Dividing wall rectifying tower

A divide-wall rectification tower and rectification tower technology, applied in the field of new divide-wall rectification tower, can solve problems affecting wide application, lack of design method, operation and control scheme, etc., and achieve the effect of easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

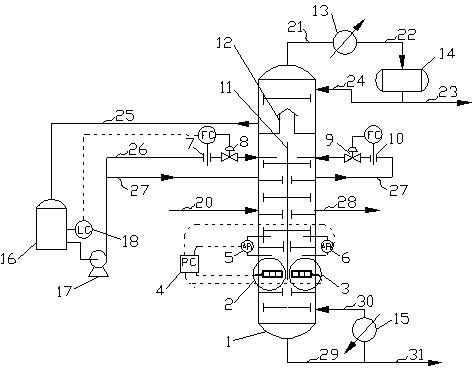

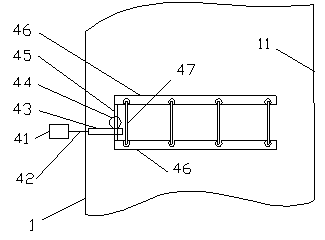

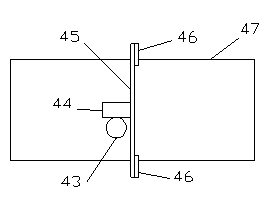

[0034] Below in conjunction with accompanying drawing, divide-wall rectification column of the present invention is described in detail:

[0035] Such as figure 1 As shown, a dividing plate 11 is arranged longitudinally in the middle of the dividing wall rectification column, and the rectifying column is divided into the bottom combination zone, the tower top combination zone, the feed side of the divider wall zone and the side line output side of the divider wall zone . The liquid mid-stage reflux distribution system includes flow meters 7 and 10 , flow regulating valves 8 and 9 , mid-stage reflux buffer tank 16 , mid-stage reflux pump 17 and liquid level gauge 18 . The rising gas distribution control system at the bottom of the tower includes gas distributors 2 and 3, differential pressure gauges 5 and 6, and a computer control system 4.

[0036] After the raw material to be separated is preheated to a certain temperature, it enters the vaporization section on the feed sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com