Forklift hub periphery grinding device

A technology for wheels and dust collectors, which is applied to grinders, belt grinders, grinding/polishing equipment, etc., can solve the problems of poor position adjustment, poor flexibility, and unstable fixation, so as to improve the grinding quality, improve the grinding effect, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

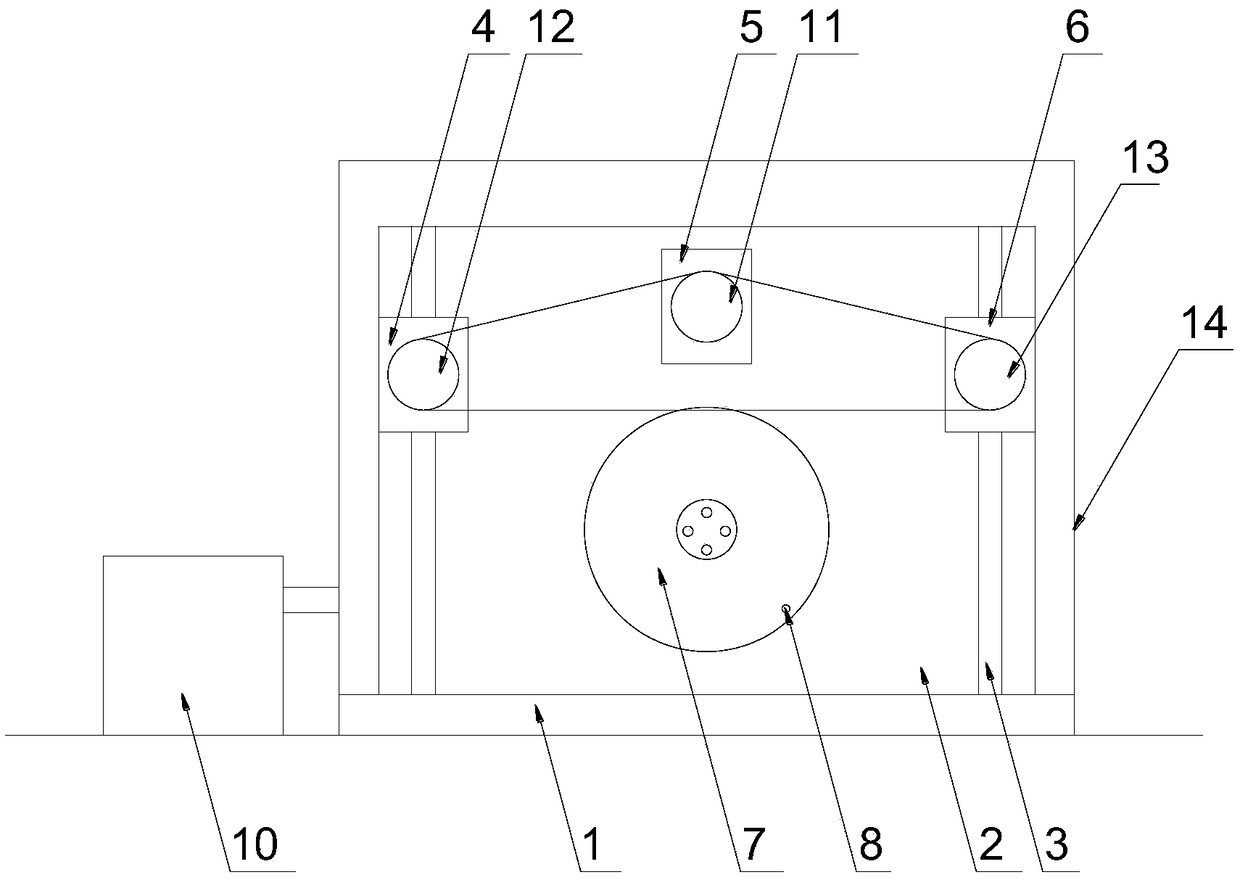

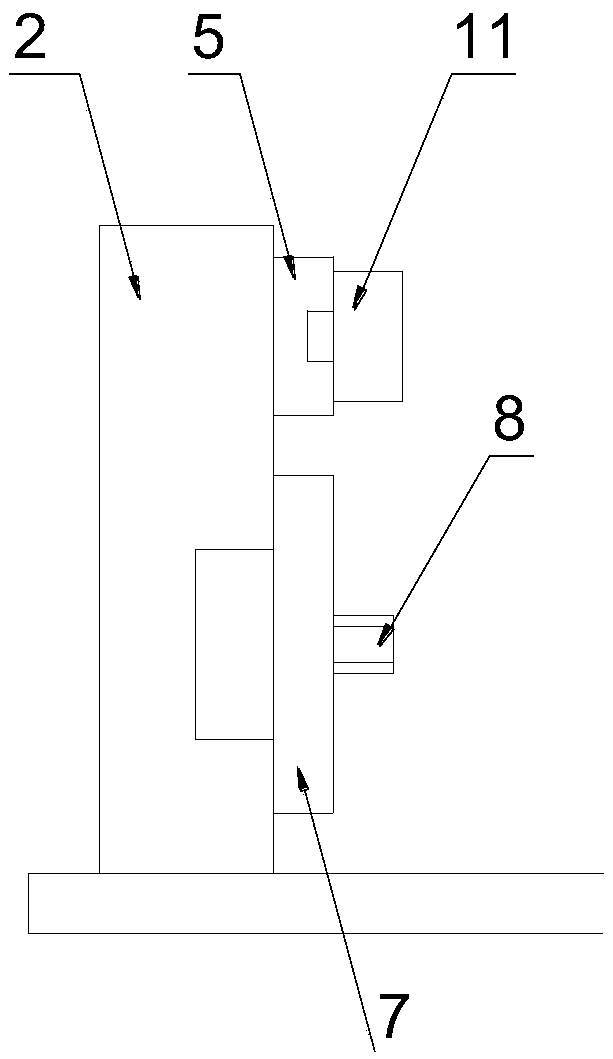

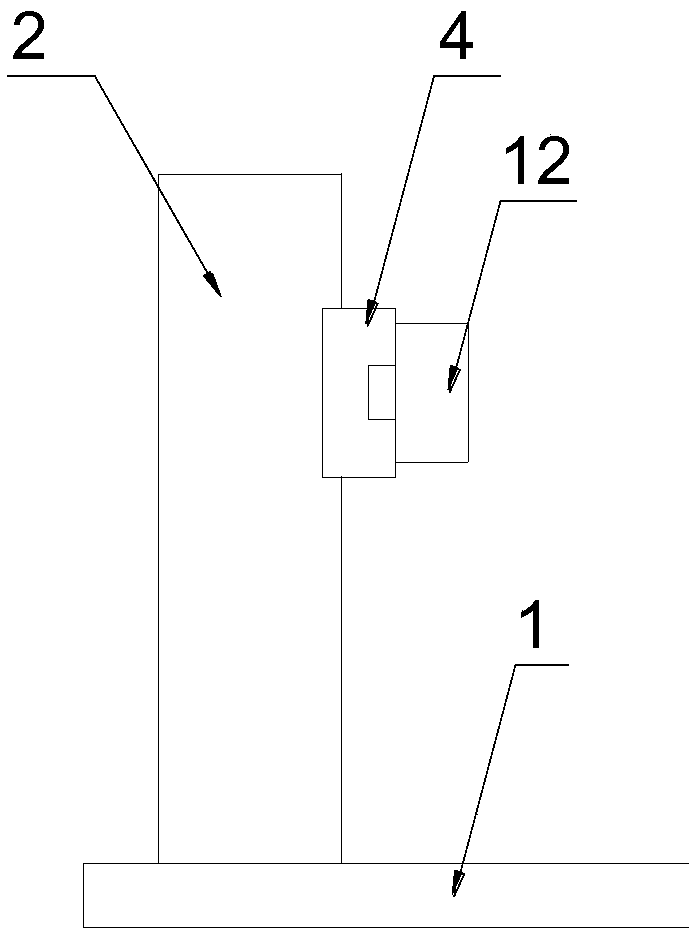

[0017] like Figure 1-3 as shown, figure 1 It is the front view of the fork wheel hub peripheral grinding device proposed by the present invention; figure 2 A side view of the fork wheel hub peripheral grinding device proposed by the present invention; image 3 It is a side view of part of the structure of the fork wheel hub peripheral grinding device proposed by the present invention.

[0018] refer to Figure 1-3 , a kind of fork wheel hub peripheral grinding device proposed by the present invention, comprising a workbench 1, a fixed frame 2, a first sliding member 4, a second sliding member 6, a fixing member 5, a driving wheel 11, a first driven wheel 12, a second Driven wheel 13 and turntable 7;

[0019] The fixed frame 2 is installed on the workbench 1; vertical slide rails 3 are arranged at both ends of the fixed frame 2; the first sliding member 4 and the second sliding member 6 are slidably installed on the fixed frame 2 through the sliding rail 3; the first driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com