Lifting rod connecting structure and lifting rod

A connection structure and lifting rod technology, which is applied in the connection of rods, connecting components, friction clamping detachable fasteners, etc., can solve the problems of large size, unsuitable for simple applications, high cost of automatic lifting devices, etc., to achieve Simple connection structure design, continuous height adjustment, and low processing and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

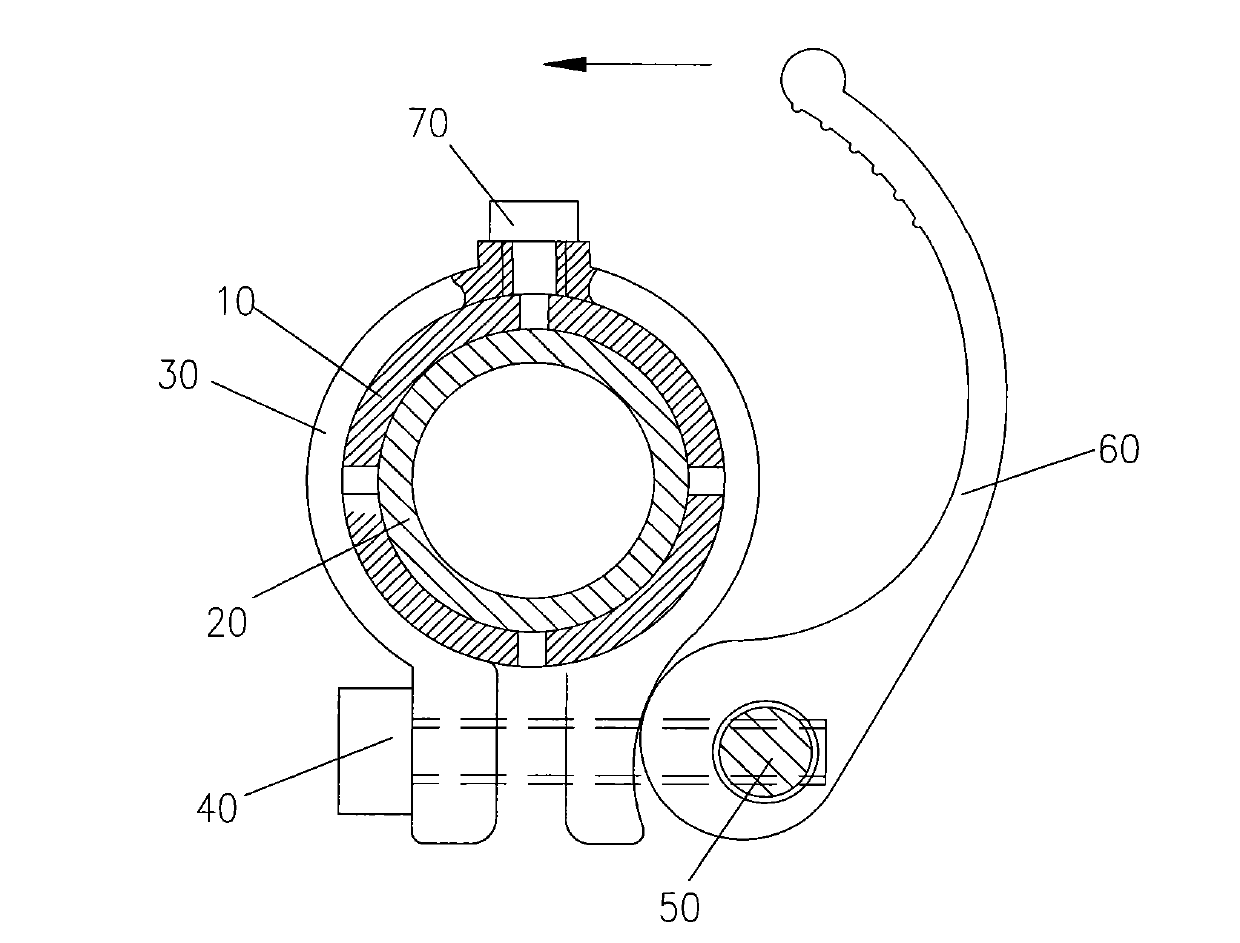

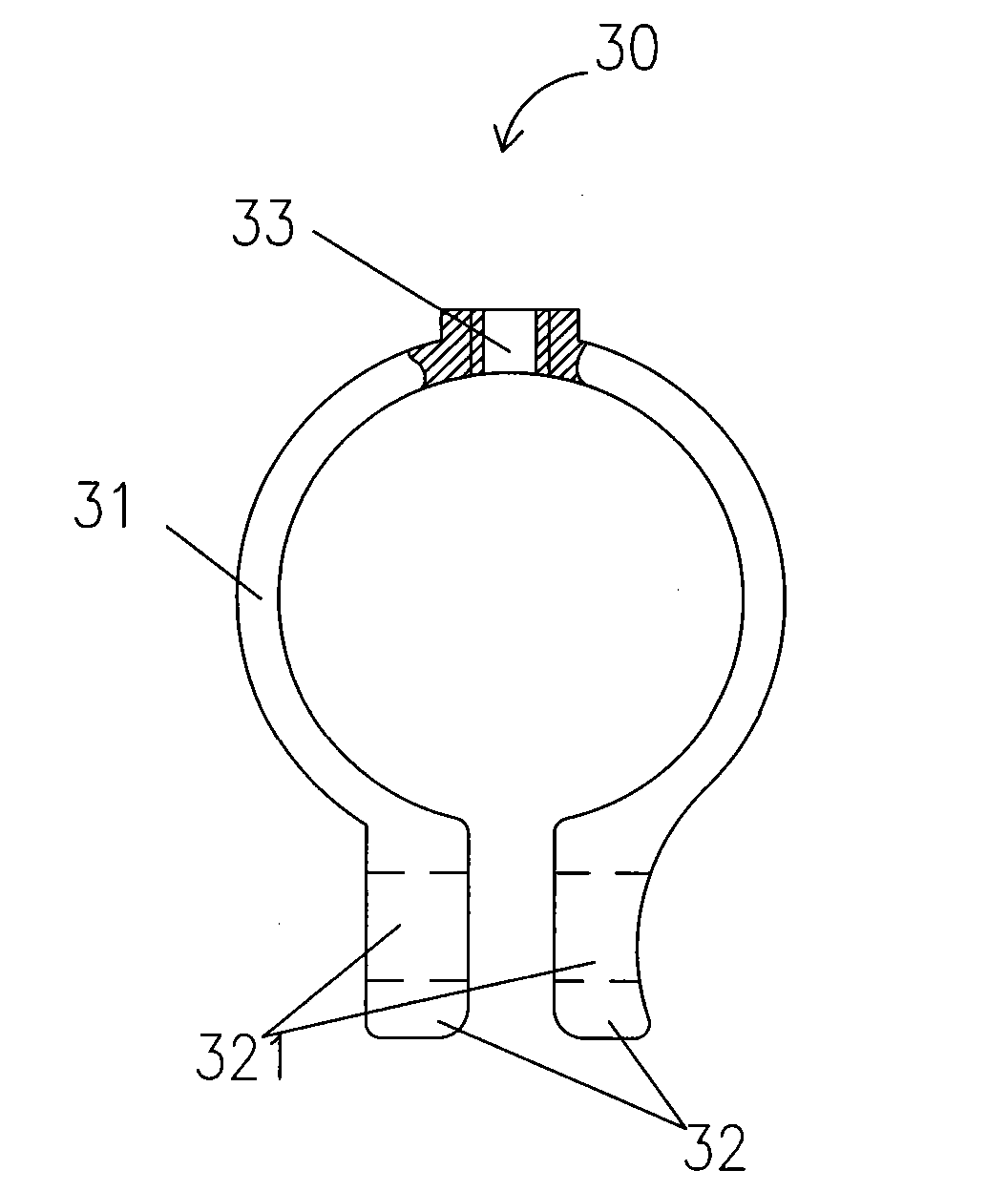

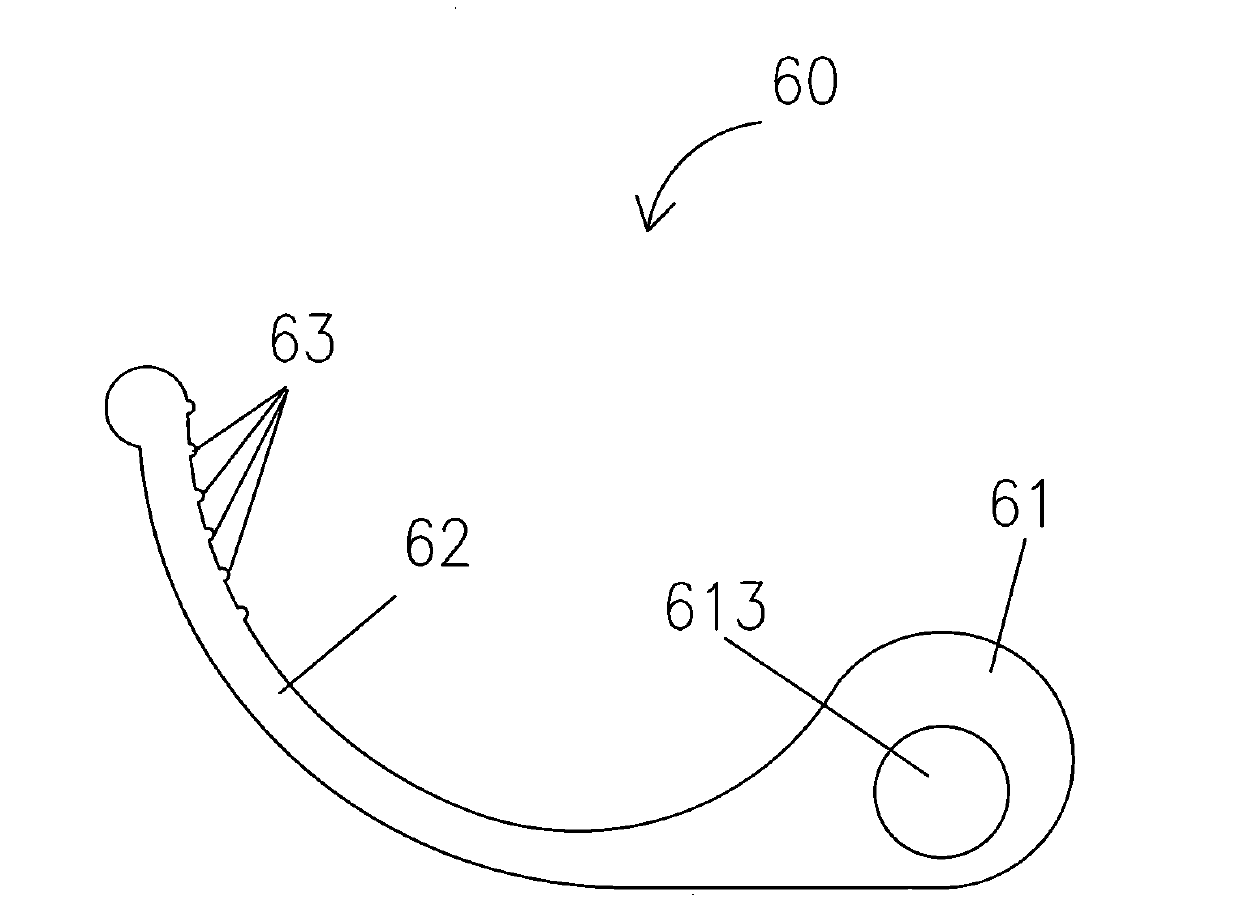

[0032] The lifting rod connection structure of the preferred embodiment of the present invention is as follows: figure 1 shown, see also figure 2 and image 3 , used to connect the outer tube 10 and the inner tube 20 coaxially socketed on the locking lifting rod to prevent the relative movement of the outer tube 10 and the inner tube 20 , including a lock hoop for applying pressure to the outer tube 10 to hold the inner tube 20 tightly 30. Wherein, the lock hoop 30 is an annular structure with an opening, the two opening ends of the lock hoop 30 are correspondingly provided with fixing holes 321, and locking screws 40 are perforated in the two opposite fixing holes 321, and the tail ends of the locking screws 40 are connected to In the screw hole (not shown) of a rotating shaft 50, the opening end of the locking collar 30 is locked to initially realize the locking and positioning of the outer tube 10 and the inner tube 20, but at this time, the inner tube 20 can still be lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com