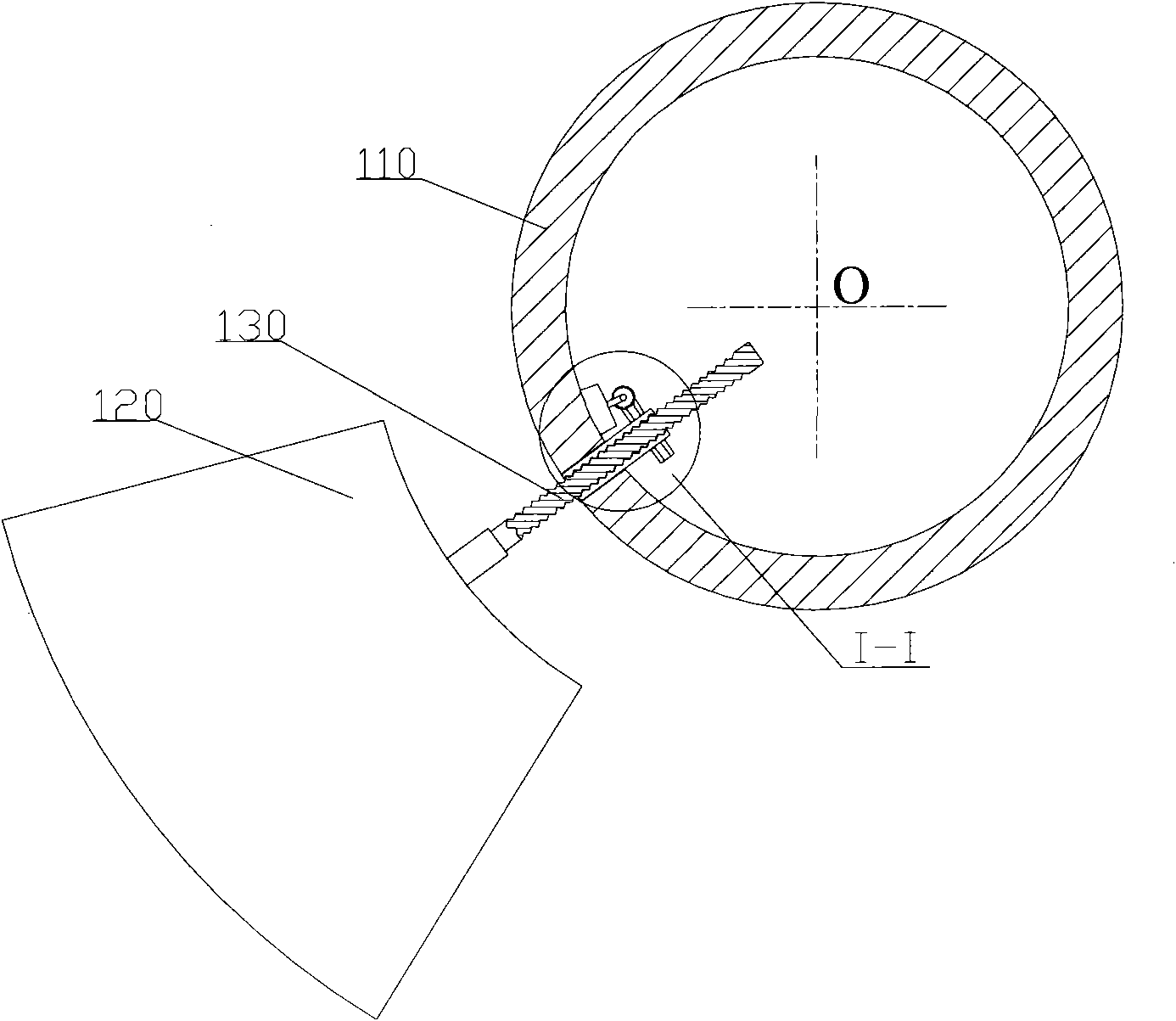

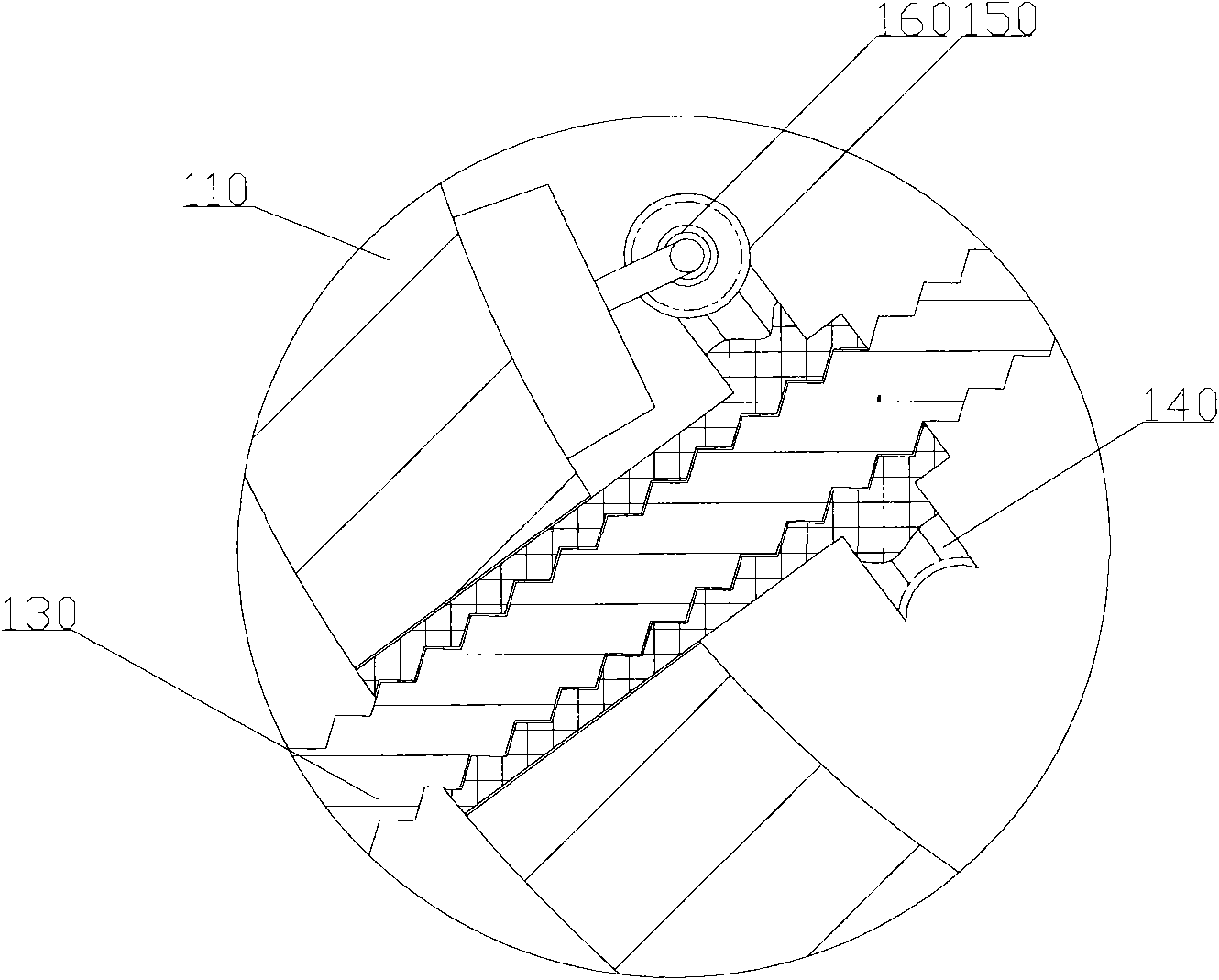

[0059] In the second embodiment, the distance adjustment mechanism of the rotating body 100 includes a screw rod 130 , a worm wheel 140 , a worm 150 and a distance adjustment motor 160 . The worm wheel 140 and the worm 150 cooperate, and the two are respectively rotatably installed on the rotating base 110 . The output shaft of the distance adjusting motor 160 is connected with the worm 150 , and the worm wheel 140 can be driven to rotate through the worm 150 . One end of the screw rod 130 is connected to the worm wheel 140 through a transmission thread, and the other end is connected to the eccentric weight 120 ; In this way, when the pitch-adjusting motor 160 is started, the worm wheel 140 can drive the screw rod 130 to move in the axial direction through the transmission thread when the worm wheel 150 can drive the worm wheel 140 to rotate, thereby changing the distance between the eccentric weight 120 and the rotation axis O-O, realizing The adjustment of the position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com