Spinning preparation machine and contactless measuring method

A preparation machine, non-contact technology, applied in the direction of textile and paper making, deburring device, fiber treatment, etc., can solve the problem of expensive etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

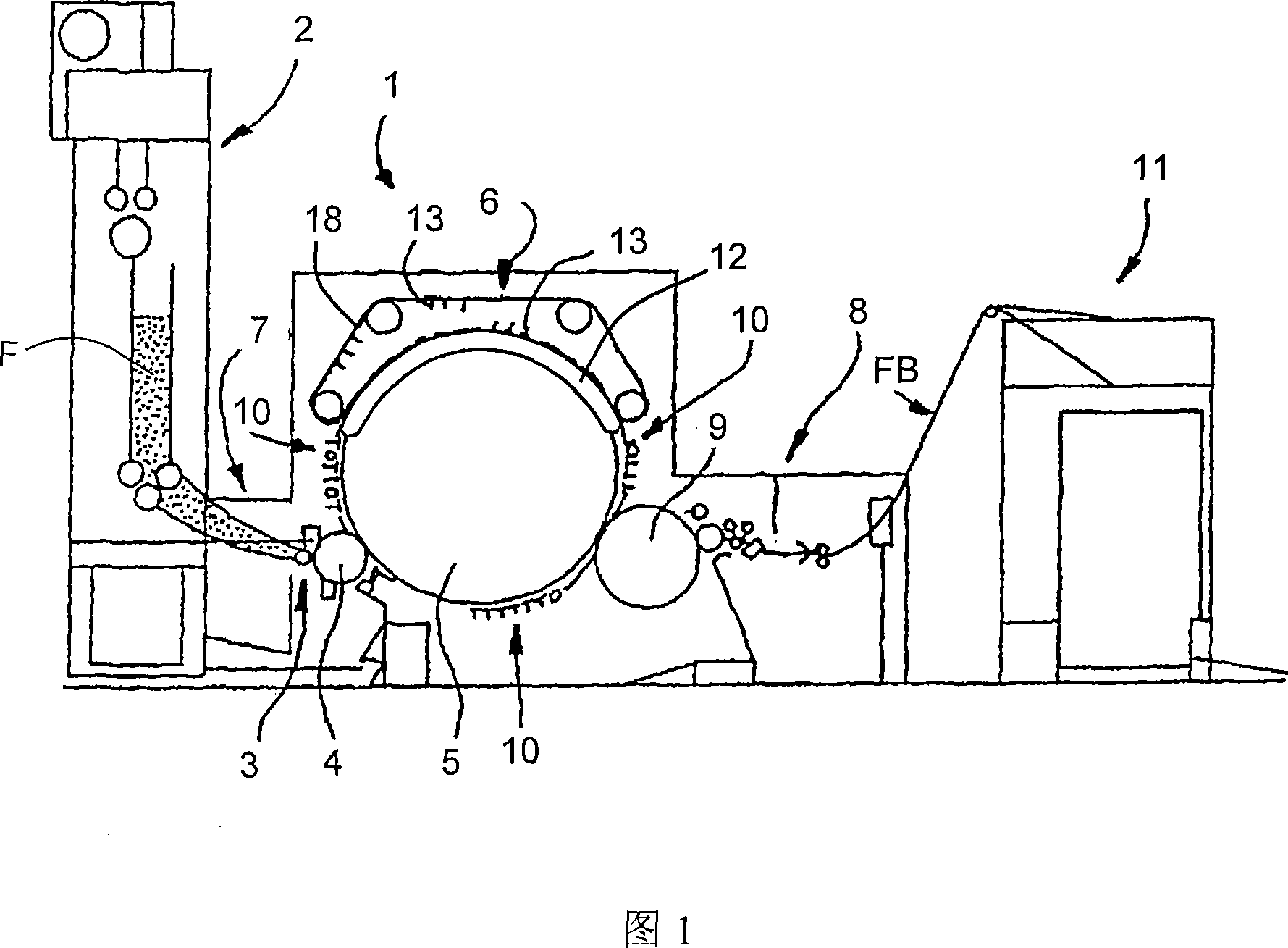

[0058] FIG. 1 shows a known card 1 in which the batt F is fed from a feed box 2 to a feed roller 3 and subsequently to a licker-in roller 4 . The card 1 comprises a single cylinder 5 (main cylinder or so-called tenter drum) which is rotatably mounted in a frame. The cylinder 5 operates in a known manner with a rotary flat device 6, a fiber feeding device 7 and a fiber doffing device 8, the fiber feeding device 7 particularly comprising a feed roller 3 and a licker-in roller 4, and the fiber doffing device 8 In particular the so-called Doffer 9 is included. Carding elements 10 can be installed in the pre-carding zone, post-carding zone and secondary carding zone of the card 1 . Between the revolving flat arrangement 6 and the carding element 10 is located a fiber guiding element, which is not shown in detail here and will be described in further detail below. The fiber doffing device 8 conveys the fiber sliver FB to the fiber sliver depositing device 11 .

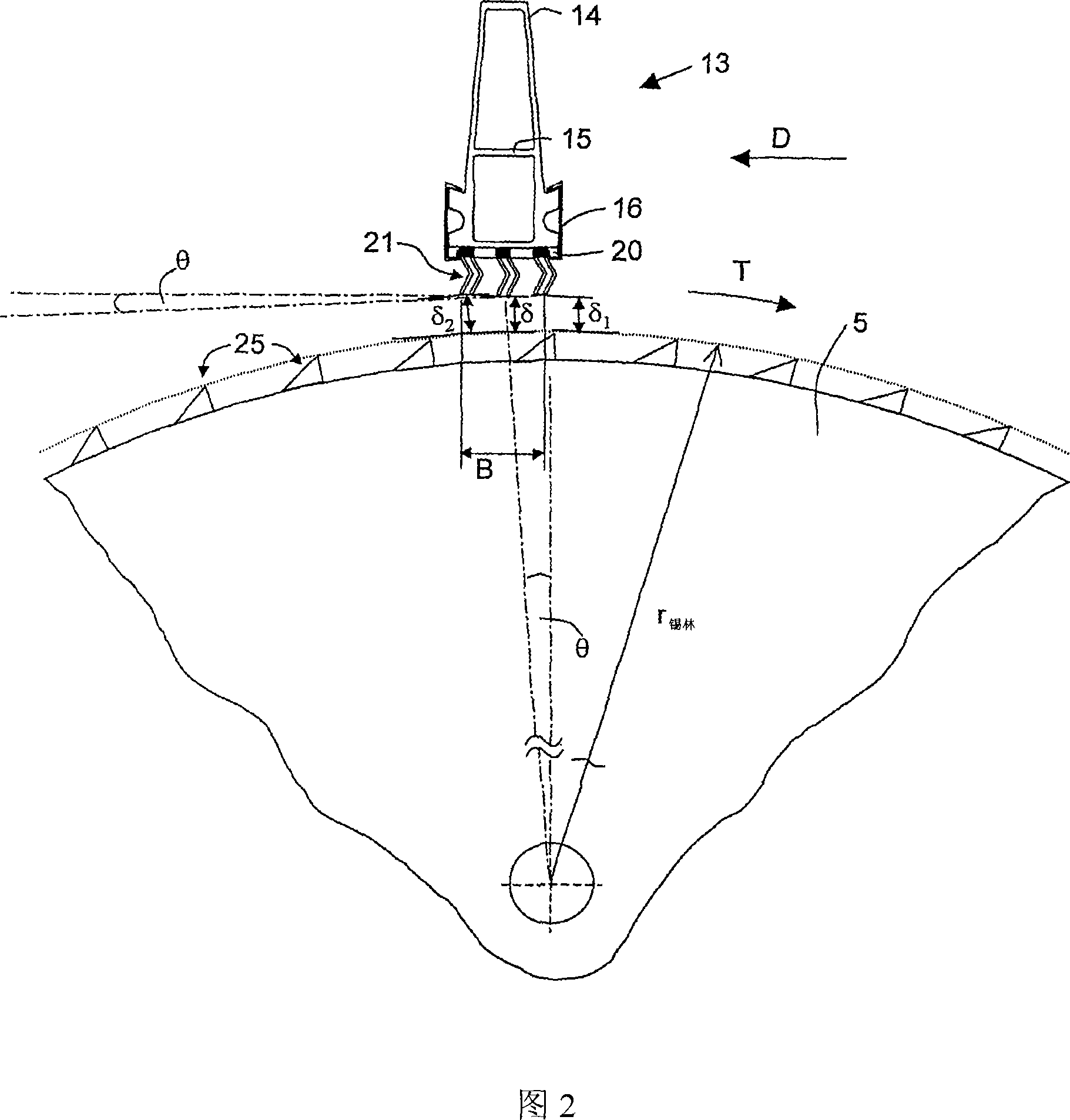

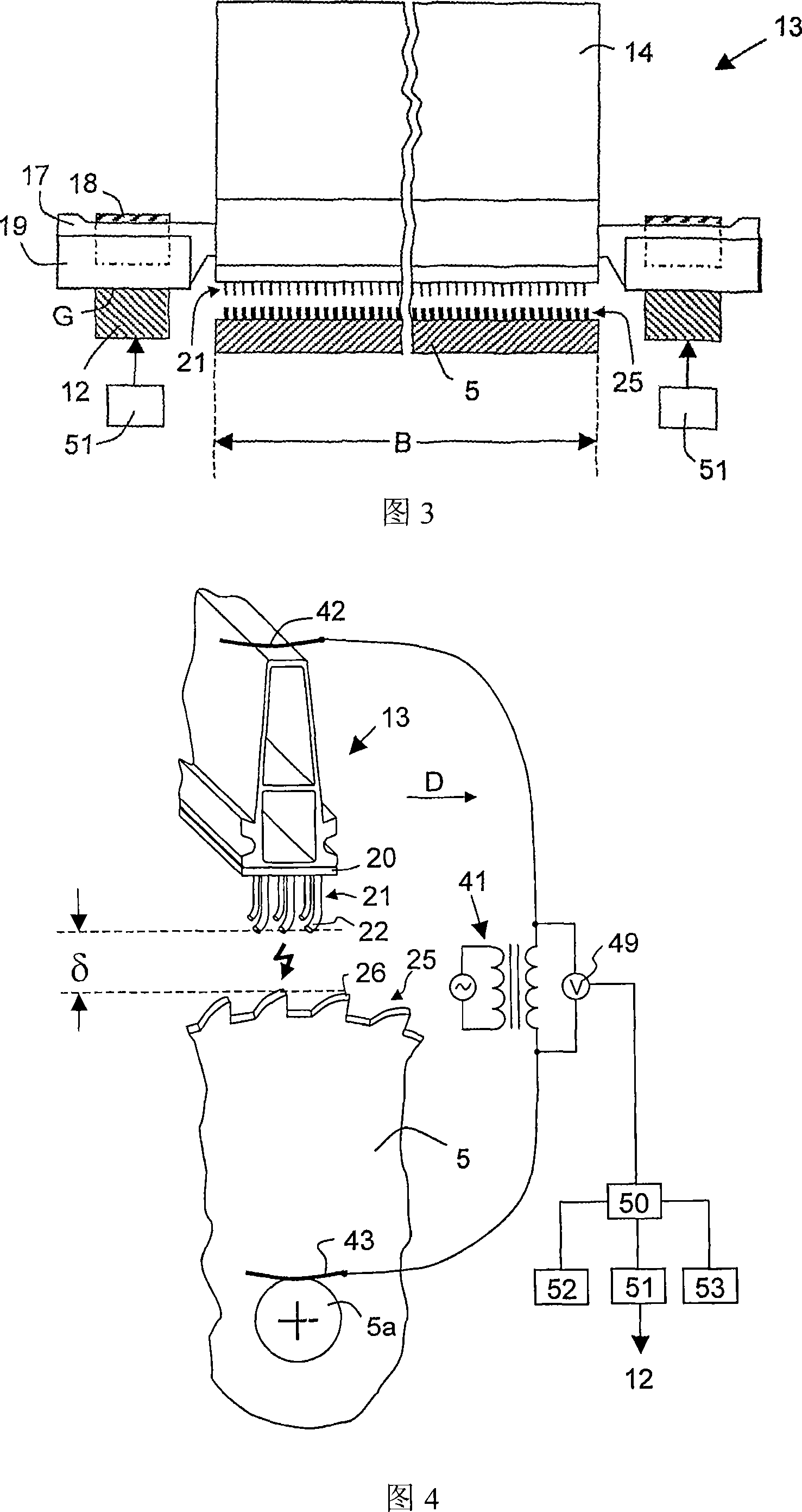

[0059] A pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com