Novel plate shearer based on optimized crank-rocker mechanism

A shearing machine, a new type of technology, applied in the direction of shearing machine equipment, shearing devices, metal processing equipment, etc., can solve the problem of inability to achieve precise and fine adjustment of the knife edge gap, weaken the service life of the eccentric wheel and eccentric connecting rod, and cannot achieve shearing Angle continuous adjustment and other issues, to achieve the effect of compact structure, improved service life and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

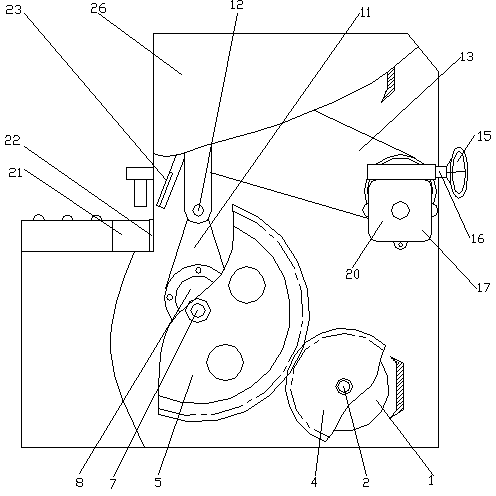

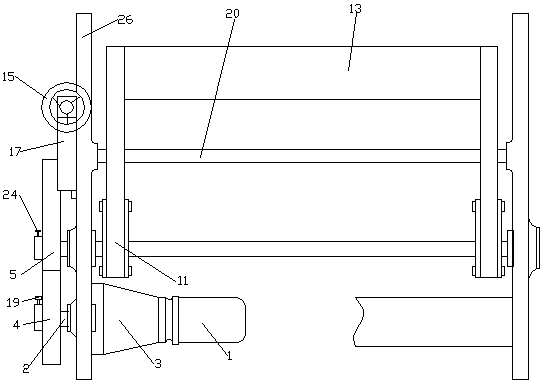

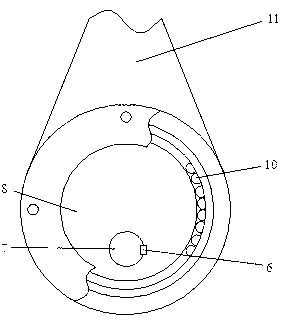

[0015] From figure 1 It can be known that the present invention is a novel shearing machine based on an optimized crank-rocker mechanism, which includes the main shaft 7 of the shearing machine, the upper tool rest 13, the shearing machine wallboard 26, and it also includes a driving device, a transmission device, and a knife-edge gap. The adjustment mechanism; the driving device includes a switched reluctance speed regulating motor 1 and a transmission shaft 2, the switched reluctance speed regulating motor 1 is connected with the transmission shaft 2, the transmission device is connected with the driving device, and the knife edge gap adjustment mechanism is connected with the upper knife rest 13.

[0016] As a preferred mode of the present invention, a deceleration device 3 is arranged between the switched reluctance speed regulating motor 1 and the transmission shaft 2, the switched reluctance speed regulating motor 1 and the deceleration device 3 are integrally connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com