Accurate screw high-speed detection device capable of feeding materials through glass rotary plate

A technology of turntable feeding and testing equipment, which is applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effects of stable transmission, improved detection efficiency, and stable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

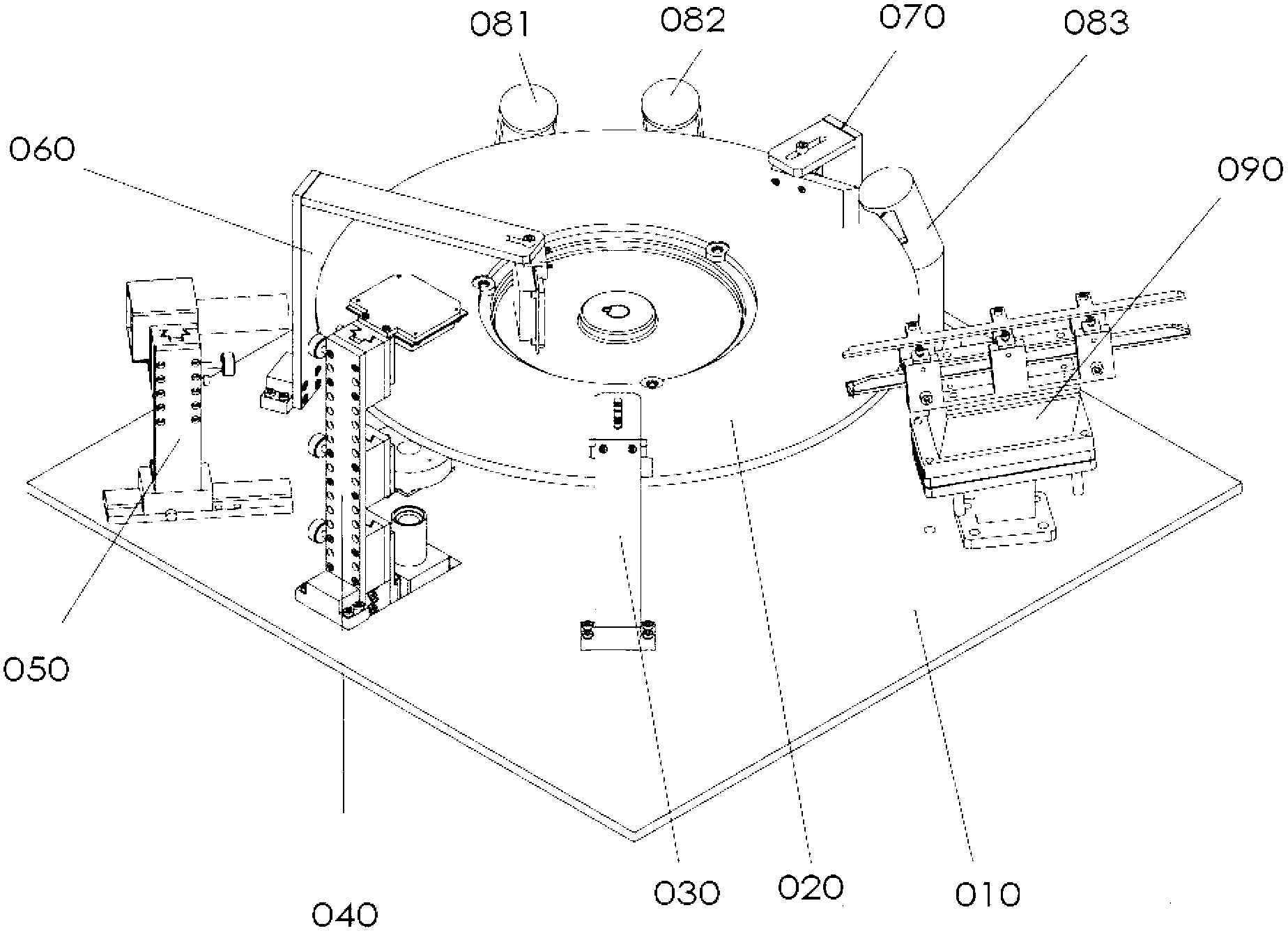

[0038] like figure 1 As shown, a high-speed detection equipment for precision screw parts fed by a glass turntable, including: a controller, a turntable 020 installed on a flat workbench 010, a limit device 030, a vertical light source and a camera adjustment seat 040, and a horizontal camera Adjusting seat 050, horizontal light source adjusting seat 060, material shifting device 070, feeding mechanism 090, unqualified product discharge port 081, mixed material discharge port 082, qualified product discharge port 083; the controller controls the rotation of the turntable 020 And process the image data input by the camera.

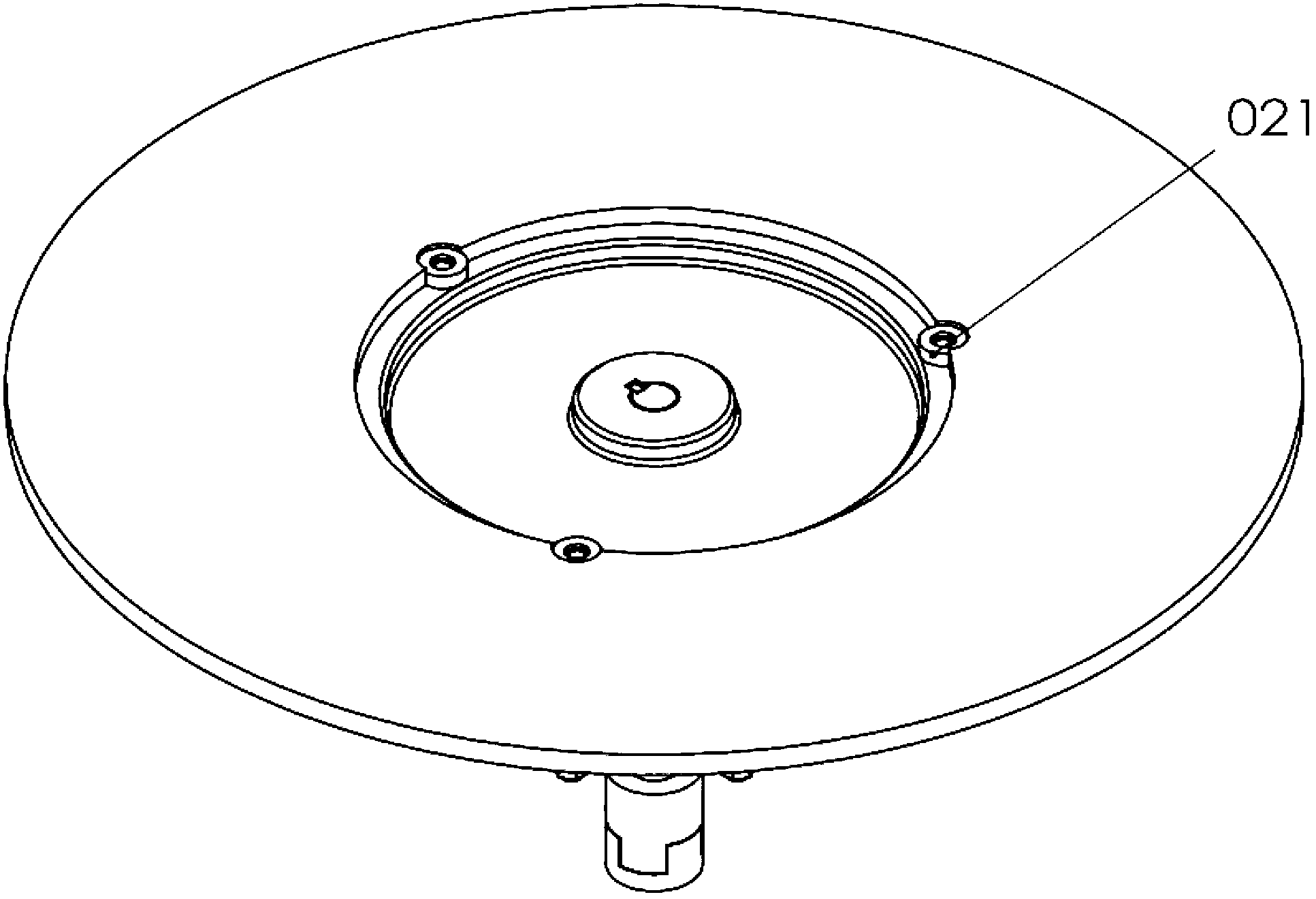

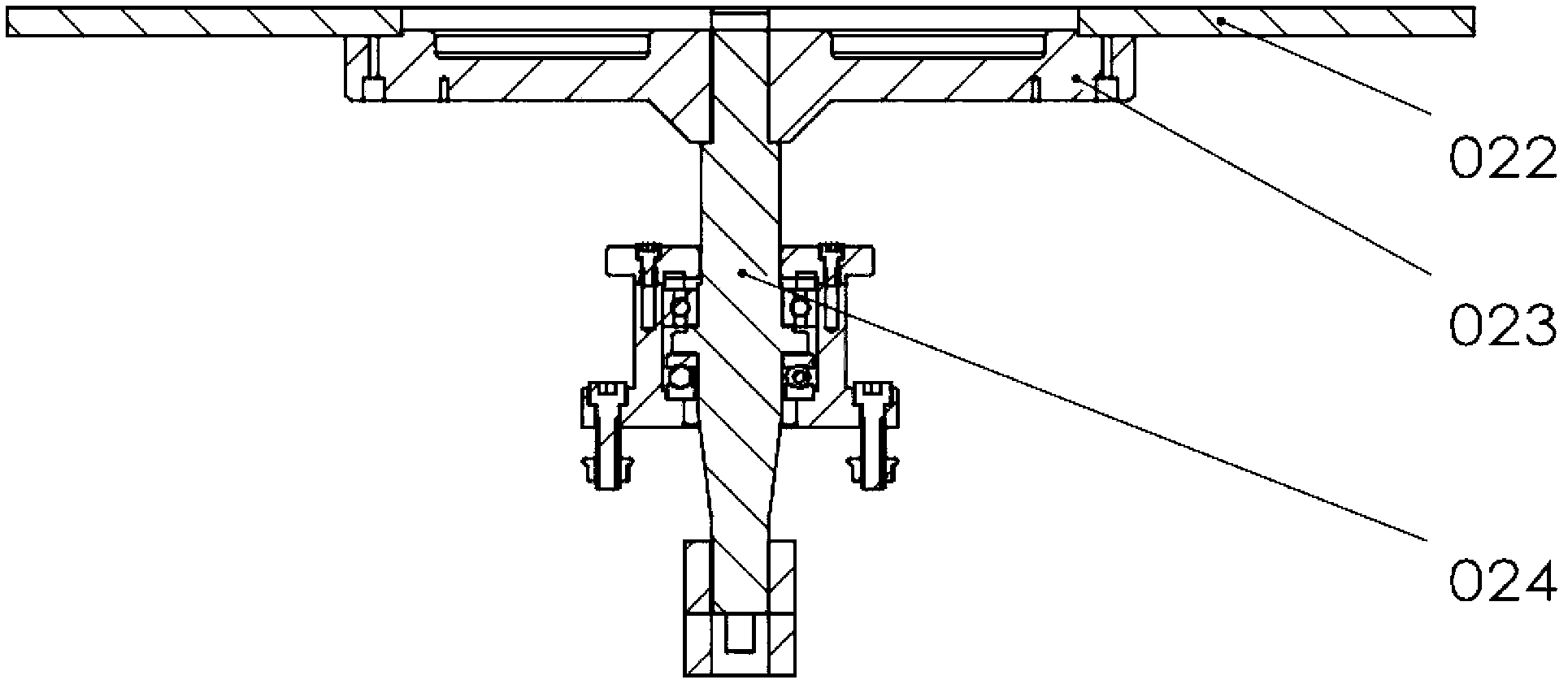

[0039] like figure 2 , 3 As shown, the turntable 020 is used to place and transport the threaded parts to be tested, and includes a glass disc 022, a glass tray 023 and a rotating shaft 024. The glass disc 022 is fixed on the rotating shaft 024 through the glass tray 023 and follows the rotating shaft 024 rotates together, and the glass tray 022 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com