Auxiliary wire filling GMA additive manufacturing device and method for gradient material manufacturing

A gradient material and additive manufacturing technology, used in manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of inability to achieve continuous adjustment of components, limited types of processing materials, and unreasonable energy distribution, and improve energy utilization. High efficiency, low cost, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

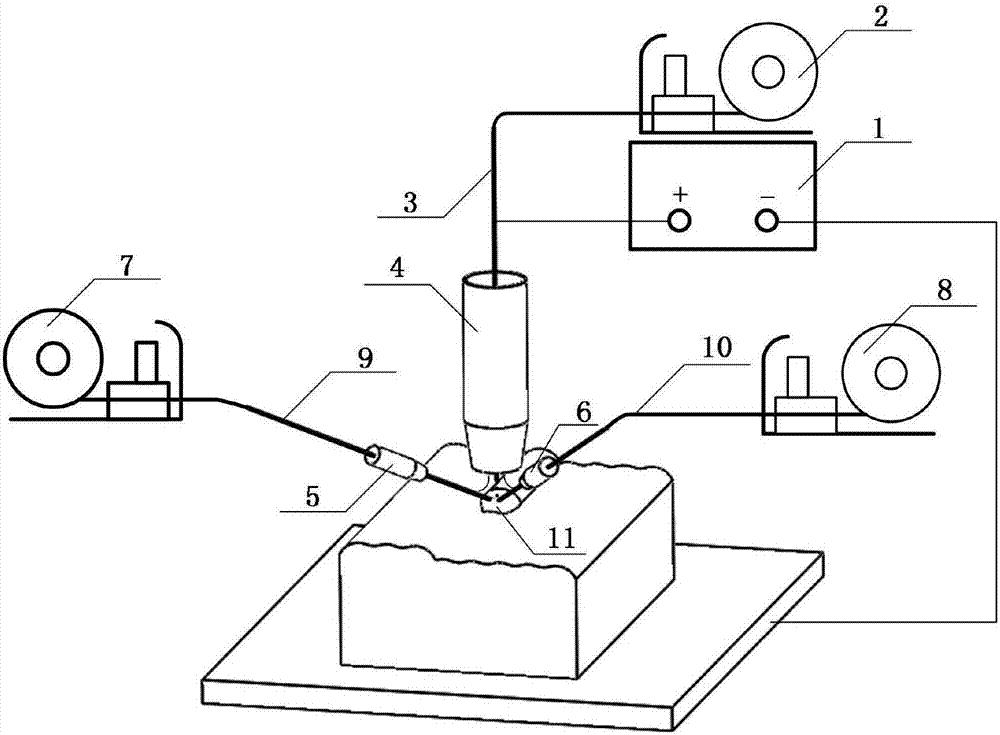

[0022] The invention provides an auxiliary wire-filling GMA additive manufacturing device for the manufacture of gradient materials, such as figure 1 As shown, the device includes a GMAW arc welding power source 1, a wire feeder 2, a melting electrode welding wire 3, a GMAW welding torch 4, a first wire guide nozzle 5, a second wire guide nozzle 6, a first auxiliary wire feeding machine 7 and The second auxiliary wire feeding machine 8, wherein:

[0023] The wire feeder 2 is used to transport the melting electrode welding wire 3, and its wire feeding hose is connected with the GMAW welding torch 4;

[0024] The GMAW welding gun 4 is vertically arranged directly above the molten pool 11, and is used to guide the melting electrode welding wire into the molten pool 11, and the generated arc is located between the melting electrode welding wire 3 and the molten pool 11;

[0025] The first auxiliary wire feeder 7 is used to feed the homogeneous filler wire 9 having the same compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com